Download DWYER INSTRUMENTS, INC. Phone: 219/879-8000

Transcript

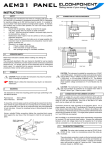

D-27 9/26/07 8:57 AM Page 1 Bulletin D-27 Series WWDP Wet-to-Wet Differential Pressure Transducers Specifications - Installation and Operating Instructions 6 [152.4] 2 [50.5] 5-9/16 [141.29] R7/64 [R2.78] 4-39/64 [117.08] 11/32 [8.73] 4-53/64 [122.63] 4 [101.6] 2 [50.8] 1-15/64 [31.35] 1-43/64 [42.47] 5-11/64 [131.37] 1/8” NPTF 1-9/16 [39.69] 61/64 [24.21] 1/2” CONDUIT OPENING The Series WWDP Wet-to-Wet Differential Pressure Transducer offers everything in one package by having 30 field selectable variations in just 3 models. The WWDP provides field selectable unidirectional and bidirectional pressure ranges, configurable 0-5, 1-5, 0-10 VDC, and 4 to 20 mA output. It also provides an auto-zero capability. The field selectable port swap feature eliminates costly replumbing if the unit is improperly installed or if the transducer is simply replaced. An optional LCD display is available for on-site indication of line and differential pressure. The all cast aluminum housing is rated NEMA 4 (IP66). These features make the WWDP transducer an ideal instrument for measuring the flow of various liquids and gases, pressure drop across filters, measurement of liquid level or pressurized vessels, and for use in energy management and process control systems. INSTALLATION The Series WWDP Wet-to-Wet Differential Pressure Transducer has 1/8” NPTF internal fittings. The high pressure port and low pressure port are located on the bottom of the unit, labeled “HI” and “LO”, respectively. MOISTURE PRECAUTIONS The Series WWDP is provided with a 0.875 DIA. conduit opening for electrical termination, intended for a 1/2” I.D. conduit connection. This opening must be sealed according to standard industry practices in order to prevent moisture ingress into the Series WWDP. MOUNTING The Series WWDP can be easily mounted using the two mounting screws located on the side of the unit. INSTALLATION PROCEDURES For differential pressure measurements at high line pressure, it is recommended that the pressure sensor be installed with a valve in each line, plus a shunt valve across the high and low (reference) pressure ports as shown in Figure 1. The remote zero is a normally open relay wired between COM and REMOTE ZERO terminals. In order to initiate ZERO function, the relay contact shall be closed. Important: Do not exceed maximum range pressure with a total of differential pressure and line pressure. SPECIFICATIONS Service: Gases or liquids compatible with 17-4 PH stainless steel. Accuracy: All pressure ranges have ±1% full scale accuracy except the lowest selectable range of each unit is ±2% full scale. Stability: ±0.5% per year. Temperature Limits: Compensated Temperature Range: 32 to 130˚F (0 to 54˚C); Operating Temperature Range: -4 to 185˚F (-20 to 85˚C). Pressure Limits: Max working pressure: WWDP-1: 50 PSI; WWDP-2: 100 PSI; WWDP-3: 250 PSI; Proof Pressure: 2.2X of full scale; Burst Pressure: 40X of full scale. Thermal Effect: 2% FS/100˚F (50˚C) includes zero and span. Power Requirements: 12 to 30 VDC/18 to 28 VAC (Reverse Excitation Protected). NOTE: 4-20 mA output cannot be powered with AC voltage. Output Signal: Selectable 0-5, 0-10 and 1-5 VDC; 4 to 20 mA. Zero & Span: Digital “re” zero button (should be used when changing ranges). Span can be adjusted by changing between field selectable ranges. Response Time: 1 to 5 sec (selectable). Loop Resistance: 1000 ohms. Current Consumption: VDC power: 0-5, 1-5 VDC output 4 mA (typ); 010 VDC output 5 mA (typ); 4-20 mA output 20 mA max. Current Consumption will equal the transmitter output in current mode. VAC power: 0-5, 1-5, 0-10 VDC output 40 mA (typ). Electrical Connections: 1/2” Conduit. Process Connections: 1/8” Female NPT Internal. Enclosure Rating: Designed to meet NEMA 4 (IP66). Mounting Orientation: Vertical; Mount the pressure ports down (keeps debris from building up inside the pressure port). Size: 4 x 6 x 2 in (102 x 152 x 51 mm). Weight: 1.5 lb (680.4 gm). Agency Approvals: CE. Low High Valve B Valve A Valve C ELECTRICAL INSTALLATION To access the electrical connections, turn the screws on the top of the case counter clockwise until the hinged cover can be flipped up. The screws are captured and secured in the cover. Wiring is through the 1/2” conduit opening. Both current and voltage outputs are reverse excitation protected. Low High Differential Pressure Sensor Valve A = High Side Valve Value B = Low Side Valve Valve C = Shunt Valve Figure 1 DWYER INSTRUMENTS, INC. P.O. BOX 373 • MICHIGAN CITY, INDIANA 46361, U.S.A. Phone: 219/879-8000 Fax: 219/872-9057 www.dwyer-inst.com e-mail: [email protected] D-27 9/26/07 8:57 AM Page 2 Installation of the Series WWDP is now complete. ELECTRICAL TERMINATION Wiring: 2-Wire - 4 to 20 mA (Current Output) and Remote Zero The Series WWDP when configured as a current output transducer is a true 2-wire, 4-20 mA current output device and delivers rated current into any external load of 0-1000 ohms. When configured as a 4-20 mA current output device, the current flow is in one direction only. PLEASE OBSERVE POLARITY. We suggest that an electrical cable shield be connected to the system’s loop circuit ground to improve electrical noise rejection. Min. Supply Voltage: Max. Supply Voltage: Important: Prior to putting the unit into service, press the “Zero” button, then use the “Range Selection Switch” to select a range. After selecting a range, press the “Zero” button again. For instructions regarding operation of the Series WWDP, please refer to the following, Operation. OPERATION Range Selection Switch 12 + .02 x (Resistance of receiver plus line) 30 + .004 x (Resistance of receiver plus line) ZERO A B C D RANGES A WWDP-1 50 WWDP-2 100 WWDP-3 250 EXC. B C D 25 10 50 20 125 50 5 10 25 OUTPUT A B C 4-20 0-5 0-10 BAR A.REV SLOW BI-DIR SWAP D 1-5 PSI NORM FAST UNI-DIR NORM C D 25 10 5 50 20 10 WWDP-3 250 125 50 25 OUT COM Caution: Do Not Connect “+” exc to “+” out. The Series WWDP can operate from 12-30 VDC (18-28 VAC) nominal output power supply. NOTE: The ZERO terminals, connected to digital output, provide a contact closure relay for automatic reset to zero pressure by the monitoring system. CAUTION: ZERO input is for dry contact, do not apply voltage to ZERO Terminals. D A B WWDP-1 50 25 WWDP-2 100 50 WWDP-3 250 125 PSI NORM FAST UNI-DIR NORM Figure 4 Figure 2 Wiring: 3-Wire, 0 to 5, 0 to 10, 1-5 VDC and Remote Zero The Series WWDP when configured for voltage output is a 3-wire circuit device with three terminals available for wiring. The -Excitation and -Output are commoned on the circuit. C BAR A.REV SLOW B C D A BI-DIR 4-20 0-5 0-10 1-5 SWAP 4-20 MA REMOTE ZERO Relay EXC. B A B C D Configuration Electrical Connections Controller Current (4-20 mA) B A WWDP-1 50 WWDP-2 100 Electrical Output ETC. OUT COM DC Power Supply A ZERO A B C D Note: The Zero terminals, connected to digital output, provide contact closure relay for automatic reset to zero pressure by the monitoring system. CAUTION: ZERO input is for dry contact, do not apply voltage to ZERO Terminals. A B C D Auto Zero Button A C 10 20 50 D 5 10 25 A 4-20 B B 0-5 C D C D 0-10 1-5 BAR A.REV SLOW BI-DIR SWAP PSI NORM FAST UNI-DIR NORM OUT COM Range Selection Switch: The unit is set to the highest range when calibrated. To select the other ranges, slide the switch to the right. Important: Push “zero” button after installing the Series WWDP, and after changing range. Auto Zero Button: Press and hold the “ZERO” push-button for 2 seconds to automatically reset zero or provide contact closure on “Remote Zero”, see Figure 2 and Figure 3. Electrical Output: The unit is set to 4-20 mA. To select another output, move the slide switch to the right. Electrical Connections: Electrical termination for power supply, 3-wire voltage output and 2-wire true 4-20 mA current output, and remote zero wiring. A.Rev/NORM: A.REV: Analog Reverse: When in reverse mode, the output increases when the differential pressure decreases and decreases as pressure increases. NORM: When in Normal mode, output increases as pressure increases and decreases as pressure decreases. SLOW/FAST: When Slow mode is selected, 5-second averaging is provided for surge damping. BI-DIR/UNI-DIR: Select UNI-Directional or BI-Directional mode. Unidirectional mode measures from 0 to full scale differential pressure. Bidirectional mode measures pressure from minus 1/2 of full scale to plus 1/2 of full scale differential pressure. Output will read 1/2 full scale when differential pressure is zero. SWAP/NORM: Jumper selectable Port Swap feature eliminates costly replumbing when incorrectly installed or replaced. Go from NORMAL to SWAP and the jumper makes the “HI” Port “LO” and the “LO” Port “HI”. RETURNING PRODUCTS FOR REPAIR Please contact Dwyer Instruments, Inc. before returning unit for repair to review information relative to your application. Many times only minor field adjustments may be necessary. When returning a product to Dwyer Instruments, Inc., the material should be carefully packaged and shipped. Upon final installation of the Series WWDP Differential Pressure Transducer, no routine maintenance is required. A periodic check of system calibration is recommended. The Series WWDP is not field serviceable and should be returned if repair is needed (field repair should not be attempted and may void warranty). Be sure to include a brief description of the problem plus any relevant application notes. Contact customer service to receive a return goods authorization number before shipping. Note: Please remove any pressure fittings and plumbing that you have installed and enclose any required mating electrical connectors and wiring diagrams. DC/AC Power Supply Controller Voltage Relay Figure 3 ©Copyright 2007 Dwyer Instruments, Inc. Printed in U.S.A. 9/07 DWYER INSTRUMENTS, INC. P.O. BOX 373 • MICHIGAN CITY, INDIANA 46361, U.S.A. Phone: 219/879-8000 Fax: 219/872-9057 FR# R1-443565-00 Rev.1 www.dwyer-inst.com e-mail: [email protected]