Download Wiener VME 602X Crate Service Manual

Transcript

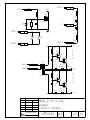

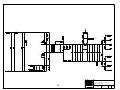

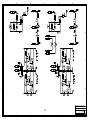

VME 602X – Series Service Manual UEP 6000 Service Manual 1 10/16/06 General Remarks The only purpose of this manual is a description of the product. It must not be interpreted a declaration of conformity for this product including the product and software. W-Ie-Ne-R (WIENER Plein & Baus Corp. and Plein & Baus GmbH) revises this product and manual without notice. Differences of the description in manual and product are possible. W-Ie-Ne-R excludes completely any liability for loss of profits, loss of business, loss of use or data, interrupt of business, or for indirect, special incidental, or consequential damages of any kind, even if W-Ie-Ne-R has been advises of the possibility of such damages arising from any defect or error in this manual or product. Any use of the product which may influence health of human beings requires the express written permission of W-Ie-Ne-R. Products mentioned in this manual are mentioned for identification purposes only. Product names appearing in this manual may or may not be registered trademarks or copyrights of their respective companies. No part of this product, including the product and the software may be reproduced, transmitted, transcribed, stored in a retrieval system, or translated into any language in any form by any means with the express written permission of W-Ie-Ne-R. W-Ie-Ne-R declines all responsibility for any damage of the VME crate or part of it and / or crate or of any equipment used inside or outside of the crate caused by improper use of it or operation / action of unauthorized not-qualified personal. This Service manual is only for qualified and authorized persons. UEP 6000 Service Manual 2 10/16/06 UEP 6000 Power Supply Configuration and Test Software The MUH6000 program is a software for Windows based PC’s to test and set-up the configuration and calibration of WIENER power supplies of the UEP 6000 series. The communication is via RS232 using the WIENER UEP 6000 adapter cable. WIENER Plein & Baus Corp. / GmbH is not responsible for any damage of the power supply and / or crate or of any module inside the crate caused by changing the factory prepared configuration and calibration of the power supply. The test and diagnostic box and MUH 6000 software has to be used by authorized and qualified personnel only! To protect the UEP 6000 power supply for unauthorized access there is a hardware write protection. This write protection prevents unauthorized users from changing the nominal voltages, calibration values, and current limits. To override this protection you most have the Flash6.exe program. !!!!! DANGER - HIGH VOLTAGE !!!!! For authorized, qualified service personnel only This power supply uses high voltage up to 400V inside. Unauthorized persons are not allowed to open the UEP 6000 power supply or to connect them to AC mains or use them without completely closed chassis. Do not open while connected to AC mains, unplug first from the wall outlet. After opening the power supply discharge first all capacitors of primary side (AC input module and 3-pin primary distribution cables/connectors) as well as of the MUH AUX power supply with a load resistor. In case of questions please contact: W-IE-NE-R Plein & Baus Ltd., Dr. A. Ruben 300 East Auburn Ave. Springfield, Ohio 45505 Phone : (937) 324 2420 FAX : (937) 324 2425 E-mail: [email protected] URL : http://www.wiener-d.com UEP 6000 Service Manual 3 10/16/06 1) MUH 6000 installation and start Please copy the RS232.DLL as well as the WIENER.INI configuration file to the Windows directory of your computer. Before starting the program make sure that the power supply is not connected to the AC-line. Connect the UEP 6000 power supply to the serial port of the PC via the WIENER adapter cable. DO NOT CHANGE THIS CONNECTION WHILE THE POWER SUPPLY IS CONNECTED TO AC MAINS!!! Change the COM setting to fit your setup the WIENER.INI file by changing COM2 to the correct COM port of the used serial port. Connect the power supply to the AC mains line. During program start the software automatically detects and connects to the power supply if the RS232 connection is available through the selected COM port. The main window displays the power supply setting and status as shown in the following example. In case of any communication problem (wrong COM port, cable connection not ok, …) the „RS232 connection is interrupted” error message is shown. The main window shows further the power supply ID (serial number or part number). The UEP 6000 power supply can be switched on or off by mouse clicking on the POWER ON / POWER OFF line or by selecting the menu item. After switching on all power supply channels should show an „OK“ status. UEP 6000 Service Manual 4 10/16/06 2) Power supply operation and configuration file Please save the present configuration of the connected power supply as a file to hard or floppy disk before changing any item. It is recommended to keep all configuration files to allow an easy restore of the configuration data at a later time. 3) Power supply set-up and calibration To access any (available) parameter point the cursor on it and click with the left mouse button. If you do not see the parameters mentioned below, click on the “Configuration” menu. This will bring up a window that allows you to choose which parameters are shown. WIENER Plein & Baus Corp. / GmbH is not responsible for any damage of the power supply, VME crate or of any module inside the crate caused by changing the factory prepared configuration and calibration of the power supply. To protect the UEP 602X power supply for unauthorized access there is software write protection. All parameters that are gray are write protected. UEP 6000 Service Manual 5 10/16/06 To enable "WRITE „ you must use the WIENER flash6.exe program. This is available only to authorized personnel. Please contact WIENER for more information. Software Parameter Descriptions: CHANNEL Module definition define channel name set voltage and current range setting (digits) Example: STBY: 31V / Ampere XXXX. / Volt XX. Note: Wrong range settings can result in a wrong current and voltage display on the UEL 6020 display even in case of correct output values. UEP 6000 Service Manual 6 10/16/06 Voltage Calibration Voltage Calibration With the UEP6000.EXE software, the lines "Calibration (Kovp)", "Calibration (Ku)" and "Calibration (Kf)" are available. This values describe the module ovp voltage divider, the module sense voltage divider, and the relation between the module coarse and fine DAC. Typical values for different modules: To find the correct calibration values for a specific module, click in the UEP6000.EXE to the Ku value. Then the following window is displayed: UEP 6000 Service Manual 7 10/16/06 Set the Ku and Kf values to the table values of the module that is used, click OK, and click to the Ku value again. Then click on the CALIBRATE button. An automatic calibration is started. Now enter the real output voltage (measured with a voltmeter) into the "measured Voltage" field. Hit the ENTER Key or click on the CALIBRATE button again. Ready. Now you have the calibrated values for Ku and Kf. By comparing the Ku value with the table above, you could see which module you have got. Click to the Kovp value and change it to the table value. Now the calibration is ready, and you should set the Output Voltage and OVP levels. Default values Value Maximum Output Voltage [V] The voltage the customer wants Umax (module table) 125% of the Output Voltage OVPmax (module table) OVP[V] REMARKS In some cases, the MUH6 voltage measurement range is lower than the maximum module output voltage. (e.g., if you connect a 24V module to U0, which could measure max. 7.5V). During calibration, the DACu value of 255 is used by default. (This will give the best accuracy). But if the module output voltage exceeds the MUH6 measurement range, the calibration will fail. In that case, you should reduce the DACu value before pushing the "CALIBRATE" button. Cal I-Monitor Current Calibration The current calibration should be done for a current limit close to full load (90%) for each voltage channel. Connect the power supply output to a load and measure the actual current. The calibration factor is automatically calculated if writing the data for the measured current and monitor voltage to the computer and pressing “CALIBRATE”. If the calibration factor is known it can be typed in directly. To store the new calibration setting for the channel press “OK”. UEP 6000 Service Manual 8 10/16/06 After a current calibration the correct current monitoring should be checked for lower loads ( ½ and ¼ of nominal current value). Output Voltage Define Nominal Voltage Value is the nominal voltage of the voltage channel. Minimum Value is the minimum allowed value for the nominal voltage. Maximum Value is the maximum allowed value for the nominal voltage. Exponent gives the number of digits after the decimal. Current Limit output current limit (Secondary programmable current limit) Standard setting: Hardware Limit This Current Limit is the maximum current value that the module is permitted to produce. When this current limit is reached the module will enter into a constant current mode by lowering the voltage until it reaches the minimum allowed voltage. By default this value is set to the hardware limit of the module. Monitoring:Umin Software minimum voltage limit Standard settings: 97.5% of nominal voltage Unom The minimum voltage limit is the minimum allowed voltage for a given channel. If the voltage of that channel ever reaches or drop below the minimum value, the power supply will turn off with an “Undervoltage “ error. UEP 6000 Service Manual 9 10/16/06 Value is the minimum allowed voltage for the channel. Minimum Value is the minimum allowed value. Maximum Value is the maximum allowed value. Exponent gives the number of digits after the decimal. Monitoring:Umax Software maximum voltage limit Standard settings: 105% of nominal voltage Unom The maximum voltage limit is the maximum allowed voltage for a given channel. If the voltage of that channel ever reaches or exceeds the maximum value, the power supply will turn off with an “Overvoltage “ error. Value is the maximum allowed voltage for the channel. Minimum Value is the minimum allowed value. Maximum Value is the maximum allowed value. Exponent gives the number of digits after the decimal. UEP 6000 Service Manual 10 10/16/06 Monitoring:Imin Software minimum current limit Standard settings: No minimum (0) The minimum current limit is the minimum allowed current for a given channel. If the current for that channel ever reaches or drop below the minimum value, the power supply will turn off with an “Undercurrent “ error. Value is the minimum allowed current for the channel. Minimum Value is the minimum allowed value. Maximum Value is the maximum allowed value. Exponent gives the number of digits after the decimal. Monitoring:Umax Software maximum cuurent limit Standard settings: 100% of Hardware Limits The maximum cuurent limit is the maximum allowed current for a given channel. If the cuurent of that channel ever reaches or exceeds the maximum value, the power supply will turn off with an “Overcurrent “ error. UEP 6000 Service Manual 11 10/16/06 Value is the maximum allowed voltage for the channel. Minimum Value is the minimum allowed value. Maximum Value is the maximum allowed value. Exponent gives the number of digits after the decimal. OVP OVP setting Standard settings: 125% of Unom OVP is a secondary voltage protection. It sets the maximum voltage that a module may produce. If the module ever detects a value greater than OVP it will turn off the power supply with an “Overvoltage” error. Value is the maximum allowed voltage for the module. Minimum Value is the minimum allowed value. Maximum Value is the maximum allowed value. Exponent gives the number of digits after the decimal. Temperature Limit Temperature Limit settings UEP 6000 Service Manual 12 10/16/06 Standard settings: 127 Temperature Limit settings sets the maximum internal temperature of the power supply module before turning off the power supply. The default settings allow the module to run to the maximum temperature. Power-on Delay Delay between power-on and ramp Standard settings: 0 To allow flexibility of the voltage ramp, it is possible to set channels to begin their voltage ramp at different times. This is done by delaying the start of the ramp by some time in steps of ms. Temperature OK or Fail Status OK Power ON - OFF by software ( mouse click or <P>) AC OK - Fail (status of AC mains) Trip off Enable - Disable (temperature and OVP control enabled - disabled) WARNING Disable TRIP OFF only if necessary, don’t leave the power supply with TRIP OFF disabled! The power supply and crate or modules in the crate can be damaged in case of error conditions without enabled automatic trip off protection. UEP 6000 Service Manual 13 10/16/06 Complete Test Instruction for UEP 6000 1. Visual test Power Supply surface ok? Final set-up ok? Cable mounting ok? 2. HV-Test 2.4kVDC: AC-mains - PE Short circuit test @ 50V DC: Output - PE. - since 1998 sticker: HIGH VOLTAGE TESTED - high voltage test has to be repeated if there are changes of the power configuration or set-up 3. Put into Operation (with complete function control) Configuration, calibration (trimmer) , current measurement adjustment ( I-Mon ) Measurement of current limit (short circuit current) - since 1998 sticker CALIBRATED - sequence of test steps according to test procedure 4. Burn In Long time test with full load and multiple on / off ( - since 1998 sticker LONG TIME TESTED - Attention: do not exceed the maximum total power (mains fuse!) - in case of parallel working AC inputs take care for equal load for both - power supply levels 5. Mechanical Set-up a) Mounting screws OK? b) Power terminal contacts OK? c) Mount missing mechanical parts and check all screws d) test fitting of power supply into VME bin 6. End check to be done with protocol - since 1998 sticker END CONTROLLED - sequence of test steps as for 3. Put into Operation - write protection enabled? - visual check for stickers and device label UEP 6000 Service Manual 14 10/16/06 Test Procedure Sequence UEP6000 1. Test AC input switch AUTO/FIX for Power Supplies with auto range AC inputs - AUTO : feed 3V DC in AC mains cable, measure current (typically 0,08mA) - switch to 115V ( current typically 0,52mA). - prepare for delivery with switch position to AUTO with locking and sticker 2. Start Power Supply Operation: - disable Write protection (jumper), connect power supply to IBM-PC (RS 232) - feed AC mains in power supply - start software UEP 6000, create or copy configuration file - if the fan tray unit is connected to the power supply the write protection jumper has to be disabled during start for power supply software version MUH 1.00 3. General behavior / settings Main configuration OK ? RS 232 OK ? Channel? Module-current/limit? Module OVP? Module Unom? min/max Voltage? 4.Test each Voltage Channel Check adjustment Master-Slave Imon and CV. Coding for slave U-nom under full Load : fine tuning ? display OK ? Noise and Ripple OK ? Current calibration for 3 load values (full, half, no load): I-nom Full load Half Load No Load Display Fan tray ? ? ? ? ? ? Signal I-nom At this time proof static regulation (U) ( Sense wiring) T-Hold after AC-Fail, U-Dynamic, T-Recovery have been checked within power module test 7. Adjustments Voltage Error adjusted? Current Error checked with different current values? Reference Table for Test and Adjustment of UEP 6000 UEP 6000 Service Manual 15 10/16/06 CHANNEL Module selected Are all installed voltage channels present? Example: STBY: 31V / Ampere XXXX. / Volt XX. Cal I-Monitor Calibration measure current Enter measured current and hit “CALIBRATE” Output Voltage output voltage Nominal voltage for the channel Current Limit The max current allowed for that channel (constant current) maximum current Monitor U-min minimum voltage 90% of nominal voltage Monitor U-max maximum voltage 112.5% of nominal voltage Monitor I-min minimum current Generally 0 Monitor I-max maximum current 112.5% of nominal expected current (“Overcurrent” error) Module OVP maximum voltage 125% of nominal voltage Power on Delay ramp Delay Delay, in ms, between power-on and start of voltage ramp Temperature OK or Fail Status OK Power ON - OFF by software ( mouse click or <P>) AC OK - Fail (Status of AC mains at Elko) Trip off Enable - Disable UEP 6000 Service Manual 16 10/16/06 UEP 6000 Module Replacement Instructions In troubleshooting WIENER crates it is very useful to substitute Fan trays and power supplies from working crates into the crate which is problematic, this is often the best way to determine which component (fan tray, power supply, or crate) is causing the failure. It is also useful to place the power supply on a bench top and use the UEP6000 software to troubleshoot power supplies. MNPFC-16 The MNPFC-16 is the primary rectifier for the UEP6000 power supply. Common symptoms of a power supply with a faulty are MNPFC are: • No indication that the power supply is operating. • The green LED on the board is not lit. (Visible with case closed). • No “click” when power supply is plugged in. • No internal primary DC voltage from MNPFC-16 (385VDC) If the MNPFC is found to be the problem, the following steps should be taken to replace it: • Disconnect A/C power and remove power supply from the VME crate. • Remove the top cover from the power supply and discharge capacitors • Remove the side panel on which the MNPFC is mounted, including the nuts with which the module is mounted. • Disconnect the A/C wires (Brown & Blue) as well as the flat ribbon cable and DC connector from the module. • Installation is the reverse of removal. • After replacing the cover, connect the A/C input and ensure that functionality is OK. UEP 6000 Service Manual 17 10/16/06 MEH/MDH The MEH/MDH modules are the secondary rectifier modules that produce the voltages used by the VME crate. Common symptoms of a faulty MEH/MDH module are: • An over/under voltage error for a certain channel (On UEL display or via UEP6000 software). • The power supply will start up but turn itself off quickly. If an MDH/MEH module is found to faulty the following steps should be taken to replace it (valid only for standalone modules): • Disconnect A/C power and remove power supply from the VME crate. • Remove the top cover from the power supply and discharge capacitors • Determine which power module is faulty. This is done by locating the right channel along the top of the MUH board and following the control cable to the correct module. • Disconnect the power cables and the flat control cable(s) from the module. • Remove the screw that holds the module to the case. • Slide the module forward and remove the module. • Installation is the reverse of removal. • Calibrate the voltage and current measurements • After replacing the cover, connect the A/C input and ensure that functionality is OK. UEP 6000 Service Manual 18 10/16/06 MUH The MUH module is the microprocessor control board for the power supply. Common symptoms of a faulty MUH module are: • No function although internal operating voltage is present (385VDC). • Under/over voltage error for 1 or more voltage channel. • No remote interface (errors when connected to UEP6000 software). If an MUH module is thought to be faulty the following steps should be taken to replace it: • Disconnect A/C power and remove power supply from the VME crate. • Remove the top cover from the power supply and discharge capacitors • Remove the side panel next to the MUH module. • Disconnect the flat ribbon control cables, recording where they were plugged in. • Disconnect the sense, CAN, DC, and control cables. • Remove the 25-pin D-sub connector to gain access to the screws holding the MUH board to the chassis. • Remove the module from the crate. • Remove the EEPROM from the module and place it into the new MUH module. This will transfer the channel calibration information. • Installation is the reverse of removal. • Once power supply cover is replaced, check that the current and voltage calibrations are correct. UEP 6000 Service Manual 19 10/16/06 UEP 6000 Channel Calibration Voltage Calibration Voltage calibration values vary depends on what kind of module you are calibrating and which nominal voltage you wish that channel to have. To calibrate a power supply channel: • Connect the power supply to a PC and start the UEP6000 software • Start Flash6.exe and turn off “write disabled” • Click on “Voltage OVP” and enter the value specified in the table below. • Turn the power supply on and measure the channel voltage. Current Calibration Correct current calibration ensures that the power supply reports the correct current readings. To calibrate the current values for a given channel, the following steps should be taken: • Connect the power supply to a PC on which the UEP600 software is installed via a appropriate adapter cable. • Connect a current sink to the channel that you wish to calibrate. • Connect A/C power and ramp the current up to 90% of the channel maximum. • Click on “Calibration [I-monitor]” and enter the measured current. • The UEP6000 will calibrate the current monitor and should now report the same value as the measured current. The calibration procedure above only works for master modules. If you have two or more modules running in co-operation with each other, you will have to do a master-slave calibration. Please contact a WIENER representative for guidance with this task. UEP 6000 Service Manual 20 10/16/06 Module-Data MRP Resistor DAC[k] R6[k] Version .B2 and below Version .B3 and above 12 20 R5[k] alpha 75 0,81308 750 0,97442 Kf 7533 860 Modules Uref(U) [10mV] Uref(OVP) [10mV] MRP: R13, R14 [k] MRP: R17, R18 [k] MRP: R4, R12 [k] Module Type 5V-MEH, <= Index A5 5V-MEH, >= Index A6 MEH10 MEH12, <= Index A1 MEH12, >= Index A2 MDH7-15, >= Index A0 MDL12/24, (MEH24) MEH48 510 250 10 20 10 R4,R12 [kOhm] 13,3 22,1 33,2 61,9 56,2 56,2 110 221 DACovp = U[V]*Kovp/655.36 Modul-DAC-Values.xls MRP :B2 Ku Poti[mV] 34729 4,34 25208 5,98 18731 8,04 11254 13,39 12223 12,33 12223 12,33 6743 22,34 3503 43,01 MRP :B3 Ku Poti[mV] 28978 0,59 21034 0,82 15630 1,10 9391 1,83 10199 1,69 10199 1,69 5627 3,06 2923 5,88 Umax R9,R10 [V] [kOhm] 5,92 27,4 8,15 43,2 10,97 56,2 18,26 82,5 16,82 82,5 16,82 82,5 30,48 133 58,67 274 Kovp 24492 15534 11941 8134 8134 8134 5046 2449 OVPmax R5/8 R6/7 GND-floating [V] [V] 6,82 1 0 12,0 10,76 1 0 12,0 14,00 2,21 2,21 24,0 20,54 2,21 2,21 24,0 20,54 2,21 4,75 37,8 20,54 33,12 1 0 12,0 68,23 4,75 30 87,8 alte Module 21 27.03.03 Connection of a Personal Computer to the Power Supply UEP6021 This connection is intended to service functions only. Because of the direct connection between the PC and the power supply, the ripple and noise of the outputs will increase! The needed stuff is an PC running Windows, the control program UEP6 and a simple adapter (“Dongle”). The power supply is connected to the COM port of the PC. For more details, view the document *00461.A0. X3, 9 Pin DSUB male (UEP6) 9 Pin DSUB female (PC) 3 2 8 3 7 1 kOhm 5 6 1 kOhm 100nF 22 PL6021 Connection Diagram POWER CONNECTOR 17 - 14 - 11 - 8 - 5 - 2 - U6 U5 U1 U3 U4 U0 16 + 13 + 10 + 7 + 4 + 1 + Pin 10,11,13...18: Pin 1...9+12: Polarity: + positive 6mm, 120A max. 8mm, 240A max. - negativ 3 + U0 to U7 = standard pinning only! SENSE/SIGNAL CONNECTOR D-SUB 37 19 TEMP RETURN 37 TEMP 0 18 TEMP 1 36 TEMP 2 17 TEMP 3 35 TEMP 4 16 TEMP 5 34 TEMP 6 15 TEMP 7 33 BIN EEPROM: IIC SDA 14 BIN EEPROM: IIC SCL 32 BIN EEPROM:+5V 13 VME LOGIC: SYSRESET 31 BIN EEPROM: GND 12 VME LOGIC: ACFAIL 30 VME LOGIC GND 11 VME LOGIC: SYSFAIL 29 U0 SENSE - 10 U0 SENSE + (VME: +5V) 28 VW SENSE (reserved) 9 VW SENSE (reserved) 27 VX SENSE (reserved) 8 VX SENSE (reserved) 26 U4 SENSE + 7 U4 SENSE - 25 U7 SENSE + 6 U7 SENSE - 24 U2 SENSE - 5 U2 SENSE + (VME: 48V) 23 U6 SENSE + 4 U6 SENSE - 22 U1 SENSE - 3 U1 SENSE + (VME: +12V) 21 U5 SENSE + 2 U5 SENSE – (VME: -12V) 20 U3 SENSE - 1 U3 SENSE + (VME: +3.3V) FAN/CONTROL CONNECTOR D-SUB 9 5 Spare 37 6 - D-SUB 9 + U7 9 12 - U2 D-SUB 15 + 18 - CAN_H 9 CAN_L 4 CAN GND 8 RXD 3 TXD 7 +15V (for fan only) 2 +15V (for fan only) 6 -15V (for fan only) 1 -15V (for fan only) 23 WIENER VME Crate Temperature Sensors 24 VME 6000 Series Bin EEPROM configuration WARNING!!! Changing the BIN EEPROM setting could damage modules in the VME crate. WIENER 6000 series VME crates contain an EEPROM which contains data about what power supplies to accept. This prevents users from accidentally plugging in power supplies that could damage modules within the crate. If the crates function is changed and the EEPROM needs to be reprogrammed, it can be done by following the steps below. 1. Remove the fantray from the crate. This will give you access to a subD 9 pin connector. Plug one end of a WIENER power supply adapter into the connector, connect the other a computer. 2. Insert a jumper on the write protect pins for the EEPROM. The pin locations are shown below. Write jumper 25 3. Open the UEP6000 program. The current bin settings should now be visible as highlighted below. 4. If screen does not show BIN configuration, select configuration and highlight these lines: 26 5. Select bin parameter to be changed and enter new value 6. Changes are saved automatically when you hit OK 27 UEL6000 Ethernet Firmware-Update The UEL6000 Firmware is stored in a FLASH ROM and can be updated via the RS232 connector. Necessary equipment: - Computer with RS232 interface, running Microsoft Windows (98 or above) - A patch cable to connect the UEL6000 with this computer - This software Installation Steps: 1. Unzip the UEL6402.zip to your had disk. 2. Connect the computers COM port to the UEL6000 3. Switch the UEL6000 into “Load Update” mode The “Load Update” mode is a submenu of the “RS232 Configure” menu of the configuration menu. You will use the following switches of the fan tray: P▲ P▼ M▲ M▼ Push “Power” switch up(ON) Push “Power” switch down (OFF) Push “Mode Select” switch up Push “Mode Select” switch down Steps to get into the “Load Update” mode: Description switch the crate off P▼ Display ________________ enter configuration menu M▲(push and hold), P▲ Config: Wait hold both switches up Config: Wait... after 4 seconds you can Config: Ready ! release the switches +5V0 0.01V Now select the “RS232 Configure” menu Enter this menu Switch 0A M▲ or M▼ (until right menu RS232 Configure is displayed) Baudrate: 115.2k P▲ Select submenu “Firmware” M▲ or M▼ (until right menu UEL6000 Firmware is displayed) UEL6000 4.02 Enter submenu P▲ Load Update: No Change to yes M▲ Load Update: Yes Accept settings and enter update mode P▲ Scanning RS232.. 4. Run the upload software on the computer Open a command window, change to the folder of the unzipped file. At the prompt enter the command C:UEL6402> F28xxConsole.exe -v -p com1 -i UEL6E.4.02.out Plein & Baus GmbH 1 UEL6000E Firmware Update, 15 Jun 2004 28 Replace “com1” with the COM port which you are using. The software now connects to the UEL6000, the following is displayed: Installed output message callback Loading F2810SerialFlash.out Entry point 0x003f8000 Section Address = 0x003f8000, Number of words = 3235................................................................. Section Address = 0x003f8ca3, Number of words = 4. Section Address = 0x003f8ca7, Number of words = 84.. Section Address = 0x00000792, Number of words = 67.. .Boot code loaded Connected to \.\COM1 at 5 baud Target is programmed with "UEL6000 4.01" Erase the flash ?(y/n) y This is the last chance to interrupt the update. If you say 'y' here, the UEL6000 flash is erased. Next messages are: Erase the flash. Program the flash ?(y/n) y You should say 'y', too. If not, you have got an empty flash which can only be reprogrammed at the factory. Program Section Section Section Section Section Section Section Section Section Section Section Section Section Section Section Section Section Section Section Section UEL6E.4.02.out Address = 0x003e8000, Number of words = 3676 Address = 0x003e8e5c, Number of words = 253 Address = 0x003e8f59, Number of words = 21 Address = 0x003e8f6e, Number of words = 629 ".stack" IGNORED (vaddr=0x8200 out of flash area) Address = 0x003e91e3, Number of words = 3 ".args" IGNORED (vaddr=0x1fc out of flash area) "" IGNORED (vaddr=0x340 out of flash area) ".trace" IGNORED (vaddr=0x47c out of flash area) Address = 0x003e91e6, Number of words = 256 Address = 0x003e92e6, Number of words = 32 Address = 0x003f7ff6, Number of words = 2 Address = 0x003f7ff8, Number of words = 8 Address = 0x003f7f80, Number of words = 118 Address = 0x003e9306, Number of words = 23754 Address = 0x003eefd0, Number of words = 3628 Address = 0x003f7f70, Number of words = 16 Address = 0x003efdfc, Number of words = 30 Address = 0x003efe1a, Number of words = 12 Address = 0x003efe26, Number of words = 1539 Verify UEL6E.4.02.out Section Address = 0x003e8000, Number of words = 3676 Section Address = 0x003e8e5c, Number of words = 253 Section Address = 0x003e8f59, Number of words = 21 Section Address = 0x003e8f6e, Number of words = 629 Section ".stack" IGNORED (vaddr=0x8200 out of flash area) Section Address = 0x003e91e3, Number of words = 3 Section ".args" IGNORED (vaddr=0x1fc out of flash area) Section "" IGNORED (vaddr=0x340 out of flash area) Section ".trace" IGNORED (vaddr=0x47c out of flash area) Section Address = 0x003e91e6, Number of words = 256 Section Address = 0x003e92e6, Number of words = 32 Section Address = 0x003f7ff6, Number of words = 2 Section Address = 0x003f7ff8, Number of words = 8 Plein & Baus GmbH 2 UEL6000E Firmware Update, 15 Jun 2004 29 Section Section Section Section Section Section Section Address Address Address Address Address Address Address = = = = = = = 0x003f7f80, 0x003e9306, 0x003eefd0, 0x003f7f70, 0x003efdfc, 0x003efe1a, 0x003efe26, Number Number Number Number Number Number Number of of of of of of of words words words words words words words = = = = = = = 118 23754 3628 16 30 12 1539 Press [Enter] key to exit OK, the update is ready. Now restart the crate by removing the mains cord. If there are new data items in the EEPROM, after the restart they will be initialized. You have to acknowledge the “CHECKSUM xxxx” messages by pushing the “SYSRES” button at the fan tray. Plein & Baus GmbH 3 UEL6000E Firmware Update, 15 Jun 2004 30 UEL6 Ethernet Pin Description 1. CAN-Bus (X1, X2) RJ45 Pin 1 2 3 4 5 6 7 8 Signal CAN-H CAN-L GND n.c. n.c. reserved GND n.c. Comment This is the standard CIA pinning. Both connectors are wired in parallel, so it’s easy to connect many crates in a daisy-chain. 2. RS232 (X2) RJ45 Pin 1 2 3 4 5 6 7 8 Signal n.c. n.c. n.c. GND RXD TXD CTS RTS Comment Output Input Output Input This is the standard RS232D DCE pinning. Connection to DTE (e.g. computer) with a 1:1-cable. 3. Ethernet (X4) RJ45 Pin 1 2 3 4 5 6 7 8 Signal TX+ TXRX+ GND 1 GND 1 RXGND 2 GND 2 Comment 75 Ohm 75 Ohm This is the standard NIC configuration. You need a 1:1-cable to connect a to a HUB, or a cross-over cable to connect to another NIC (e.g. a computer) 31 32 33 34 35 R3 C2 C10 S1 S2 U1 S3 S4 U2 R4 D5 U3 U4 S5 U5 D6 D7 U6 U8 U7 S6 D8 C12 C3 C13 C4 C9 C8 C7 C6 D3 R2 D4 C1 C5 D2 R1 D9 C11 S7 X6 C10, C11: max. Bauhöhe 7mm, sonst legen w-ie-ne-r Plein & Baus GmbH D-51399 Burscheid +49-2174-678-0 www.wiener-d.com Title SG;I/O-Complete Number Rev 1407053 36 Plot Tue Jul 13, 2004 Date Filename 10.04.03 Drawn by io-neu.PCB A5 Fri C12 100N/63V C9 2N2/50V C13 2N2/50V 100P/63V 100P/63V C8 100P/63V C6 X6:F X6:D X6:C LED:3GN:F:S D2 LED:3RT:F:S D3 LED:3RT:F:S D4 LED:5GN D9 LED:3GE:F:S D6 LED:3GN:F:S D5 LED:3GE:F:S D7 LED:3RT:F:S D8 5 100N/63V 100N/63V C5 100N/63V C3 X6:A 100N/63V C1 1 100N/63V C2 X6:B 22u/50V C4 2 22u/50V C11 X6:E C10 C7 6 4 3 w-ie-ne-r Plein & Baus GmbH D-51399 Burscheid +49-2174-678-0 Title 37 www.wiener-d.com I/O-Modul Sheet1 Number Rev 1407053 Plot Thu Jun 24, 2004 Date Filename A5 02.April2003 Drawn by io-neu.sch Sheet Fri 1 of 1 C1 nicht bestücken! 10 X5 6 1 1 1 X8 X7 6 w-ie-ne-r Plein & Baus GmbH D-51399 Burscheid Title +49-2174-678-0 UEL6000 CPU with Ethernet Number 38 Plot Wed Mar 10, 2004 Date Filename www.wiener-d.com 1464212 10.03.2004 Drawn by uel6e.pcb Rev A3 GE X8:D 100N/16V 4 RS232_TXD RS232_CTS RS232_RTS 1.00k/0.125W X_CS X8:F 6 X8:E 5 R67 10.0k/0.125W B_SOMI R72 GND V3.3_RS R73 C77 R70 GND GND_RS X_SOMI V3.3 10.0k/0.125W GND R13 5 15.0k/0.125W 15P/50V X7:E 3.30k/0.125W UEP_CANH CANH 8 X5:H UEP_CANL CANL R7 GND 3.30k/0.125W CTS R5 R1 Q1 RTS V30 GND_RS CANGND GND 1.80k/0.125W UEP_CANGND 1.80k/0.125W R8 X5:G 1.80k/0.125W R2 7 R10 R21 D3 10.0k/0.125W GND V3.3 BC857C R19 GND_RS BC857C R18 X5:I 15.0k/0.125W Die Drosseln waren bisher immer gebrückt! 9 Q2 10.0k/0.125W BC847C V3.3 Connection to CAN 6 33.0k/0.125W X5:F Q4 SCIRXDA R17 V3.3_RS 3.30k/0.125W 74ACT14PW C76 15.0k/0.125W 15P/50V R69 R27 X_SIMO R71 R12 220P/50V R26 BC847C GND_RS RS232_RXD SCITXDA UEP_TXD Q9 R64 1.00k/0.125W 3.30k/0.125W 4 V3.3_RS 100N/16V 3 B_CS X_CLK C6 6 3 1.00k/0.125W 100N/16V C11 X7:F R86 IO_SOMI GND C15 R34 B_SIMO 8 74ACT14PW U10:B IO_LOAD 4.70k/0.125W 33.0k/0.125W R25 33.0k/0.125W R24 BC847C 3.30k/0.125W 4 1.00k/0.125W SPI_SOMI Q6 SCITXDB X7:D 9 10.0k/0.125W V30 LL103A 6 12 74ACT14PW U10:D R87 74ACT14PW Connection to MUH D4 R88 X8:C RS232 Transceiver DTE Pinning (we are DCE <-> 1:1-Cable) 11 Bauteile (0805+SOT23) weniger, wenn statt MAX232 MAX3520 verwendet wird! 15.0k/0.125W 5 SPI_CS 13 B_CLK 1.00k/0.125W IO_SIMO 74ACT14PW U10:C 3 1 2 Q3 2 X7:C X8:A X8:B 1U0/50V IO_CLOCK 74ACT14PW U10:A SPI_SIMO V5.0 U10:F 1.00k/0.125W 10 1 GND BC847C 11 SPI_CLK 1 2 C5 V5.0 U10:E X7:A X7:B C9 GND Connection to external IF (HCT!!) 100N/16V C10 Connection to I/O (HCT!!) SCIRXDB LL103A R23 GND_RS 39 1.80k/0.125W GND GND 1.80k/0.125W R20 V3.3 CANRX 1.80k/0.125W R15 GND CANTX R65 BC847C R9 10.0k/0.125W 100R/0.125W UEP_RXD R22 X5:E 1.00k/0.125W 5 V3.3_RS Q5 w-ie-ne-r Plein & Baus GmbH D-51399 Burscheid +49-2174-678-0 Interface Number GND www.wiener-d.com UEL6000 CPU with Ethernet Title Plot Wed Mar 10, 2004 Filename Rev 14644212 Date 10.03.2004 Drawn by uel6e.sch Sheet A3 Koe/Ge 1 of 4 100N/16V C40 100N/16V C21 100N/16V C65 100N/16V C52 100N/16V C43 100N/16V C49 100N/16V C64 100N/16V C22 100N/16V C23 100N/16V C35 100N/16V C66 100N/16V C42 100N/16V C20 C38 100N/16V C39 C45 100R/0.125W ADC0 ADC1 ADC2 ADC3 ADC4 ADC5 ADC6 ADC7 ADC8 ADC9 ADC10 ADC11 V3.3 ADC12 R66 C72 R59 ADC13 ADC14 ADC15 ADC_LO 47U/10V/600mR C71 V3.3 10.0k/0.125W 24.9k/0.125W 10.0k/0.125W R48 GND 47U/10V/600mR V3.3 47U/10V/600mR C29 R52 R45 V1.8 1.80k/0.125W C50 100N/16V 100N/16V C51 SPI_SIMO SPI_SOMI SPI_CS SCITXDA CANTX 100N/16V 100N/16V C63 100N/16V C62 CANRX B_CLK V3.3A GNDA B_CS B_SIMO 0R0/0.125W WP SCL INTE C18 SDA DATA D0 GND DATA RESET 15P/50V D1 D2 D3 C19 D4 D5 GND SDA CTS AEN RESET D6 D7 15P/50V D8 D9 D10 TMS D11 TRST D12 TDI D13 D14 V3.3 D15 TDO TCK TCK GND EMU0 EMU1 GND1 GND 40 GND 1.80k/0.125W GND IOW INDEX /DATA 10.0k/0.125W R39 SCL GND RTS V3.3 WP GND IOR V3.3 GND GND 25MHZ R47 R16 R6 10.0k/0.125W GND SCIRXDB 1.00k/0.125W R4 SCITXDB FAN_PWM2 10.0k/0.125W R11 FAN_PWM1 V3.3 R68 B_SOMI 10.0k/0.125W R46 C47 SCIRXDA 100N/16V C60 C54 GND 47U/10V/600mR SPI_CLK V3.3 47U/10V/600mR 10.0k/0.125W C32 RESET GND GND1 V1.8 100N/16V V3.3 100N/16V V5.0 X6:1 X6:2 X6:3 X6:4 X6:5 X6:6 X6:7 X6:8 X6:9 X6:10 X6:11 X6:12 X6:13 X6:14 1 2 3 4 5 6 7 8 9 10 11 12 13 14 JTAG Interface w-ie-ne-r Plein & Baus GmbH D-51399 Burscheid +49-2174-678-0 www.wiener-d.com UEL6000 CPU with Ethernet Title Processor Number Plot Wed Mar 10, 2004 Filename Rev 14644212 Date 10.03.2004 Drawn by uel6e.sch Sheet A3 Koe/Ge 2 of 4 Softstart (Hot-Swap) 5V-Converter 1.50k/0.125W 4.70k/0.125W R3 R14 C61 100N/16V 330u/35V 1U0/50V C3 C2 C4 10N/50V D1 1U0/50V 330u/35V C12 GND GND C79 10N/500V 10N/500V C78 R80 ADC5 0R47/1W R81 0R47/1W R82 0R47/1W 0R47/1W R84 0R47/1W R85 0R47/1W R83 330u/35V 1U0/50V C57 C74 X15:2 X15:1 ADC4 GND IRF7342 X11:2 X11:1 X10:2 X10:1 ADC9 X9:2 X9:1 ADC10 ADC11 R74 ADC8 R75 0R47/1W R79 X12:2 X12:1 ADC7 0R47/1W X13:2 X13:1 ADC6 R76 X14:2 X14:1 330u/35V 1U0/50V C56 C70 MBRS340T3 1U0/50V D7 330u/35V C31 330u/35V C1 C13 3.30k/0.125W 3.30k/0.125W R89 3.30k/0.125W R31 D9 X16:2 X16:1 ADC3 0R47/1W R43 X17:2 X17:1 ADC2 0R47/1W TPS2812D Trennstellen Q11:B X18:2 X18:1 ADC1 R77 3 C16 4.70k/0.125W Q7 5 3R9/0.125W LL103A V30-10V GND GND ADC_LO R62 1.00k/0.125W Connect at one point! V3.3A ADC12 41 1.00k/0.125W R63 ADC14 GNDA R90 1k0/25°C R57 ADC14 1k0/25°C R61 33.0k/0.125W ADC13 V30 R60 V0 1.80k/0.125W R29 4 U5:B X19:2 X19:1 ADC0 R78 R32 6 X20:2 X20:1 0R47/1W FAN_PWM2 BC847C 1.00k/0.125W R30 D10 V3.3 GND IRF7342 LF2.1 R44 LL103A PE GND LF2.2 TPS2812D Q11:A MBRS340T3 3 3R9/0.125W LF1.1 7 LF1.2 R33 U5:A 1U0/50V D6 6 2 330u/35V C33 FAN_PWM1 330u/35V C36 4.70k/0.125W Q8 1.00k/0.125W BC847C V3.3 R28 PE 1U0/50V C17 V30 0R47/1W Q10:A V0 Q10:B X5:A X5:B IRF7341 C25 1 2 1U0/50V R40 LL103A 10MEG/0.125W IRF7341 D8 V30-10V V30 C37 C73 22N/50V R41 V30 10MEG/0.125W X5:C X5:D MBRS340T3 V5.0 3 4 GNDA w-ie-ne-r Plein & Baus GmbH D-51399 Burscheid +49-2174-678-0 www.wiener-d.com UEL6000 CPU with Ethernet Title Power+Fan Number Plot Wed Mar 10, 2004 Filename Rev 14644212 Date 10.03.2004 Drawn by uel6e.sch Sheet A3 Koe/Ge 3 of 4 4.70k/0.125W INT low V3.3 R42 100M LINK H2 330/0.125W V3.3 V3.3 LED:3GE R35 H1 330/0.125W R36 LED:3GN 4.70k/0.125W LED mode 1 V3.3 R49 D19 D17 D18 D16 V3.3 GND IO32 EEDI GND EEDO EECS EECK V3.3 V3.3 DATA32 GND D20 D21 GND D22 RESET D23 GND D24 D15 D25 D14 D26 D13 GND D12 D27 D11 D28 D10 D29 V3.3E INDEX /DATA TX- GND TX+ GNDE 100N/16V V3.3 100N/16V C46 D31 V3.3 51R/0.125W C34 D30 D8 51R/0.125W R54 R53 D9 V3.3E TX- RJ45_TX+ TX+ RJ45_RX+ RJ45_TX- GNDE GND RJ45_TM5 GND RJ45_TM8 75R/0.125W 75R/0.125W R37 GNDE 75R/0.125W R38 75R/0.125W R51 GNDE 10N/500V RJ45_TM8 R50 6.80k/0.125W R58 GND 25MHZ V3.3 V3.3 GND GND GND V3.3 RESET D7 D6 D5 D3 D4 D2 D0 D1 AEN V3.3 IOR IOW GNDE DATA RJ45_RXRX+ C24 V3.3E INTE RJ45_TM5 100N/16V GND C53 V3.3E 51R/0.125W V3.3 51R/0.125W R55 RX- 100N/16V RX+ R56 RX- V3.3 C58 GND 10N/500V C30 100N/16V 100N/16V C48 C59 100N/16V 100N/16V C26 100N/16V C44 100N/16V C41 100N/16V C27 100N/16V C69 100N/16V C28 100N/16V C67 C7 C68 100N/16V C55 42 47U/10V/600mR GND V3.3E 100N/16V 100N/16V C8 V3.3 GND C14 w-ie-ne-r Plein & Baus GmbH D-51399 Burscheid Title +49-2174-678-0 www.wiener-d.com UEL6000 CPU with Ethernet Ethernet GNDE Number Plot Wed Mar 10, 2004 Date Filename Rev 14644212 10.03.2004 Drawn by uel6e.sch Sheet A3 Koe/Ge 4 of 4 43 Plot Filename D-51399 Burscheid R73 R74 R81 R82 R79 R97 R98 Tue Feb 07, 2006 Date D55 R100 U25 D56 20 U24 D57 U19 D58 R76 C87 X14 R92 U22 Q12 C91 C90 Q11 F1 D59 1 R94 R95 R96 20 X11 U20 X12 Q7 D11 R65 C43 C89 S1 X13 D51 1 U21 D52 C99 R80 X10 D46 1 C100 D40 D41 20 D53 D47 U18 C101 C103 C104 C105 C106 C107 C108 C109 C94 U23 X9 D42 1 L10 C86 R87 R86 20 D48 D43 R91 C110 R83 R84 R85 Q8 R66 C36 C38 L4 D1 C95 20 D44 X8 D35 1 R75 D36 U17 20 D37 X4 X7 D31 1 C92 R67 D32 C93 C85 C84 C83 C74 C73 C72 C71 L8 R64 4 X6 D26 1 R26 R29 R32 C46 C40 D2 D18 20 D33 D27 D21 1 C75 X5 D22 U16 C80 U12 X3 C64 C60 C61 C62 C63 U15 1 C34 D5 D6 C25 U1 C76 20 D28 20 D23 Q5 C82 C81 Q1 D9 Schraube Q4 C68 R53 R60 R62 C48 C35 L2 Q6 U-Scheibe Federscheibe Q2 C66 C65 R51 R54 R33 R34 Isoschlauch C59 C58 C49 C50 C51 C53 C54 C55 C56 C57 U8 Iso-Rolle Montage D1, D2, U1 Q7, Q8 U11 L3 R11 R13 R15 R17 R20 R22 R24 R27 R30 R35 R37 R39 R41 R43 R46 R48 R8 R9 R10 R19 U7 U6 U4 J2 R5 R6 R7 U10 Alu-Oxid RM0 RP0 RP4 RM4 RM3 RP3 RP5 RM5 RM1 RP1 RP7 RM7 RM2 RP2 RP6 RM6 R50 R52 R59 R61 R63 J1 X2 U3 Kuehlkoerper Mutter Iso-Buchse D1, D2, U1 Cho-Therm Kuehlkoerper 1 Federscheibe U2 R55 R56 R45 R57 R58 C70 X1 C42 C47 Q10 R88 U5 U9 Q9 R77 C26 C27 C28 C29 C30 C31 C32 C33 C45 D12 D13 D24 JC1 3 XTEMP1 C17 L6 U14 Q3 C41 L7 D15 C37 C77 D14 C39 C67 D17 10 Schraube C52 D16 C18 C23 C24 L5 D10 C1 C2 C3 C4 C5 C6 C7 C8 C9 C10 C11 C12 C13 C14 C15 C16 C44 2 L1 C78 C111 C88 1 H1 H2 H3 S2 C102 X15 D49 U26 X16 K1 K2 U13 Montage Q7, Q8 w-ie-ne-r Plein & Baus GmbH Title +49-2174-678-0 muh6.PCB www.wiener-d.com MUH6000 (low Noise) Number 1437008 Rev B6 25.01.2005 Drawn by Koe / Ge 44 45 46 47 48 49 Lüfterkabel kürzen Wärmeleitpaste zwischen: Alox und D5, D4, Q5, Q6, Alox und KK1, KK1 u. Rippenkühlkörper, D18 u. Rippenkühlkörper w-ie-ne-r Plein & Baus GmbH D-51399 Burscheid +49-2174-678-0 Title MNPFC16 Number 50 Plot www.wiener-d.com 1441690 Fri Jul 20, 2001 Date Filename 18.07.01 Drawn by Mnpfc16.pcb Rev A4 Ge 2K43/0.6W 22N/630V P6KE200A C24 BYV26C L5:A D15 L5:B 2K05/0.6W R14 L5:C C25 1000U/35V R15 Q8 C21 C18 100n/100V C23 R11 220P/100V C22 6R81/0.6W 47u/35V 22N/630V C13 L1:B A:300/B:1 4 {Value} R5 D7 C4 1K11/0.6W D3 1 C12 4N7/250VAC X2:B 2 X3:B 2 X3:C 3 X2:C 3 w-ie-ne-r Plein & Baus GmbH D-51399 Burscheid +49-2174-678-0 Title Plot www.wiener-d.com MNPFC16 Number 51 1 X3:A C17 1n/400V/Y2 47U/450V 47U/450V C6 47U/450V C3 47U/450V C10 C8 47U/450V 47U/450V C11 47U/450V C9 C2 1n/400V/Y2 IRFB11050A 47U/450V C7 C15 1U16A/24V= 470P/500V Q6 D1 SD103A 3 4 C1 BD138-16 DSEC15-06A 4N7/500V 4 D6 C16 R8 Q3 DSEC15-06A 5 X2:A D4 SD103A 4R75/0.6W 1 47U/450V L3:B 100n/63V DSEC15-06A 6 1K11/0.6W 1K11/0.6W R35 R36 R12 R10 C19 10P/500V 10 1 BD138-16 C5 1 2 5 6 K1:B R16 Q2 4N7/250VAC R20 R19 4R7/5.1A R21 R18 4R7/5.1A 4R7/5.1A R33 R34 4R7/5.1A 1K11/0.6W 1K11/0.6W DSEP30-06B 3 L3:C R31 R32 1K50/0.6W IRFB11050A 2 1K11/0.6W 1K11/0.6W R27 R4 3 C20 R3 BD138-16 10K0/0.6W Q1 R25 33k2/0.6W L3:A R7 R6 10R0/0.6W 2U2/275VAC/X2 C29 R29 R30 1 HGTG30N60A40 Q4 R28 4N7/250VAC C31 C28 R22 1K11/0.6W 22N/630V C27 1K11/0.6W 4N7/250VAC D18 BC557B/RM5.08 9k09/0.6W Q5 4R75/0.6W 1N0/500V 2 D10 C14 20K0/0.6W L1:A 6R81/0.6W 275VAC/0.6W R24 X4:20 A:300/B:1 BAV21 20 R26 D17 D5 300U/23A L:300U/23A:E65H 22N/630V C30 182K/0.6W169K/0.6W R9 11 X4:11 R23 332K/0.6W L6 332K/0.6W 332K/0.6W BC547B/RM5.08 392R/0.6W Q7 D14 R17 33k2/0.6W GBPC3506N 39u/50V R13 1U16A/24V= 12K1/0.6W/1% 8 R1 K1:A D12 1K50/0.6W BZX85C18 D16 1N4148 7 D13 BYV27-150 BZX85C6V2 R2 1441690 Fri Jul 20, 2001 Date Filename Rev 19.07.01 Drawn by mnpfc16.SCH Sheet A4 Ge 1 of 1 52 53 54 OVP 7 X2 COMP-U UD+ R27 5 X2 100K Q3 R1 1K00 BZX83C15 D8 1N5 R28 C19 STVHD90 CV 10N 11 C1 X2 10N 10K0 C2 X2 1 T S3 2 T S1 OP62-100 R2 COMP-I X2 13 GPL+ LOW SIDE DRIVE R35 Q4 1N4148 1K00 PWM+ 18 X2 PWM0 17 X2 6 L1 3 Q6 BF247 D10 D13 BD139-16 1N4148 1 BZX83C3V9 2 5 D14 GPL0 GPH+ R36 4 ZKB409-019 X2 Q5 1K00 Q7 BF247 HIGH SIDE DRIVE 6 100R 1N4148 TEMP0 1 U- 2 8 OP62-100 TEMP+ D12 BD139-16 1N4148 BZX83C3V9 GPH0 D11 DATE DRAWN 03.12.93 NAME Fri CHECK PLOT 14.03.97 11:13 wiener Plein & Baus GmbH D15 DESCRIPTION MEH_2-5V/100A Power CIRCUIT DIAGRAM DRAWING NUMBER REV. 1409266 A3 55 SHEETS SHEET 02 02 L R X1 5K 3 F1 4AF-TR5 UP+ S IPMON0 R3 R22 R5 R8 10N STPS24045TV 18 22 23 K1 24 D9 26 Q2 10 21 20 19 A1 3R3 R32 R33 C21 R30 100R X2 4 US+ 4N7 ETD44/500W/5V C28 C25 C26 C30 C27 C29 2200UF 2200UF 2200UF2200UF 2200UF U+ 27K4 C35 C34 C32 C31 2200UF M2 R10 C33 2200UF C3 1 3R3 10R0 4 3R3 500uR C9 1U US+* ISMON+ ISMON- 2 10R0 UD+ R34 C6 220UF 12 14 R31 D9 STPS24045TV C5 25 X2 X2 R11 GPH0 220UF R7 0R10 A2 L3 220P K2 1N0 PE C11 10 R4 10U 3R3 C15 IRFP450 100K R6 3 3R32 GPH+ C22 R29 C20 Q1 C8 100K 220P 4N7 D6 MUR460 R23 X2 13K3 3R32 2200UF 2200UF 2200UF X2 2 U+* X2 1 U-* 2200UF R24 1U0 GPL+ C24 IRFP450 GPL0 27K4 D5 MUR460 3R32 C17 220P EF32/RM14 R25 E4 L4 C16 100P R21 10R0 IPMON0 16 L4 22K1 10U 10N C4 C18 R12 X2 3 US- X2 9 US-* 150P 13K3 X2 UP0 1 U- 100R R13 7 R20 L2 D7 C23 8 X2 ZKB472-120 4 3 15 M1 A1 3R32 1N4148 IPMON+ R9 EF32/RM14 A4 E1 X1 DATE DRAWN 03.12.93 NAME Fri CHECK 56 PLOT 14.03.97 11:11 wiener Plein & Baus GmbH DESCRIPTION MEH Single_Module_500W CIRCUIT DIAGRAM DRAWING NUMBER 1409266 REV. A3/1 SHEETS SHEET 02 01 S D Transistoren Q4,Q5 G D G S C2 C1 R12 R1 R2 X2 3 2 1 X1 R4 R3 L5 D11 R9 R10 R8 R5 L1 R6 R7 R21 R35 Q4 D14 Q6 BF246A C4 D R36 Q5 D15 Q7 G D13 D10 S D12 C3 C9 D7 D R13 R11 D5 C16 C11 L2 R20 BF247A MOTOROLA C5 G S F1 S BF247A PHILIPS NS G D R22 C8 C6 R23 C15 Q2 Q1 C18 D6 R24 R25 D und S sind tauschbar C17 R27 R28 D8 C19 S3 S1 Kühlkörper 1409291 Index <= A3: Isoplatte bis zu F1 schieben und mit Silicon an C6 ankleben L3 Q3 R37 C20 R29 C22 C21 R32 R33 R31 D9 R30 C23 C25 C27 C34 DATE NAME 199.64x99.82 FR405_1.5mm Fri DRAWN 03.12.93 250um CHECK 2 ja nein M 1:1 beidseitig part.verzinnt PLOT 09.07.98 21:24 nein 57 wiener Plein & Baus GmbH M2 C30 C24 C29 C35 M1 C28 C32 C26 C31 C33 L4 Platinenmasse [mm]: Platinenmaterial: Kupferstaerke: Lagen: Durchkontaktierungen: Bestueckungsaufdruck: Loetstop: Oberflaeche: Nutzen: R34 DESCRIPTION MEH Single_Module_500W PARTS LAYOUT REFERENCE NO. DRAWING NUMBER REV. 1409266 A6 SHEETS SHEET 01 01 w-ie-ne-r Plein & Baus GmbH D-51399 Burscheid Title +49-2174-678-0 MDH Modul Double Highpower Number Plot 58 www.wiener-d.com Tue Oct 08, 2002 Date Filename 1460193 02.02.02 Drawn by Mdl.pcb Rev A3 GE w-ie-ne-r Plein & Baus GmbH D-51399 Burscheid 59 +49-2174-678-0 www.wiener-d.com MDH Modul Double Highpower Title Sheet2 Number Plot Thu Nov 14, 2002 Date Filename Rev 1460193 A3 02.02.02 Drawn by Mdl.sch Sheet GE 2 of 2 60 w-ie-ne-r Plein & Baus GmbH D-51399 Burscheid +49-2174-678-0 www.wiener-d.com MDH Modul Double Highpower Title Sheet1 Number Plot Thu Nov 14, 2002 Filename Rev 1460193 Date 02.02.02 A3 Drawn by Mdl.sch Sheet GE 1 of 2 1 U9 20 U6 X1 w-ie-ne-r Plein & Baus GmbH D-51399 Burscheid +49-2174-678-0 www.wiener-d.com Title MRP-DA Number 61 Plot Thu May 18, 2006 Date Filename Rev 1409657 BC 18.05.06 Drawn by GE mrp SMD.pcb R27 100N/50V R41 5 11 R38 5.10k/0.125W X5:11 220P/50V 2.70k/0.125W R30 R47 X1:3 reserved R9 R49 R34 BC857C BC857C 510R/0.125W R62 7 C46 X5:18 18 X5:17 17 L6 X1:1 Q8 D-51399 Burscheid BSH114 R60 BSH114 10.0k/0.125W w-ie-ne-r Plein & Baus GmbH R61 47u/35V 10.0k/0.125W 1U0/50V C30 C29 47u/35V Q7 1U0/50V 62 C41 C31 C44 100N/50V 100N/50V C47 100N/50V C45 15P/50V C34 220P/50V 220P/50V C37 500R R74 220P/50V C42 BSH114 2.00k/0.125W C48 Q9 C49 X1:2 R66 R75 R78 3SMDL1:SA 220P/50V 10.0k/0.125W 5.60k/0.125W X6 2 6 1K/100MHz/R35/0.23A R77 1 X5:7 47P/50V X5:16 R65 16 1.00k/0.125W 1.00k/0.125W X5:15 X1:6 Q6 R7 15 10.0k/0.125W 100K/0.125W 2.20k/0.125W R11 R10 10.0k/0.125W BC847C C26 100K/0.125W 10.0k/0.125W X1:4 R12 10.0k/0.125W 4 Q3 10.0k/0.125W 100N/50V R8 Q2 R64 X1:9 R39 9 5.10k/0.125W X1:5 C43 5 1U0/50V R48 22.0k/0.125W 33.0k/0.125W C18 C24 3 X5:5 2.70k/0.125W C9 R25 100N/50V C11 C10 24k/0.125W R21 15P/50V C4 15.0k/0.125W R46 R35 10N/500V C5 15P/50V 10.0k/0.125W X5:13 R37 2.00k/0.125W 150K/0.125W C23 R40 C22 R22 15.0k/0.125W 13 100N/50V 100N/50V C8 X5:10 10.0k/0.125W reserved R44 R19 R16 R17 C7 R15 10.0k/0.125W 47N/50V R23 1.00k/0.125W R20 R18 15P/50V C3 R42 330R/0.125W 24k/0.125W X5:9 R24 1.00k/0.125W 10 C6 reserved reserved 0R0/0.125W47N/50V 1.60k/0.125W 100N/50VC13 1.00k/0.125W100P/50V 10.0k/0.125W 9 R13 R31 C55 8 R45 X1:8 2.00k/0.125W X5:3 C54 3 C53 1U0/50V 10 10.0k/0.125W X1:10 15P/50V X5:4 1U0/50V 470/0.125W 4 +49-2174-678-0 Title www.wiener-d.com MRP-DA Sheet1 Number Rev 1409657 Plot Mon Jun 12, 2006 Date Filename BC 18.05.06 Drawn by mrp SMD.sch Sheet GE 1 of 2 R86 510/0.125W 100N/50V C52 C51 R82 C50 750k/0.125W 510/0.125W R83 100N/50V 15 X1:15 17 X1:17 R84 510/0.125W X1:20 R85 20 X1:19 510/0.125W 19 X1:18 18 100N/50V R53 C17 20.0k/0.125W 100N/50V 100N/50V R56 C35 750k/0.125W 1 8 R71 R79 160/0.125W X1:7 7 R2 R72 reserved 100N/50V 8 X5:8 24k/0.125W R36 R32 R28 100P/50V 10.0k/0.125W R52 24k/0.125W R29 15P/50V Q4 100K/0.125W C12 R55 R26 R50 BC847C 100N/50V 6 10.0k/0.125W R33 X5:2 R51 10.0k/0.125W 5.10k/0.125W 1.00k/0.125W X10 10.0k/0.125W 14 X1:13 13 BC847C R54 C1 10N/50V C14 5.10k/0.125W 1.00k/0.125W C16 2 11 X5:1 C19 1 15P/50V C15 X1:11 X1:14 Q1 1MEG/0.125W 10R0/0.125W 1.0nF/50V C36 C33 100N/50V reserved R70 R67 1.0nF/50V reserved C40 10.0k/0.125W 12 3SMDL1:SA R73 X5:14 X1:12 R1 R58 R69 R57 1MEG/0.125W 500R X7 5.10k/0.125W 2.00k/0.125W R63 R80 1.00k/0.125W C39 10N/50V 510/0.125W 10.0k/0.125W 14 100N/50V 100P/50V C28 100P/50V C27 100P/50V C25 X5:12 TL431CD C32 R68 12 100N/50V C38 1.0nF/50V C20 6 U8 X5:6 w-ie-ne-r Plein & Baus GmbH D-51399 Burscheid +49-2174-678-0 Title 63 www.wiener-d.com MRP-DA Sheet2 Number Rev 1409657 Plot Mon Jun 12, 2006 Date Filename BC 18.05.06 Drawn by mrp SMD.sch Sheet GE 2 of 2