Download em-sl20_sm1.33 MB

Transcript

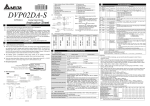

FILE No. SERVICE MANUAL STAINLESS STEEL MICROWAVE OVEN WITH GRILL EM-SL20NECO MIN SEC AUTO 150w MIN 450w SEC AUTO C 150w 450w C / Kg / Kg Product Code No. EM-SL20NECO 1-437-574-25 FOREWORD Read this manual carefully, especially precaution on microwave energy, and follow the procedure strictly. Careless servicing and testing may expose yourself to the microwave energy leakage. PRECAUTIONS PRECAUTIONS TO BE OBSERVED BEFORE AND DURING SERVICING TO AVOID POSSIBLE EXPOSURE TO EXCESSIVE MICROWAVE ENERGY (a) Do not operate or allow the oven to be operated with the door open. (b) Make the following safety checks on all ovens to be serviced before activating the magnetron or other microwave source, and make repairs if necessary: (1) Interlock operation, (2) proper door closing, (3) seal and sealing surfaces (arcing, wear, and otherdamage), (4) damage to or loosening of hinges and latches, (5) evidence of dropping or abuse. (c) Before turning on microwave power for any service test or inspection within the microwave generating compartments, check the magnetron, wave-guide or transmission line, and cavity for proper alignment, integrity, and connections. (d) Any defective or misadjusted components in the interlock, monitor, door seal, and microwave generation and transmission systems shall be repaired, replaced, or adjusted by procedures described in this manual before the oven is released to the owner. REFERENCE No. SM-2400005 TABLE OF CONTENTS Adjustment Procedures........................................1 Circuit Diagram.................................................... 4 Specifications....................................................... 2 Test Procedures and Troubleshooting................. 5-12 Power Output Measurement................................ 2 Disassembly Instructions..................................... 13-14 Precautions and Repair Service Tips...................2 Exploded View and Parts list................................15-19 Oven Control Panel..............................................3 Control Circuit Board............................................20 Overall Circuit Diagrams...................................... 21 CAUTION MICROWAVE ENERGY PERSONNEL SHOULD NOT BE EXPOSED TO THE MICROWAVE ENERGY WHICH MAY RADIATE FROM THE MAGNETRON OR OTHER MICROWAVE GENERATING DEVICE IF IT IS IMPROPERLY USED OR CONNECTED. ALL INPUT AND OUTPUT MICROWAVE CONNECTIONS, WAVE GUIDES, FLANGES, AND GASKETS MUST BE SECURE. NEVER OPERATE THE DEVICE WITHOUT A MICROWAVE ENERGY ABSORBING LOAD ATTACHED. NEVER LOOK INTO AN OPEN WAVE GUIDE OR ANTENNA WHILE THE DEVICE IS ENERGISED. Lever Stopper 1. ADJUSTMENT PROCEDURES TO AVOID POSSIBLE EXPOSURE TO MICRO-WAVE ENERGY LEAKAGE, THE FOLLOWING ADJUSTMENT OF THE INTERLOCK SWITCHES SHOULD BE MADE ONLY BY AUTHORISED SERVICE PERSONNEL Screw Positions Door Latch PRIMARY INTERLOCK SWITCH, DOOR SENSING SWITCH AND INTERLOCK MONITOR SWITCH ADJUSTMENT (Figure 1) Door Sensing Switch (1) Loosen 2 screws securing the lever stopper. (2) Adjust the lever stopper position so that it is pushed up and pull forward until there is about zero gap. 2-1. Between the lever and the switch body on the door sensing switch. 2-2. Between the lever and the switch body on the interlock monitor switch. 2-3. Between the latch lever and the switch body on the primary interlock switch. when the door latch is securely locked. (3) Tighten the lever stopper screws securely. (4) Make sure the interlock monitor is closed after the primary interlock switch opens when the door is opened very slowly, according to “CHECKOUT PROCEDURE FOR SWITCHES” on page 8. (5) Make sure the interlock monitor is open before the primary interlock and secondary interlock switches close when the door is closed very slowly, according to “CHECKOUT PROCEDURE FOR SWITCHES” on page 8. (6) Make sure the microwave energy leakage is below the limit of the regulation (5mW/cm2) when measured with a detector. ( All service adjustments must be made for minimum energy leakage readings.) Lever Interlock Monitor Switch Latch Lever Primary Interlock Switch Figure 1 -1- 2. SPECIFICATIONS - EM-SL20N Rated Power Consumption........ Micro 1450±10%W Grill 1100+5/-10%W Dual 2500+5/-10%W (After 15mins.) Microwave Output...................... 900W( Adjustable 90W through 900W ) Frequency.................................. 2,450MHz ± 50MHz Power Supply............................. 230V,50Hz Rated Current.............................Micro 6.3±10% Amps Grill 4.75+5/-10% Amps Dual 10.9+5/-10% Amps (After 15mins.) Safety Devices........................... Thermal Protector for Magnetron and Cavity, Open at 122˚C Thermal Protector for Heater, Open at 150˚C Fuse (Cartridge Type 8A) Primary Interlock Switch Door Sensing Switch Interlock Monitor Switch Timer.......................................... Electronic Digital Overall Dimensions.............490(W)x378(D)x322(H)mm Oven Cavity Size.................304(W)x304(D)x248(H)mm Turntable Diameter.....................262mm Net Weight..................................Approx. 19.0Kg. 4.PRECAUTIONS AND REPAIR SERVICE TIPS PRELIMINARY A.SINCE NEARLY 4,000 VOLTS EXIST IN SOME CIRCUITS OF THIS MICROWAVE OVEN, REPAIRS SHOULD BE CARRIED OUT WITH GREAT CARE B.TO AVOID POSSIBLE EXPOSURE TO MICROWAVE ENERGY LEAKAGE, THE FOLLOWING PRECAUTIONS MUST BE TAKEN BEFORE SERVICING. (1)Before the power is applied. (a)Open and close door several times to make sure the primary interlock switch, the door sensing switch, and the interlock monitor switch operate properly. (Listen for the clicking sound from switches). Make sure the interlock monitor switch is closed after the primary interlock switch is opened, when the door is opened. (See pages 1 and 7). (b)Make sure the perforated screen and the dielectric choke of the door are correctly mounted. (2)After the power is applied. (a)Open and close the door to see if the interlock mechanism operates properly. (b)Check microwave energy leakage with a leakage detector and confirm the energy leakage is below 5mW/cm2. 3. POWER OUTPUT MEASUREMENT (1) Prepare 1000cc tap water in a wide mouthed Pyrex container. (2) Stir thoroughly and note initial water temperature T1 (˚C). (3) Place container in centre of oven and operate for 60 seconds at full power. (4) Remove container, stir thoroughly and note final water temperature T2 (˚C). (5) Calculate power output= 70 x Temp. rise (T2-T1). NOTE: This is only an approximate test method, not IEC705 test method to which the microwave oven has been tested and rated. (3)Do not operate the unit until it is completely repaired, if any of the following conditions exists. (a)Door does not close firmly against the cavity front. (b)The hinge is broken. (c)The choke dielectric or the door seal is damaged. (d)The door is bent or warped, or there is any other visible damage to the oven that may cause microwave energy leakage. NOTE: Always keep the seal clean (e)Make sure there are no defective parts in the microwave generating and transmission assembly. (especially waveguide). (4)Following items should be checked after the unit is repaired. (a)The interlock monitor switch is connected correctly and firmly. (b)The magnetron gasket on the magnetron is properly positioned. (c)Wave guide and oven cavity are intact ( no leakage of microwave energy). (d)The door can be properly closed and the safety switches work properly. (e)The oven must be stopped when the door is opened or the time is up. The oven must not be operated with any of the above components removed or bypassed. -2- 5. OVEN CONTROL PANEL 1 2 MIN SEC 3 4 AUTO 5 7 6 150w 450w 8 9 10 C 11 12 13 / Kg 14 Figure 1 KEYS: 1. Display Window 2. Function and Accessary Indicator 3. Kitchen Timer Display 4. Auto Program Key 5. Auto-Defrost 6. Kitchen Timer Key 7. More/Less Key 8. Personal Menu Keys 9. MIcro Power 10. Delay Start 11. Quick Start 12. Clear/Stop 13. Start 14. Rotary Dial Notes : A "beep tone" sounds when a "pad" on the control panel is touched, to indicate a setting has been entered. When setting the controls you can keep your finger on a key until the desired setting is reached. -3- 6.CIRCUIT DIAGRAM EM-SL20N 230V ~ 50Hz OVEN CONDITION DOOR : OPEN L1,L2 = 1mH C1 = 0.22 F C2,C3 = 4700PF R = 1M C1 R TOUCH KEY BOARD L2 L1 C2 C3 S101 S1 ST COM 5 SC1 RL1 NO L 1 MTCO/ CFTCO(122ûC) GM 3 FUSE (8A T) BM RL4 CONTROL CIRCUIT BOARD RL3 HT(150ûoC) RL2 H IR (25 ) SC3 21 NC COM NO SC2 HIGH VOLTAGE TRANSFORMER COM MAGNETRON 2M-253H(IF)-N H.V. FUSE 0.75A 1.14 F HIGH VOLTAGE RECTIFIER HIGH VOLTAGE CONDENSER 2x500PF/2x1.5uH SC1 : PRIMARY INTERLOCK SWITCH SC2 : DOOR SENSING SWITCH SC3 : INTERLOCK MONITOR SWITCH MTCO/CFTCO : MAGNETRON/CAVITY FIRE THERMAL CUT OUT HT : HEATER THERMOSTAT RL1 : MAIN RELAY RL2 : POWER CONTROL RELAY RL4 : GRILL HEATER RELAY BM : BLOWER MOTOR GM : GEAR MOTOR L : CAVITY LAMP ST : STEP DOWN TRANSFORMER IR : INRUSH RESISTOR - The parts marked with are supplied with a high voltage which exceeds 250V. - The parts marked with have special characteristics important for macrowave leakage. When replacing any of these parts use only manufacturer's specified parts. -4- 7. TEST PROCEDURES AND TROUBLESHOOTING Filament Windings CAUTION - DISCONNECT THE POWER SUPPLY CORD FROM THE WALL OUTLET WHENEVER REMOVING THE CABINET FROM THE UNIT. PROCEED WITH THE TESTS ONLY AFTER DISCHARGING THE HIGH VOLTAGE CAPACITOR AND REMOVING THE LEAD WIRES FROM THE PRIMARY WINDING OF THE HIGH VOLTAGE TRANSFORMER. ( See Figure 3 ) Secondary Winding Primary Windings Figure 4 A. TEST PROCEDURE COMPONENT CHECKOUT PROCEDURE 1) Check for resistance : Across the filament terminals of the the magnetron with an ohmmeter on Rx1 scale. RESULTS Normal reading : Less than 1 ohm. Figure 5 2) Check for resistance : Across the filament terminals of the magnetron and the chassis ground with an ohm-meter on highest scale. MAGNETRON Figure 6 The chart below shows the firing times of the variable power relay for the EM-SL20 model. The table should be used as a means to check the magnetron is operating correctly and producing any other power setting apart from full power. Power Level High (900W) M-High(750W) Roast (450W) Simmer(300W) Warm (150W) Low (80W) On Time/s % On Time (inc.’ramp up’ time) 30.0 100 28.0 93 18.0 60 13.0 43 8.0 27 6.0 20 -5- Normal reading : Infinite ohms COMPONENT HIGH VOLTAGE TRANSFORMER CHECKOUT PROCEDURE RESULTS 1) Measure the resistance : With an ohmeter on Rx1 scale. a. Primary Winding ; b. Filament Winding ; c. Secondary Winding ; 2) Measure the resistance : With an ohm-meter on highest scale. a. Primary winding to ground ; b. Filament winding to ground ; Normal readings : Approximately 1.75 ohms. Less than 1 ohm. Approximately 90.11 ohms. Normal readings : Infinite ohms Infinite ohms Note : Remove varnish of measured point. Figure 7 1) Measure the resistance : Across two terminals with an ohm-meter on highest scale HIGH VOLTAGE CAPACITOR including BLEEDER RESISTOR Normal reading : Momentarily indicates several ohms, and gradually returns to 10 Meg-ohm. Abnormal reading : Indicates continuity or 10MΩ from the beginning. Figure 8 Measure the resistance : Across two terminals with an ohm-meter on its highest scale. HIGH VOLTAGE DIODE Figure 9 Normal reading : Indicates over 10MΩ in one direction (forward direction) and infinite ohms in the reverse direction, using meter which is provided with a 9-volt battery. NOTE Some digital meters may show over even in a forward direction because low measuring voltage of meter does not allow the meter current to pass through the high voltage diode. Abnormal reading: Indicates continuity or infinite ohms in both directions. -6- COMPONENT CHECKOUT PROCEDURE RESULTS Measure the resistance : Across two terminals with an ohm-meter on its highest scale. Normal reading : Indicates continuity. HV FUSE Abnormal reading : Indicates infinite ohms. Figure 10 CONTROL CIRCUIT BOARD COMPLETE Measure the voltage : Between test points TP-1,TP-2, and ground (See control circuit board on page 20 ). NOTE Proceed with the check of the step down transformer, to see if any one of the measured values is different from the specified values -7- Test TP-1 TP-2 point Voltage -5V -15V DC DC CHECKOUT PROCEDURE FOR SWITCHES Disconnect the lead wires from the switches and check the continuity of the switches, connecting an ohm-meter to its terminals. SWITCH CHECKOUT PROCEDURES DOOR OPEN DOOR CLOSE Primary Interlock Connect an ohm-meters leads to terminals "COM" and "NO" of switch Door Sensing Interlock monitor Connect an ohm-meters leads to terminals "COM" and "NC" of switch CAUTION : After checking the switches, make sure that the interlock monitor switch is properly connected according to the CIRCUIT DIAGRAM on page 4. -8- -9-9- Control Circuit Board Check power supply voltage on control circuit board. (See page 7 ) b Check 230V AC power supply of connector S1 between Pin3 and Pin 5 after removing connector S1 from control circuit board. a No display or mis-display in the display window by touching the keys. (1) PROBLEM STEP B. TROUBLESHOOTING V V Voltage incorrect 0 Each Voltage OK 0 230 Volt 0 230 0 Volt 0 230 Check continuity of FUSE, Thermal Protector for cavity, Thermal Protector for magnetron and AC Power Cord. If the fuse has blown see "D. REMOVING FUSE" on page 13 SEQUENCE Replace control circuit board. Correct seating of connector S101 or replace control circuit board. Replace it if necessary Normal control circuit board Normal control circuit board Time Start Runs EM-S350 100 150 450 700 850 1000 Auto Def. Runs PROBLEM 1-b Runs RESULT -10-10- Touch START key and measure voltage between the two wire leads from primary windings of H.V transformer after removing the wire leads from terminals of H.V transformer a Oven does not heat up (3) PROBLEM Check continuity of connector S102 between pins with the door closed after removing connector S102 from control cct board. 0 0 0 Volt 0 230 230 Volt 0 230 No Continuity ∞ Continuity OK ∞ SEQUENCE Check contact of connector S102 Cooking operation will not start. a CHECK : 1. Power Supply to Oven 2. Primary Interlock Switch 3. Thermal protector for Cavity and Magnetron (2) PROBLEM STEP Poor Contact Contact OK Replace Control Circuit Board Normal Door Sensing Switch Normal Contact Normal Control Cct. board Adjust or Replace Door Sensing Switch Correct Seating Runs PROBLEM 3-b Runs Runs PROBLEM 3a RESULT -11-11- Check operation of blower motor when START key is touched. a Low microwave power output. No Operation Normal Operation Check resistance of each winding after removing lead wires. 5 (See page 6) (4) PROBLEM b STEP 0 0 Temporarily short across terminals of thermal protector for magnetron or thermal protector for cavity by using jumper lead. Resistance Correct ∞ Resistance OK ∞ No Operation Normal Operation 0 0 Measure resistance of blower motor (Approx 274 ohms) 0 Normal Resistance ∞ 274 Resistance incorrect ∞ Normal H.V capacitor , diode or fuse. Normal Magnetron Normal HV Transformer Replace HV capacitor, H.V diode or H.V. fuse. Replace HV Magnetron. Replace HV Transformer Defective H.V capacitor, H.V diode or H.V. fuse. ∞ Normal H.V capacitor, H.V diode or H.V. fuse. ∞ Replace control circuit board. Normal control circuit board Replace Blower Normal Blower Motor motor Normal thermal protector for Replace thermal protector magnetron or thermal for magnetron or thermal protector for cavity. protector for cavity. Check H.V capacitor , H.V. diode or H.V fuse with an ohm-meter after removing the lead wires.( See page 76 ) SEQUENCE Up Time Start Up Time Start Up Time Start Up Time Start Up Time Start Up Time Start Runs Auto Def. Runs Auto Def. Runs Auto Def. PROBLEM 3-b Runs Auto Def. Runs Auto Def. Runs Auto Def. RESULT -12- Auto Def. Dual Grill Time Start SEC MIN AUTO Pizza Time of day Chilled Meal Up EM-G451 Start / 450w C Kg Set power level at low. Down 450w Delay Start Dual 150w Pork Chops Dual Chicken Pieces Timer/Weight Clear/Stop C Power Grill Auto Defrost Jacket Potato D I R E C T AC C ESS 150w Liquid 100 150 450 700 850 1000 a Checkresistance resistanceofof Check heater. heater. Aproximately41.7Ω 48.7Ω Approximately measured measuredover overboth terminals. both tubes. 0 Resistance Incorrect. ∞ Normal Resistance. ∞ 52 Touch START key and measure voltage between leads for primary winding of H.V transformer after removing the wire leads from terminals of H.V transformer. Unit does not heat up even if display counts down when key is touched for "Grill Cooking". (6) PROBLEM a The magnetron operates on high level when a lower cook power is selected. (5) PROBLEM STEP 230 Volt 0 230 0 Volt 0 230 SEQUENCE Replace Heater Replace control circuit board. Normal control circuit board Normal Heater Normal control circuit board Replace control circuit board. Time Start Runs EM-S350 100 150 450 700 850 1000 Auto Def. Runs Runs No problem Measure water temperature rise exactly. RESULT 8.DISASSEMBLY INSTRUCTIONS - OVEN MUST BE DISCONNECTED FROM ELECTRICAL OUTLET WHEN MAKING REPLACEMENTS, REPAIRS, ADJUSTMENTS, AND CONTINUITY CHECKS BEFORE PROCEEDING WITH ANY REPAIR WORK AFTER DISCONNECTING. WAIT AT LEAST 1 MINUTE, UNTIL THE CAPACITOR IN THE HIGH VOLTAGE AREA HAS FULLY DISCHARGED. - WHEN REPLACING ANY DOOR MICRO SWITCH, REPLACE WITH THE SAME TYPE SWITCH SPECIFIED ON THE PARTS LIST. A. REMOVING PRIMARY INTERLOCK SWITCH, DOOR SENSING SWITCH AND INTERLOCK MONITOR SWITCH (See Figure 1 on page 1 and Figure 12 on this page) (1) Remove 2 screws securing the lever stopper. (2) Disconnect all lead wires from the primary interlock switch, door sensing switch and the interlock monitor switch (3) Ease away the retaining clips holding the Primary interlock switch onto the lever stopper and remove. (4) Remove the door sensing switch by reference to the step (3). (5) Remove the interlock monitor switch by reference to step (3). (6) Make the necessary adjustment, and make microwave energy leakage check according to “1. ADJUSTMENT PROCEDURES” on page 1. After the switch is replaced with a new one, check proper operation of it according to “CHECKOUT PROCEDURE FOR SWITCHES” on page 8. LEVER STOPPER MICROSWITCH C. REMOVING MAGNETRON (See exploded view on page 16 ) (1) Remove the antenna complete according to B. REMOVING THE ANTENNA. (2) Disconnect the 2 lead wires from the magnetron. (3) Remove 1 screw securing the duct to the magnetron, and take out the duct. (7) Remove 4 screws securing the magnetron to the waveguide. Take out the magnetron VERY CAREFULLY. NOTES - When removing the magnetron, make sure that its dome does not hit any adjacent parts, or it may be damaged. - After replacing the magnetron, be sure to check the microwave energy leakage with a leakage detector and confirm the leakage is below 5 mW/cm2 . D. REMOVING FUSE (A) Remove the 8A fuse with a screwdriver. - When replacing the 8A fuse, be sure to use an exact repair part. - If the 8A fuse blows immediately, check the primary interlock switch and the interlock monitor switch (termi nals “C” and “NC”) according to “CHECKOUT PROCEDURE FOR SWITCHES” on page 8, and make sure to check the microwave energy leakage according to “1. ADJUSTMENT PROCEDURE” on page 1, when the primary interlock switch or the interlock monitor switch is replaced. - If the primary interlock switch is defective, replace not only the primary interlock switch but also the interlock monitor switch. Then install a new 8A fuse. - If the primary interlock switch and the interlock monitor switch (terminals “C” and “NC”) operate properly, determine which of the following is defective: blower motor, turntable motor, high voltage transformer, high voltage capacitor, high voltage diode or magnetron. - If the high voltage diode is defective , replace not only the high voltage diode but also the HV fuse. E. REMOVING DOOR RETAINING CLIPS (1) Remove the 2 screws securing the upper hinge. (2) Tilt the top of the door toward you. (3) Lift up the door to remove it. Figure 12 Interlock Switch Replacement - when replacing faulty switches, be sure switch retaining clips are not bent, broken or otherwise deficient in their ability to secure the switches in place. B. REMOVING THE ANTENNA (See exploded view on page 15 ) (1). Remove the screw securing the cavity cover to the cavity. (2). Remove the antenna complete by slightly bending it so the retension clips holding it slide out of the cavity wall. When replacing the door body or door assembly the new door has to be set properly ensuring the correct door gap between door body and cavity front. To set the new door; 1. Mount door loosely on cavity. 2. Before tigthening the top and bottom hinge screws place feeler gauges (the thickness varies for different models- see table below) between the door assembly and the cavity front plate between the top and bottom hinges. NB. Be careful not to scratch the door cover with the feeler gauges. 3. The door should then be aligned with the control base and held firmly in place leaving a gap within 1-2mm. between the door cover and control base. -13- 4. The hinge screws should then be tightened to hold the door in place, and the feeler gauges removed. 5. The door gap should then be checked again using feeler gauges. Below is a table giving the door setting for the:EM-SL20N (3) Remove power cord from cavity assembly by lifting cord bush, moving it to the left and pulling it away from cavity rear plate. (4) Install the new power supply cord with the reverse procedure of above (1) to (3). WARNING For changing the power supply cord, never use parts other than the following : Part Name : Power Supply Cord Assembly Part No : 617 213 2990 (Continental) DOOR GAP Lower Limit Upper Limit 0.2mm. 0.8mm. After setting the door gap, the door is closed with the door latch fully engaged and the screws securing the switch base are loosened. The switch base is then eased to the right to pull the door face hard onto the front of the microwave. The screws are then secured tight. To check if the operation has been carried out correctly push the door top and bottom. Any movement should be minimal, and the door should feel tight to the front face of the microwave.Confirm that the operation has been successfully carried out by depressing the door release lever until the microswitches are heard to operate. This occurs just before the door opens. NOTES - After replacing the door, be sure to check that the primary interlock switch, door sensing switch and the interlock monitor switch operate normally. (See page 1). - After replacing the door check for microwave energy leakage with a leakage detector. Microwave energy leakage must be below the limit of 5mW/cm2. H. REMOVING TURNTABLE MOTOR COVER (Refer to Figures 13 and 14 below ) (1) Turn the unit and cut the 6 joints of the bottom plate and the motor cover using diagonal pliers (nipper). (See Figure 13 ) (2) Seperate the motor cover and the bottom plate. NOTES - Bend the cut joints inside slightly for safety and be careful of the sharp edges. RE-INSTALL : (1) Rotate the motor cover through 180˚. (2) Insert the edge of the motor cover into the tab on the bottom plate. (3) Secure the motor cover by screwing it to the bottom plate (See Figure 14 ) Use screw 411 156 5502 (not supplied with oven) F. DISASSEMBLYING DOOR ( See exploded view on page 18 ) (1) Insert a thin flat blade screwdriver between the choke dielectric and the door mainframe and lift up the choke dielectric to release the hooks one by one. (2) To remove door cover, remove the 2 screws securing the door cover to the door main frame (3) Insert a thin flat blade screwdriver between the door cover and door mainframe and release the hooks one by one. (4) To detach the glass door panel, insert a thin flat blade screwdriver between the door panel and door cover and release the clips one by one. NOTES - The choke dielectric, the glass door panel and the door cover may be damaged when they are removed. When re-installing them, replace them with new ones if they are damaged. - After installing the door in place, check for microwave energy leakage with a leakage detector. Microwave energy leakage must be below the limit of 5mW/cm2. Clip metal here and at other 5 locations. Metal Tabs Retaining Lugs Figure13 Insert screw here to secure. G. CHANGiNG POWER SUPPLY CORD (See exploded view on page 16 ) Tabs fit into retaining lugs. (1) Removing the earthing screw. (2) Remove the power supply cord from the terminal of PCB complete. -14- Figure14 8. EXPLODED VIEW AND PARTS LIST CAVITY PARTS 2 2 15 2 2 13 1 14 16 19 2 11 12 17 10 3 18 9 8 4 5 7 6 EM-SL20N Key Part No. No. 1 617 220 4376 2 411 156 5601 3 MO-A0730 4 MO-S1121 5 411 001 6005 6 MO-R0132 7 617 184 7659 8 617 215 9560 9 617 167 1421 10 MO-A0737 11 617 169 8930 12 412 037 5901 Description Cabinet SCR TPG PAN+F+S 4x10 Cavity Gear Motor SCR S-TPG PAN 4x8 Special Washer Turntable Shaft Roller Base Ass'y Glass Tray Antenna Complete Cavity Cover SCR TPG TRS 4x6K Q'ty Key No. 13 14 15 16 17 18 19 1 7 1 1 2 1 1 1 1 1 1 1 -15- Part No. 617 221 0025 617 202 4554 617 167 0431 617 169 6875 617 166 2153 617 170 5058 411 010 5600 Description Heater Complete Thermostat, 150˚C Duct Frame Rear Plate Cook Net (H) Cook Net (L) SCR EVR PAN 3x6 Q'ty 1 1 1 1 1 1 1 SWITCHES AND MICROWAVE PARTS 5 3 3 3 27 2 6b 6a 26 19 3 14 13 7 28 25 18 3 20 4 24 1 21 22 8 15 17 9 3 16 10 12 11 EM-SL20N Key No. 1 2 3 4 5 6a 6b 7 8 9 10 11 12 13 14 15 16 Part No. 411 010 5600 411 156 5601 411 156 5502 411 171 9004 617 213 2990 617 179 0746 423 027 8802 617 167 0417 617 162 2041 MO-S0856 MO-S0947AS 617 234 1934 617 182 2915 617 229 3769 MO-S1118 617 112 1025 MO-M1211 Description SCR EVR PAN 3x6 SCR TPG PAN+F+S 4x10 SCR S-TPG PAN+F+S 4x10 SCR TPG TRS+FLG 3x8 Power Supply Cord PCB Complete (N-F) Fuse Space Partition Capacitor Band Capacitor 1.14uF Diode Ass'y Lead Wire Ass'y HV Fuse Blower Motor Magnetron Fan Duct Q'ty 1 1 6 1 1 1 1 1 1 1 1 1 1 1 1 1 1 Key No. 17 18 19 20 21 22 24 25 26 27 28 -16- Part No. 617 195 3428 617 189 0839 617 244 0651 617 244 0644 617 244 0651 MO-S0587 617 202 4561 617 220 1757 617 218 9673 411 004 5609 402 071 0703 Description Latch Lever Lever Stopper Door Sensing Switch Interlock Monitor Switch Primary Interlock Switch Lamp Ass'y Thermostat V122˚C Stay Plate Special Screw NUT HEX M4 Ceramic Resistor Q'ty 1 1 1 1 1 1 1 1 4 1 1 MICROWAVE PARTS 1 3 6 5 8 2 2 4 7 EM-SL20N Key No. 1 2 3 4 5 6 7 8 Part No. 617 209 4557 617 225 1721 617 225 6153 -----------------617 144 5435 617 166 7493 411 156 5602 617 102 7495 Description Transformer Special Screw Bottom Plate Assembly Gear Motor Cover Foot Cushion Assembly Bottom Hinge SCR S-TPG PAN+F+S 4x10 Special Screw -17- Q'ty 1 2 1 1 4 1 1 2 DOOR PARTS Inner Door Panel always supplied with Door Main Frame but can be ordered seperately quoting number below. 3 2 1 4 5 6 EM-SL20N Key No. 1 2 Part No. MO-A0748 MO-A0768 Description * 3 4 5 6 617 144 2472 617 167 0189 617 167 1292 617 195 3411 617 101 1494 Door Cover Assembly Door Main Frame(Supplied with inner Door Panel) Glass Inner Door Panel Hinge Choke Dielectric Door Latch Spring * MO-A0756 Door Assembly Q'ty 1 1 1 1 1 1 1 1 NB. Please refer to the detailed instructions for door setting on page 14 of the service manual before changing, adjusting or repairing these parts. -18- CONTROL PANEL PARTS 4 1 11 3 2 11 6 10 13 7 12 9 8 EM-SL20N Key No. 1 2 3 4 6 7 8 9 10 11 12 13 * * Part No. Description Q'ty MO-A0749 617 236 6463 617 219 5520 617 224 0275 617 197 4836 617 181 7980 MO-A0747 617 188 3329 617 224 1067 411 064 6608 617 231 3047 617 331 3047 Control Base Assembly Knob Body PCB Complete PCB Complete PCB Complete Latch Lever Handle Assembly Spring Knob Assembly SCR TPG BIN 3x8 Special Nut (Metal) Special Nut (Resin) 1 1 1 1 1 1 1 1 1 11 1 1 MO-P5257 MO-P5276 Operating Instructions (EES) Carton Box 1 1 * These items not illustrated -19- 10.CONTROL CIRCUIT BOARD EM-SL20N Model EM-SL20N Spares No. 617 224 0275 RL3 Yes M.Processor IC11 LM8842 49700 TP1 TP2 -24- C2 HEATER THERMO -21- D14 PT1 PD5TK-S150 C15 1000P /50V D12 D13 C13 470u /35V ZD12 ZD13 Q12 D15 B123B 1N4002 R1 4 C11 470u /35V R1 3 3 Q11 A564A ZD11 RD5.6ESB3 R12 2.7K R11 4.7K C16 0.01u /50V RD7.5ESB3 X2 C14 0.01u /50V 1 D103 1N4002 D102 -15V R117 10K C103 0.01u 50V BZ1 2KHZ 10K 10K 10K D107 D109 -5V C107 0.1u /25V OPEN OPEN OPEN C106 0.01u 50V VL1 93 AVSS 40 VSS 13 P55/CNTR1 91 VCC 92 VREF C1 100 C2 1 24 P42/INTO 2 VL3 99 VL2 98 P62/AN2 8 P63/AN3 7 33 32 31 30 29 28 41 42 43 44 45 Q101 DTA123X OPEN OPEN R56 12K R54 12K 38 39 XIN XOUT R301 10K 16 14 15 1 3 2 SW6 7 6 SW5 5 4 2.2K -5V RS1 4MHZ R102 10K 10K -5V ZD101 RD3.9 ESB2 R101 1K SW9-2 -15V SW11 SW10 SW14 SW13 SW12 16 1 MORE/ LESS AUTO A.DEF MICRO START POWER QUICK START KITCHEN TIMER GRILL 1-4 COM1-4 5-27 39-28 DELAY START GRILL 150W GRILL 450W S101 52045-1645 S103 52044-1645 SW BOARD (12700) CLEAR/ STOP 14 15 SW8 SW4 SW9-1 SW3 12 13 9 8 10 11 8 9 6 11 7 10 12 13 SW2 3 2 R132 TIMER SW 4.7K X5 R131 3 5 4 R130 R302 10K -5V 4 23 12 2 1 S301 EH3P R151 390Ω LED1 LED2 LED3 LED4 LED5 Q151 A564A R52 12K R153 1.2K R152 10K OPEN OPEN OPEN OPEN OPEN OPEN R125 10K R126 10K R12710K R12810K R129 10K R304 10K R303 10K R101 100K x5 -5V C302 1000P /50V OPEN OPEN OPEN OPEN OPEN OPEN OPEN C301 1000P /50V R103 C101 560K 1µ D101 /50V RST 35 P80 37 P81 36 P70 34 P66/AN6 4 P67/AN7 3 P77 27 P71 P72 P73 P74 P74 P75 P76 P27 P26 P24 P24 P23 COM0-3 97-94 SEG0-22 90-68 SEG23-34 67-58 55 P11/SEG35 54 P12/SEG36 53 P13/SEG37 52 P14/SEG38 51 P15/SEG39 P16 50 P17 49 P20 48 P21 47 P22 46 P56/TOUT 15 P53 16 P52 17 P51 Q106 DTA143X 14 P54 23 P43 25 P41 26 P40 22 P44 21 P45 20 P46 18 P50 19 P47 -5V 10 P60/AN0 5 P65/AN5 6 P64/AN4 9 P61/AN1 11 P57 Q107 DTA143X 4.7K 12 R120 10K 10K OPEN OPEN OPEN 4.7K OPEN OPEN 10K -5V D111 R121 10K R122 100K R123 100K R124 100K 2.2K Q104 DTA123Y OPEN D108 Q103 OPEN 2.2K DTA123Y Q108 A564A R119 10K -5V R118 10K R105 4.7K R140 4.7K C102 0.01u /50V Q102 OPEN 2.2K DTA123Y R104 10K R116 1K R114 150Ω R115 3.3K D110 RL1 R112 4.7K R110 R111 18Ω x 2 R108 R109 18Ω x 2 R106 R107 18Ω x 2 -5V C12 47u /10V -15V Q105 C1741 R113 CL 47K 1 OPEN OPEN OPEN OPEN IC 11 LM8842 D11 1N4002 X4 S1 3/5P 53062-0310 5 HIGH VOLTAGE CONDENSER 2x500PF/2x1.5uH INRUSH RESISTOR D106 GRILL HEATER INRUSH D105 BM GM RL2 MQ D104 DOOR SENSING SWITCH S102 5267-03A 2 CL HIGH VOLTAGE RECTIFIER RL3 RL2 RL4 MQ/OVEN THERMO FUSE 8A(T) GRILL HEATER CAPACITOR HIGH VOLTAGE TRANSFORMER MONITOR SWITCH R C3 L1,L2 = 1mH C1 = 0.22µF C2,C3 = 4700PF C1 R = 1MΩ MAGNETRON PRIMARY SWITCH V5T1 L2 RL1 L1 SW BOARD (31900) LCD1 H4062 230V 50Hz 11. OVERALL CIRCUIT DIAGRAM EM-SL20N Please Note All the information that appears in this service manual was correct at the time of production. SANYO Electric Company reserves the right to make changes to parts or processes in order to maintain their policy of continuing improvement. 2002-09