Download 258407 RA300 Op Man LTR.qxp

Transcript

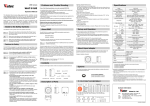

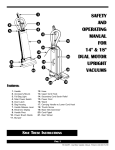

SAFETY, OPERATION AND MAINTENANCE MANUAL RA-300 SCRUBBER This Unit is intended for commercial user. READ & FOLLOW ALL INSTRUCTIONS, WARNINGS & CAUTIONS BEFORE USING THIS SCRUBBER This scrubber will afford you many years of trouble-free operating satisfaction, provided it is given proper care. All parts have passed rigid quality control standards prior to being assembled to produce the finished product. Prior to packaging, the scrubber was again inspected for assurance of flawless assembly. Your scrubber is protectively packed to prevent damage in shipment. We recommend that upon delivery, unpack your scrubber and inspect it for any possible damage. Only a visual examination will reveal damage that may have occurred in transit. If damage is discovered, immediately notify the transportation company that delivered your scrubber. As a shipper, we are unable to report any claim for damage. You must originate any claim within 5 days of delivery. The manufacturer takes no responsibility for damages caused to property or persons due to improper use of the scrubber. Operating instructions must always be available for the operator. The scrubber may only be operated by persons who have been fully trained and authorized to use it. READ ALL INSTRUCTIONS BEFORE OPERATING SAVE THESE INSTRUCTIONS PAGE 1 RA-300 Manual - Part No 258407 - Printed in USA 01-27-10 IMPORTANT SAFETY INSTRUCTION WARNING: To Avoid Electric Shock, Do Not Expose To Rain Store Indoors. When using this equipment basic precautions should always be followed, including the following: 1) DO NOT leave the electric scrubber when plugged in. Unplug from outlet when not in use and before servicing. 10) DO NOT use this scrubber for dry vacuuming. This scrubber is not fitted with a fine dust filter. 2) Turn OFF all controls before unplugging. 11) DO NOT use the scrubber to pick up flammable or combustible liquids such as gasoline or use in areas where they may be present. 3) This is NOT a toy. Close attention is necessary when used around or near children. 4) Use only as described in this safety manual. Use only manufacturer's recommended attachments and accessories. 5) DO NOT use electric scrubber with damaged cord or plug. If the scrubber is not working as it should, because it has been dropped, damaged, left outdoors or dropped into water, contact an authorized service center or the factory. 6) DO NOT pull electric scrubber by the cord, use cord as a handle, close a door on cord or pull cord around sharp edges and corners. DO NOT run scrubber over cord. Keep the cord away from heated surfaces. 7) DO NOT unplug the scrubber by pulling on the cord. To unplug, grasp the plug, not the cord. 8) DO NOT handle the plug of the electric scrubber with wet hands. 9) Store scrubber indoors in a dry area. DO NOT expose to freezing temperatures. CARE OF THE SCRUBBER This scrubber is designed to be safe when used to per-form cleaning functions as specified. Should damage occur to electrical parts, the unit should NOT be used until the damage is repaired by the manufacturer or an authorized service center. This will avoid further damage to the scrubber or injury to the user. PAGE 2 12) DO NOT use this scrubber to clean surfaces that have dust or substances which are flammable, poisonous, caustic, or irritants and represents a health hazard. 13) DO NOT use where anesthetics or oxygen are used. 14) DO NOT use an extension cord unless absolutely necessary. If an extension cord is used, then wire size must be #14 or larger and should not exceed 50 feet in length. The extension cord must be a three-wire grounded type. 15) Replace damaged or worn parts immediately with genuine original equipment parts to maintain safety and to protect your limited warranty. 16) DO NOT run pump dry. When the solution tank is empty, turn off the pump. 17) NEVER drive scrubber over steps. Electrical equipment must be connected to a properly grounded outlet only. (See grounded instructions) These instructions are for your protection and information. PLEASE READ CAREFULLY! Failure to follow instructions or precautions could result in injury or damage to the user and/or the scrubber. DANGER: Improper use of the grounding plug can result in a risk of electric shock. Electrical equipment must be grounded. If it should mal-function or breakdown, grounding provides a path of least resistance for electrical current to reduce the risk of electric shock. The scrubber is equipped with a cord having an equipmentgrounding conductor and grounding plug. The plug must be inserted into an appropriate outlet that is properly installed and grounded in accordance with all local codes and ordinances. GROUNDING SAFETY INSTRUCTIONS If repair or replacement of the cord or plug is necessary, DO NOT connect the grounded wire to either flat blade terminal. The wire with insulation having an outer surface that is green with or without yellow stripes is the grounding wire. GROUNDING METHODS This electric equipment is for use on a nominal 120 volt circuit, and has a grounded plug that looks like the plug illustrated in (Fig A). A temporary adaptor that looks like the adaptor illustrated in (Fig B & C) may be used to connect this plug to a 2-pole receptacle as shown in (Fig B) if a properly grounded outlet is not available. The temporary adaptor should be used only until a properly grounded outlet (Fig A) can be installed by a qualified electrician. The green color rigid ear, lug or the like extending from the adaptor must be connected to a permanent ground such as a properly grounded outlet box cover. Whenever the adaptor is used, it must be held in place by a metal screw (Fig 3). WARNING: Improper connection of the equipment-grounding conductor can result in a risk of electric shock. Check with a qualified electrician or service person if you are in doubt as to whether the outlet is properly grounded. DO NOT modify the plug provided with the equipment. If it will not fit the outlet, have a proper outlet installed by a qualified electrician. Note: In Canada, the use of a temporary adaptor is not permitted by the Canadian Electrical Code. PAGE 3 OPERATION SCRUBBER OF 1) This scrubber is designed for wet cleaning on waterproof surfaces inside buildings. All other usage is improper. 2) The manufacturer takes no responsibility for damage due to improper use of the scrubber. The user takes the entire risk for damage due to improper use. 3) Following the operating, maintenance and repair instructions are required. 4) The appropriate accident prevention rules, as well as other known regulations for health and safety in operation must be followed. SAFETY & CHEMICAL INFORMATION 5) Any changes to the scrubber will void the warranty. Any damage that may occur as a result of those changes will be the sole responsibility of the owner. 6) Check the suitability of the floor surface before using the scrubber. 7) Check that the wheels and brushes will not damage any surface to be cleaned, especially gymnasium floors. 8) If the scrubber is misused, the manufacturer will not be responsible for any form of warranty. Operation Safety Chemicals 1) DO NOT run the brushes when the scrubber is stationary as it may cause damage to the surface being cleaned. 1) Always consult correct use and safety precautions as detailed on manufacturers label. If required, wear appropriate recommended clothing and safety glasses. 2) Tilt scrubber back when moving, especially over thresholds or sills to prevent damage to the brushes. 3) When transporting in elevators, there safety regulations and precautions are to be respected as well as maximum load capacity of the elevator. 2) Only use low foaming and non-flammable chemicals which do not include hazardous components. 3) DO NOT use flammable, poisonous, hazardous or explosive chemicals. WHAT TO USE WITH SCRUBBER Type Of Cleaning Chemicals Scrub Brushes/Pads Daily or weekly cleaning on waterproof surfaces. Floor cleaner, degreaser, maintenance cleaner, scented cleaner depending upon the degree of dirt on surface. Nylon brushes, red, green or white pads depending on condition of floor. Note: Maximum water and chemical temperature is 72° F ROUTINE MAINTENANCE If you maintain this scrubber properly it will stay in working order for a long period of time. Check the unit regularly for any wear and tear. 1) Check rubber squeegee blades. 2) DO NOT clean scrubber with pressure washer. 3) When servicing or making repairs use only genuine original equipment parts. PAGE 4 4) Repairs and service should only be made by an authorized service center or the factory. 5) Monthly Maintenance: Check all gaskets, tighten loose nuts and bolts. 6) Every (6) months check vacuum motor carbon brushes, if worn to 3/8” length or less replace. SCRUBBER FEATURES Intermittent Solution Lever Vacuum Switch Brush/Solution Switch Cord and Cord Wrap Adjustable/Folding Handle Quick Release Brush ystem Sight Dome Solution/Recovery Tank Compact Fold-Up Design Handle Grip Squeegee Disc Brushes Removable Easy Fill Tank Tank Construction: Scrub Path: Cleaning Direction: Brush Spread: Squeegee Width: Solution Capacity: Recovery Capacity: Vacuum Motor: Brush Motor: Brush Speed: Brush Pressure: Water Output: Power Cord: Storage Dimensions: Includes: Net Weight: Rotationally Molded Polyethylene 13.5” Forward/Back Two (6.5”) 15” 3.5 Gallons 4 Gallons 120 Volt, By-Pass - 850 Watts 200 Watts 200 RPM 22 Lbs .2 (GPM) 25 Ft, 3 Wire Grounded 15” W X 22” L X 16” H 6.5” Counter Rotating Scrub Brush 48 Lbs Net/54 Lbs Shpg PAGE 5 SCRUBBER SPECIFICATIONS OPERATING PROCEDURES 1) Prepare the floor surface by sweeping or vacuuming before using the scrubber. 10) Plug-in the power cord, turn on the vacuum switch,and then the brush switch. 2) Make sure all the switches are OFF. Solution Lever 3) Select the proper floor brushes or pad drivers and floor pads for the cleaning operations. Handle Height Adjustment Handle Angle Adjustment 4) Adjust the handle to the best position for comfortable operation. 5) Add the chemical required. Check the label for dilution rates. 6) Fill a clean bucket with clean water, and pour it into the solution tank opening, maximum capacity 3.5 gallons. Gasket 11) Start cleaning by squeezing the solution lever and push the scrubber forwards or backwards. Squeegee Lever 12) If the floor is very dirty, turn OFF the vacuum switch. Using the squeegee lever, lift the squeegee off the floor. Squeeze the solution lever to add more cleaning solution to the floor. Scrub the floor thoroughly. 13) Turn ON the vacuum switch, lower the squeegee to the floor, and vacuum up the dirty solution. Short Solution Hose 14) While cleaning, monitor foam level in the recovery tank. If heavy foam is building, pour a quality defoamer into the recovery tank. Rear Rim 7) Place the solution hose to the far side of the tank making sure the hose is not bent. Place the dome to the rear rim of the tank and press the dome gasket gently into the front rim. 8) Check to make sure the short solution hose located at the bottom right on the scrubber is plugged into the female QDC connector. 9) When using an external cleaning tool unplug the hoe and plug in the solution hose to the attachment you are using. PAGE 6 15) Periodically check the solution level in the tank. NEVER allow brushes or pads to run dry, otherwise both the pump and the floor may be damaged. 16) Periodically inspect the squeegee blades for obstructions (sand, cigarette butts, paper etc) clear, then continue the cleaning. 17) Before refilling the solution tank, flush the recovery tank with clean water. 1) Remove dome cover from the tank and set it down behind the scrubber. DAILY 6) Empty the solution bladder and rinse with clean water. 7) Hang up the solution bladder to dry. 8) Flush out the recovery tank with clean water to remove dirty solution. Drain tank. 9) When replacing the bladder make sure it fits properly into the recovery tank. 2) Lift tank by the grip and carry it to a floor drain or sink. 10) The bladder tab must be fitted on the left side of solution tank opening seen from the rear operators position. Drain Plug 11) Clean the dome, cover, vacuum hose and solution hose thoroughly. Make sure that the solution hose filter is also cleaned. 3) Remove the drain plug from recovery tank and empty the tank. 4) Remove solution bladder from tank by pulling tab on the bladder upwards gently. 5) Once the edge of the bladder comes over tank rim opening, push the entire bladder into the tank and remove bladder through the large opening of the recovery tank. 12) Clean the scrubber and squeegee with a damp cloth. 13) Store squeegee in the raised position to prevent damaging the blades. 14) Rinse brushes or pads with clean water. To remove brushes or pads, tilt scrubber back and slightly pull them downward. When replacing make sure they lock into the grooves. IMPORTANT: DO NOT leave solution in the bladder. After each use thoroughly wash out the bladder. This will help extend the bladder’s life. PAGE 7 MAINTENANCE TROUBLE SHOOTING GUIDE CAUTION: Before working on the scrubber disconnect power cord. PROBLEM: Scrubber does not run, no power. Possible Cause Possible Solution 1) Fuses or circuit breakers have tripped. 1) Check and replace fuses or reset circuit breakers. PROBLEM: Insufficient vacuuming power. Possible Cause Possible Cause 1) Debris caught under squeegee blades. 1) Remove debris and wipe blades with clean cloth. 2) Connect hose. 3) Reseat tank cover correctly or replace gasket. 4) Clean filter with water. 5) Check drain plug and replace properly. 2) Vacuum hose not connected. 3) Tank cover not properly seated or gasket on the dome cover is damaged. 4) Filter in tank cover blocked. 5) Recovery tank drain plug not properly placed. PROBLEM: Squeegee not picking up water. Possible Cause 1) 2) 3) 4) Possible Cause Rubber blades on squeegee dirty or worn-out. Squeegee not in contact with floor. Recovery tank full. Vacuum hose loose or hose is damaged. 1) 2) 3) 4) Clean or replace blades. Check blades and replace if necessary. Empty recovery tank. Reinstall or replace hose. PROBLEM: Little or no water flow going to brushes. Possible Cause Possible Cause 1) Solution line blocked. 1) Flush out solution tank and lines with clean water. 2) Unclog filter. 3) Refill solution tank. 2) Solution tank filter clogged. 3) Solution tank empty. WARNING: Service and repairs, should only be performed by an authorized service center. 777 South Street P.O. Box 3210, Newburgh, NY 12550-0606 TEL: (800) 835-7812 (845) 565-8850 FAX: (845) 565-9392 www.mastercraftusa.com - [email protected] PAGE 8 RA-300 Manual - Part No 258407 - Printed in USA 01-27-10