Download Sens NRG24-20 Specifications

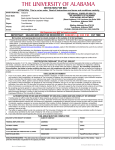

Transcript