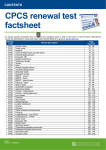

Download standard theory test questions for catergories a41

Transcript