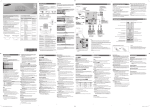

Download Samsung CLP-660ND Product specifications

Transcript