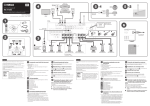

Download 950/1025/1050/1055 950 ProRacer Computer Wheel Balancers

Transcript