Download COMPANION 315.241940 Operator`s manual

Transcript

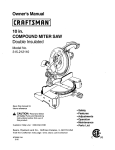

OPERATOR'S

MANUAL

4

10 in. COMPOUND

MITER SAW

Model No.

315.241940

WARNING: To reduce the risk of

iniury, the user must read and understand the operator's manuat before

using this product,

Customer Hetp Line: 1-800-932-3188

Sears, Roebuck and Co., Hoffman Estates, IL 60179 USA

Visit the Craftsman web page: www.sears.com/craftsman

983000-437

3-04

Save this manual for future reference

• Warranty and introduction.................................................................................................................................................

2

• General Safety Rules.....................................................................................................................................................

3-4

• Specific Safety Rules.....................................................................................................................................................

4-5

• Symbols.........................................................................................................................................................................

6-7

• Electrical............................................................................................................................................................................

8

• Glossary ofTerms..............................................................................................................................................................

g

• Features.....................................................................................................................................................................

10-12

• Tools Needed .................................................................................................................................................................

12

•

13

Loose Parts ....................................................................................................................................................................

• Assembly...................................................................................................................................................................

13-20

• Operation...................................................................................................................................................................

20-26

• Adjustments..............................................................................................................................................................

27-28

•

Maintenance...................................................................................................................................................................

29

•

Parts Ordering/Service...................................................................................................................................................

30

ONE YEAR FULL WARRANTY

ON COMPANION TOOL

If this Companiontool fails due to a defect in material or workmanshipwithin one year from the date of purchase,

RETURN IT TO THE NEARF__TSEARS STORE IN THE UNITED ffrATE8, and Sears will replace it, free of charge.

This warranty is void if this tool is used for commercial or rental purposes.

This warranty gives you specific legal rights,and you may also have other rights which vary from state to state.

Sears, Roebuck and Co., Dept. 8t7 WA, Hoffmen Eatates, IL 60179

This tool has many features for making its use more pteas_nt and enjoyable. Safety, performance,end dependability

have been given top pr)oriL'yin the design of this product making )t easy to maintain and operate.

2

,_

• SECURE WORK. Use clamps or a vise to hold work

when practical. It's saferthan usingyour hand and

|rees both hands to operate tool

WARNING: Read and understand all inatrucl

tlone. Failureto follow all inst_'uctionslisted below,

may rssuttin etecLricshock, fire and/or serious

persona_iniury.

•

DON'T OVERREACH. Keep proper footingand bah

ance at all times.

•

MAINTAIN TOOLS WITH CARE. Keep toolssharp and

clean for better and safer performance. Follow instructionsfor lubricating and changingaccessories.

•

DISCONNECT TOOLS. When not in use, before servicing,or when changing attachments,blades, bits,

cutters, etc., all tools shouldbe disconnected.

AVOID ACCIDENTAL STARTING. Be sure switch is off

when pluggingin anytool.

USE RECOMMENDED ACCESSORIES. The use of

improper accessories may risk injury.

READ ALL iNSTRUCTIONS

•

•

•

•

•

•

•

•

KNOW YOUR POWER TOOL. Read the operator's

manual carefully.Learnthe eawls applicationsand limitations as well as the specific potential hazardsrelated

to this tool.

GUARD AGAINST ELECTRICAL SHOCK BY PREVENTING BODY CONTACT WITH GROUNDED

SURFACES. For examp]e, pipes, radiators, ranges,

refrigeratorenclosures.

KEEP GUARDS IN PLACE and In good working order.

REMOVE ADJUSTING KEYS AND WRENCHES.

Form habit of checking to see that keys and adjusting

wrenches are removed frpm tool before turning it on.

KEEP WORK AREA CLEAN. Cluttered areas and

benchesinvite _ccidenta.

00 NOT _aavetoolsor

pisces of wood on the saw whila It is in operation.

DO NOT USE IN DANGEROUS ENVIRONMENTS.

Do not usa power tools in damp or wet focations or

expose to rain. Keep the work areawell tit.

KEEP CHILDREN AND VISITORS AWAY. All visitors

shouldwear safety glassesand be kept a safe dLslance from work area. Do not let visitorscontact tool or

extensioncord white operating.

•

•

• NEVER STAND ON TOOL, Serious injury could occur

if the tool istipped or if the cutting tool is unintentionally contacted.

• CHECK DAMAREO PARTS. _fore further LLSe

Of

the tOO[,a guard or other pert that is dsmeged should

be carefullychecked to determine that it willoperate

properlyand perform its intended function.Check for

alignment of moving pe_Ls,binding of moving parts,

breakage of parts, mounting and any ot_er conditions

that may aff'ecf:its operation.A guard or other part that

is damaged must be properlyrepaired or replaced by

an authorized service center toavoid risk of personal

injury.

• USE THE RIGHT DIRECTION OF FEED. Feed work

into a blade or cutter againstthe direction of rotation of

blade or cutter only.

• NEVER LEAVE TOOL RUNNING UNATrENDED,

TURN THE POWER OFR Don't leave tool until it

comes to a complete stop.

II PROTECT YOUR LUNGS. Wear a face or dust mask if

the cutting operation is dusty.

MAKEWORKSHOPCHILDPROOFwith

padlock.sand

master switches, or by removingsLarterkeys.

•

DON'T FORCE TOOL. [t will do the job better and

eater at the feed rate for which it was designed.

• USE RIGHT TOOL. Don't force the tool or attachment

to do aiob it was not designed for. Don't use Rfor a

purpose not intended.

• USE THE PROPER EXTENSION CORD. Make sure

your extension cord is in good condition. Use only a

cord heavy enoughto carry the current your product

will draw. An undersizedcord will cause a drop In line

voltage resultingin loss of power and overheating.A

wire gauge size (A.W.G.)of at least 14 is recommended

for an extensioncord 25 feet or less in length. If in

doubt, use the next heavier gauge. The smallerthe

gauge number,the heavierthe cord.

•

PROTECT YOUR HEARING. Wear hearingprotection

duringsxtandsd periodsof operation.

• DO NOT ABUSE CORD. Never yank cord to disconnect from receptacle. Keep cord from heat, oil, and

sharp edges.

• USE OUTDOOR EXTENSION CORDS. When 'Lociis

uead outdoors,usa onlyextension cordswith approved ground connection that are intendedfor use

outdoorsand so marked.

• DRESS PROPERLY. Do not wear loose clothing,

gloves, neckties, or jewelry. They can get caught

and draw you into moving parts. Rubber glovesand

nonskid footwear are recommended when working

outdoors.Alsowear protective ha'rrcoveringto contain

long hair.

• ALWAYS WEAR SAFETY GI.ASSEB WITH SIDE

SHIELDS. Everyday eyeglasseshave only impactresistantlenses, they are NOT satety glassas.

•

KEEP BLADES CLEAN, SHARP, AND

WTTH SUFFICIENT SET. Sharp blades minimizestall l

ing and kickback.

• BLADE COASTS AFTER BEING TURNEDOFR

• NEVER USE IN AN EXPLOSNE ATMOSPHERE.

Normal sparkingof the motor could ignite fumes.

3

•

•

•

•

•

•

INSP ECT TOOL CORDS PERIODICALLY. If damaged,

have repaired by a qus_od sarvica t_.hn_lan at _n

authorizedservice fae){ity. The conductor with insulation having an outer surface that is green with or without yellow eVipse isthe equipment-groundingconductor. If repair or replacement of the electric cord or plug

is necessary,do not connect the equipment-grounding

conductorto a[[ve terminal Repair or replace a damaged or worn cord immediately.Stay constantlyaware

of cord location and keep it well away from the rotating

b_da.

INSPECT EXTENSION CORDS PERIODICALLY and

replace if damaged.

KEEP TOOL DRY, CLEAN, AND FREE FROM OIL

AND GREASE. Always use a dean c_othwhen cleaning. Never use brake fluids, gasoline, petroleum-based

products, or any solvents to clean tool

STAY ALERT AND EXERCISE CONTROL, Watch

what you are doing and use common sense. Do not

operate too{when you are tired. Do not rush.

DO NOT USE TOOL IF SWITCH DOES NOT TURN IT

ON AND OFF. Have defective switches replaced by an

authorizedservice center.

USE ONLY CORRECT BLADES. Do not use b{ades

with incorrectsize hoise. Never use blade washers or

b_de bolta that are defective or {nCOTT_"_.

"[hemBx_mum b%adaeapad_ of your saw Is 10 in. (254 ram).

•

FIRMLY CLAMP OR BOLT your miter sew to a workbench or table at approximately hip height.

• KEEP HANDS AWAY FROM CUTrlNG AREA. Do not

reach underneath wor!<or in blade cutting path wlth

your hands and fingersfar any reason. Always turn the

power off.

• ALWAYS SUPPORT LONG WORKIPIECES while cutting to minimizerisk of blade pinchingand kloid0aok.

Saw may slip, walk or slide while cutting long or heavy

boards.

• ALWAYS USE A CLAMP to secure the workplece

when possible.

• BE SURE THE BLADE CLEARS THE WORKPIECE.

Never start the sew with the blade touchingthe

wcrkpiece. Allow motor to come up to full speed

before starting cut.

• MAKE SURE THE MITER TABLE AND SAW ARM

(BEVEL FUNCTION) ARE LOCKED IN POSITION

BEFORE OPERATING YOUR SAW. Lock the miter

table by securelytightening the miter lock levers. Lock

the saw arm (bevel function}by securely tighteningthe

bevel lock knob.

•

BEFORE MAKING ACUT, BE SURE ALL ADJUSTMENTS ARE SECURE.

•

BE SURE BLADE PATH IS FREE OF NAILS. Inspect

for and remove atf na_sfrom lumber before cutting.

•

NEVER TOUCH BLADE or other moving parts during

UaS.

•

NEVER START ATOOLWHEN ANY ROTATING COMPONENT IS IN CONTACT WITH THE WORKP|ECE.

• DO NOT OPERATE A TOOL WHILE UNDER THE

INFLUENCE OF DRUGS, ALCOHOL, OR AI_Y

MEDICATION.

• WHEN SERVICING use only identic_ replacement

parts. Use of any other pads may create a hazard or

cause productdarr_ge.

• CHECKWITH AQUALIFIED ELECTRICIAN or service

personnelJfthe groundinginstructionsare not completely understoodor it in doubt as to whether the toot

LSproperlygrounded.

• USE ONLY RECOMMENDED ACCESSORIES listed

in this manual or addendums. Use of accessories

that are not listed may cause the risk of personal

injury. Instructions for safe use of accessories are

included with the accessory.

• DOUBLE CHECK ALL SETUPS, Make sure blade is

tight and not making contact w)th saw or workpiece

before connecting to power supply,

•

•

NEVER USE A LENGTH STOP ON THE FREE SCRAP

END OF A CLAMPED WORKPIECE. NEVER hold

onto or bind the free scrap end of the workplace in any

operat'_r_. If =_work clamp and length stop are used

together,they must both be installedon the same side

of the sew _abla to preventthe sew from catching the

loose end and kicking up.

NEVER out more than one piece at a time. DO NOT

STACK more than one workpiece on the saw table at a

time.

NEVER PERFORM ANY OPERATION FREEHAND.

Always place the workpJeceto be cut on the miter

table and positionit f'_mlyagainst the fence as e backstop. Always use the fence.

NEVER hand hold a workpieoethat is too small to be

clamped. Keep hands riser of the cutting arcs.

NEVER reach behind, under,or within three inches

of the blade and its cutting path w_h yourhands and

fingers for any reason.

•

•

NEVER reach to pick up a workpiece, a piece of scrap,

or anything e_ss that is in or near the cutting path of the

b_de,

• AVOID AWKWARD OPERATIONS AND HAND POSITIONS where a sudden slip could cause your hand

to move intothe blade. ALWAYS make sure you have

good balance. NEVER operate yourmiter saw on the

floor or in a crouched position.

MAKESURETHEWORKAREAHASAMPLE

LIGHTING to see the work and that no obstructionswit] intertara with saf_ oper-tion BEFORE psrtorr_in(.} any work

using your saw.

• ALWAYS TURN OFF THE SAW before disconnecting

it to avoid accidental startingwhen reconnectingto

power suppty.NEVER leave the saw unattendedwhile

connected to a powersource.

• NEVER stand or haveany part of your body in line wfth

the path of the saw blade.

• ALWAY8 release the power switch and allow the

saw blade to stop rotating beforeraising it out of the

workpiece.

• DO NOT TURN THE MOTOR SWITCH ON AND OFF

RAPIDLY. "l%his

cou(d cause the saw blade to loosen

and could create a hazard. Shouldthis ever occur,

stand cTserand at_owthe saw blade to come to s complete stop. Disconnectyour saw from the power supply

and socurolyretightenthe blade bolt.

• IF ANY PART OF THIS MITER SAW IS MISBING or

should break, band, or fail in anyway, or shouldany

electrical component fail to perform properly,shut off

the power switch, remove the miter saw plug (Tomthe

power sourceand have damaged, missing, or failed

parts replaced before resumingoperation.

• THIS TOOL should have the following markings:

a)

b)

c)

d)

e)

f)

Wear eye protection.

Keep hands out of path of saw blade

Do not operate saw without guards in pJaos.

Do not perform any operation freehand.

Never reach aroundsew b{ade.

Turnoff tool and walt for saw blade to stop before

moving work.pieceor chang(rigsettings.

g) Disconnectpower (or unplug tool as applicab{e)

before changing blade or servicing.

h) No load speed.

• ALWAYS carry the tool only by the carrying handle.

• SAVE THESE INSTRUCTIONS, Refer to them

frequently and use to instruct other usem. If you loan

someonethis tool, loan them thess instructionsalso.

• ALWAYS STAY ALERT] Do not allow familiarity (gained

from frequent use of your saw) to seuse a careless

mistake. ALWAYS REMEMBER that a careless fraction

of a second is sufficientto inflict severe injury.

WARNING: S(xr_ dust created by power sand{ng,sawing, gr(nding, drii{(ng, end other construction_ctNitiea contains chemicals known to cause cancer, birth defects or other reproductiveharm. Some examples of these chemicals are:

•

leadfrom lead-based paints,

•

crystallinesilica from bricksand cement and other masonry products, and

•

arsenic and chromium from chemically-treated {umber.

Yourrisk (Tom these exposures varies, dependingon how often you do this type of work. To reduce your exposure

to these chemicals: work in a well ventilatedarea, and work with approved safety equipment, such as those dust

masks that are specially designedto filter out microscopicparticles.

5

Someof

the followingsymbols may be used on this tool. Please study them and learn their meaning. Proper

interpretation of these symbolswill allow you to operate the tool better and s,_fsr.

SYMBOL

NAME

OESIQNATION/EXPLANATIO N

V

Volts

Voltage

A

Amperes

Current

Hz

Hertz

Frequency(cyclesper second)

W

Watt

Power

Minutes

Time

Aitemeting Current

Type of current

•-

DirectCurrent

Type or a characteristicof current

no

No Load Speed

Rotational speed, at no toad

[]

Class II Construction

Daub[s-insulatedconstruction

Per.Minute

Revolutions,stTokes,surface speed, orbits etc., per minute

Wet ConditionsAJert

Do not expose to rain or use in damp locations.

Read The Operator's Manual

operator's

manual

before

usingthis

product.

To reduce the

risk of

injury,user

must

read and understand

Eye Protection

Atwayswear

gogglesor

safety

glasseswithproduct.

side

shields

and asafety

fullface

shieldwhen

operatingthis

Safety Atert

Precautionsthat involveyour safety.

No Hands Symbo_

serious

Failuretopersonatinjury.

keep your hands away from the blade will rseu_tin

(_

No Hands Symbol

Failureto

keep yourhands away from the blade w_l result_n

serious persona{injury,

e

No Hands Symbol

serious

persona{injury.

Failureto

keep your hands away from the bladewill resultin

No Hands Symbol

Failureto

keep y_ur

hands away from the blade wi{{result in

serious

persona_

in,P/.

Ho'_Surface

To

risk of {niury

ordt_'_age, avoid contact w_th

anyreducethe

hot surface.

rain

..Jmin

(_

6

The following

this product.

SYMBOL

A

signal words and meanings are intended to explain the levels of risk associated

SIGNAL

MEANING

DANGER:

Indica.tssan imrninantlyil_.ardous situation, which, if not avoided, will

result in death or serious fniury.

WARNING:

Indicates a potentially hazardous situation,which, if not avoided, could

resultin death or serious injury,

CAUTION:

Indicates a potentially hazardous situation, which, ifnot avoided, may

result in minor or moderate injury.

CAUTION:

_/ithout Safety Alert Symbol) Indicates a situs,tion that may result in

propertydamage.

SERVICE

Servicingrequiresextreme care and knowledgeand

should be performed only by a qualifiedservice technician. For servicewe suggest you return the productto

your nearestAUTHORIZED SERVICE CENTER for repair.

When servicing, use only identicalreplacement parts.

&

with

WARNING: To avoid serious personalinjury,

do not attempt to use this product untilyou read

thoroughlyand understand comptetalythe

operator'smanual. Save this operators manual

and review frequently for continuingsafe opera

tfon and Ins_'uctingotherswho may usethis

product,

WARNING:

O

The operation of any power tool can resultin foreign objects being thrown into your eyes, which can

result in severe eye damage, Before beginningpower too[ operation,always wear safety goggles

or safety g[aseeswlth side shields and a fullface shield when needed. We reoommendWide Vision

Safety Mask for use over eyeglasses or standard safety glasseswith side shields.Always use eye

protection which is marked to complywith ANSI Z87.1.

SAVE THESE INSTRUCTIONS

EXTENSION

SPEED AND WIRING

CORDS

Use only 3-wire extension cords that have 3-prong

groundingplugs and 3-pole receptaclesthat accept the

tool's plug. When usinga power tool at s considerable

distance from the powersource, use an extension cord

heavy enough to carry the current that the tool will draw.

An undersized extensioncord will causea drop in line

voltage, resultingin a foes of powerand causing the motor

to overheat. Use the chart provided below to determine

the minimumwire size required in an extension cord. Only

round Jacketedcords listed by Underwriter'sLaboratories

(UL) shouldbe used.

The no-load speed of this tool is approximately4,500 rpm.

7his speed is not constant and decreases under a Iced

or with fewer voltage. Forvoltage, the widng in a shop

is as importantas the motor'shorsepower rating.A line

intendedonly for lightscannot properlycarry a power tool

motor. Wire that is heavy enoughfor a short distancewill

be too lightfor a greater distance.A finethat can

support one power tool may not be able to support two

or three tools.

-Ampe_

in the event of a malfunctionor breakdown, grounding

provides _ path of k_astresistancefor electriccurrentto

reduce the risk of electricshock. This tool is equipped

with an electric cord having an equipment-grounding conductor and a groundingplug. The plug must be

plugged intoa matching outletthat is properly installed

and grounded in accordance with all local codes and

ordinances.

GROUNDING

rating (on tool facep!ete)

0-2.0

2.%3,4

Cord Length

3,5-5.0

5.1-7,0

7.%_ 2.0 12,1-'{0,0

Wire Size (A.W.G.)

25'

16

16

16

16

14

14

50'

16

16

_6

_4

14

12

100'

16

16

14

12

10

--

--Ueed on12 gauge - 20 amp circuit

NO'RE:AWG = Amedcan Wire Gauge

Do not modify the plu9 provided. If it win not fit the outlet,

have the proper outlet installedby a qualifiedelectrician.

improper connectionof the equipment-groundingconductor can re,sultina risk of eiectr_ shock. The cond_,tor with insulation hav_ngan outer surface that is green

with or without yellow sffipes is the equipment-grounding

conductor.)f repair or replacementof the electriccord or

plug is necessary,do not connect the equipment-grounding conductor to a live tarmlna}.

When working with the tool outdoors, use an extension

cord that is designed for outside use. This is indicated by

the letters "WA" on the cord's jacket.

Before using an extension cord. inspect it for loose or

exposed wires and cut or worn insulation.

A

INSTRUCTIONS

WARNING: Keep the extension cord clear of the

workrngarea. Positionthe cord so that it wifl not get

caught on lumber,tools or other obstructionswhile

you are workingwith a power tool. Failureto do so

can result fnserious personal injury.

Check with a qualified electrician _r ser_ce persone_el

if

the groundinginstructionsare not completely understood,

or if in doubt as to whether the tool Is properlygrounded.

Repair or replace a damaged or worn cord immediately.

This tool is intendedfor use on a circuitthat hasan outlet

like the one shown in figure 1, It else has s groundingpin

like the one shown.

WARNING: Check extensioncords before each

use. If damaged replace immediately.Never use tool

with a damaged cordsince touching the damaged

are_ cou(d cause s(oc_cat shock resu(tingin serious

Injury.

ELECTRICAL CONNECTION

This tool is powered by a precisionbuilt electric motor.

It should be connected to a power supply that is t20

volts, 60 Nz, AC only (normal household current). Do

not operate this toot on direct current (DC). A substantial

voltage drop wilt cause a loss of power and the motor wltl

overheat, If the saw does not operate when plugged into

an outlet, double check the power supply.

GBDUNDING

PIN

I

COVEROFGROUNDED

OUTLETBOX

Fig. 1

8

Anti-Kickback Pawls (radial arm and table saws)

A dev?sewhich, when property ?nste]ladand maintained,

is designed to stop the workplace from being kioked back

toward the front of the saw during a rippingoperation.

Arbor

The shaft on which a blade or cutting tool is mounted,

Bevel Cut

A cutting operation made with the blade atany angle

otherthan 90" to the table surface.

Non-Through Cuts

Any cutting operation where the blade does not extend

completelythrough the thickness of the workpiecs.

Push Blocks and Push Sticks

Devicesused to feed the work:piecethroughthe saw

blade during cutting operations.A push stick (not a push

block)shouldbe used for narrow rippingoperations.

These aids help keep the operator's hands well away from

the blade.

Chamfer

A cut removinga wedge from • block so the end (or part

of the end) is angled ratherthan at 90 °.

Compound Cut

A cross cut made with both e miter end a bevel angle.

Crosscut

A cutting or shaping operationmade across the grain or

the width of the workpieee.

Cutter Head (Planers and Io/ntera|

A rotating plaoe of adiustablablades. The cutter heed

removes materialfrom the workplece.

Dedo Cut

A non-throughcut which producese squara-sJdsdnotch

or hough in the work,piece (requiresa epsolai blade).

Featherboard

A device used to help centre] the workpJecaby guiding Jt

securelyagainst the table or fence duringany ripping

operation.

FPM or SPM

Feet per minute (or strokes per minute), used in reference

to blade movement.

Pilot Hole (drill presses]

A small hole drilled in a workpiece that serves as a guide

for drillinglarge holes accurately.

Ra_w¢

A cutting operationto reduce the thickness of the workpiece to make thinnerpieces,

Resin

A sticky,eep-based substanoethat hashardened.

Ravoful_tonsPar Minute (RPM)

The number of turnscompleted by a spinning object in

one minute.

Ripping or Rip Cut

A cutting operation along the length of the workplace.

Riving Knife (table saws)

Also known as a spreader or splitter. A metal piece,

slightlythinnerthan the sew blade, which helps keep the

kerr open and also helpsto preventkickback.

_v Blade Path

The area over, under,behind, or in front of the blade. As

it appliesto the wcrkpiece, that areawhich will be or has

been cut by the blade.

Set

The distance that the tip of the saw blade tooth is bent (or

set) outward from the face of the blade.

Freehand

Performinga cut without the workplace being guided by a

fence, miter gauge, or other aids.

Gum

A sticky, esp-bassd residue from wood products,

Heel

Alignmentof the blade to thefence.

Kerr

The material removed by the blade in a through out or the

slot produced by the blade in a non-through or pertlal cut.

Klckback

A hazard that can occur when the blade binds or stalls,

throwingthe workpleoe back towerd operator.

Snips (planers}

DeprassJonmade at either end of s workplace by cutter

bladeswhen the workpiece is not properlysupported.

Throw-Beck

The throwing back of a workpiece usuallycaused by the

wcrkplacs being dropped into the blade or being placed

inadvertentlyin contact with the blade.

Through Sawing

Any cutting operationwhere the blade extends completely

through the thickness of the wcrkpleca.

Work.piece or Material

The item on which the operation is being done.

Worktable

Surface where the workpiece rests while perforatinga

cutting,drilling,planing,or sandingoperation.

Leedlng End

The end of the workpieoe pushed intothe tool first.

Miter Cut

A cutting operation made with the workp?eoeat any angle

to the blade other than 90 °,

g

Product Specifications:

Blade Diameter .........

• ................

Blade Arbor .............................

No Load Speed ......................

10 in.

5/8 in.

4,500/min.

Input .......

120 Volts, 60 Hz, AC Only,12 Amperes

Net Weight .............................

28 Ibs.

When the miter angle (miter t_ble) is set at O"and the bevel

angle is set at 0":

Maximum nomir_l Lumbersizes:

2 x6

When the miter angle (miter ta.ble)isset at 45"and the bevel

angle is set at 0":

Maximum nomir_i lumber sizes:

2x 4

When the miter angle (mitertable) is set at O"and the bevel

ang)e is set at 45":

Maximum nominallumber sizes:

2 x6

When the miter angle (mitertable) is set at 45"and the bevel

angle is set at 45":

Maximum nominallumber sizes:

2 x 4.

SAWARM

UPPERBLADE

GUARD

DUETGUIDE

BEVELB_LE

LOWER

BEVEL

LOCKKNOB

MITER TABLE

MITER

LOCKLEVER

WORKCLAMP

Fig. 2

10

KNOWYOUR COMPOUNDMITERSAW

SPINDLE LOCK

See Figure 4.

See Figure2.

Before attempting to use this product, familiarize yourself with elf operating features and safety requfrements.

t2 AMP MOTOR

Your saw has a powerful 12 amp motor with sufficient

power to handle tough cuttingjobs. It is made with all

bah bearings,and has externallyaccessible brushes for

ease of servicing.

BUTTON

A spindle lock button has been providedfor lockingthe

spindle which keeps the blade in your saw from rotating.

Depress and hold the lock button while Installing, changing,

or removingblade.

SWITCH

TRIGGER

10 in. BLADE

A 10 in.saw blade is included with your compound

miter saw. )t will cut materialsup to 2 in. thick or 6 in.

wide, depending upon the angleat which the out is being made.

8PINOLE

LOCKBU1]'ON

MITER LOCK LEVERS

See Figure 3.

The miter lock levers securelylock the saw table at the

desired miter angles.

MITERLOCK

LEVERS

Fig. 4

TRIGGER LOCK

See FTgum5.

To preventunauthorizeduseof your oompound miter saw,

we suggest that you disconnect it from the power supply

and lock the switch in the off position.To lock the switch,

install a padlock (not included)through the hole in the switch

trigger.A lookwith e long shackle up to 9/32 in. diameter

may be used. When the lock is installedand locked, the

switch is inoperable.Store the padlock key in another location.

SWITCH

TRIGGER

PADLOCK

Fig. 3

Fig. 5

11

WARNING:Theoperation

ofany saw can result

in foreign objects being thrown into your eyes,

which can result in severe eye damage. Before

stating power tool operation, always wear safety

goggles or safety giaeses with side shieidsand

a full face shield when needed. We recommend

wide vision safety mask for use over eyeglasses or

standard safety glasses with side shields.

BEVEL LOCK KNOB

The bevel lock knob securelylocks yourcompound

miter saw at desired bevel angles. A positive stop adjustment screw has been provided on each side of the

saw arm. These adiustment screws are for making fine

adjustmentsat 0"and 45".

ELECTRIC

BRAKE

An electricbrake has been provided to quicklystop blade

rotationafter the switch isrsreased.

FENCE

The fence on yourcompound miter saw has been provided

as a support to hold your workplace securely againstwhen

making all cuts.

SELF-RETRACTING

LOWER BLADE GUARD

The lower blade guard is made of shock-resistant, seethrough plasticthat providesprotectionfrom each side of

the blade. It feb'actsover the upper blade guard as the saw

is lowered intothe workpiece.

The followingtools (not Included) are needed for checking adjustments of your saw or for ir_talling the blade:

COMBINATION

WRENCH

(2)

10 mm,14mm

COMBINATION

SQUARE

FRAMINGSQUARE

Fig. 6

PHILLIPSSCREWDRIVER

12

Thefollowing

itemsareincluded

withyourCompound

MiterSaw:

•

Saw Blade - 10 ln,

• Blade Wrench

• Work C_amp

• Operator's Manual

=,= _

BLADEWRENCH

WnRKCLAMP

SAWBLADE

Fig. 7

,I_ WARNING: The use of atfachments or accessoriesnot listed might be hazardous and could cause ssdous

personalinjury.

UNPACKING

•

Do not discardthe packing material until you have

carefullyinspected and satlsfactodiyoperated tha tool

• The _w is factory set for accurate cutting.After

assemblingit, checkfor accuracy, ff shippinghas

inSusncedthe settings, refer to spsciflcprocedures

explained in this manual

This product has been shipped completely assambled.

• Carefully lift saw from the carton by the carryinghandle

and the saw base, and place it on a level work surface,

NOT _" This saw is heavy.To avoid back iniury,liftwith

your legs, not your back, and get help when needed.

• Yoursaw has been shipped with the saw arm secured

in t_s down position.To release the saw arm, push

down on the top of the saw arm, cut the tie-wrap, and

pull out on the lock pin.

•

Ifanypartsaredamaged or missing, please call

1-800-932-3188 for assistance.

J_l WARNING= If any partsare missing,do not operate

this toot until the missing parts are replaced. Failure

to do so could result in possibleserious personal

inlury.

• Lift the saw arm by the handle. Hand pressureshould

remain on the saw arm to prevent sudden rise upon

rslsasa of L_etie wrap.

• Inspect the tool carefuffyto make sure no breakage or

damage occurred duringshipping.

13

Your compound miter saw should be permanentlymounted to a firm supportingsurface such as a workbench.

Four bolt holeshave been provided in the saw base for

this purpose. Each of the four mountingholesshould be

bolted securely using3/8 in. machine bolts, lock washers,

and he)( nuts (not inctuded). Bolts shouldbe of sufficient

length to acconvnodate the saw base, lock washers, hex

nuts, and the thickness of the workbench.

d_lb WARNII_I" Do not attempt to modify this tool or

createaccessories not recommended for usewith

this tool. Any such aitaratlon or modifl_,tion is

misuse and could result in a hazardous condition

leading to possibleserious personalinjury.

_k

WARNINGs Do not connect to power supply until

assembly is complete. Failureto comply could

result in accidental startingand possible serious

personal injury.

MOUNTING

See Figure 8.

Tightenall four bolts securely.

The hoJepe_ern for mountingto a workbenchis shown in

figure 8. Carefullycheck the workbench after mountingto

make sure that no movement can occur during use. If any

tipping, eliding,or walking is notad, secure the workbench

to the floor before operating.

HOLES

WARNING: Ahe_ysmake sum your compound

miter saw fs securelymounted to a workbench or an

approved wcrkstand. Failureto do so could result

in an accident resultingin poSSibleseriouspersonal

injury.

TRACEHOLES

AT THESELOCATIONS

FOR

HOLEPATTERN

TRACEHOLES

ATTHESELOCATIONS

FOR

HOLEPATTERN

NmUNTINGSURFACE

BASE

Fig. 8

14

WORK CLAMP

TO INSTALL BLADE

See Figures 10- 12.

See Figure 9.

The work clamp provides greater control by clamping the

workpisce to the fence orthe saw table. It also preventsthe

workpisosfrom creepingtoward the saw blade. This Lsvary

helpfulwhen cutting compound miters,

Depending on the cutting operatlon and the size of the

workplace, it may be necessary to use a C-clamp instead

of the work clamp to secure the workpisca priorto making

the cut.

_k

WARNING: In some operations,the work clamp

assembly may interferewith the operation of the

blade guard assembly.Always make sure thata is

no interferanoewith the blade guard priorto beginning any cutting operation to reducethe risk of

sedous personal injury.

Followthese directionsto installthe work clamp:

•

•

A

Place the shaft of the work clamp in either hole on the

saw table bess.

Rotate the knob on the work clamp to move it in or out

as needed.

WARNING: When using any clamp with a stop

block, install the clamp on the same side as the stop

block, This will eliminatethe possibilityof trapping

the workpiece, resultingin the saw blade and

workplace kickingup. Failureto heed this warning

can resultin esrtous personalInjury.

_L WARNING: A 10 in. blade is the maximum blade

capaoi_ of your saw, Never use a blade that is too

thickto allow outerblade washer to engage with

the fiats on the spindle. Larger bladeswi([come in

contact with the blade guards,while thicker blades

wilt preventthe blade screw from securing the blade

on the spindle, Eitherof these situationscould result

in a serious accident and can cause serious personal

injury.

• Unplug your saw.

_k

WARNING: Failureto unplugyour saw could result

in accidental starting causing possibleserious

personalInlury.

•

Loosen phillipsscrew (A) on the blade bolt cover.

•

Remove phillipsscrew (B) on the blade bolt cover until

blade bolt cover can be raised.

•

Gently raisethe lower blade guard bracket, releasing

lower blade guard fi'omnotch so that lower blade

guard and blade bolt cover can be rotated up and back

to expose the blade bolt.

•

Depress the spindle lock button and rotate the blade

bolt until the spindle locks.

II Using the blade wrench provided,loosen and remove

the blade bolt.

NOTE: The blade bolt has left hand threads. Turn blade

bolt clockwiseto loosen.

WORK

CLAMP

BASE

Fig. 9

SCREW(,A)

LOWERBLADE

GUARDBRACKET

Fig. 10

15

LOWER

BLADEGUARD

WARNING: If inner blade washer has been

removed, replace it before placingblade on spindle.

F_lure to do so could cause an accident since blade

will not tighten properly.

BI.AOE

BOLTCOVER

BLAOE

\

PHILLIPS

SCREW

TO

LOOSEN

•

Fit saw blade inside lower blade guard and onto

spindle. The bladeteeth point downward at the front of

saw as shown in figure 11.

A

CAUTION: Always installthe blade with the blade

teeth and the arrow printed on the side of the blade

pointing down at the front of the saw. The direction

of blade rotation Is also stamped with an arrow on

the upper blade guard,

FLAT(S)

TIGHTEN

INNERBLADE

WASHERWITH

DOUBLE"17'FLATS

•

Replace outer blade washer.The double "D"flats on

the blade washers align with the fiats on the spindle,

I

Depressspindle lock button and replace blade bolt.

NOTE: The blade bolt has left hand threads. Turn blade

bo{tcountsrc(ockwiseto tighten.

•

Tightenblade bolt securely.

BLADE

BOLT

OUTERBLADEWASHER

W_H DOUBLE"D'FLATS

• Replace the lower blade guard and blade bolt cover.

II Retightsn phillipsscrews (A and B) secudng blade bolt

cover.Tighten straw securely.

Fig. 11

•

Remove outer blade washer. Do not remove inner

blade washer.

CAUTION: Make sure the spindle lock button is

not engaged before reconnectingsaw into power

source. Never engagespindle Jookbutton when

blade is rotating.

• Wipe a drop of oil onto Inner blade washer and outer

blade washer where they contact the blade.

Your compound miter saw has been adjusted at the factory for making very accurate cuts. However,some of the

componentsmight have moved out of alignment during

shipplng.Also, over a period of time, read]ustmenL will

probabtybecome necessary due to wear. After unpacking

your saw, check the followingadiustmentebefore you begin using saw. Make any readjustmentsthat are necessary

and periudica((ycheck the parts a(ignment to make sure

that your saw is cutting accurateJy.

SPINDLE

LQGK

BUTTON

Fig. 12

16

NOTE:Manyoftheillustrations

inthismanual

showonly

portionsofyourcompound

mitersew,Thisisintentions]

sothatwecanciearlyshow

pointsbeingmadeintheIl-

FRAMING

SQUARE

/

FENCE

MITERTABLE

lustrations. Never operate your Raw without all guard==

securaJy in place end in good operating condition.

SQUARING

THE MITER

FENCE

See Figures 13- 16.

TABLE

TO THE

• Unplug your saw.

• Push down on the sew arm and pu[I out the lock pin to

release

the saw arm.

• Raise saw arm to its fult raised position.

• Loosen the miter lock levers.

• Rotate the miter table untTIthe pointer is positioned

atO'.

• Securelytighten the miter lock levers.

• Lay a framing square fiat on the miter table. Place one

tag of the square against the fence. Pla.cethe other

(eg of the square beside the throat plate in the miter

table. The edge of the square and the slot in the throat

plats in the miter table shouldbe parallelas shown in

figure 13.

• If the edge of the framing square and the throat plate

in the miter tabfe are not paraliefas shown in figures 14

and 15, adjustments are needed.

• Using the blade wrench, loosen the socket head

screws securingthe fence. Adjust the fence left or right

untilthe h'amlngsquare and throat plate are paraReL

THROATPLATE

VIEWOFMITERTABLENOTSQUARE

WITH

FENCE,ADJUSTMENTS

AREREQUIRED

F_g.f 4FRAMING

SOUARE

• Retighten the screws securelyand recheck the fenceto-table alignment,

FRAMING

SQUARE

FENCE

THROATPLATE

VIEWOFMITERTABLENOTSQUARE

WITH

FENCE,ADJUSTMENTS

AREREQUIRED

FENCE

Fig. 15

MITERTABLE

SOCKET

HEAD

SCREW(S)

SOCKFTHEAD

SCREW(S)

THROATPLATE

VIEWOFMITERTABLESQUAREWITHFENCE

CORRECTLY

ADJUSTED

Fig. 13

Fig. 16

17

SQUARINGTHE SAW BLADETO THE FENCE

FENCE

See Figures 17 - 20.

• Unplug your saw.

•Pu[[ the saw arm a[I the way down and engage the lock

p_nto hold the saw arm in transport position.

• Loosen the miter lock Ievere.

•

Ro_ztethe miter table unti[the pointer is positioned

at0".

•

Securely tighten _le miter [ook levers.

•

Lay a framing square fiat on the miter table. Place one

leg of the square against the fence. Slide the other leg

of the square against the fiat paTtof saw blade.

NOTE: Make sure that the square contacts the fiat pert

of the saw blade, not the blade teeth.

BASE

VIEWOFBLADENOTSQUARE

WITH

FENP..,E,

ADJUSTMENTS

APEREQUIRED

• The edge of the square and the saw blade should be

parallelas shown in figure 17.

• If the front or back edge of the saw blade angles away

from the square as shown in figures 18 and 19, adjustmerits are needed.

•

FRAMING

SQUARE

Fig. 18

FENCE

BLADE

Using a 14 mm wrench, loosen the hex screws that

secure the mounting bracket to the miter table.

• Rotate the mounting bracket lei_tor right untilthe saw

blade Lspara.[[e(w}th the squaze,

• RatJghtenthe screwssacure[y and recheck the b[adeto-fence alignment.

FRAMING

SQUARE

FENCE

BASE

VIEWOFBLADENOTSQUARE

WITH

FENCE,ADJUSTMENTS

AREREQUIRED

F_.lg

BASE

HEXHEAD

FRAMING

SQUARE

VIEWOFBLADE

SQUAREWITH FENCE

Fig. 17

MOUNTING

BRACKET

MI'I'ER

TABLE

Fig. 20

18

SQUARINGTHE BLADETO THE

MITERTABLE

FENCE

See Figures21 - 24.

• Unplug yoursaw.

• Puffthe saw arm all the way down and engage the lock

pin to hold the saw arm In transportposition.

• Loosen the miter lock {avers.

•

Rotate the miter table untUthe pointer is positioned

_t0".

•

•

Securelytighten the miter Locklevers.

Loosen bevel lock knob and set saw arm at 0"bevel

(io)adeset g0"to miter table)."nghtenbevel lock knob.

•

Place a combinationsquare against the miter table and

the fiat part of saw b{ade.

MITER

TABLE

COMBINATION

SQUARE

CORRECT

VIEWOFBLADE

SQUAREWITHMITERTABLE

NOTE: Make sure that the square contacts the fiat part

of the saw blade, not the blade teeth.

• Rotate the blade by hsnd and check the blade-to-table

alignment at severe{

points.

FENCE

FiO.

BLADE

• The edge of the square and the saw bladeshould be

paraIle&as shown in figure21.

•

If the top or bottom of the saw blade angles away from

the square es shown in figures22 and 23, adjustments

ere needed.

• Using a 10 mm wrench or adjustable wrench, loosen

the lock nut sscur(ng positive stop adjustmentscrew.

ALsoloosen beve_lock 'Knob.See F_gum23.

MITER

TABLE

• Adjust positive stop adjustment screw to bring

saw blade Into alignmentwith the square.

•

COMBINATION

SQUARE

Retighten bevel lock knob. Next, retightenlock nut

securingthe positive stop ad,h._tmsntscrew. Recheck

bk_de-to-tsb{e alignment.

VIEWOFBLADENOTSQUAREWITHMITER

TABLE,AOJIJSTMENTS

AREREQU(REO

NOTE: The above procedure can be used to check

blade squareness of the saw blade to the miter table at

both 0"and 45"angles.

F(g. 22

POSITIVE

8TOP

ADJUSTMENT

SCREWFOR

45"ANGLES

LOCK

J

19

FIG.23

Yoursawhastwoscaleindicators,

oneonthebevelscale

andoneonthemiterscale.Aftersquaring

adjustments

havebeenmade,it may be necessaryto loosenthe indi-

FENCE

BLADE

cators screws end reset them to zero.

COMBINATION

SQUARE

MITER

TABLE

VIEWOFBLADENOTSQUARE

WiTHMITER

TABLE,ADJUSTMENTS

AREREQUIRED

CU'I-rlNG

SAW

_1, WARNING" Do not allow familiarity with yourtool

to make you careless.Remember that a careless

fraction of a second is sufficient to inflict severe

injury.

_,

WARNING: Always wear safety goggles or safety

glasseswith side shieldswhen oparat]ngtools.

Failureto do so could resultin objects being thrown

into your eyes, resulting in possibleserious injury.

A

WARNING: Do not use _ny attachments or accessories not recommended by the manufacturer of

this tool The use of attachments or scceseorise not

recommended can result in serfous persona| fnJ'ury.

_k

WITH

YOUR

COMPOUND

Fig. 24

MITER

WARNING: When using a work clamp or C-clamp

to secure yourworkpisce, clamp workpisce on one

side of the blade o_y. The workpisce must remain

_'ee on one side of the bradsto prevent the blade

from bindingin workpisoe.The workpiece binding

the blade will cause motor stallingand kickback.

This situationcould cause an accident resultingin

possibleserious personalinjury.

CROSSCU'n'ING

See Figure 25.

A crosscutis made by cuing across 1hegrain of the

workplace. A sVa",ghtcrosscutis made with the miter

table set at the 0" position.Miter crosscutsere made with

the miter table set _t some angte other than zero.

APPLICATIONS

Thisproduct has been designedonlyfor the purposeslisted

below:

• Cross cutting wood and plastic.

• Cross cutting miters, joints, etc. for pictureframes,

moldings, door casings, and fine jotnery.

• Bevel cutting and compQundcutting.

NOTE=The blade provided is fine for mostwood cutting

operations,but for fine jofnerycuts or cutting pisstlc, use

one of the accessory blades available from your nearest

Sears store.

_,

_TRAIGHT

CRD38CLIT

WARNING: Before stetting any cutting operation,

_brnp or bolt your compound miter saw to a

workbench. Never operate your miter saw on the

floor or in s crouched position.Failureto heed this

warning can resultin serious personalinjury.

Fig. 25

2O

TO MRrERCUT

• Pullout the lock pin and lift saw arm to its full height.

• Loosen the miter lock levers.

• Rotate the saw table until the pointer alignswith the

desired angle on the miter scale.

• Tighten the miter lock levers securely.

_k

• Rotate the saw table untilthe pointeraligns with zero

on the miter scale.

• Tighten the miter lock leverssecurely.

_lb WARNING: To avoid serious personalinjury,always

tighten the miter lock lever securelybefore makinge

cut. Failureto do so could resultin movement of the

controlarm or miter tabte while makinga cut.

WARNING: To avoid serious personalinjury, always

tighten the miter lock handle securely before making

a cut. Failureto do so could result in movement of

the controlarm or miter table while makinga cut.

MOUNTING

BRACKET

INDICATOR

POINT

• place the workpiece flat on the miter table with one edge

securely againstthe fence. If the board is warped, placa

the convex side against the fence. If the concave edge

of a board is pisced against the fence, the board could

collapse on the blade at the end of the cut, jamming the

blade.

• When cutting long pieces of lumber or molding, support

the opposite end of the stock with a relier stand or with

a work surface isve( with the saw tabte. See Figure 30.

• Aligncutting line on the werkplece with the edge ot saw

blade.

• Grasp the stock firmly with one hand and secure

it against the fence or use the optional work clamp or a

C-clamp to secure the wcrkplece.

_L

WARNING: To avoid seriouspersonal injury,keep

your hands outside the no hands zone; at least 3

in. from blade. Never perform any cutting operation

freehand (withoutholdingworkpisoa against the

fanoa). The blade could grab the workpieoaif it slips

or twists.

•

Beforeturningon the saw, performa dry runofthe cutting

operation just to make surs that no problemswilt occur

when the cut is made.

Fig. 26

•

Loo_¢ the bevel lock knob end move the saw arm to

the left to the desired bevel angle.

• Bevel engles can be sat from 0"to 45".

• Align the indioator point for the desired angis.

• Once the saw arm has been set at the das_'edangle,

seou_ly tighten the beve_lock knob.

•pisce the workpiace flat on the miter table with one

edge escurotyagainst the fence, it the board is warped,

place the convex side againstthe fence. If the concave

edge of a board is placed againstthe fence, the board

could collapseon the blade at ths end of the cut, jamming the blade.

• When cutting long pieces of lumber or molding, support the opposite end of the stock with a roller

stand or with a work surface [eve]with the saw table.

See F-Tgure30.

• Alignthe cutting lineon the workpiecawith the edge of

saw b_de.

• Grasp the stock firmlywith one hand and secureit

against the fence or use the optional work clamp or a

C-oiamp to secure the workpleoa.

• Grasp the saw handle firmly then squeeze the switch

kiggsr. Allow several seconds for the blade to reach

maXimumspeed.

• Slowly lower the blade into and throughthe workpieoa.

• Releasethe switchtriggerand allow the saw bledetostop

rotating before raisingthe blade out of workpisca. Wait

until the eiscb'icbrake stops blade from turning before

removingthe workplece from the miter table.

TO BEVEL CUT

see Figures26 - 27.

A bevel cut Is made by cutting across the grain of the

werkpisce with the bradeangled to the workpleoa. A

straight bevel cut is made with the miter table set at the

zero degree positionand the blade sot at an angle

between 0"and 45".

_1_ WARNING: To avoid serious personalinjury,keep

your hands away from Guttingarea. Never perform

,,ny cuffing operation freehand(without holding

workpisce against the fence}. The btade could grab

the workpisoa if it slips or twists.

•

• Pull out the (ock pin and riftsaw arm to its full height.

• Loosen the miter lock levere.

21

Beforeturning on the saw, perform a dry run of the cutting operationjust to make sure that no problemswill

occur when the cut Is made.

• Grasp the saw handle firmlythen squeeze the switch

trigger.Aflowseveral secondsfor the blade to reach

maximum speed.

• S1owlylower the blade into and throughthe workplece.

• Release the switch triggerand allow the saw blade to

stop rotating beforeraisihgthe blade out of workplace.

Wait untilthe electric brake stops blade from turning

before remo,_in_the wark_iece fro_'nmiter table.

WARNING: To avoid seriouspersonal injury,always

tightenthe miter lock levers securelybefore making

a cut. Failureto do so could result in movement of

the controlarm or miter table while making a cut.

•

•

•

BEVELCUT

•

•

•

•

•

Loosenthe bevel lock knob and move the saw arm to

the {eft to the desired bevel angle.

Bevel angtes can be set from 0° to 45 °.

Once the saw arm has been set at the desiredangle.

securelyt{ghtenthe bevel lock knob.

Recheck mher angle setting. M_e a test out in scrap

mstedaL

Place the workpiece flat on the miter table with one

edge securelyagainst the fence. If the board is warped,

place the convex side against the fence. If the concave

edge of a board could collapse on the blade at the end

of the cut, jamming the blade.

When cutting long pieces of lumber or molding,support the opposite end of the stock with a rollerstand or

with a work surface ]evelwith the saw table.

Alignthe cutting line on the workplece with the edge of

saw blade.

Grasp the stock firmly with one hand and secure It

against the fence or use the optionalwork clamp or a

C-clamp to secure the workplace when possible.

NOTE When maLdnga 45" left miter and a bevel angts

greater than 30", you must use a C-cismp to secure

the workpiece or move clamp to the right side of the

base.

Fig. 27

TO COMPOUND

_1= WARNING: To avoid seriouspersor_ injury, always

keep your handsaway from cutting area. Never perform any cutting operationfreehand (wiLhoutholding

workpiece againstthe fence). The blade could grab

the wed<pieceif it slipsor twists.

MITER CUT

A compound miter cut is e cut made usinga miterangle

and a bevel angle at the sarhe time. This type of cut is

used to make picture frames, cut molding,make boxes

with sloping sides, end for certain roof framing cuts.

•

To make this type of cut the conVol arm on the miter table

must be rotated to the correct angle and the saw arm

must be tilted to the correct bevel angle. Care shouldalways be taken when making compound miter setups due

to the interaction of the two angle settings.

Beforeturning on the saw. perform a dry run of the cutting opera,|oni_ to make sure tha_no probk_nswilt

occur when the cut is made.

Adjustments of miter and beveJsettings are interdependent with one another.Each time you adjust the miter

setting you change the effect of the bevel setting. Also,

each time you adjust the bevel setting you change the effect of the miter setting.

It may take several settingsto obtain the desiredcut. The

first angle setting should be checked after setting the

second angle, since adjusting the secondangle affects

the first.

Once the two correct settings for a particularout have

been obtained, always make a test cut in scrap material

beforemaklng a finish cut in good material.

TO MAKE A COMPOUND

CUT

• Puffout the lock pin and rift saw arm to its full height.

• Loosen the miter lock levers.

• Rotate the saw table untilthe pointeraligns with the

desired angle on the miter scala.

• Tighten the miter lock levers securely.

Fig.

28

22

• Grasp the saw handle firmlythen squeeze the switch

trigger.Allow several seconds for the blade to reach

m_x_mum speed.

•

Slowly lowerthe blade into and through the workp(ece. See/:{gum 28.

•

Release the switch trigger and allow the saw bladeto

slop rotatingbefore raisingthe blade out ofworkpiece.

Wait untilthe electric brake stops blade from turning

before removingthe workpiece from miter table.

SUPPORT LONG WORKPIECES

See Figure 30.

Long workpiecas need extra supports. Supportsshould

be placed along the work,piece so it does not sag. The

support should let the workplace lay fiat on the base

ot the saw and work table duringthe cutting operation.

Use the optional work c[,_Tlpor a C-clamp to secure the

workplace.

A

WARNING: To avoid seriouspsreona_injury, always

keep your hands outside the no hands zone; at least

3 in, from blade. Never perform any cutting operatfon

freehand (withoutholdingworkpiece against the

fencel. The bhde coutd grab the workplace if It sl(ps

or twists.

45"X 45"COMPOUND

MITERCUT

Fig. 29

LONGWORKPIECE

WORKPIECE

_LIPPOITI_

Fig. 30

23

CUTTING COMPOUND

MITERS

"toa_din makingthe correct settings,the compound angle se_ing chart botowhas been provided.Since compound cuts

are the most difficultto accurately obtain,trial cuts should be trade in scrap material, and much thoughtand plannfng

made, priorto making your requiredcut.

prrcH

NUMB-:R

ol:=o,=

4

I

5

OF $1DE,_

6

I

7

I

8

I

9

I

10

0o

M-45.00 ° M-36.00 °

B- 0,00 ° B0,00 =

M-30,00 =

B- 0.00 =

M-25.71 = , M-22.50 =

B- 0.00 ° B- 0.00 °

5=

M-44.89 = M.35.90 °

B" 3,53 = B- 2.94 -=

M-29,91 =

B,- 2.50 =

M-25.63 =

B- 2.17 =

M-;?.2.4.2 == M-19.93 °

B- 1.91 ° B- 1.71 =

10 °

M-44.56 °

B- 7.05 °

M-35.58 =

B- 5.86 °

M-29.62 °

B- 4.98 °

M-25.37 °

B- 4.32 °

M-22.19 =

B- 8,81 =

M-19.72 = M-17.74 °

B- 3.40 ° ]_- 3.08 °

1'5°

_-44,01 = M-35.06 °

B-10.55 Q B- 8.75 °

M-29.15 =

B- 7,44 °

M-24,85 =

B- 6,45 =

M-21.81 °

B- 5.68 °

M-19.37 =

B- 5.08 °

M-34,32 ° ;M-28.48 °

_-_1.60 °

B- 9,85 °

M-24.35 =

B- 8.53 °

M-21.27 = M-18.88 = M-16.98 =

B- 7.52"

B- 6.72 ° B,- 6.07 =

20=

M-43.22 °

B-'_4.00 °

M-20.00 ° M- 18.00 ° :

B0.00 ° B- 0.00 =

M-17.94 =

B- 1.54 °

M-17.42 °

IB- 4.59"

25 °

M-42.19 = M-33.36 °

B-17.39 ° B-14,38 °

M-27.62 °

B-12.20 °

M-23.56 °

B-10.57 °

M-20.58 ° M-18.26 °

B- 9.31 ° B- 8.31 °

M-16.41 °

B- 7.50 =

300

M-40.89 °

B-20.70 °

M-26.57=:

B-14.48 °

M-22.84 °

B-12,53 °

M-19.73 °

B-11,03 °

M-17.50 °

B- 9.85 °

M-15.72 =

B- 8,89 °

35 °

M-39.32 = M-30.76 =

B-23,93 ° B- 19.70 =

M-25.31 =

B- 16.67 °

M-21.53 °

B- 14.41 °

M-18.74 °

B- 12,68 °

M-16.60 °

B- 11.31 _

M-14.90 °

B- 10.21 =

40"

M'37'45=

B- 27.03"

M-2g'_0°

B- 22.20 q

M'23'86°

B- 18.75 °

M'20"25=

B- 16.19 =

1_'17"6G°

B- 14.24 °

M'15"56°

B- 12.70 q

M'13'98=

B- 11.46 °

45"

M-35.28 ° M-27.19 °

B- 3O.O0° B-24,56 °

M-22.21 °

B-29.70 =

M-18.80 =

B-17,57 °

M-16.32 °

B-15.70 =

M-14.43"

6-14.00 °

M-12,94'

6-12,62 °

M-32.73 °

B-32.80 °

M-25.03 =

B-26.76 °

M-20.36 °

B-22.52 °

M-17.20 °

B-19.41 °

M-14,91 ° IM-13.17 °

B-17.05 ° B-15.19°

M-11.80 =

B-13.69 =

55 =

M-28.84 °

B-35.40 °

M-22.62 =

B-28.78 °

M-'t8.32 °

B-24,18 =

M-15.44 o M-13,36 = M-11.79 °

B- 20.82 `> B-18.27 ° B-18.27 °

M-10.56 o

B-14.66 °

60 °

M-26.57 ° M-19.96 °

B-3736 ° B-30.60 °

M-18.10 °

B-25._6 °

M-13,54 °

B-99.07 °

M-11.70 = M-10.31 °

B-_9.35 = B-17.23 °

M- 9.23 =

B-16.52 °

65 °

M-22,91 = M-17,07 =

B- 39.86 ° B- 32.19 °

M-13,71 =

B- 25.95 _

M-11.50 =

B- 23.16 °

M- 9.93 °

13-20.29"

M- 8.74"

13-18.06 °

M- 7.82 °

B -16.26 °

70 =

M-18.88 = M-13.95 =

B-41.64 ° B- 33.53 =

M-11.17 °

B-28.02 °

M- 9.35 =

B- 24.06 =

M- 8.06 =

B-21.08'

M- 7.10 =

B- 18.75 =

M- 6.34 °

B- 16.88 °

75 °

M-14.51 °

B- 43.08 °

M-10.65 °

B-34.59 =

M- 8.50 °

B-28.88 =

M- 7.10 °

B-24.78 =

M- 6.12 = M- 5.38 °

B- 21 .Cog

= B- 19.29 =

M- 4.81 °

13- 17.37 =

80 °

M- 8.85 °

B" 44.14 =

M" 7,19 =

B-35.37 °

M- 5.73 =

B-29.50 °

M" 4.78 =

B-25,30 °

M- 4.11 °

B" 22.14 °

M" 3,62 = M" 3.23 °

13"19.68 ° B" 17.72 °

M-

M-

M-2.07

M-1,82

50°

M85 °

90 °

M-32.18 =

B-17.09 °

4.98 ° M-

3.62 =

B. 44.78 o 18-35.84o

I M- 0.0O° M0.00 °

6- 45.00 = B- 36.00 =

2.88 °

2.40 °

°

°

B-19.92 °

M-

1.62 =

B-29.87 °

B-25.61 °

B-22.41 °

M- 0.00 =

B- 30.00 °

M- 0,00 =

B- 25.71"

M.- 0.00 _ M- 0.00 ° M0.00 =

B- 22.50 ° B- 20.00"

B- 18.00 °

Each B (Bevel)and M (_iter) Setting is Given te the Closest 0.005°.

COMPOUND-ANGLE SETTINGS FOR POPULAR STRUCTURES

24

1_.17.93 °

CUT'rING CROWN MOLDING

Your compound mRer saw does an excellent Jobof cutting

crown molding. In general, compound miter saws do a

better job of cutting crownmolding than any other tool

made.

When setting the bevel and miter angles for compound

miters, rememberthat the settingsare interdependent;

changing one angle changes the other angle as well.

Keep in mind that the angles for crownmoldings are very

precLseand diffLcuitto sat. Since it tsvery easy for these

angles to shift, all settings should first be tested on scrap

molding.Also most wells do not have angles of exactly

90", therefore, you witl need to fine tune yoursettings,

In order to fit properly,crown molding must be compound

mitered with extreme accuracy.

The two contact surfaces on a piece of crown molding

that fit flat against the ceilingand the wall of a room are at

angles that, when added together, equal exactly go'. Most

crown molding has a top rear angle (the section that fits

fiat against the cs[Ting)of 52"and a bottom rear angle (the

section that fits fiat against the wall) of 38".

When cutting crown molding by this method the bevel

angle should be set at 33.85".The miter angle shouldbe

set at 31.62" either dght or left, dependingon the desired

cut for the application. See the chart below for correct

angle settings and correct positioningof crownmolding

on miter _ble.

LAYING MOLDING

FLAT ON THE

MITER TABLE

See Figure 31.

"1"o

usethis method for accucateLycut_mg crownmolding

for a 90"inside or outside corner,lay the molding with its

broad back surface flat on the miter table and against the

fence.

52"

The settings in the chart below can be used for cutting All

Standard (U.S.) crownmolding with 52"and 38"angles.

The crown motdthgis plaoe(i fiat on the miter table us'rag

the compound features of your miter saw.

CEILING

INSIDE

CORNER

TOPEDGEAGAINSTFENCE=

* LEFTSIDE,IH$IDE¢6RNER

•

RIGHTSIDE,OWSIDECONNER

FEHCE

•

•

MITERTABLE

0

OUTSIDE

CORNER

0

BOTTOMEDGEAGAINSTFENCE=

RIGHT81DE,iNSIDECORNER

LEFTSLOE,OUTStOE

CORNER

MITERTABLE

0

0

CROWNMOLDINGFLATONMITERTABLE

F(g. 31

25

Bevel

Angle

Typeo#Cut

Setth_g

33.85"

33.85"

33.85"

side, inside comer

1. Top edge.of molding against fence

2. Miter table set fight 31.62"

3. Save left end of cut

Right side, Irmlde comer

1. Bottom edge of molding against fence

2. Miter table set left 31.62"

3. Save (eft end of cut

Left side, outside corner

_. Bottom edge of motding against fence

2. Miter tsble set left 31.62"

WRONG

Fig.33

3. Save right end of cut

33.65"

Right aide, outside comer

1. Top edge of molding against fence

2. Miter table set right 31.62"

3. Save right end of cut

_,

WARNING: To avoid a kickback and to avoid

seriouspersona_injury,never positionthe concave

edge of bowed or warped marsala[ against the fence.

CLAMPING

WIDE WORKPIECES

8ee Figure 34.

CUTIBNG WARPED

See Figures32 - 34.

MATERIAL

When cutting wide workpiecas such as a 2 in, x 6 in.,

boards should be clamped with a C-clamp as shown in

figure 34.

When cutting warped material, always make sure it is

positionedon the miter table with the convex side against

the fence as shown in figure 32.

If the warped material _spositionedthe wrong way as

shown in figure 33, it will pinch the blade near the completion of the out.

RIGHT

Fig. 32

Fig. 34

26

BEVEL PIVOT ADJUSTMENT

_1_ WARNING: Before performingany adjustment,

make sure the tool is unplugged from the power

supply and the switch is in the OFF ( O ) position.

Failureto heed this warning could result in serious

personalinjury.

• Yourcompound miter saw should bevel easily by loosening the bevel lock knoband tiltingthe saw arm to the

left.

• If movement is tight or if there is play in the pivot, have

saw repaired by a qualifiedservicetechnician at your

nearest Sears store or repair center to avoid risk of

personalinjury.

POSITIVESTOP

ADJLIS'TMENT

SCREWFDR

45"/i_GLE8

DEPTH STOP

See Figure 35.

The depth stop limits the blade's downward b'avel.It

allows the blade to go balow the rn_artable enough1o

maintain full cutting sapacitles. The depth stop positions

the blade 1/4 in. from the miter table support.

NOTE; The miter table support is located inside miter

table.

LOCK

The depth stop is factory set to providemaximum cutting

capacity for the "tOin. saw blade providedwith yoursaw.

Therefore, the saw with blade provided shouldnever need

adjusbx_ents.

However, when the diameter of the blade has been reduced due to sharpening,it may be necessary to adjust

the depth stop to providemaximum cutting capacity. ALso,

when a new blade is installed,it is necessaryto check the

clearanos of the blade to the miter table supportbefore

start'rngthe saw. Make adjustmentstf needed.

J

Fig. 35

PIVOT ADJUSTMENTS

NOTE; These adjustments were made at the factory and

normallydo not requirereadjustment.

TRAVEL

PIVOT ADJUSTMENT

• The saw arm should rise completelyto the up position

by itaeif.

• If the saw arm does not raise by itself or if there is play

in the pivot joints, have saw repaired by a qualified

service technician at your nearest Sears store or repair

center to avoid r_skof personal tn)ury.

27

DEPTH STOP ADJUSTMENTS

See Figure 36.

OEPTHSTOP

ADJUSTMENT

8CREW

•

A

Unplugyour saw.

WARNING" Failureto unplug yoursaw could result

in accidents| starting causing possibleserious

personal injury.

• To adjust the depth atop usaa 10 mm wrench or adjustable wrench and Loosenthe hex nut at the rear of

the miter saw arm.

MITER

TABLE

Use a 5 mm hex key wrench to adiuat the depth stop

adjus_ent screw. The saw h_adele lowered by turning

the screw counter-c[ook'wkse

and raised by turning the

screw clockwise.

Lowerthe blade intothe miter table. Check brads

clsarance and maximum cutting distance (distance

from fence where blade enbars)_ front of miter table

slot.

• Readjust if necessary.

• Tighten the hex nut with a 10 mm wrench or adiustable

wrench.

POSITIVE

STOP

ADJUSTMENT

SCREW

FOR

O"ANGLES

• To prevent the depth stop adjustmentscrew from turning while tighteningthe hax nut, carefuJ]yhold Jtwith

the hax key wrench while tighteningthe hax nut.

LOCKNUT(S)

Fig. 36

WARNING:. Do not start youTcompound miter saw

without checking for interferencebetween the blade

and the throat plate, Damage could resultto the

blade if it strikes the throat plate during operation of

the saw.

28

BRUSH

CAP

_l_ WARNING: When servicing, use onlyidentical

replacement parts. Use of any other part may create

a hazard or cause productdan'_ge.

AI_ WARNING: Always wear safety gogglus or safety

glasseswith side shields during power tool operation

or when blowing dust. If operation is dusty,also

wear a dust mask.

BRUSH

AESEMBLY

BRUgd-I

ASSEMBLY

GENERAL

Avoid usingsolvents when cleaning p_sUo parts. Most

plasticsare susceptibleto damage fTomvarious bJpesof

commemialsolventsand m_y be damaged by theirusa.

Use clean clothsto remove dirt, carbon dust, etc.

BRUSH

CAP

_IL WARNING: Do not at any time let brake fluids,

gasoline, petroleum-basedproducts, penetrating

oils, etc. come in contact with plastic parts.

Chemicals can damage, weaken or destroyplastic

which may result in serious personal injury.

Fig. 37

BRUSH REPLACEMENT

See Figure 37.

It has been found that electric tools are subject to accalarated wear and possibleprernaturelailurawhen they are

used on fiberglassboats, sportscars, wstiboard,spackling compounds, or plsstar.The chips and grindings_om

these materials are highlyabrasive to electric tool parts

such as bearings, brushes,commutators, etc. Consequently,it is not recommended that this tool be used for

extended work on any fiberglassmaterial, wallboard,

spackJIngcompounds, or piaster.During any use on these

materials it is extremely importantthat the tool is cleaned

frequently by blowingwith an air iet.

Your saw has externally accessiblebrush assembliesthat

should be periodicallycheck_edfor wear.

LUBRICATION

• Check for wear. Replace both brusheswhen eitherhas

less than 1/4 in. length of carbon remaining.Do not

replace one side without repfacingthe other.

• Reassemble using new brush assemblies.Make sure

curvature of brush matches curvatureof motor and

that brush moves freely in brush tubs.

• Make s_'s brushc_ is odented correctly (s_'aight)and

replace.

Proceed as follows when rapla¢emant Is required:

• Unplug your saw.

_k

• Remove brushcap with a screwdriver.Brush assembly

is springloaded end wLtlpop out when you remove

brush _,ap.

• Remove brush assembly.

Aft of the bearingsin this tool are lubricatedwith a sufficient amount of high grade lubricant for the life of the unit

under normal operating conditions.Therefore, no further

lubricationIs requlrad.

_IL

WARNING: Failureto unplug your saw could result

in accidental starting causing serious iniury.

WARNING: To ensure safety and raJJabJJil"_,

aJ_

repairs -- with the excaption of the externally

accessible brushes - should be performed by a

qualifiedservice technicianat a Sears store to avoid

risk of personalinjury.

• "l'ightenbrush cap securely.Do not overtighten.

29

Your Home

For repair-In your home-of all major brand appliances,

lawn and garden equipment, or heating and cooling systems,

no matter who made It, no matter who sold Itl

For the replacement parts, accessories and

owner's manuals that you need to do-it-yourself.

For Sears professional installation of home appliances

and items like garage door openers and water heaters.

1-800-4-MY-HOME ® (1400-469-4663)

Call anytime, day or night (U.S_, and Canada)

_/._81'LCOm

re.sears.ca

Our Home

For repair of carry-in items like vacuums, lawn equipment,

and electronics, call or go on-line for the location of your nearest

Sears Parts & Repair Center.

1-800-488-1222

Call anySme, day or night (U,SJ_. only)

_.ZrM_'I_COIR1

To purchase a protection agreement (U.Sa_.)

or maintenance agreement (Canada) on a product serviced by Sears:

1-800-827-6655

(u.s_.)

Pare pedir servicio de repamci6n

a domicilio, y para ordenar piezas:

1-888.SU.HOGAR

s"

1-800-361-6665

(Canada)

Au Canada pour service en franQais:

1-800-LE-FOYER uc

(1-8oo-533-6937)

(1-888-784-6427 q)

® Reglst8red Tradema_ / _ Trademaz-kI _ Se_loe Marko__m, RoebuckandCo,

® Marca Regb_ada / "raMarca de FJbdca/ =* Marca de Servldo de _Hm=, Roel_ck _

_ Ma_ue de _mmerce f u" Msro_e d_poz_e de _

RoeSucksndCo.

WWW.sears.ca

_.

©Seans, Roebuc_snd Co.