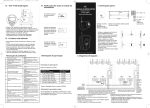

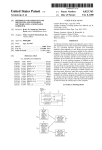

Download Development and Implementation of the ClearPEM

Transcript