Download Crown Boiler 32 Series and Operating instructions

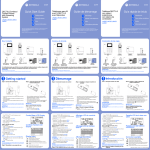

Transcript