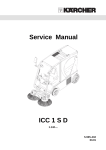

Download KMR 1250 Service Manual - Cleaning Equipment Parts.com

Transcript