Download Craftsman 113.232210 Owner`s manual

Transcript

MODEL NO.

113.232210

JOINTER/PLANER WITH

LEGSAND MOTOR

Serial

Number

Model and serial numbers

may be found on the backside of the jointer base.

You should record both

model and serial number in

a safe place for future use::

tHl' '

't

i

FORYOUR

6-!!E-INCH

JOmHTER'PL ER

SAFETY:

READALL

INSTRUCTIONS

CAREFULLY

• assembly

e operating

e repair parts

"L""

Luu'u .

Sold by SEARS, ROEBUCK AND CO., Chicago,

Part No. SP5447

--

,,__'_

iL 6068,4 U.S.A_

?r_

ir_ r._,,_c_r_

NTER/PLANER

due to a

of charge.

CONTACTING THE NEAREST SEARS SER-_

while this product is used in the United States.

rights, and you may also have other rights which

ROEBUCK AND CO. Dept: 698/731A. Sears Tower, Chicago, IL 60684

;:;I

GENERAL SAFETY iNSTRUCTiONS

_

_

i

KNOW;YOUR POWER TOOL

Read and understand the owner_ manual and

labels affixed to the tool. Learn its application and

limitationsas well as the specific potential hazards

peculiar to this tool.

2; GROUNDALL TOOLS

. This tool is equipped with an approved 3-conductor

::i:_cordanda 3-pr0nggr0unding type :plugto fit the

proper grounding

receptacle. The green conductor _inthe cord: is:the: grounding wire, Never

" i _ connect the green wire to a live terminal.

_3; KEEPGUARDS

INPLACE

: i_i _ln wo[kingl order, and in: proPer adjustment and

!. alignment;

I::'_

...........

i

;_:':'

;_'_....

_.

_:i!

::_:;:::_i

_::_

i:::::

_:';i;:

SH0_ ICHIL_ROOF

_

i_maste_switchesilby removing star-_

5ring tools where: children Can_ get::

;_'_::_

::_i;_: i_

::i_I:_ :

job better and safer at the rate for

it was designed::

:i : :

_:

:::

J

FOR POWER TOOLS

12, USE SAFETYGOGGLES [HEAD PROTECTION)

Wear safety goggles (must comply with ANSI

Z87.1 ) at all times. Everyday eyeglassess are not

safety glasses. They only have impact resistant

lenses. Also, use face or dust mask if cutting operation is dusty, and ear protectors (plugs or muffs)

during extended periods of operation.

13, SECURE WORK

Use clamps or avise tO hold work when practical.

It frees both hands to operate tooll

14, DON'T OVERREACH

" Keep proper footing and balance at all times.

15. MAINTAIN TOOLS WITH CARE

Keep tools sharp and clean for best and safest

:performance. Follow instructionsfor lubricating and

NEVERSTAND ON TOOL OR ITS STAND ;i _i::

._

Sed0us!njU_could

occur if the toot is tipped or ff

CUtting:tool is accidentally contacted: Do not'

:: ::_:, ::store, materials above or near the tool such that it

is;tieCessaryto standon the to01 or its;stand to

:reachthern_ ::;

......

: :

_2o;: CHECK DAMAGED PARTS

1:

Before furtheruse of the tool, a guard or other part

:: ::i thatJs damagedshouid

be carefully checked to

:_::_i:::;:::::i::i

_;Don;t for_i:io01s 0_ _achment to do a job it was

:_:_: ensure::that it:wi!l operate properly and perform its

i_::::

intended Tunction:Check for alignment ol" moving

_::: ::::_::i_:::

....

.... _ :_.... ' ...... : parts, bfndlngor mowng parts, breakage of parts,

"_

'

_"

: ..... .........

mountin .....

.... conditions that may anect

"

_;::::_ _ _".......

:::_:;_!;::D6

_ "': .........

ov_: :_nec_ies

_:or::....................

:: :::

g; ana any other

_::

:';:_i_:i;;:r_,_': _ri_+:_

_n t*.t _.nht_inrnov . : :

=tsoperat;on. A guardor other part that =sdamaged

_:' _ ......... .............

...................

: ......

_ ......_ e nded ;:

:_::: • :::should

be properly

.........:

.... repaired or rep aced

::: 21;: NEVERLEAVETOOLRUNNING

UNATTENDED

; :::

=_:';:R_i

_ge .............

:el_w: ..........

;

.....' ...............

Turn power off Don't leave toot untl it comes to a

complete stop.

::!

....

..... nal.........

..... "n...........

"..... for jointer-planer

add=tBo

sa fsty

structaons

BEFORE

Safety is!a combination ofcommon sense, staying alert

and knowing flow your jointer-pianer works_.....

BEFORE

1. Inspect your jointer-pfaner.

USING THE JOINTER-PLANER:

WARNING: THE 2-INCH JOINTER-PLANER PULLEY

AND THE 2-1/2 INCH MOTOR PULLEY FURNISHED

WILL RUNTHE CUTTER HEAD AT ABOUT 4300 RPM

WHEN USED WITH A 3450 RPM MOTOR. USE OF

DIFFERENT TYPES OF PULLEYS OR MOTORS

WILL CHANGE THIS SPEED AND COULD CAUSE

JAMMING,

BINDING,

KICKBACK,

THROWN

BLADES OR OTHER DANGERS.

WARNING: TO AVOID MISTAKES THAT COULD

CAUSE SERIOUS, PERMANENT INJURY, DO NOT

PLUG THE JOINTER-PLANER IN UNTIL THE FOLLOWING STEPS HAVE BEEN SATISFACTORILY

COMPLETED.

1. Assembly and alignment.

2. Learn the function and proper use of the on-off

switch, fence slide locking handle, cutter guard,

depth of cut hand wheel, locks and stops, fence

bevel lock handle, ouffeed table, infeed table and

hold-down/push-blocks.

a. If any part of this jointer-p_aner is missing, or bent,

or has failed in any way, or any electrical parts

don't work properly, turn the jointer-planer off and

unplug the jointer-planer. Replace damaged, missing, or failed parts before using the jointer-planer

again.

3. Read and understand all safety instructions and

operating procedures throughout the manual.

4. Read the following labels which appear on the

jointer-planer:

b. Make sure the cutter head turns in the right direction. The top should move toward the infeed table.

Call your Sears Service Department for help if

the cutter head turns the wrong way.

WARNING

c. Make sure the cutter guard works properly. With

the switch off and key removed, pull the cutter

guard open and let go. If the guard doesn't

smoothly swing closed, contact Sears Service,

THESTARTING

RELAYIN THIS

JOINTER

ISAGRAVITY

SENSmVE

TYPE.NEVER

TURNTHEPOWER

ON UNTILTHE JOINTERHAS

BEEN

MOUNTED

ONTHELEGSET

ANDISINUPRIGHT

POSITION.

d. Keep blades sharp. Dull or knicked blades tend

to "pound" and chew at the wood, causing

kickbacks.

r

JlDANGER|

FOR YOUR OWN SAFETY: KnowThis Tool!

Read and Understand

the Owner's

Manual

Befo=_

Using

• Wear Safety Gogg]es complying

with ANSI Z87,1.

S Always

Make sure it springs

Use Cutter

Head Gua,d.

AIways=se_,iveg.=d.

,

• Use HoldlDown

Push Blocks

_: Jointlngmsteri,l

narrower

Machine_

shut automaticaily:

_i ::: : ,: ::i

for:

:

than

3 inches

or

,

....

P_.tng,.a_r_,_thi.,,.,tha.

__n=,_s. :_:

!n=h.:

_

i

......

WHEN INSTALLING

JOINTER-PLANER:

:

....

: :: :

_

:

;:

_

_ _ :_ :

:

e. To avoid injury from thrown pieces, make sure

the blades are properly installed and the cutter

blade wedge, screws are tight.

2. Plan Your Work to protect your eyes, hands, face,

ears.

....

:

a_.

Bef0re trying a new or fittte used operation, carefully pianyour hand placement. Make sure you

have proper hold-down/push-blocks,

jigs, fix'

tures,.stops, etc. ready to use.

i : i:

_: : : ':i_ i'"

_OR MOVING

_ ,

EACH USE:

:

THE

key removed.

c. Wear safety goggles (not glasses) that comply

with ANSI Z87.1 (shown on package). Using any

power tool can result in foreign objects being

thrown into the eyes, which can result in permanent eye damage. Safety goggles are available

at Sears retail catalog stores. Use of glasses or

use of goggles not in compliance with ANSI Z87.t

could result in severe injury from breakage of the

eye protection.

11 To avoid injury:fromltmexpected jOinter-planer or

workpiece imovement;. ;

i:

.....

:i::

a. Use the jointer-ptaner indoors °na firm level surface in a well lit area,

b. Place the jointer-planer where:

i. there is plenty of room for moving the workpiece through the entire cut.

ii. no one must stand in line with the wood while

planing or jointing it.

C;

Adjust the jointer-planer so the tables are level

and the jointer-ptaner does not rock.

d.

Turn off and unplug the jointer-planer before moving it to a new area. To avoid back injury, get help

when you need to tift the jointer-planer.

e,

Bolt the jointer-planer to the floor if it tends to

slip, walk, slide or tip over during work like cutting

long, heavy boards.

Do layout, assembly or set up work on the tabte

only while the jointer-planer is off and the switch

WEAR

3

YOUR

:IL: ¸.

using only one hold-down/push-block to feed

the wood, do not put your other hand on the

jointer-planer, workpiece, or hold-downtpushblock.

cut FREEHAND. Guide your work_

piece s01idiy against the if;nCe: and

table:top.:

"

:

:

Small ori!thin workpieces can kick back when they tip

0ver onthe tab esor: into the Cutter head, To aV0id head

contact or :Workpiece kickback:

3_ Make sure all clamps and locks are tight and

there is no excessive play m any parts.

l,. Adjust the depth of cut to between 1/32 and t/16

of an inch for best results in most operations. A

deep cut makes feeding the wood harder and

can cause the wood to kickback. To be sure you

wilf make a depth of cut you planned, always

lower the infeed table slightly farther than

you wanted. Then, raise the table to the

desired depth.

m. Before using the jointer-planer, clear the table of

all objects not needed to feed the workpiece.

.....i. Never joint or bevel workpieces less than

3/4:inch:wide: or 1t4 inch thick_

ii.,:AlWays USe::the;i hold-downtpush-blocks

when j6ir_ting: or: beveling wood: narrower

than3 inches;

.:

4:: i When Planing:

......... ; i.: Nevei; piar}e; wood thinner than 1/2 inch.

:....... i:_ii.: Always use hold-down/push-blocks when

:i:: ' ri::;:_:;::ii :planing wood thinner than3 inches:,

f::i,i_To'::avbidilr

skof! hearing damage, wear ear plugs

.:Or muffs during extencied periods of Operation.

:..... g. T0:aV0id:be{n_j:!Suddeniy pulled i nto the blade:

i :I::I.:D0

not wear: gi0vesi: :: .....

.... ;:'::.2. Removeaii:']ewelry and::looseCi0thing,

.... 3. :Tieback

long hair_: :_

4_ Roll long sleeves above the elbow_' :

h_ To avoid inju[yfrom accidental startingll always

turn- switch off_ remove switct_ key and: unplug

jointer-planer before installing or removing, any

;blade, accessory or attachment, or making any

adjustments.

i. To avoid an electrical shock, make sure your fingers do not touch the metal prongs on the plug

when inserting or removing the plug to or from a

live outlet.

j. To :avoid burns or other fire damage, never use

the jointer-planer near flammable liquids, vapors

or gases.

n, :Toavoid injuryfrom unsafe accessor es,.use only

recommended accessories.

WHENEVER

ISRUNNING:

JOINTER-PLANER

WARNING: DON'T LET FAMILIARITY (GAINED

FROM FREQUENT

USE OF YOUR JOINTERPLANER) CAUSE A CARELESS MISTAKE. ALWAYS

REMEMBER THAT A CARELESS FRACTION OF A

SECOND: IS SUFFICIENT TO INFLICT SEVERE INJUR_

1. Make: sure bystanders are clear of the tool and

workpiece.

2. Before actually cutting with the jointer-planer, let it

run for a while. If your jointer-ptaner makes an unfamiliar noise or if it vibrates excessively, stop immediately. Turn the jointer-ptaner off. Unplug the

jointer-planer. Do not restart until finding and correcting the problem.

3. To avoid injury from slips, stalls or kickback, feed

the workpiece into the jointer-ptaner only fast enough

to let the tool cut without bogging down or binding.

4. Before freeing jammed material, turn switch off, remove switch key, unplug the jointer-planer and wait

for all moving parts to stop.

5. Never leave the jointer-planer while it is running or

before it has come to a complete stop. Remove the

switch key and store it in a safe place.

,

glossary of terms for Woodworking

1, JOINTING

The removal Ofwood along the edge

Of a piece Of wood so as to make the edge both

straight and smooth.

8. REVOLUTIONS PER MINUTE (R.RM.)...

The

number of turns completed by a spinning object in

one minute.

2. PLAN! NG... Removing wood from the widest surface of a board so as to make it flat and smooth.

g_

3. WORKPIECE...

The piece of wood on which the

cutting operation is being performed.

4. DEPTH OF CUT,.. A term used to indicate how

deep into the workpiece the cutter knives will cut,

10. FENCE...

attached to the jointer-planer in a more

or less vertical position .... helps support and guide

the workpiece as workpiece is pushe_l across the

cutter head.

5, INFEED TABLE... The section of the table upon

whichthe workpiece is placed before being pushed

into the cutter.., its height is adjustable which allows the operator to select the depth of cut into

the workpiece,

6. OUTFEEDTABLE.,.

The section of a table which

supports the workpiece after it passes over the

cutter.

,

,

nl

11. FREEHAND...

trying to use the toot without holding the workpiece firmly against the fence and table.

This can let the workpiece twist and kick back.

12. LEADING END... the end of the workpiece which

is pushed into the cutting tool first.

13. TRAILING END...

the blades.

HOLD-DOWN/PUSH-BLOCKS,..

They are required for your own safety,., they are used to hold

thin or narrow workpiece down against the table

and fence when planing or jointing.

iii

,11,,11 ii ,1

,

i

KICKBACK,..

a kickback occurs when the

operator loses control of the workpiece causing it

to be kicked back toward him by the rotating cutter

knives.

iiip_!!!,,

!,,1_11

iii

i

iiiiiiiii

..................

the workpiece end last cut by

ii

i

II

II

I

II

I

table of contents

Page

Guarantee .................................

2

Installing the Fence

"

General Safety Instructions for Power Tools ......

2

Installing Belt Guard and Sliding Guard ........

Additional Safety Instructions for Jointer/Planer .... 3

Getting to Know Your Jointer/Ptaner ............

Glossary of Terms of Woodworking

.

5

• Basic Jointer/Planer Operations ...............

Electrical Connections ..................

,.:.._.:. :6

Maintenance. ...........

. ...................

Unpacking and Checking Contents ........ i:._ .... ,. :8

Sharpening Cutter Knives

Location and Function of Controls. ;.: _. _._ ,, _ i_i_:11

Installing (Replacing) Cutter Guard Spring

Assembling the Steel Legs .... ._............ _ii..

,:._12 , Lubrication

Installation of Drive Belt .... i ..... .... ..... _...:_

::'.,; .._ 13

Trouble Shooting ...........................

Mounting the Jointer/Pianer ,., .:.. o::_:::

_. i_., 15

Repair Parts ..............................

Checking Cutter Knives and Screws .

_ .:.. :,. 16

Page

17

18

20

27

31

34

34

35

36

38

FIRE HAZARDS, OR DAMAGE TO THE TOOL, USE

::PROPER:CIRCUIT

PROTECTION. YOUR JOINTER,

PLANER ISWIRED ATTHEFACTORY F0R 120V OPERATION. CONNECTTO::A i20V 15-AMP, BRANCH

CIRCUIT AND USE::A: 15-AMP, TIME DELAY FUSE

OR CIRCUIT BREAKER.

IF NOT PROPERLYGROUNDED, THIS POWER TOOL

CAN , CAUSE ELECTRICAL

SHOCK,PARTICU.

: looks;like beloW,

WARNING: TO MAINTAIN PROPER TOOL GROUNDING WHENEVER THE OUTLET YOU AR E PLANNING

TO USE FOR THIS POWER TOOL IS OF THE TWO

PRONG TYPE, DO NOT REMOVE OR ALTER THE

GROUNDING PRONG IN ANY MANNER. USE AN

ADAPTER AS SHOWN AND ALWAYS CONNECT

THE GROUNDING PRONG TO KNOWN GROUND.

CAUTION: To avoid motor damage, this motor

should be blown out or vacuumed frequently to

prevent sawdust build-up which will interfere with

normal motor ventilation.

3-PRONG

PLUG

PROPERLY

GROUNDED

OUTLET

,

GROUNDING

PRONG

;

a' 3-conductor cord

Underwriters _

Connect this tool to a 120V, 15-Amp branch circuit

with a 15-Amp time delay fuse or circuit breaker.

Failure to use the proper size fuse can result in dam*

age to the motor.

If the motor fails to start, turn the power switch to

the "OFF" position immediately. UNPLUG THE

TOOL. Refer to the "MotorTrouble-Shooting Chart."

Freq uent "blowing':' of fuses or tripping of circuit

breakers may result if:

a._ MOTOR IS OVERLOADED--Overloading

can

oCcur if you feed too rapidly into cutter knives.

b,: MOTOR:CIRCUIT

IS FUSED DIFFERENTLY

:FROM RECOMMENDATIONS--Always

follow

: instructions for the proper fuse/breaker. Do not

; :use:a fuse/breaker of greater capacity without

consulting a qualified electrician.

c. LOWVOLTAGE.Althoughthe

motorisdesigned:: WIRE: SIZES

f0i'i operation:on

the voltage and frequency

specified:on motor nameplate, normal loads will

be handled safelyonvoltages notmore than 10%

above or below the nameplate voltage. Heavy

loads, however, require that voltage at motor terminals equals the voltage specified on nameplate:

The use of any extension cord wilt cause some loss of

power, To keep this to a minimum and to prevent overheating and motor burn-out, use the table below to

determine the minimum wire size (A.W.G,) extension

cord. Use only 3 wire extension cords which have 3

prong grounding type p_ugs and 3-pole receptacles

which accept the tools plug.

4. Most motor troubles may be traced to loose or incorrect connections, overloading, reduced input voltage

(such as small size wire in the supply circuit) or to

overly long supply circuit wire. Always check the

connections, the load and the supply circuit

whenever motor fails to perform satisfactorily. Check

wire sizes and length with the Wire Size Chart shown

to the right.

• i ¸¸¸ :....

CAUTION: For circuits that are farther away from

electrical service box, the wire size must be increased proportionately in order to deliver ample

voltage to the saw motor.

• •

7

Length of the

Conductor

Wire Sizes Required

(American Wire Gauge Number)

120V Lines

0-25 Ft.

26.50 Ft.

51-100 Ft.

No. 16

No. 14

No, 12

,el:1i 3;232210! 6,1/8 :JOINTER

E MISSINGPARTSARE OBTAINED

ICORRECTLY.

0il that:isapplied to all unpainted

TOXIC REACTION.

E,:_NAPTHA OR SIMILAR

SOL:VE S;

:: Applya coat of paste:wax t0the table.

Wipe all partsth0rough

y w tha clean, dry cloth.

WARNING:- FOR:YOUR OWN SAFETY, NEVER CONNECTP LU G::TOi_

POWER SOURCE 0 UTLET UNTIL

ALLASSEMBLY STEPS ARE COMPLETEiANDYOU

HAVE READiANDUNDERSTAND

THE SAFEW AND

OPERATIONAL :iNSTRUCTIONS,

i

: L--,!

¸: _

• :•:

L•_••I•/

••

••

/

:

.

.

item

;

:::Description _

A JointerBase,,;!i.

;..,

..; .......

B Fence .:; ,.:i..

, ......................

C;Push Bocks...:ii.::i_.i

:..:...

;i; ;...

D Siding Fence Guard...

;.....:

........

E Belt Guard ..........................

F Owner's Manual ......................

G Legs ...................

............

H Top Side Stiffener ....................

I Bottom Side Stiffener .................

J Top End Stiffener ....................

K Bottom End Stiffener ..................

L Loose Parts Bag #507711 .............

M Loose Parts Bag #508210 .............

N Loose Parts Bag #508092 .............

Qty.

1

1

, 2

1

t

1

4

2

2

2

2

1

1

1

E

\

K

i' ;•••i i•'_::•

•i• ¸¸I¸:•:

•ii_i!!i:

¸ •_•_•

O

List of Loose Parts in Bag #508210

Item

Description

O ,V"Belt

..

i. .....................

P Siding Guide Rod. ...............

Q Pulley....

:: .......................

R Lock Knob ._.: ........

................

:S iLoose Parts Bag. ....................

: (#508091and #508093)

,...

Qty.

1

1

1

1

2

9

G

0

i

i

ii

i

iii ii

!

LIST OF LOOSE

Item :i:_::

i:i

PARTS: IN BAG #508091

:Description: :

_H .::::Spacer :: ::.!_

_::_.

Qty.

ill::. ...... ..... :. i

:i

Washer380x

19/64x7/64,

.:. .....:,,:;;..

1

*3

Retainerli

,.

_/,:!_:i ,.,'

i

*::K . Carriage:Bolt3/8-16

x2.1/2,

i.....

:.;:. ;_ 1

O

: L

Description

!:*L

Switch Key, ...........

.:.....i::.

..... -.. 1:......

i[]

iJJ

LIST OF LOOSE

Item

PARTS IN BAG #508093

Description

Qty.

G

M

,Lllltppnltl_lllWUlWllimltlli!g

0

N

S

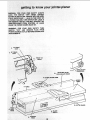

90° AND 45 °

FENCETI_

SCALE

7

FENCE STOPS _

1 DEPTH OF CUT

HANDWHEEL

5 SLIDING GUARD

KNOB

3 CUTTER

GUARD

2 ON-OFF

_: :i_ ::!!: ::;: i

SWITCH

4 FENCELOCK

KNOB

LOCATION

:

AND FUNCTION

1. Depth of cut handwheeh

_

OFCONTROLS

i: : _

_:

5. Sliding Guard Knob:

By,turning the handwheel you can controihow much

wood will be removed from the workpiece.

2. On-Off Switch_

_:

Turns the tool on and off.

3. Cutter Guard:

Helps protect the operator from the sharp knives on

the cutterhead,.

It is spring loaded so it automatically keeps the cutterhead covered before, during,

and after a cutting operation,..

It must always be

used,

:

Allows the fence to be repositioned at any location

from the front to the rear of the tables and to

be locked at that position. To unlock--turn the knob

counterclockwise.To lock--turn the knob clockwise,

6. 90° and 45 ° Fence Stops:

When adjusted properly, these stops provide a

method for quickly moving the fence to a 90 ° or 45 °

position from the table,

7, Fence Tilt Scale:

Helps the operator accurately and quickly position

the fence at any angle between 45" and 90 °.

4. Fence Lock Knob:

Allows the fence to be: repositioned and locked at

any angle from 45 ° to 90 °. To lock--turn the knob

clockwise:. To unlock--turn

the knob counterclockwise.

11

EDGE:OF: :

NCH THICK:

......

_ : :

• ....... ......

_::: :: :

PERFECTLY STRAIGHT

:\

,sCREWDRiVEF

\_

/

"_:'/

;_

_

il

I

:

, ....

: :7116'!SOCKET

,,2SOC<E,

.

.....

_

_

SQUARE

_

-

I(____

I:

: : _

!

:

I[_, ,'_'-_

DRAW LIGHT ..... i

I'#'il

LINE ON BOARD

L!_

ALONG THIS EDGE '_

I:

1/2":OPEN END WRENCH

7ii6": OPEN END:WRENCH

9/16;';OPEN END WRENCH

:

i

,

'%

:6_':SOCKET EXTENSION

I

COMBINATION

:

.......

: '

.....

9/16" SOCK_

I

_

.....

/

/

/

I

,\J, --

.... I

: iN

/

SHOULD BE NO GAP OR OVERLAP HERE WHEN

[

SQUARE IS FLIPPED OVER IN DOTTED POSITION

3/4"OPENENDWRENCH

3/8"..16

HEX NUT

Q

LEVELING FOOT

THEJOINTER

: :

i

:

PLANER;:::::::!

©Q

leg set, hand

TRUSS

HEAD SCREW

LOCK

WASHER

114"-20

HEX NUT

STIFFENER

STII

\

j,ll,_l

INSTALLING

ADJUSTING

DRIVE BELT AND

BELT TENSION

MOTOR

CUTTER HEAD

WARNING: DO NOT LETANY PART OFYOUR BODY

TOUCH THE CUTTER HEAD. tT CONTAINS VERY

SHARP CUTTER KNIVES WHICH COULD CUT YOU

BADLY.

1. Fromthe loose parts find the drive belt and the putiey.

From the packing material used in the jointer box,

find two (2) large pieces of styrofoam.

SPECIAL NOTE: When turning the JointeriPtaner upside down do not put the weight of the Jointer/Planer

on the guard or the guard may be broken. Do not roll

the JointedPlaner over because this may also break

the guard.

2. Put the two pieces of styrofoam on the floor and put

the JointeriPlaner upside down on the cardboard as

illustrated.

WARNING: DO NOT TURN: THE MOTOR ON UNTIL

:THE JOINTERiPLANER

IS COMPLETELY ASSEM:

:

BLED AND TURNED RIGHTSIDE: UP WITHiTHE i : i_: :

LEVELING FEET SETTING AGAINSTTHE FLOOR_ :_:

IF THIS WARNING IS NOT FOLLOWED THE MOTOR

MOTOR

AND START SWITCH MAY BE BURNED OU_'YOUI

MOUNTING

COULD ALSO BE BADLY CUT BYTHE VERY SHARP =

BOLTS

KNIVES ON THE CU_ER HEAD_ :: ', :'

:

3. Locate the two motor: mounting bolts on the underside of the j0inter. Using a 1/2, _Socket, 6" extension,

and a Socket wrench loosen these two moto_ mounting bolts.

.........

4. Slide the motor: pUiley onto the motor shaft as illustrated with the set screw side of pulley toward the

jointer,

:

•

MOTOR

PULLEY

i

13

CUTTER

PULLEY

screw,isover the fl,

!: :motor stiaft before tightening set screw.

on the

!

THIS

AOJUST.E.T

.V

MoVING!THE CUTTERHEAD!PULLEY. FAILURE TO

OBSERVE THiS IWARNING MAY CAUSE THE CUTTERHEAD TO MOVE OUT OF ITS: PROPER POSITION ALLOWING THE CUTTER: KNIVES TO HITTHE

'METAL BASE CASTING.

MOTOR

PULLEY

,

,

,

,

DRIVE

BELT

,, ,111

CUTTERHEAD

MOTOR

BOLTS

\

CUTTER

PULLEY

\

.

.,q_DiIiiNim

•

DRIVE

BELT

MOTOR

PULLEY

•14

CUTTER

PULLEY

MOUNTING

THE JOINTER/PLANER

1.:From the loose parts find three (3) 3/8-t6 x 3/4" hex

head bOlts, and three (3) 3/8 internal lock washers.

2: Place the teg set on top of the jointer!planer and

align the three (3) mounting holes on the bottom

side of the jointer/ptaner with the holes in the leg

set (see illustration).

3. Place a lock washer on each bolt. Using your fingers,

screw the bolts through the leg set holes and into

the mounting holes in the jointer/planer. Tighten the

bolts securely using a 9/16 inch wrench.

HEX HEAD

BOLT

4. Using a 7/16" socket wrench tighten all nuts and

bolts that hold the leg set together.

5. Get another person to help you turn the jointer right

side up so the leveling feet are against the floor.

I

)

'

>

15

INTERNAL

LOCKWASHER

STRAIGHT

EDGE

OUTFEED TABLE

INFEEDTABLE

--

i

i

i

:

_••: Hi •

e, If cutter knife adjustment is not required, check::

each locking screw on each wedge (5/32" HeX,L

"

wrench): and tighten if necessary. Hold :the2inch

pulley in a stationary position to prevent the Cut;

terhead from turning during this tightening procedure.

WEDGE

CU'I_ERHEAD

i,_,

i_!i_ii

_!_

ii_i

il_ii__,}_i'i

i_!_i_'_¸¸_¸¸_

INSTALLING

FENCE

1. Rotate the cutter guard counterclockwise and place.

the fence on the jointer table as shown.

2.: Locate the following parts from the loose parts bag

and install as shown:

,

One (1) 318-16 x 2-1/2 carriage bolt, one (1) retainer,

one (1) .380x 1-5/32 x 3/32 flat washer, one (1)

spacer, and one (1) knob.

Attach the fence to the jointer as illustrated below.

RETAINER

4. Rotate the cutter guard counterclockwise away from

the fence and then release it. The spnng tension on

the guard must cause it to swing back against the

fence, if the guard does not swing back against the

fence, recheck your assembly procedure. Do not

use the jointer/planer if the guard wilt not automatically swing back against the fence and cover the

cutter head,

SPACER

FLAT WASHER

CARRIAGE

BO_

KNOB

CARRIAGE

BOW

SPACER

FLAT

WASHER

RETAINER

VIEWED

t7

• !!!i....

FROM REAR

\

KNOB

one

One (1)Split Iockwasher 1/2,, two (2) 10-32 x 1/4, Pan.

I-ld_Screws, two (2)#10 External Lock Washers, two

-32 x2-3/4' PaR Hd: SCrews, One (i) Belt Guard.

Illl!lltlllllliflllillllllllllWIIIIIlllltlitltlllll]]

...

PAN HD SCREW 2-314"

SLIDING GUARD

SLIDING GUARD

•KNOB

PLASTIC

WASHER

HEX NUT

112"

©

Os

PAN HD

EXTERNAL

LOCKWASHER #10

BE_

GUARD

LOCKWASHER

1/2"

ROD

1/2" NUT

!

i:

i

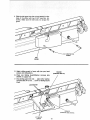

4. Slide the belt guard over the rod and attach it to the

base of the jointer with two 2-3/4" long Pan. Hd.

screws. Make sure the belt does not scrape the

guard.

O

j2-3/4" LONG PAN HD.

SCREW

BE_

GUARD

5. Attach sliding guard to fence with two pa n head

screws and Iockwashers;_ i _ : _

WASHER

.....

(CONCAVE

SIDE UP)

6. Place one Sliding Guard!Washer, concave side

DOWN on support rod.

......

7. Drop sliding guard onto rod .:. place other washer,

concave side UPon rod ;. screw on Sliding Guard

Knob.

LOCKWASHER

WASHER

(CONCAVE

1/4" PAN HD.

SCREW

19

SIDE DOWN)

know your _'ointerwplaner

J;

ID KEEP

F

WH

UP AGAIN

L:

WARNING:

FOR YOUR: OWN SAFETY TURN

SWITCH i_i"OFF":

AND i REMOVE PLUG

FROM

POWER SOURCE OUTLET BEFORE MAKING ANY

ADJUSTMENTS;

4 4S_FENCE

_

STOP

STOP

,

0N-OFF SWITCH.

The on-off switch is shaped to make turning it "ON"

accidentally less likely.

In an emergency, it can be turned "OFF" by striking

it with the palm of the hand.

The "yellow button" is a key. When it is inserted in

the switch lever, the power may be turned ON and

0FE When it is removed, the power cannot be turned

ON.

THIS FEATURE IS INTENDEDTO HELP PREVENT

UNAUTHORIZED

AND

POSSIBLE

HAZARDOUS USE BY CHILDREN AND OTHERS,

a. Insert Key into switch.

NOTE: Key is made of yellow plastic.

b. To turn the tool on, insert your finger under the

switch lever and pull the end of the switch out.

i ii1_

C,

To turn the tool OFF _.. PUSH the lever in.

Never leave the machine unattended until it has

come to a complete stop.

d, To lock the switch in the OFF position..,

hold

the switch IN with one hand ... REMOVE the

key with the other hand.

WARNING: FOR YOUR OWN SAFETY, ALWAYS

LOCK THE SWITCH "OFF" WHEN MACHINE IS NOT

IN USE...

REMOVE KEY AND KEEP IT IN A SAFE

PLACE..,

ALSO . .. IF THE TOOL STOPS UNEXPECTEDLY, TURN SWITCH OFF . . . AND REMOVE

THE KEY. THIS WILL PREVENT THE MACHINE

FROM STARTING UP AGAIN WHEN THE POWER

COMES BACK ON.

21

!:tii:Sji::i

posiwood.

tior

If.guard::does

not return automatically,

ichecked by :a Sears Service :Center.

have it

CUTTER GUARD

"

i ¸

:

•

[i

i

ii

,

SLIDING GUARD

KNOB

\

PUSH DOWN

WHEN LOCKING

FENCE LOCK KNOB

blades. _: .......

Most: of_the Cutting (usually joiniing)wilibe

!i

FENCE

done

45° FENCE

STOP

.. .... with the fence in this posifioni As :the:blades become

OUTFEEDTABLE

:

To tilt fence, loosen the fence 10ck knob and slid:

ing guard knob and pull the stop out; Tilt to desired

angle and tighten both knobs:

:::.:: :

d. To set fence at 90 ° to tables, loosen the

knobs, titt fence so the stop springs back

place. Tilt fence back so the stop rests on

table. Hold fence down on outfeed table

tighten both knobs.

two

into

the

and

FENCE LOCK

KNOB

:.:: e.:i 45_ Fence Stop positions the fence at 450 to the

: .......;::

tables.:

.

to:45t, loosen the two knobs, pu!l 90°

stop rests on the

....

:th

._,:

::

i{i

:::•:i:h

::>::

;T

•:

"•!!ii,:!::::i{)}

:,:,

,i

22

":

:

:/-:,

=i :

:: ::.-

.:

"

FENCE SLIDE

BRACKET

5. FENCE TILT SCALE.

Indicates the ang!e of the fence to the tables: When

the 900 fence stol_ s correct y adjusted; the fence

will be90Q to the table and the scale wil! read 90°_

FENCE

To Check for squareness, place an accurate square

on infeed table and check fence while_locked at 90°

position, MAKE SURE 90 ° STOP IS AGAINST

SLIDE BRACKET.

HEAD

OF

JSQUARE

tf fence is not square to table:

a. Slightly loosen fence lock knob and guard lock

knob.

b. Loosen 90 ° stop screw with small screwdriver

and turn knurled sleeve which will cause fence

to tilt. Turn sleeve in either direction until fence

is square with infeed table.

NOTE: If you cannot square fence by turning

knurted sleeve, loosen three screws "A" and adjust fence square to table.

c. Tighten 90 ° stop iockscrew and both fence lock

knobs.

dr

tNFEED

TABLE

CUTTER

GUARD

SCALE

ADJUSTING

SCREW

If 90 ° reading on tilt scale does not line up with

top surface of the slide bracket, loosen screws

holding scale and move it... tighten screws,

45=STOP

LOCKSCREW

A

TILT

KNURLED

SLEEVE

45 ° STOP

90 _ STOP

45°STOP

KNURLED

SLEEVE

90 ° STOP

SCALE

ADJUSTING

SCREW

90°STOP

SLIDE

BRACKET

FENCELOCK,_ _"

KNOB

INFEED

TABLE

SQUARE

\

FENCE

FACE

e. Adjust 45 ° stop in the same manner.

NOTE: Tilt scale will n_ _require adju_ment if it was

adjusted for 90 ° 0osition.

v

,,,

•

CUTTERGUARD

23

T

MUST ALWAYS:BE PARALLEL TOTHE OUTFEED

TABLE.

ifthe _cut edge or surface of the workpiece is

CROWNED,I it is

indication that the oUTWARD

{_

:_

CONCAVE CUT

._-'_-_

_L--_-!

_

_,

:adjusted.

If thecut edge or surface o{ the workp ece is CONCAVE, it is an indicati0n;that the OUTWARD END

._.-_: of the INFEEDtable is LOW and must be adjusted,

,.

_TO:check the infeed table to determine the "out of

"_...

J

INFEED TABLE LOW

cutter}uard

touches

the:

\

INFEED TABLE

OUTFEED TABLE

::::: :::

:::!_

:: :i::

::::i::

:::_: :

::_!_:i ::¸_

_:!:i:=:_:

'::: ::!::_!:,::_

:i¸_ii :!:_:

::::::

::::::::

::::::::: :

::::::::::::::::::::::::::::::::

the infeed tabi_ SO:it'is pamiiel::to the oui:: : ::::::

:::::

:feed:tab!e Call::be:a:::tme: €onsuming::processl :To::::::

:::Co_ER:Gu:AR_:::

:i

::::_.::

!:i::::

::::::

:::::

::: :complete:the adjustment in as: littletime as possible

':

: : :: ::

:

Put:the:yeiiow:on::offswitch:keyinthe rectangular

shaped indentation exposed as you turn the cutter guard counterclockwise. This will hotd cutter

guard open.

:

!

YELLOW

SWIT/CHKEY

f:

....

_'_ _:::_..._

S

L.._--._ _..,_.J___F.,,'_

_-'-'--.:-/7_'_._

-"_"/_ ;/,,_./_

/

VIEW FROM BACKSIDE

JOINTER/PLANER

b. Wrap a peice of cardboard around cutterhead to

protect your fingers and the blades..,

secure

cardboard with a piece of tape.

CARDBOARD

c. Using a 1/2 inch open end wrench; Ioosenthe

Iockboits 1/2 turn under the section of the table

that is low. Loosen no more of the lockboits than

is necessary.

STUD

LOCKBOLTS

25

I/Z'OPEN

END

WRENCH

LEVELING

STUD

•

h the straightedge to make sure the

infeed _tabie :is teveL If it is not, go through the

above Steps :again

.

"

7",

LOCK BOLTS

i•

-i ••-

i

illl

i

i

i

i

ii

ii

i

i

i

i

8.1,MOUNTING HOLES FOR AUXILIARY FENCE;

TheSe _holes are proVided so you may attach an

auxiliary fence to the front of the cast iron fence. An

auxiliary fence should be used anytime you joint

boards _/ider than 4-1/2 incheS_The auxiliary fence

should.be, made from a smooth straight board and

cutto a widtPithat witt cause the auxiliary fence tO

be::no more :than 1 inch narrower than the board

being jointed_ i :::

_

!.Attach theaUxiiiary fence as i!lustrated;

MOUNTING

HOLE

AUXILIARY

FENCE

\

\

i

basic jointer=pUaner operation

BEFORE

EACH USE

Plan Your Work to protectyour eyes, hands, face, ears.

b. Remove all jewelry and loose clothing.

1. Carefully plan your hand placement. Make sure you

have proper hold-down/push-blocks, jigs, fixtures,

stops, etc. ready to use.

c. Tie back long hair.

d. Roll long sleeves above the elbow,

6. To avoid burns or other fire damage, never use the

jointer-p_aner near flammable liquids, vapors or

gases.

7. To avoid injury from slips and jams:

2. Do layout, assembly or set up work on the table

only while the jointer-planer is off and the switch

key removed.

3. Wear safety goggles that comply with ANSI Z87.1

a. Use this jointer-planer to cut only wood.

b. Plan your hand placement so your fingers will not

be anywhere a sudden slip could cause them to

slide or fall into the cutter head. When using only

one hold-down/push-block to feed the wood, do

not put your other hand on the Jointer-Planer,

workpiece or hold-down/push-blocks.

4, For dusty operations, wear a dust mask along with

safety goggles.

5. Plan your work to match your workpiece:

a. Surface plane warped wood on the concave side

for best results,

b. Don't joint or plane plywood, particle board, other

composition materials or wood that has glue,

paint or varnish on it. Materials like these will

quickly dull the blades.

c. Make sure all clamps and locks are tight and

there in no excessive play in any parts,

8. Adjust the depth of cut to between 1/32 and 1/16

of an inch for best results in most operations. A

deep cut makes feeding the wood harder and can

cause the wood to kickback. To be sure you will

make a depth of cut you ptanned, always lower the

infeed table slightly farther than you wanted. Then,

raise the table to the desired depth.

c. Make sure there are no nails or foreign objects

in the part of the workpiece to be cut.

d. Never cut FREEHAND. Guide your workpiece

solidly against the fence and table top.

Small or thin workpieces can kickback when they tip

over on the table or into the cutterhead. To avoid cutterhead contact or workpiece kickback:

9. Before using the jointer-pfaner, clear the table of

all objects not needed to feed the workpiece.

1. NEVER joint, plane or bevel workpieces shorter

than 12 inches.

10. To avoid injury from unsafe accessories, use only

recommended accessories.

2. When Jointing or Beveling:

a. Never joint or bevel workpieces less than 3/4

inch wide or 1/4 inch thick.

Whenever Jointer-Planer is running

1. Make sure bystanders are clear of the toot and

workpiece.

2,: Before actually cutting with the joiner-planer, let it

run for awhile, tf your jointer-planer makes an unfamiliar noise or if it vibrates excessively, stop immediately. Do not restart untilfinding and correcting

the problem.

b. Always use the hold'down/push-blocks

when

jointing or beveling wood narrower than3 inches.

3_

When Planing:

....

a. Never plane wood thinner than i/2 inch.

b. Always use hoid=down/push_btockswhen planing wood thinner than 3 inches: _ :,

,

To avoid risk of hearing damage, wear ear plugs

or muffs during extended periods of ope!ation.

5, To avoid being suddenly pulled into the blade!

a. Do not wear gloves.

3. To avoid injury from slips, stalls or kickback, feed

the workpiece into the jointer-planer onty fast

enough to let the tool cut without bogging down or

binding.

4. Before freeing jammed material turn switch off,

remove switch key, unplug the jointer and wait for

aU moving parts to stop.

27

/

JOtNTING WOOD THAT IS WIDER THAN 3 INCHES

i

:

r,,:., ,./,,,r,,,

•

H k

As:the TRAILING hand passes over the cutterhead,

remove the LEADING hand. :. CONTINUE feedingwhile

placing the:LEADING hand behind:the TRAILING hand.

_ntirlue: feeding in this manner "hand over hand:until

causes a:"rippled, cut:: i ._makesit difficult to guide the

workP!_ _ccuratety anti.could; be hazardous.

JOtNTING WOOD THAT IS THICKER THAN 3 INCHES

_

. Always feed WITH THE GRAIN whenever possible. If .......

:

the nature of :the workpiece iS such that it must be fed

AGAINST THE GRAIN. take very light :cuts and feed

s_owly.

:•

•

i ¸_

•

:

WiTH THE GRAIN

ROTATION

AGAINSTTHE

ROTATION

GRAIN

Support Long Workpieces

To avoid injury from slips or kickbacks, use extra sup_

ports (tables,, sawhorses etc.) at both infeed and outfeed ends if your workpiece is hard to hold down to the

table.

A SAWHORSE OR HOMEMADE

SUPPORT WILL DO

I

I

, i

ii/

ii

J ii1,1 iii

i,ii

iiiiJl.lllmU

I

I I

I

lull IIIII

I

I1'1'111111111111111111111

IIIIIIII1_11

!i

Using the hold-down/push-blocks

ALWAYS use the hold-down/push-blocks when JOINTING wood that is NARROWER than 3 inches or planing

wood that is thinner than 3 inches (as illustrated).

Grasp the hold-down/push-blocks firmly with the fingers

close together and wrapped around the handle_ Position

the hold-down!push-blocks flat on topof workpiece ....

and push the workpiece down againstthe tabieto pro,

.

, .

....

: : .... . .....

vide a qual cut and minimIzethe chance ofa kickback.

.....

::

i'i:

Hold-down pressure must atso :be sufficient to prevent :

hotd-down/push-bock sliding or slipping Onthe top face: of workpiece when advancing workpiece Over cutter

head.

:.........

: ...... _,

::i

Use a hand-over-hand motion of the hold-down/push,

blocks, being careful tOmaintain ControtOver the workpiece at alttimes;

_

:

: :: _ :

This means that once the workpiece has been fed past

the cutter head onto the outfeed table, one hold-down/

push-block must always maintain contact of workpiece

with ouffeed table.:

.....

i:

_....<_-_._--_----__.,_-_._

,

_-...__

_.-...

: ._.i_...__

1 i

t._

JOINTINGWOODNARROWER

THAN3 INCHES

WARNING: iF THE HOLD-DOWN/PUSH-BLOCKS

TEND TO SLIP WHILE FEEDING, CLEAN RUBBER

SURFACE IMMEDIATELY WITH SANDPAPER,

-_,

PLANING WOOD THINNER THAN 3 INCHES

29

lJ

°

:h; Iti,,

greater tenden(

iv

PLANING WOOD 3/4 INCH THICK AND NARROWER

THAN THE PUSH BLOCK

II

'

I

Beveling

Adjust the fence to the desired angle..,

lock fence in

positionusing fence lock knoband sliding guard knob.

pieces of wood 3 inches or wider hold the board

firmly doWn on both tables and firmly against the fence

(asitiustrated) with:your hands on the side and top of

the workpiece ... keep fingers close together:

CHAMFER

BEVEL

BEVELING

......

.........

• ••

30

WOOD NARROWER

THAN 3 INCHES

NOTE::Rabbeting

on a Jointer is considered to be a

dangerous operatioh because it requires removal of the

cutter guard and increases the potential of kickback

because of excessive depth of cut,

NEVER ATTEMPT TO PERFORM A RABBETING OPERATION ON THIS JOINTER. DO NOT OPERATE

JOINTERiPLANER

WITH CUTTERHEAD

GUARD

REMOVED.

Rabbet cuts should be made on the Radial Saw or

Table Saw by making two cuts with the sawblade or by

using the Dado Head or Molding Head. Rabbet cuts

can also be made using the Shaper or Portable Router.

llmllL,

i

RABBETCUT

i.ll_lllll

IIH

.ll II

II.ll

I]

I'lllll

.....,,,,,,,

,

rnaantenance

Do not allow pitch to accumulate on the tables, the

fence, the cutter guard, the cutter head or the knives.

Clean them with Craftsman Gum and Pitch Remover.

If disassembly of the motor is necessary, it should be

returned to your nearest Sears retail or mail order store

in order to prevent voiding the guarantee.

NOTE: The speed of this motor cannot be regulated or

changed.

Apply a thin coat of paste type wax to the tables and

the fence so that the wood slides easily while feeding.

This also deters rusting.

Do not allow chips to accumulate on the underside of

the jointer-planer.

Motors used on wood-working tools are particularly susceptible to the accumulation of sawdust and wood chips

and should be blown out or ,'vacuumed" frequently to

prevent interference with normal motor ventilation.

If power cord is worn Or cut, or damaged in any way,

have it replaced immediately.

iu

.Lllll=i i

H

llll

HHILI

II"IH

I

HIHIll

=

:

....

REPLACING

CUTTER

iiii

!llrllllllli iLJ

ii

i k

IIII

IIII IIII

SLIDING GUARD

KNOB

KNIVESI

WARNING: FOR YOUR oWN:

SAF_

TURN

SWITCH "OFF" AND REMOVE PLUG FROM POWER

SOURCE OUTLET BEFORE ADJUSTING, MAINTAINING, OR LUBRICATING

YOUR i JOINTERPLANER.:

.....

1. Remove the belt guard as follows:

a. Use a screwdriver to loosen both screws, shown

in illustration.

b. Remove sliding guard knob from sliding guard

rod. Turn the knob counterclockwise to unscrew

it from the rod. Raise sliding guard to a vertical

position;

/

c. Slide the belt guard out away from the jointer and

up off the rod,

SLIDING GUARD

31

2-3/4 PAN HD

SCREW

BELT GUARD

U JJ

I

I

I

I

iiiii

i

[111

lJl

i

ii

CUTTERHEAD

5.

cu,erhead pulley

firmly

with or

one

hand and

ii :Hold

lo0seniockscrews!n

each

wedge3

4turnsusing

.

:::-

w oQe

.....

Hex 12:wrench:

ieeVi?

,

i .%._.__.

._LEY

....

.---------

_.-_._..___

.

-----

.

iiii

i]

HLI[

I

I

]1

CUTTERHEAD

PULLEY

EXPECTEDLY. PARTS:MAY LOOSENSUDDENL_ TO

AVOID EYE INJUR_ WEAR SAFETY GOGGLES,

BARS: THEIRHARDENED TIPS CAN SHATTER UNhand,_gent_y pry up each Wedge using a small pry

bar. Remove wedges andknives. :

:

knives is as foliows: :

....

a. Locate the two lifter screws under the knife.

b. Hold the cutterhead pulley firmly with one hand

to prevent ,the cutter head from turning.

c. Using a i18 Hex-L wrenchl turn one of the lifter

screws 1/4 of a turn counterclockwise.

d. Now turn the other lifter screw 1/4 of a turn

_.€ontinuetUrning first one lifter screw and then

turn at a time until the knife

-

counterclockwise.

remove the knives using

oil soak in be-

.....

"

..,,

.......

5/32 IN. SETSCREW

WRENCH _'_

LIFTER

7. Using a 1/8" Hex "t.'.'wrench, remove the six lifter

screws, (Two under each blade.)

8, Clean cutterhead, wedges and screws thoroughly

with Craftsman Gum and Pitch Remover. Also remove the oil from new blades.

9. Replace the six lifter screws and screw them in all

the way, but do not tighten,

10. Insert a knife in one of the slots,.,

so it projects

1/t6 of an inch beyond each end of the cutterhead.

Note that the face with the cutting edge is against

the wedge as shown,

11. Insert a wedge next to knife so the flat side of the

wedge is against the knife. Push wedge in manually-do not install two locking setscrews at this

time.

• _i<_:ii_!!_, _ :i,i, _!,i_i,_i,_i/_ ii ii_i !_

12. Adjust cutter knives as follows::

:

a. Put a piece of notebook paper on top of the

NOTEBOOK

outfeed table.

:_

....... __

PAPER

b. Put the head of a squareon topof the paper.

The end of the square must extend past the end

of the outfeed table and above one end of the

cutterhead;

i ,

i....

c, Turn the lifter screws counterclockwise to raise

the knife until if just touches the square.

d, _To check your adjustrnenti I;gently turn the cutterhead back and forth by moving the cutterhead

pulley, The knife should just touch the square

without raisinglthe square off the paper. This

same adjustment must be made at the other

end of the cutterhead.

e. tfthe adjustment:is done correctly, the knives

will nowbe slightly above the ouffeed table by

approximately :003 of an inch (the thickness of

an, average piece of paper),

.... NOTE: This adjustment can be made more accurately by:using a knife setting gauge (Cat,

#9-2647) available at Sears.

i

¸

OUTFEED

TABLE

•

33

N(_ irtsta!! bothlockingsetscrewsandtighten(with

tt_e5/32_'Hex:L Wrench)alternately a little:at a:time.

.....ttoigi_tenboth:

securely.;

::"i:

make sure Screws

it didonot

change Recheck:the

_sitioni::

: blade

::i

-!4:1=l_stai! the other: twokiiiveS

_ i5: Ret_stail the belt guaid,; sliding guard, and slid ng

....

guard knob.

::.

:

CAUTION=THE CUTTER KNIVES ARE VERY SHARR

TO PREVENT A SLIP OF THE HAND WHICH COULD

CAUSE CUTTING OF YOUR HAND, ALWAYS HOLD

ONTO THE CUTTERHEAD PULLEY TO PREVENT

ACCIDENTAL ROTATION OF THE CUTTERHEAD.

SHARPENING

CUTTER

_

__

KNIVES

The knives can be honed individually with an ordinary

oilstone,

Make sure your oilstone is not worn in the center. It

must be flat.

Besure to remove the burr on the flat side.

11/16

IN.

NEW BLADE

if the knives are nicked, they must be replaced or reground:: They can be regrounded several times until

they become 9/16 in. wide: Never install reground

knives

less than 9/16 in, wide 0r unbalanced knives_

.

ave your knives reground by s0m_0newho:iscompetent. I_ooki_: the Yellow Pages 'of your:telephonedirec_

tory :i .:;:!See::,SharpeningService's."

..........

_=

-

34

5

RAISE the end of the FENCE, rotate the guard

COUNTER clockwise onIy enough to CLEAR fence

6. LOWER the fence and tighten

both knobs

The normal position of the guard (at REST) when the

fence is stationed at MAXIMUM WIDTH OF CUT, is

shown as position

"A" NEVER

ROTATE GUARD

BEYOND

POSITION

"B" BECAUSE

THIS WOULD

EXERT EXCESSIVE TENSION ON SPRING WHICH

COULD WEAKEN OR BREAK IT

Check operation

of GUARD

POSITION

"A _'

and SPRING

1 With fence in MAXIMUM WIDTH OF CUT position,

pass a piece of 1/4 in thick wood on edge (jointing

position) over cutterhead

2

The guard should return automatically

to its REST

position against the fence when free of the wood

3. If guard does not return to its REST position, remove

the guard by following steps 1 thru 6 above Make

sure the spring is installed correctly and not broken

If the spring is broken it must be replaced

Reassemble the guard and spring

following steps 1 and 2

and test again by

If guard still does not return to its REST position, consult

your local Sears Retail Store before using the jointer

planer

lubrication

The BALL BEARINGS in this machine are packed with

grease at the factory. They require no further lubrication

The following parts should be oiled occasionally

SAE No 20 or No 30 engine oil

1 Dovetail

spacer and dovetail

"with

slide

2, Elevating screw (first clean with Craftsman

Pitch Remover).

\

\\

Gum and

DOVETAIL

SPACER

AND

SLIDE

ELEVATING

35

SCREW

VIEW LOOKING

UP FOR

PARTS fDENTIF1CAT!ON

i:Motorwtiinot _ni: ::i: :i

::i;_:Defective onLoff Switchl;:II '

ii;::;_::

::

::::

:: :!:::i : i: :.Def_ive relay.::

:::i _: i i:

;

;:: _:

Defectivecapabitor,

i

i;::

!:_:::i

:

:i

Defectiv_ motor::: '::

:

:

::

: :_Low line voltagel

:; :

• i :,_ ':.:

i :......

t : Belt tension too high, :

ConSult sears Serv c'ei'Any attempt i 'o'repa r th s e ecirical

dev ce may createa HAZARD unless repair is dode by a

qua fiedserv cetechnic an Repa rserv ce is ava able

at your nearest Sears store

Adjust belt tension.

:Wood strikes outfeed

,table after passtng over

€uu_head_

Blades improperlyadjusted

'""'

Re-adjust b ades see Ma ntenance section.

: belowsurfaCe Ofouffeed table.

I _

:

:

i

i 1

R|ppii_$ on planed

: surface. I

i:

:

Kickl_cks.

: ......

:i ..... i

_, :

.....

:

other:

;

;

:i: 2;i Feedingwoodtoo fast.

I 3. Cutting knives am settoo h gh

I _aboVe ouffeed table ortheyare

not leveled with outfeed table.

1. Re-adjustblades

seeManienancesecton.

2. Feed wood slower.

3. Re-adjustbades

see Ma ntenance sect on

:

i

lnfeed tab e out of adjustment

Re-adjust infeed table, see Gett ngTo Know Your Jointed

P aner section:

:

,:l,...........

5/16"-181ockbotloose.

11 Tighten Iockbolts

....

|

Cutter gtiard does not ,

furllctiorl:properly.

:

: :

::

:: :i=:;

:: :: :

: t. Return spdng broken;:or:

...... i spr ng has bt_en Weakenedl

: _::

:

_

_

_

:::i

_ :

:;ii;i_i

:

_i_: i

:ii_:i;i'i!!i;:i!i

'_:::::': :i;:i_:_ii:::i,;::i

:i

WHITE

:

_,_....

C0nsult Sears Serv{Ce immediately, Any attempt to repair

: th sguard maycreate a hazard un ess repair is done by a

qua lfied servlcetechntclan. Repair service ts available at

atyournearestSebrsstore_

WHITE

_

WIRE

TROUBLE

SHOOTING--

MOTOR

NOTE: Motors used on wood.working tools are particularly susceptible tothe accumulation

of sawdust and wood chips and sho_Jid be blown Out or"vacuumed" frequently to prevent

interference with normal motor ventilation.

PROBABLE

CAUSE

TROUBLE

Excessive noise.

..........

REMEDY

I

1. Motor.

1. Have motor checked by qualified service technician.

Repair service isavailable at your nearest Sears store.

2. Tighten setscrew, ........

2. Pulley setscrew loose,

Motor fails to develop

full power. NOTE:

LOWVOLTAGE: (Power

outputof motor

decreases rapidlywith

decrease in voltage at

motor terminals. For

example, a reductionof

10% involtage causes a

reductionof 19% in

maximum poweroutput

ofwhich the motor is

capable, anda reduction

of20% in voltage causes

a reductionof 36% in

maximum power output.)

t. Circuit overloaded with

lights,appliances and other

motors,

2, Undersize wires or circuit

too long,

Motor starts slowly

or fails to come up

to fullspeed.

1,

Request voltage check from the power company.

1. Low voltage will not trip

relay.

2. Have motor repaired or replace&

2. Windings burned outor

open.

3. Have re_ay replaced,

3. Starting relay notoperating.

4. Drive belt tension..to.0..h.!gh. . 4. Adjust belt tension.

Motor overheats.

1, Motor overloaded.

2. Impropercooling. (Air

circulationrestricted

through motordue to

sawdust accumulating

inside of motor.)

3. Defective

relay.

:

=

:

Motor stalls (resulting

in blown fusesor

: :

trippedcircuit breakers,)

2. Increase wire sizes, or reduce length of wiring. See

"Motor Specificationsand Electrical Requirements"

section.

3. Request a voltage check from the power company.

3. General overloadingof

power company facilities.

1. Feed work slower into blade.

2. Clean out sawdust to provide normal air circulation

through motor. See !'Maintenance and Lubrication"

section.

I

....

2. Voltage too;lowto permit:

motor to reach operating

3. Fuses0rcircuitbreakers

_

: :do not have sufficient .....

:capacity.

Frequent opening of

fuses or circuit

breakers,

1. Do not use other appliances or motors on same circuit

when using the jointer.

i :i

:.

2. Request voltage check from the power company.

'

3; Installpropersizefusesorcircuitbreakers.Seeelectdcal

connection section.

:.... .......... ...........................................

1, Motoroverloaded. _

2. Fuses orcircuit breakers

do not have sufficient

,capacity.

SEARS RECOMMENDS

ITEM

Cutter Blades .,..

:.,.

.................

Power Tool Know-how Handbook:

.........

Knife Setting Gauge ,.. ;

............

Chip Collector.._.

....

: ........

. ......

3.: Have relay replaced,

t......

, 'i, Feed work slower.

i 2. Install proper size fuses or circuit breakers. See electrical

connection section.

THE FOLLOWING

CAT. NO.

9-2293

9-29117

:. 9-2647

9-29974

ACCESSORIES

Sears may recommend other accessories not listed in

the manual. See your nearest Sears store or Catalog

department for other accessories.

Do not use any accessory unless you have received

and read complete instructions for its use.

37

i_ :i _iz_ :

LIST FOR CRAFTSMAN 6,1/8-INCH

MODEL NO;1113;232210

34

JOINTER-PLANER

FENCE ASM.

SEE FIG. 2

_

TABLE ASM.

SEE FIG, 3

/

31

32

•

+

5

/

SEE FIG. 4

• ui:

-u

_/: :,

_+

9

:_ _

:•i••:•; ••

_t

10

12

15 14 13

:_;ii:::/¸¸

1+

• •:':

FIGURE 1

i i :

,ii

parts

PARTS

LIST FOR CRAFTSMAN 6-1/8,.INCH

MODEL NO:113.232210

JOINTER-PLANER

Always order by Part Number -- Not by Key Number

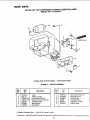

FIGURE 1 - JOINTER ASSEMBLY

*

Key

No.

Part

No.

t

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

2O

2t

21237

2t 738

STD533725

18437

818099

820081

102832

STD541031

18516

STD551131

STD523117

67017

STD551025

STD551225

STD522505

STD551210

STD511103

63418

STD328022

820074

60025

Description

Bracket Fence Slide

Retainer Bolt

* Bolt-Crg 3/8-16 x 2-1/2

Washer

Knob Elevation

Base-Jointer/Planer

Screw-SL Set 5/16-18 x 1

* Nut-Hex 5/16-18

Stud-Leveling

* Lockwasher-5/16

* Screw-Hex 5/16-18 x 1-3/4

Spacer

* Washer-17/64 x 3/4 x 7/64

* Lockwasher-1/4

* Screw-hex Hd 1/4_20 x1/2

* Lockwasher-Ext t0 .....

*Screw-Pan Hd 10-32x 3/8 :'

Clamp-Cord ....

:

*Pulley

" ....

,....

Motor

Screw-Hex ad 5/16-18 x 3t4

•

Key

No.

Part

No.

Description

22

23

24

25

26

27

28

29

30

31

32

33

34

--

STD551031

818098

806196-3

8! 6573

STD328012

STD304210

818100

808277-1

62331

47624

STD551037

132.275

: 67062

508091

*Washer-21/64 x 5/8 x 1/16

Support-Motor

Grommet-Rubber

Cord w/Plug

*Pulley

*Beit-V4L21 inch

Guard-Belt

Screw-Pan Hd 10-32 x 2-3/4

Knob-Lock

Spacer

* Washer-.380 x 19/64 x 7/64

Screw-Fil Hd 1/4-20 x 1

Block-Push

Bag of Loose Parts

(Not Illustrated)

Bag of Loose Parts

(Not Illustrated)

Bag of Loose Parts

(Not Illustrated)

Owners, Manual

(Not Illustrated)

i ¸

i

508093

508210

SP5447

Standard Hardware item -- May Be Purchased Locally.

i

39

2

3

4

10

15

Always orderby

Part !Number-"

FIGURE2

[ Key _i

_NO,

"

Part

......

_ No.

"|

.1

III J!

• Description

i

"FENCE

:

.

Not byKey

Number

ASSEMBLY

Key

No.

Part

No,

11

STD55!010

12

13

!4

15

16

17

STD510802

STD551150

STD541050

818104

21622

.67020

i

I

67OO9

STD51 i102

Description

Guard-Cutter

:

* Screw-Pan Hd 10-32 x 1/4

:i:i!i:5::!,

i:••_•: .

40::•••.

l,

*Washer

t3/64 x 1/2 x 3/64

* Screw-Bind Hd 8-32 x 1/4

* Lockwasher-1i2

*Nut-Hex Jam 1/2-13

Rod-Sliding Guide

Washer-Sliding Guard

Knob-Sliding Guard

repair parts

PARTS LIST FOR CRAFTSMAN 6-1/8-iNCH

MODEL NO. 113.232210

JOINTER-PLANER

Atways order by Part Number -- Not by Key Number

IFIGURE 3 -- TABLE ASSEMBLY

Key

No,

Part

No.

IKey

Description

No,

Part

No.

'111'

1

2

3

4

5

818101

21204

STD55!031

STD551131

STD523112

STD522505

7 _ STD551025

*

Table-Front

Linkage-Assembly

*Washer-11/32x 11/16x t/16

* Lockwasher-5/16

* Screw-Hex Hd

5/16-18x 1-1/4

*Screw-Hex Hd !/4-20 x t/2

Washer-17/64 x 47/64 x 1/16

10

11

12

13

14

Standard Hardware Item -- May Be Purchased Locally.

41

21812

21422

21635

21219

21218

60388

817734

816871

Description

I

Plate-Tension

Spacer-Dovetail

Screw-Special

Guide*Male

Guide-Female

Nut-Self Threading

Spring-Torsion Guard

Guard

•/:<

ii_:_i

_

=_

i_i::/i_

_

:i¸: _i: i-¸

1

/

2

3

4

3

/

/

5

/

?

7

Aiwaysorderby

Part Number _-Not

by Key Number

FIGURE 4 -- CUTTER ASSEMBLY

Key •

No.

Part

No.

Description

i

¸¸¸¸i¸1

¸

':_3:

Stock Item --May _:S_cure,

8

9

!0

! 11

_, !2

21450

21632

9-2293

60116

60118

I

Head Asm.-Complete Cutter

Wedge

I"Blade

Screw-Soc Cap 10-32 x 3/4

Screw Ftat Hd Soc

10-32x !/2

; Retail or Catalog Order Houses.

repair parts

PARTS LiST FOR CRAFTSMAN 6-1IS-INCH JOINTER-PLANER

MODEL NO. 113.232210:

13

11

1

7

Always order by Part Number -- Not by Key Number

FIGURE 5 -- SWITCH ASSEMBLY

Key ...................

Part

No.

No.

Description

i_

:i:

Pan

No.

Key

No.

1

1

2

3

4

5

6

7

816924-1

Lead

816t 13

Switch,Locking:

STD551210

* Lockwasher-Ext #10

STD51 t103

*Screw-Pan Hd 10-32 x 3/8

8037091

: Connector-Wire

816880

i Bezel-Switch

9-22256

i t Key-Switch

.......

8

9

10

11

12

13

816274-2

817399-6

816560-1

816881

820075

816560-2

Description

i•

i

Screw-Pan Hd #10 x 1

Relay Model !01

Lead-Jumper

Housing-Switch

Capacitor-Dry Film

Lead-Jumper

i i....................

* Standard Hardware Item "

May Be Purchased Locally.

1- Stock Item -- May Be Secured Through The Hardware Department Of Most Sears Retai} or Catalog Order Houses.

43

JOINTER.PLANER

....,: ::

1

\

7

Always order by Part Number--Not

by Key Number

FIGURE 6 -- LEG SET ASSEMBLY

Key

No.

ii

Part

No.

,

,

7

8169O8

8

805589-5

9

STD551225

10

STD541025

--50771

!

Description

i

Stiffener-Lower

Screw-Truss Hd 1/4-20x 1/2

,Lockwasher-Ext. 1/4

, Nut-Hex 1/4-20

Bag of Loose Parts

(Not Illustrated)

NOTES

45

i'

i!

6-I/8

JOIHr RoPLANER

SERVICE

MODEL NO.

113.232210

Now that you have purchased

your jointer-planer,

need ever exist for repair parts or service, simply

any Sears Service Center and most Sears, Roebuck

stores. Be sure to provide all pertinent facts when

or visit.

should a

contact

and Co.

you call

The model number of your 6-I/8 inch jointer-planer

found on a plate attached to the base.

will be

JOINTER/PLANER WITH

LEGS AND MOTOR

HOW TO ORDER

REPAIRPARTS

WHEN ORDERING REPAIR PARTS,ALWAYSGIVE THE FOLLOVvlNG

INFORMATION:

PARTNUMBER

PARTDESCRIPTION

MODEL NUMBER i

113.232210

NAME OF ITEM

6-I/8 INCH JOINTER-PLANER

Allpartslistedmay be ordered from any Sears Service Center

and most Sears stores.Ifthe partsyou need are not stocked

locally,

your order will

be e|ectronica|ly

transmittedto a Sears

Repair PartsDistribution

Center forhandling.

J

Form

No. SP5447

PrintedinTaiwan 8/90