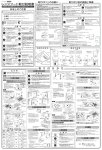

Download e-STUDIO160/200/250 Service Manual

Transcript