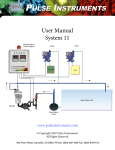

Download Pollution Prevention Technology Profile Conductivity

Transcript