Download Craftsman 113 Owner`s manual

Transcript

Save This Manual

For Future Reference

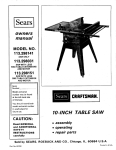

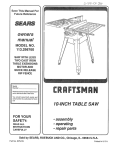

ISears

owners

manual

*

MODEL NO.

113.298142

SAW ON LY

113,298032

SAW WITH LEGS

TWO TABLE EXTENSIONS

AND MOTOR

113.298240

SAW WITH LEGS

TWO TABLE EXTEN SIONS

MOTOR AND HOLD DOWN

Serial

Number

_

_

Model and seria

number may be found

at the left-hand side

of the base.

You should

record both

model and serial number

in a safe place for

future use.

10-INCH

TABLE SAW

CAUTION:

• assembly

Read GENERAL

and ADDITIONAL

SAFETY

. operating

• repair

INSTRUCTIONS

parts

carefully

Sold by SEARS,

Part No. 62781

ROEBUCK

AND

CO.,

Chicago,

IL. 60684

U.S.A.

Printed

_n U.S.A.

FULL ONE YEAR WARRANTY

If withirl-one

year

workmanship,

States.

Sears

from

the

will

date

repair

of purchase,

this

it, free of charge.

WARRANTY

SERVICE

IS AVAILABLE

CENTER/DEPARTMENTTHROUGHOUT

ON CRAFTSMAN

Craftsman

This warranty

Table

applies

Saw

TABLE

fails

only while

BY SIMPLY

CONTACTING

THE UNITED STATES•

due

to

SAW

a defect

this product

THE

in material

or

is in use in the United

NEAREST

SEARS

SERVICE

This warranty gives you specific legal rights, and you may also have other rights which vary from state to state.

SEARS, ROEBUCK AND CO., Dept. 698/781A.

Sears Tower, Chicago, I L 60684

GENERAL SAFETY INSTRUCTIONS

FOR POWER TOOLS

1. KNOW YOUR POWER TOOL

Read

and

understand

affixed

limitations

peculiar

to

the owner's

manual

and

labels

the

tool

Learn

its application

and

as well as the specific

potential

hazards

to this tool.

2. GROUND

ALL TOOLS

This tool is equipped

with an approveo

3*conductor

cord and a 3-prong

grounding

type plug to fit the

proper grounding

tvpe receptacle.

The green conductor

in the cord is the grounding

wire. Never connect the

green wire to a live terminal.

3. KEEP GUARDS

in working

alignment.

IN PLACE

order,

and

in

4. REMOVE ADJUSTING

AND WRENCHES

proper

adjustment

and

KEYS

Cluttered

must

areas

and

not be slippery

6. AVOID

CLEAN

benches

invite

accidents,

Floor

due to wax or sawdust.

DANGEROUS

All visitors

area,

should

8. MAKE WORKSHOP

-- with

padlocks,

starter keys.

9. DON'T

from

work

KID-PROOF

master

switches,

or

by

removing

FORCE TOOL

It will do the job better

it web dc_igncd.

10. USE RIGHT

or attachment

to do a job it was not

11. WEAR PROPER APPAREL

GOGGLES

Keep proper

footing

15. MAINTAIN

and balance

at all times.

TOOLS WITH CARE

Keep

tools

sharp

and clean

performance,

Follow

instructions

changing accessories.

before

blades,

17. AVOID

Make

in.

the

safest

and

Follow

STAND

position

such

as

before

plugging

ACCESSORIES

manual

the

The

accessories

STARTING

is in "OFF"

owner's

the accessories.

cause hazards.

Serious

cutting

best and

lubricating

for

changing

ACCIDENTAL

sure switch

accessories.

for

TOOLS

servicing;

when

bits, cutters, etc.

for

recommended

instructions

use of

that

improper

accompany

accessories

may

ON TOOL

injury could occur if the tool

tool is accidentally

contacted.

is tipped

or if the

Do not store materials above or near the tool such that

it is necessary to stand on the tool to reach them.

Before

further

Check

parts,

PARTS

use of the tool,

for alignment

breakage

of

conditions

Do not wear loose clothing, gloves, neckties or jewelry

(rings, wrist watches) to get caught in moving parts.

Nonslip

footwear

is recommended.

Wear protective

hair covering to contain

long hair. Roll long sleeves

above the elbow.

12. USE SAFETY

of

a guard

or other

part that

is damaged should be carefully

checked to ensure that it

will operate properly

and perform

its intended function.

TOOL

Don't force tool

designed for.

periods

14. DON'T OVERREACH

20. CHECK DAMAGED

and safer at the rate for which

extended

Use clamps or a vise to hold work when practical.

It's

safer than using your hand, frees both hands to operate

tool.

19. NEVER

a safe distance

during

13. SECURE WORK

Consult

AWAY

be kept

or muffs)

18. USE RECOMMENDED

ENVIRONMENT

Don't

use power tools in damp or wet locations

or

expose them

to rain. Keep work

area well lighted.

Provide adequate surrounding

work space.

7. KEEP CHILDREN

(plugs

• 16. DISCONNECT

Form habit of checking

to see that keys and adjusting

wrenches

are removed

from tool before turning

it on.

5. KEEP WORK AREA

protectors

opera_ion

(Head Protection)

Wear Safety goggles (must comply

with ANSI Z87.1)

at all times.

Everyday

eyeglasses only have impact

resistant

lenses, they are NOT safety glasses. Also, use

face or dust mask if cutting operation

is dusty, and ear

that

other part that

or replaced.

21. DIRECTION

Feed work

of rotation

may

its

binding of moving

and any

other

operation.

should

A

be properly

guard

or

repaired

OF FEED

into a blade or cutter against

of the blade or cutter only.

power

complete

'affect

is damaged

22. NEVER LEAVE

UNATTENDED

Turn

of moving parts,

parts,

mounting,

off.

stop.

TOOL

Don't

the

direction

RUNNING

leave

tool

until

it comes

to a

ADDITIONAL

WARNING:

FOR

OPERATE

YOUR

ASSEMBLED

AND

INSTRUCTIONS...

AND UNDERSTAND

1.

SAFETY

YOUR

OWN

SAFETY,

DO

NOT

SAW

UNTIL

IT IS COMPLETELY

INSTALLED

ACCORDING

TO THE

AND

UNTIL

YOU

HAVE

READ

THE FOLLOWING.

2.

GENERAL

TOOLS...

GETTING

3.

4.

5.

6.

BASIC SAW OPERATION

. . . SEE PAGE

ADJUSTMENTS

. . . SEE PAGE 29

MAINTENANCE...

SEE PAGE 34

STABILITY

OF SAW

If there

INSTRUCTIONS

SAFETY

INSTRUCTIONS

SEE PAGE 2

TO KNOW YOUR SAW ...

is any tendency

FOR

(sawing entirely

thru

all loose pieces from

wood IMMEDIATELY

20

E.

23

for the saw to tip over or move

during

certain

cutting

operations

such as cutting

extremely

large heavy panels or long heavy boards, the

saw should be bolted down.

If you attach

any kind of table extensions

over 24"

wide to either end of the saw, make sure you either bolt

the saw to the bench or floor as appropriate,

or support

the outer end of the extension from the bench or floor,

SAWS

the work)

AND by removing

the table with a long stick of

after they are cut off

Use extra

caution

when

the guard assembly

is

removed

for

resawing,

dadoing,

rabbeting,

or

molding

replace

the guard as soon as that

operation

is completed.

For rip or rip-type

cuts, the following

end of a

workpiece

to which a push stick or push board is

applied must be square (perpendicular

to the fence)

in order that feed pressure applied to the workpiece

by the push stick

or block

does not cause the

D.

POWER

SEE PAGE

FOR TABLE

workpiece

to come

away

possibly cause a kickback.

During rip and rip type cuts,

held down on the table and

push

stick,

push

block,

J_a[berboard

is made of solid

F,

from

the

fence,

and

the workpiece

must be

against the fence with a

or featherboards.

A

lumber per sketch.

as appropriate.

7.

LOCATION

5/16"

The saw should be positioned

nor a casual observer

is forced

saw blade.

8.

G.

KICKBACKS

A "KICKBACK"

occurs during

a rip-type

operation

when a part or all of the workpiece

is thrown

back

violently

toward the operator.

Keep your face and body to one side of the sawblade,

out of line with a possible "Kickback."

Kickbacks

and possible

injury

from

them --- can

usually be avoided by:

A. Maintaining

the rip fence parallel to the sawblade.

B. Keeping

the sawblade

sharp.

Replace or sharpen

antikickback

pawls when points become dull.

C.

D.

E.

F.

Keeping sawblade guard, spreader, and antikickback

pawls in place and operating

properly.

The spreader

must be in alignment

with the sawblade and the

pawls

must stop a kickback

once it has started.

Check their action before ripping.

NOT ripping work that is twisted or warped or does

not have a straight edge to guide along the rip fence.

NOT releasing work until you have pushed it all the

way past [he sawblade.

Using a push stick for ripping widths of 2 to 6 in.,

and an auxiliary

fence and push block for ripping

widths

narrower

than

2 in.

(See "Basic

Saw

Operation

9.

Using The

G.

NOT confining

cross-cutting.

H.

When ripping

the workp!ece

fence.

the

Rip Fence"

cut off

piece

C.

Wear safety

and a face

plugs

or

H.

I,

J.

when

ripping

or

apply the feed force to the section of

between

the saw blade and the rip

NEVER

turn

the saw "ON"

before clearing

the

table

of all tools,

wood scraps, etc., except

the

workpiece

and related

feed or support

devices for

the operation

planned.

NEVER

place your face or body in line with the

cutting tool.

NEVER

place your fingers or hands in the path of

the sawblade or other cutting tool.

NEVER

reach in back of the _,t]tting tool with

either hand to hold down or support the workpiece,

remove wood scraps, or for any other reason. Avoid

awkward

operations

and hand positions

where a

sudden slip could cause fingers

or hand to move

into a sawblade or other cutting tool.

K. DO NOT perform

layout, assembly, or setup work

on the table while the cutting tool is rotating.

L DO NOT perform

any operation

"FREEHAND"

-always use either the rip fence or the miter gauge to

position

and guide the work.

M. NEVER

use the rip fence when crosscutting

or the

miter

gauge when ripping.

DO NOT use the rip

fence as a length stop.

Never hold onto or touch

the "free end" of the

section.)

N.

workpiece

or a "free piece"

that is cut off, while

power is "ON"

and/or the sawblade is rotating.

Shut "OFF"

the saw and disconnect

the power cord

when

cutting

removing

the

tool, removing

table

insert,

changing

the

or replacing the blade guard,

or making adjustments.

Provide adequate

support

to the rear and sides of

the saw table for wider or long workpieces.

P. Plastic and composition

(like hardboard)

materials

may be cut on your saw. However, since these are

usually

quite

hard and slippery,

the antikickback

pawls may not stop a kickback.

Therefore,

be especially

attentive

to following

proper

set-up and cutting

procedures

for ripping.

Do not stand, or permit anyone else to stand, in line

with a potential

kickback.

O. If you stall or jam the sawblade in the workpiece,

turn saw "OFF",

remove the workpiece

from the

sawblade,

and check

to see if the sawbtade

is

parallel

to the miter

gauge grooves

and if the

spreader is in proper alignment

with the sawblade.

If ripping at the time, check to see if the rip fence is

O.

PROTECTION:

EYES, HANDS,

FACE, EARS, BODY

A. If any part of your saw is malfunctioning,

has been

damaged or broken..,

such as the motor switch, or

other

operating

control,

a safety

device

or the

power

cord ...

cease operating

immediately

until

the particular

part is properly

repaired or replaced.

B.

APART

so neither

the operator

to stand in line with the

goggles that comply

with ANSI Z87.1,

shield if operation

is dusty. Wear ear

muffs

during

extended

periods

of

operation.

Small loose pieces of wood or other objects

that

contact

the rear of the revolving

blade can be

thrown

back at the operator at excessive speed. This

can usually

be avoided by keeping

the guard and

spreader

in place for

all thru-sawing

operations

parallel

with

the sawblade.

Readjust

as indicated.

R. DONOTremove

smallpieces

of cutoff material

that maybecome

trappedinsidethe bladeguard

whilethesawisrunning.

Thiscouldendanger

your

handsor cause

a kickback.

Turnsaw"OFF"and

waituntilbladestops.

S. Useextracarewhenripping

woodthathasatwisted

grainor istwistedor bowed- it mayrockonthe

tableand/orpinchthesawblade.

10.KNOW

YOURCUTTING

TOOLS

A Dull,gummy,

or improperly

sharpened

orset cutting

B.

tools can cause material to stick, jam, sta!l the saw,

or kickback

at the operator.

Minimize

potential

injury

by proper

cutting

tool

and machine maintenance.

NEVER

ATTEMPT

TO

FREE

A STALLED

SAWBLADE

WITHOUT

FIRST

TURNING

THE

SAW OFF.

Never use grinding

wheels, abrasive cut-off

wheels,

friction

wheels (metal slitting

blades) wire wheels or

buffing wheels.

11. USE

ONLY

ACCESSORIES

DESIGNED

FOR

THIS

SAW.

12. Crosscutting

operation_

are more conveniently

worked

and with greater safety if an auxiliary

wood facing is

attached

to the miter gauge using the holes provided.

However, the facing must not interfere

with the proper

functioning

of the sawblade guard.

13. Make sure the top of the arbor or cutting

tool rotates

toward

you

when

standing

in normal

operating

position.

Also make sure the cutting

tool, arbor collars

and arbor nut are installed properly.

Keep the cutting

tool

as low

as possible

for

the operation

being

0erformed:

Keeo all guards in place whenever

possible,

14. Do not use any blade or other cutting tool marked for

an operating

speed less than 3450 RPM. Never use a

cutting

tool

larger in diameter

than the diameter

for

which

the saw was designed.

For greatest safety and

efficiency

when ripping,

use the maximum

diameter

blade for which

the saw is designed, since under these

conditions

the spreader is nearest the blade.

DO

NOT

pull

the

workpiece

through

the

sawblade

-

position your body at the nose (in-feed) side of the guard:

start and complete

the cut from the same side. This will

require added table support for long or wide workpioces

that extend beyond the length or width of the saw table.

18.THINK

Safety

SAFETY.

is a combination

of operator

common

sense and

alertness at all times when the saw is being used.

19. NOTE

AND

FOLLOW

SAFETY

INSTRUCTIONS

THAT APPEAR

ON THE FRONT

OF YOUR SAW.

FOR YeUR

READ

1

AND

WEAR

OWN SAFETY

UNDERSTAND

OWN£R'S

BEFORE

OPERATING

SAFETY

GOGGLES

M_.NUAL

MACHINE:

PER ANSI Z871

AT ALL

TIMES

1

USE SAW

BLADE

GUARD

FOR

"TI-IRU

SAWING'"

KEEP

HANDS

OUT

OF PATH

OF $AWBLADE

USE

l i

A

KNOW

*'PL_H.SlrlCK

HOW

'' WHEN

DANGER

AVOID

"KICK

TO

De NOT PERFORM

NEVER

REACH

REOU)RED

RACRS"

OPERATleNS

AROUND

eR

"FREEHAND"

eVER

SAW

BLADE

20.WARNING:

DO

NOT

ALLOW

FAMILIARITY

(GAINED

FROM

FREQUENT

USE OF YOUR

SAW)

TO

BECOME

COMMONPLACE.

- ALWAYS

REMEMBER

THAT A CARELESS

FRACTION

OF A

SECOND

IS SUFFICIENT

TO

INFLICT

SEVERE

INJURY,

21.WARNING:

THE 2-1/2"" SAW PULLEY AND THE

2-1/2" MOTOR PULLEY FURNISHED,

WILL RUN

THE

BLADE AT APPROXIMATELY

3450 RPM

WHEN USED WITH A 3450 RPM MOTOR. NEVER

SUBSTITUTE THESE PULLEYS TO INCREASE THIS

SPEED BECAUSE IT COULD BE DANGEROUS.

NOTE:

to just

Do not overtighten

"snug"

it.

arbor

WEAR

nut.

Use the arbor

wrench

YOUR

15. Adjust

table inserts flush with the table top. NEVER

operate the saw unless the proper insert is installed.

16. NEVER

rear of

result

feed material

into the cutting

too

from the

the saw. An accident

and serious

njury could

17. NEVER

use another

person

as a substitute

for a table

extension

or as additional support for a workpiece that

is longer or wider than the basic saw table, or to assist in

feeding

or supporting

MOTOR

or pulling

the workpiece

SPECIFICATIONS

This saw is designed

use any motor that

AND

to use a 3450 RPIV motor only. Do not

runs faster than 3450 RPM. It is wireo

for operation

on 110-120 volts, 60 Hz., alternating

current.

IT MUST NOT BE CONVERTED

TO OPERATE

ON 230

VOLTS.

EVEN

THOUGH

SOME

OF

THE

RECOMMENDED

MOTORS

ARE

DUAL

VOLTAGE.

Changing

changing

to 230 volt wil not conserve

the power cord plug.

The Outlet in the

motor plug.

switch

box will

RECOMMENDED

THIS SAW.

CRAFTSMAN

energy

accept

MOTORS

and requires

only a 15 amp.

FOR

The operation

objects

being

of any power tool

can result in foreign

thrown

into

the eyes, which

can result in

severe eye damage. Always

wear safety goggles complying

with

ANSI Z87.1 I;hown

on Package) before commencing

power tool operation.

Safety Goggles are available at Sears

retail or catalog stores.

ELECTRICAL

CONNECTING

REQUIREMENTS

TO POWER

SOURCE

OUTLET

This saw must be grounded

operator from electrical shock

while

If power cord is worn

it replaced immediately,

or damaged

or cut,

If your saw is for use on less than

that looks like below.

n use to protect

in any way, have

150 volts

3-PRONG

it has a alug

PLUG

USE ON

H.P.

R.P.M.

Volts

Catalog

1

3450

110-120

1217

1

3450

110-120

1220

No.

CAUTION:

Do not use blower or washing machine motors

or any motor with an automatic reset overload protector as

their use may be hazardous.

GROUNDING

_PROPERLY

3NRONG

the

PRONG

GROUNDED

OUTLET

Plug power cord into

110-120V

properly

outlet

protected

by a 15-amp. time delay

fuse or circuit

breaker.

IF

YOU

ARE

PROPERLY

QUALIFIED

NOT

SURE

GROUNDED,

ELECTRICIAN.

WARNING:

DO

THE TERMINALS

REMOVING

THE

THAT

HAVE

grounded

type

or Circuit-Saver

LUG

ADAPTER

YOUR

IT

GROUNDING

OUTLET

CHECKED

IS

BY

MAKE

A

3-PRONG

SURE

THIS

CONNECTED

PLUG

KNOWN

NOT PERMIT

FINGERS

TO TOUCH

OF PLUG

WHEN

INSTALLING

OR

PLUG TO OR FROM THE OUTLET.

TO

IS

A

GROUND

2-PRONG

RECEPTACLE

WARNING;

IF NOT

PROPERLY

GROUNDED

THIS

POWER TOOL CAN INCUR

THE POTENTIAL

HAZARD

OF

ELECTRICAL

SHOCK,

PARTICULARLY

WHEN

USED

IN DAMP

LOCATIONS,

IN

PROXIMITY

TO

PLUMBING,

OR OUT OF DOORS.

IF AN ELECTRICAL

SHOCK

OCCURS

THERE

IS THE POTENTIAL

OF A

SECONDARY

HAZARD

SUCH

AS YOUR

HANDS

CONTACTING

This

saw

THE

is

SAWBLADE.

equipped

with

a

3-conductor

cord

and

grounding type plug which has a grounding

prong, approved

by Underwriters'

Laboratories

and the Canadian Standards

Association.

The ground conductor

has a green lug and is

attached to the too! housing at one end and to the ground

prong in the attachment

plug at the other end.

This

plug requires

outlet as shown.

a mating

3-conductor

grounded

NOTE: The adapter illustrated

is for use only

have a properly

grounded 2-prong receptacle.

if you already

The

some

An adapter

to 2-prong

you have a qualified

outlet

with a properly

cord

will

cause

loss

of

to a minimum

and to prevent

burn-out,

use the table below to

wire size (A.W.G.)

extension

cord.

cords

which

have 3 prong

3-pole

receptacles

which

will

110-120V

Wire Size A.W.G.

Up to 50 Ft .................

14

50 to 100 Ft ................

12

100-200

Ft .................

10

200-400

Ft .................

8

CHECK MOTOR

ROTATION

WARNING:

FOR YOUR OWN SAFETY, MAKE SURE

PLUG IS NOT CONNECTED

TO POWER SOURCE

OUTLET WHEN CHANGING MOTOR ROTATION.

as shown below is available for connecting

plugs

receptacles.

The green grounding

lug extending

from the adapter must be connected

to a permanent

such as to a properly

grounded outlet box.

extension

1 H.P. MOTOR

Extension Cord Length

type

electrician

grounded

any

Use only

3 wire extension

grounding

type

plugs and

accept the plug on the saw.

If the outlet you are planning

to use for this saw is of the

two prong

type

DO NOT

REMOVE

OR ALTER

THE

GROUNDING

PRONG IN ANY MANNER.

Use an adapter

as shown and always connect the grounding

lug to a known

ground.

It is recommended

that

replace the TWO prong

TH REE prong outlet.

use of

power.

To

keep this

over-heating

and motor

determine

the minimum

ground

The motor must rotate CLOCKWISE when viewed from the

shaft end to which you witl mount the pulley. (See page

16.) If it does not, change the direction according to the

instructions furnished with the motor.

CONTENTS

WARRANTY

......................................

GENERAL SAFETY INSTRUCTIONS

FOR POWER "TOOLS ............................

ADDITIONAL SAFETY INSTRUCTIONS

FOR TABLE SAWS ..............................

MOTOR SPECIFICATIONS

AND ELECTRICAL

REQUIREMENTS

...............................

UNPACKING AND CHECKING CONTENTS

........

Tools Needed ...................................

List of Loose Parts ..............................

ASSEMBLY

.......................................

Installing Handwheels

...........................

Checking Table Insert ...........................

Checking Blade Squareness to Table .............

Assembling Steel Legs ...........................

Mounting Saw ...................................

Attaching Table Extensions

.....................

Installing Rip Fence Guide Bars .................

Aligning Rip Fence .............................

Adjusting Rip Scale Indicator

...................

Installing Blade Guard ..........................

Mounting the Motor ............................

Installing Belt Guard ...........................

Assembling Hold-Down

.........................

Plugging in Motor ..............................

GETTING TO KNOW YOUR SAW .................

On-Off Switch ..................................

Elevation Handwheel

...........................

Tilt Handwheel

.................................

Tilt Lock Handle ...............................

Rip Fence ......................................

Miter Gauge ...................................

Blade Guard ...................................

2

2

3

4

6

6

6

8

8

8

8

9

9

10

10

12

14

14

16

18

19

19

20

20

21

21

21

21

21

21

Table Insert ....................................

Removing and Installing Sawblade

..............

Exacti-Cut

.....................................

BASIC SAW OPERATION USING THE MITER GAUGE

Work Helpers

..................................

Crosscutting

...................................

Repetitive Cutting

..............................

Miter Cutting .... . ..............................

Bevel Crosscutting

.............................

Compound Miter Cutting

.......................

Using the Hold-Down

..........................

BASIC SAW OPERATION USING THE RIP FENCE

Ripping ........................................

Bevel Ripping ..................................

Ploughing and Molding .........................

Resawing ......................................

Cutting Panels .................................

Rabbeting ......................................

Dadoing

.......................................

Using Featherboards

......................

.....

ADJUSTMENTS

..................................

Miter Gauge ...................................

Heeling Adjustment or Parallelism of

Sawblade to Miter Gauge Groove

..............

Blade Tilt, or Squareness of

Blade to Table ................................

Tilt Mechanism .................................

MAINTENANCE

..................................

LUBRICATION

...................................

RECOMMENDED

ACCESSORIES

.................

TROUBLE SHOOTING

...........................

REPAIR PARTS ..................................

21

22

22

23

23

24

24

25

25

25

26

27

27

27

29

29

29

29

30

30

31

31

31

32

34

35

35

35

36

38

UNPACKING

AND CHECKING

CONTENTS

COMBINATION

SQUARE

NEEDED

MUST

BE TRUE.

STRAIGHT EDGE OF BOARD

3,/4"

DRAW LIGHT

BOARD ALONG

Medium Screwdriver

Small Screwdriver

LINE ON

THICK.

THIS

EDGE

MUST

BE PERFECTLY STRAIGHT.

THIE EDGE, <_'\x

Phillips Type

___rewdriver

Wrenches

_,'+'Tr!;iiii_il

I:III_,L.'III:II',III!I

ii.11'i::]ii_ii' I

Combination

/

3/8 In.

7/16 in.

1/2 in.

9/16 In.

3/4 In.

Square

SHOULD BE NO GAP OR OVERLAP

HERE WHEN SQUARE IS FLIPPED

OVER

Model

carton

113.298142

but DOES

Table Saw is shipped

NOT INCLUDE

Table

complete

in one

Extension,

Steel

IN

DOTTED

POSITION.

LIST OF LOOSE PARTS

Legs, or motor.

Model 113.298032

Table Saw is shipped complete

in one

carton

but INCLUDES

Two Table Extensions,

Steel Legs,

and Motor.

Model

carton

Motor,

Item

113.298240

Table Saw is shipped complete

in one

but INCLUDES

Two Table Extensions,

Steel Legs,

and Hold Down.

Separate

one with

all parts from

the illustration

certain

all items

packing material.

packing

materials

and check each

and the list of Loose Parts to make

are accounted

for.

before

discarding

any

f any parts are missing, do not attempt

to assemble the

table saw. plug

n the power cord or turn the switch on

until

the missing

parts

are obtained

and are installed

correctly.

Remove the protective

oil that is applied

and edges of the table. Use any ordinary

grease and spo_ remover.

CAUTION:

Never

volatile solvents.

Apply

use gasoline,

a coat of automobile

Wipe all parts thoroughly

WARNING:

CONNECT

FOR

PLUG TO

naptha

to the table top

household

type

or

similar

highly

wax to the table.

with

a clean, dry cloth.

YOUR

POWER

OWN

SAFETY,

SOURCE

OUTLET

NEVER

UNTIL

ALL ASSEMBLY

STEPS ARE COMPLETE,

AND

HAVE

READ

AND UNDERSTAND

THE SAFETY

OPERATIONAL

INSTRUCTIONS.

A

B

YOU

AND

....C

Part Name

Qty.

A

B

C

Blade Guard and Spreader ..................

Rip Fence ..............................

Owners Manual ..........................

1

1

1

D

E

Miter Gauge ............................

Arbor Nut Wrench* .......................

F

6

H

J

K

Switch w/Key

...........................

Rip Fence Guide Bar with Rip Scale (Front] ....

Handwheel

.............................

V-Belt 1/2 in. x 41 in.* ....................

Pulley, 2-1/2 in. die., with 5/8 in. bore*

.......

1

1

2

1

1

L

M

N

0

P

Q

R

S

T

U

V

1

3

2

1

1

1

1

1

1

1

1

W

W

W

Belt and Pulley Guard .....................

Belt Guard Clip ..........................

Self-Threading Screw, 10 32 x 1/2 in. long .....

Belt GLard Support .......................

Belt Guard Support Brackel

................

Motor Base .............................

Spreader Rod*

. .........................

Blade Guard Support with Screw*

...........

Spreader Support * .......................

Rip Fence Guide Bar (Rear) ............

....

Ri!c Fence Guide Bar Rod ..................

"Pkg. of Miscellaneous Smell Parts No. 62751

Consisting of the Following:

Setscrew Wrench 3/32 in ................

Setscrew Wrench 1/8 in .................

Setscrew Wrench. 5/32 in ................

X

Y

Y

Y

Y

Y

Self-Threading Nut

....................

Hex Head Screw, 5/16-18 x 1-3/4 in. long ...

Hex Head Screw. 5/16-18 x 5/8 in. t0ng ....

Hex Head Screw, 5/16-18 x 1 in. long ......

Hex Head Screw, 1/4-20 x 5/8 in. 10ng .....

Hex Head Screw, 5/16-18 x 3/4 in. long ......

2

2

3

4

2

2

.

1

1

1

1

1

*These parts are packaged in Loose Parts Bag No. 62750

LENGTH

s=zE

/

AA

AB

L

K

J

Y

X

AC

ItemPart Name

Z

Z

AA

AA

AA

AB

AC

AD

AE

AF

AG

Qty.

Hex Nut, 5/16-18

(approx.die. of hole 5/16 in.) ...........

Hex Nut, 1/4-20

(approx.die. of hole1/4 in.) ............

Lockwasher,5/16 in. ExternalType

(approx.die. of hole 5/18 in.) ...........

Lockwasher,1/4 in. ExternalType

(approx.die. of hole 1/4 in.) ............

LockwasherNo. 10 ExternalType

(approx.dia. of hole3/16 in.) ...........

CarriageBolt, 5/16-18 x 3/4 in. long .......

Rip FenceGuideBarSpacer ..............

Wire Tie ...............................

Thumbscrew, 5/18-18 x 1 in. long ..........

ScrewPanHd. 10-32 x 3/4 ..............

Flat Washer(die. of hole 21/64) ...........

A

9

2

11

2

1

4

2

2

1

1

2

Leg ...................................

Side Stiffener ...........................

End Stiffener ............................

Table Extension ...................

Motor .................................

4

2

2

2

1

G

H

H

H

J

Hex Head_crew 5/16-18 x 1-I/4 in. long ....

Loekwasher,1/4 in. ExternalType

(approx.dia.of hole 1/4 in.) ..............

Lockwasher,5/16 in. ExternalType

(approx. die. of hole 5/t6 in.) ............

Hex Nut, I/4-20

(approx. dia. of hole 1/4 in.) .............

Hex Nut, 5/16-18

(approx.die. of hole5/16 in.) .............

Hex Nut, 1/2-13

(approx.die. of hole 1/2 in.) .............

Flat Washer(die. of hole, 11/32 in.) .........

The Hold Down is included with Model 113.298240

only.

L

M

N

Qty.

K

Truss Head Screw, 1/4-20

L

(top of screw is rounded) ................

Leveling Foot

.........................

x 5/8 in. long

2 ea. for Model 113.298032

8., 113.298240

Consisting of the following:

Hex Hd. Screw, 5/16-18 x 1-1/4 in. long .....

Lockwasher, External Type

(approx. die. of hole 1/4 in.)

'

Loekwasher, External Type

(approx. die. of hole 5/1G in.) .............

Hex Nut, 1/4-20

(approx. die. of hole 1/4 in.) ..............

Hex Nut, 5/16 18

(approx. dia. of hole 5/16 in.) .............

24

H

4

H

24

J

J

Flat Washer (die. of hole 17/64 in.)

Flat Washer (die. of hole 11/32 in.)

4

K

8

8

M

N

Truss Head Screw, 1/4-20 x 1 in. long

(top of screw is rounded)

................

Corner Stiffener Bracket ..................

Corner Support Bracket ..................

Qty.

I

2

2

D

Support

1

24

4

Pkg. of Miscellaneous Small Parts No. 62745 for

Table Extensions.

G

Clamp Assembly ..........................

Wing Screw .............................

Washer .................................

............................

K

H

4

A

B

C

Rod

J

F

G

Pkg.of Miscellaneous

Small Parts No. 62752

for Legs

F

G

G

Item Part Name

The following parts are includedwith Model 113,298032

and 113.298240.

A

B

C

D

E

©

_"_D

.........

.........

4

8

4

8

4

2

4

8

2

2

ASSEMBLY

Before mounting

the saw on legs, a stand or a bench, the

Table Insert and Blade Squareness must be checked

at this

time.

LOC:KWASHER

INSTALLING

1.

HANDWHEE

/

LS

Line up FLAT SPOTS on shaft and handwheel,

push

handwheel

onto shaft. Install screw and Iockwasher

to

lock handwheel

on shaft.

ELEVATION

HANDWHEEL

CHECKING

2.

TABLE

INSERT

Insert should be flush with table top. Check as shown.

Loosen flat head screw tha_ holds insert and adjust the

four set screws as necessary. Tighten

flat head screw•

Do not tighten screw to the point where it deflects the

insert.

3/32 IN

SETSCREWWRENCH

3.

To remove

insert•

A)

Loosen

Screw

B)

Lift

insert

from

front

end. and pull

toward

front

of

saw,

To replace

insert.

Place insert

into

insert

opening

in table

toward

rear of saw to engage spring clip

keyslot in insert will drop over screw. Tighten

Do not tighten

the insert.

CHECKING

screw

to the point

where

CHECKING

IMPORTANT:

it will

deflect

BLADE SQUARENESS TO TABLE

IMPORTANT:

I_LADE must be _QUARE

in order to proceed with assembly.

To check for

SQUARENESS

page 32.

and push

and until

screw.

(90 O) to TABLE,

blade squareness, refer to "BLADE

TILT,

OF BLADE

TO TABLE"

adjustment

BLADE

FOR

OR

on

HEEL

Saw blade MUST

be parallel

to miter

gauge

groove.

To

check

for

parallelism,

refer

to

"HEELING

ADJUSTMENT

OR PARALLELISM

OF SAVBLADE

TO

MITER GAUGE GROOVE"

adjustment on page 31 and 32.

TILT

10-32 X 3/4 IN.

PAN HEAD SCP_W

/

rtANDWHEEL

ASSEMBLING

STEEL LEGS

NOTE:

Steel Legs are furnished

and 113.298240.

From among

following

Hardware:

24 Truss Head Screws,

screw is rounded)

24 Lockwashers,

hale 1/4 in.)

24 Hex Nuts,

8 Hex Nuts,

4 Leveling

Assemble

1.

2.

1/4 - 20 x 5/8

in. long

(top of

(approx.

dia. of

SIDE STIFFENER

1/4 in. External

1/4 - 20 (approx.

1/2 - 13 (approx.

Type

dia. of hole

dia. of hole

I/4

in.)

1/2 in.)

feet.

the legs as shown

...

Insert the Truss Head Screws through

the holes in the

legs, then through

the holes in the stiffeners.

MAKE

SURE THE SCREWS GO THROUGH

THE HOLES IN

THE SIDE STIFFENERS

MARKED

"X "°.

Install

the

not tighten

3.

wLth Model

113.298032

the loose parts, find the

Install

Iockwashers

until

leveling

...

completely

screw

on the

nuts

but

END

STIFFENER"

do

assembled.

feet.

IN.

MOUNTING

1.

SAW

From

among

hardware:

the

4 Hex Head Screws,

loose

5/16

parts,

find

- 18 x 1-1/4

the

following

in. long.

4 Hex Nuts, 5/16 - 18 (approx. dia. of hole 5/16

4 Lockwashers,

5/16 in. External Type (approx.

hole, 5/16 in.)

8 Flat Washers, (dia. of hole 11/32 in.)

2.

3.

Place saw on legs so that

with holes in top of legs.

Instatl

HEX NUTS

screws,

washers,

holes in bottom

Iockwashers

of saw line up

and nuts as shown.

SAW BASE

HEX

H A0

SCREW

FLAT

END

in.)

dia. of

[

7/]6

1

i

_E_

"

FLAT WASHER----__

LOCKWASHER "I'"_'

HEX N UT '_"_'_U_

STIFFENER-"-_1

1

If you mount the saw on any other bench, make sure that

there is an opening in the top of the benc h the same size as

the opening

in the bottom

of the saw so that the sawdust

can drop through.

Recommended

working

height is 33 to

37 inches from the top of the saw table to the floor.

DIA

HOLES

ATTACHING

AND

ASSEMBLING

TABLE

If you

received

Table

them at this time.

Extensions

1.

loose

From

among

hardware.

the

Support

Stiffener

with_ou,r

parts

find

4

4

Corner

Corner

16

16

16

8

8

8

Truss Hd. Screws 1/4-20 x 1

Ext. Lockwashers

1/4

Hex Nut I/4-20

Hex Hd. Screws 5/16-18x

1-1/4

Ext. Lockwasher

5/16

Hex Nut5/16-18

Flat Washers

(Dia. of hole 17/64)

8

Flat Washers

(Dia.

brackets

ONS

Saw attach

the

following

Brackets

Brackets

4

Assemble

i:XTENS

with

of hole 11/32)

hardware

as listed.

Insert 5/16-18

x 1-1/4

in. long screws through

holes in

EXTENSION

then

through

table.

Install

flat

washer,

Iockwashers,

and screw

on the nuts . . . DO NOT

TIGHTEN.

Align

Pull

front edge of extension

Extension

UPWARDS

SLIGHTLY

TIGHTEN

BLOCK OF WOOC

\

with front edge of saw table.

above table

surface

...

SCREWS

using

1/2 in. wrench.

Using small block of hardwood

and hammer, tap extension

DOWNWARDS

at front,

center & rear, until it is EVEN

with table surface ... TIGHTEN

SCREWS.

Lay

REAR

FENCE

straightedge.

If outer

than table surface;

GUIDE

BAR

on table to

edge of extension

is higher

holding

bracket

act as a

or lower

A.

Slightly

loosen nuts

using 7/16 in. wrench.

to extension

B.

Move end of extension

u _ or down until outer edge

is even with

table surface

...

check with GUIDE

BAR

... tighten nuts.

C.

Recheck

INNER

edge of extension

to make

has not moved

... readjust, if necessary.

sure it

\

INSTALLING

BOX

RIP FENCE GUIDE

From

among

hardware:

the

loose

parts

\

BARS AND SWITCH

find

the

following

2 Hex. Head Screws, 5/16-18 x 1-3/4 in. long

2 Hex. Head Screws, 5/16-18 x 1 in. long

2 Hex. Head Screws 5/1&18

x 3/4 in. Ion_

6 External

Lockwashers,

5/16 in.

(approx. dia. of hole 5/16 in.)

6

2

2

2

1

Hex. Nuts, 5/16-18

(approx. dia. of hole 5/16

Flat washers (dia. of hole 21/64 in.)

Spacers, 3/4 in. dia. x 1/2 in. long

Self-threading

nuts

Fence Guide Bar Rod

Lay guide

in.)

/

/

bars on saw table.

1-3/4

NOTE:

The various holes in the bar allow them to be

positioned

on this saw and also makes them adaptable

to other models.

3.

inch

long

screw

through

the

SEVENTH

hole

in

bar. Insert two 3/4 inch long screws through

two flat

washers,

through

holes in switch,

and then through

holes EIGHT

and TEN in bar. Instal

two Iockwashers

and nuts then tighten.

Insert a 1-3/4 inch tong screw through the THIRD

hole

from

LEFT

IN THE FRONT

BAR ...

Insert another

4.

10

Place spacers on screws.

Insertboltsthroughholesin

front

of

saw

table

...

middle and on right side of

install

Iockwashers

and nuts.

DON'T

SCREW

NUTS

ON

them started on the screws.

6.

7.

Remove

the 3 screws from

ALL

THE

rear of table

WAY,

just

extension.

Insert 1 in. long screws in SECOND and FOURTH

of rear bar and attach to table the same way.

Insert

round

ends of FENCE

GUIDE

holes at outer end of bars.

BAR

get

ROD

holes

through

NOTE: The ends of the ROD are not threaded

... the

SELF THREADING

NUTS will cut threads on the rod

as they

9.

Hold

are screwed

rod with

pliers start

OR TWO...

10.

Using TWO

the nuts.

on.

one hand

and with

a 1/2 in. wrench

or

screwing on ONE of the nuts only A TURN

screw on other nut the same way.

1/2

in. wrenches

11, Slide the bars so that

slotted holes.

screws

12. Position

rip fence over miter

the rear end while

engaging

lower fence onto table.

or pliers

tighten

are in the MIDDLE

both

of

of the

gauge groove, holding

front

end with

bar

up

...

11

8 THICKNESSES

OF PAPER

13, Raise blade all the way up,

14. Carefully

move fence against

15. Move

front

approximately

blade.

bar

until

"'0"" mark

inline with indicator.

on

rip

scale

is

16. Move FRONT

bar upwards until fence is approximately

1/32 in. above table

...

tighten

screw at left end of

bar.

NOTE:

Fold a piece of newspaper making 8 thicknesses

and place between rip fence and table to act as a spacer.

This will hold the fence off of the table approx.

1/32

in.

17. Adjust

rear bar so that the fence is approximately

in. above table make sure it is square with fence

bar rod ... tighten screw at end of bar.

18. Replace

screws

in rear of

top surface of extension

of rear guide bar.

table

extension

is PARALLEL

. ..

to top

1/32

guide

be sure

surface

8 THICKNESSES

OF PAPER

19. Move fence to RIGHT edge of table ...

approx.

1/32 in. above table at front

tighten screws,

ALIGNING

make sure it is

and rear and

RIP FENCE

The fence should slide easily along the

remain

in alignment

(parallel to sawblade

grooves),

bars and always

and miter gauge

The alignment

is maintained

by a spring underneath

fence which bears against the front guide bar.

To move the fence, loosen the

fence with one hand at the front.

lock

handle

the

and grasp the

12

For very close adjustments, grasp the guide bar with both

hands and move the fence with your thumbs,

Place fence on saw but DO NOT

LOCK

IT.

Move the REAR

END of the fence slightly

to the right or

left

...

when you release it, the fence should "spring"

back to its original position.

If it does not, the spring

1. Loosen the screws.

pressure

2.

toward

Move Spring

slightly

If the fence does not slide easily

of the spring can be REDUCED.

1.

Loosen

2.

Move

must be INCREASED.

front

of fence.

along the bars, the pressure

the screws.

spring

slightly

SPRING

toward

rear

of

fence

...

tighten

3crew3.

5CR_WS

13

SCREWS

The rip fence must be PARALLEL

with

(see page 31) ana miter Gauge grooves..

until

it is along side of groove. Do NOT

should be parallel to groove. If it is not;

3,

Loosen

B.

Hold fence head tightly

aga=nst bar . . move end

of fence so that it is parallel with groove.

C.

Alternately

1. Turn

"'Hex.

FENCE HEAD

A.

ADJUSTING

the two

the sawblade

Move fence

LOCK IT. !t

tighten

Head Screws."

the screws.

RIP SCALE INDICATOR

ELEVATION

HANDWHEEL

TABLE,

in order

to ALIGN

clockwise

\

until

LOCK HANDLE

blade is up as high as it will go.

IMPORTANT:

BLADE

must

be SQUARE

{90 °)

to

rip fence.

2.

Using a rule, position

fence on right side of sawblade 2

in. from tt_e sides of the teeth..,

tighten

lock handle.

3.

Loosen screw holding the indicator..,

adjust so that

points to "2" on the rip scale..,

tighten screw.

it

NOTE:

If you cannot adjust indicator

so that it points

to "2",

loosen the screws holding

the front guide bar

and move the guide bar.

INSTALLING

1.

From among

BLADE

GUARD

the loose parts, find

2 Hex Head Screws,

1/4 - 20x

2 Hex Head Screws,

5/16-

5/8

18x

in. long

5/8in.

......

long

2 Hex Head ScrewS, 5/1618 x 1 in. long

2 Hex Nuts, I/4 - 20

(approx. dia. of hole 1/4 in.)

2 Lockwashers,

1/4 in. External

(approx. dia. of hole 1/4 in.)

2 Lockwashers, 5/16 in. External

(approx. dia. of hole 5/16 in,)

1 Thumbscrew

Guard Support

Spreader

Support

Spreader

Rod

GUARD SUPPORT

5/]6_18

Type

HEX

SCREW

Type

.........

5/16-18

X 1' IN.

HEX HD. SCREW

2,

Lower

the blade ..........

3.

Screw the two MOTOR

way into cradle.

4.

Attach

screws.

GUARD

X

BASE

SUPPORT...

CLAMP

DO

SCREWS

NOT

part

TIGHTEN

14

THUMB SCREW

SPREADER

5o

Insert

until

it.

SPREADER

pin fits into

ROD

notch.

int0SPREADER

Insert

SUPPORT

Thumbscrew

X

ROD

\

and tighten

FLAT

SURFACE

SPREADER

SUPPORT

SUPPORT)

_,

(INTO

_,

U

6.

7.

Slide SPREADER

ROD into

left

end of ROD

extends

GUARD

SUPPORT

approximately

1/4

until

inch

beyond

edge of SUPPORT

Screw in SUPPORT.

..,

Head

Attach

screws

SPREADER

to SPREADER

up

Hex

SUPPORT

are all the way back in the SLOTS

•. • tighten

8.

Snug

1/4-20

HEX

HD. SCREW

1/4 IN.

LOCKWASHER

1/4-20

HEX NUT

so that

of SUPPORT

screws.

Raise ANTIKICKBACK

PAWLS

(hold in place with a

setscrew

wrench

see below)..,

align

spreader

SQUARE

to _able (be sure insert is properly

adjusted).

NOTE:

"true"

The framing

(or combination)

square

see start of "assembly

and alignment"

on page 6 for checking

•..

Tighten

both

END OF ROD

1/4 INCH

TO LEFT

OF EDGE OF

must be

section

method.

5/16-18

SUPPORT

x 1 in. HEX

HEAD

SCREWS.

GUARD

SUPPORT

SCREWS ALL

WAY

9.

Raise blade

with table.

all the

way

up

...

make

sure it is square

10. Raise Blade Guard ...

lift up both ANTIKICKBACK

PAWLS ... insert one of the SETSCREW

WRENCHES

in the notches

11. Lay blade

blade.

12. Loosen

to hold the pawls

of square

Hex

Head

move spreader

so

• . . tighten screw.

or other

Screw

that

out of the way.

straightedge

in GUARD

it

touches

alongside

SUPPORT

blade

of

of

and

square

13. NOTE:

The spreader is now square with the table and

apDroximate!v

in line with the sawblade. The spreader

requires

further

adjustment

to align it PARALLEL

to

the blade and in the MIDDLE

of the cul: (KERF)

made

by the sawblade.

15

THE

BACK IN SLOTS

IN SUPPORT

HEX

HD.

XIlN.

SCREWS

I

I

SPACE

EQUAL

TOAPPROX.

3 THICKNESSES

OF PAPER

KERF

WOOD

14,IMPORTANT:The SPREADER

mustalwaysbe

PARALLEL

tothesawblade

andintheMIDDLE

ofthe

cut(KERF)made

bythesawblade.

NOTE:Thespreader

is thinnerthanthewidthof the

KERFbyapproximately

sixthicknesses

of paper.

BLADE

/

SPREADER

SPACE EQUAL

TO APPROX.

3 THICKNESSES

OF PAPER

LOOKING

DOWN

ON

SAW

15. Make two folds in a small piece (6 x 6 in.) of ordinary

NEWSPAPER

making three thicknesses,

The folded

paper will

be used as a "'spacing

gauge".

FOLDED

16. Place RIP FENCE

on table

PAPER

...

CAREFULLY

move it against blade so that it is parallel

to the blade, and just TOUCHES

tips of saw teeth . .

tighten RIP FENCE LOCK KNOB HANDLE.

17. Insert

foldea

paper

between

FENCE..,hold

spreader flat

screws using 7/16 in wrench

Screws in Support.

18. To remove BLADE

THUMBSCREW...

SC R EWS.

GUARD

DO

MOUNTING

NOTE:

Motor

113.298240.

i_ included

SPREADER

against

Now

AND

NOT

fence

tighten

SPREADER,

LOOSEN

and

..tighten

Hex Hd.

7/16

loosen

OTHER

N.

WRENCH

\

THE MOTOR

with

Model

113.296032

and

KEY

/

CHECK

MOTOR

ROTATION

1.

The motor must rotate

the 5/8 in. shaft.

CLOCKWISE

2.

MAKE

IS REMOVED

3,

Place the motor

4.

Plug the cord into a prcperly

grounded

outlet

ISee

"Motor

Specifications

and Electrical

Requirements"

Section)

Notice

the rotation

of the shaft, If it is not

turning

CLOCKWISE,

REMOVE

the plug from

the

outlet, and change the rotation

of the motor according

to the instructions

furnished

with the motor,

'SURE

"KEY"

on your

workbench

when viewed from

FROM

SHAFT.

or 3n the floor.

5/8

DIA.

IN.

qON

SHAFT

WARNING: FOR YOUR OWN SAFETY, MAKE SURE

PLUG IS NOT CONNECTED

TO POWER SOURCE

OUTLET WHEN CHANGING MOTOR ROTATION.

16

5. Fromamongthe looseparts,find the following

hardware:

4 Carriage

Bolts,5/16-18x 3/4in.long

4 Hex.Nuts,5/16-18

(approx,

dia.ofhole5/16in.)

4 Lockwashers,

5/16in,External

Type

(approx.

dia.ofhole5/16in.)

6. Place

motoronMOTOR

BASE... insertboltsthrough

holesin base... then throughthemotor.Install

Iockwashers,

andnuts.

7. Positionmotorso thatedgeof MOTORFOOTand

MOTOR

BASEareeven.,,slidemotorallthewayto

theRIGHT,..tightenthefournuts.

8. Loosenset screwin motorpulleyusing5/32 in.

setscrew

wrench.

SlidepulleyonshaftwithHUBaway

frommotor.DONOTTIGHTEN

SETSCREW.

9.

10.

LOCKWASHER

._/16 IN.

5/16-]8

NUT

SHAFT

GUARD

THESE 1WO

EDGES

motor

into

HOLES

and

insert

in cradle

the

...

TWO

PINS

push motor

on motor

CARRIAGE BOLT

5/16-1_ X 3/4 iN.

!}

',i ./

BASE

MOTOR

MOUNTING

BASE

ULLEY

KEY

Install 3/16"

in. square key (furnished

with motor)

in

grooves in pulley and motor shaft. DO NOT TIGHTEN

S ETSC R EW.

Lift

EVEN

base

in as far as it will

go.

11.

Lower

pulley.

the blade..

12.

Sight

along

,install

edges

of

be:t on saw pulley

both

pulleys

arid

and motor

move

motor

pulley

so that belt is parallel

to the edges of both

pulleys..

,tighten the setscrew in the motor pulley.

13.

IMPORTANT:

Measure

the distance

from

shaft to pulley...mark

this dimension

down;

need it later when reinstalling

the pulley.

14.

15.

Make

up.

sure

blade

is g0 ° to table..

EDGE OF WASHE_

EVEN WITH END

OF SLOT

end of motor

you

will

,raise it all the way

CLAMP

Lift motor until edge of washer is even with end of slot

...

tighten

pivot screw. In this position,

pull motor

toward

you (pins will slide out of cradle) until belt is

TIGHT

...

tighten

the two MOTOR

BASE CLAMP

SCREWS.

16.

Loosen

17.

Lower

Pivot Screw

slightly,

the saw blade all the way down.

18. IMPORTANT:

Motor should

blade is lowered.

If it does

SCREW some more.

pivot freely downward

as

not, LOOSEN

the PIVOT

PIVOT

MOTOR

19. Pivot screw must be adjusted only tight enough to allow

motor to pivot FREELY

as blade is raised or lowered.

This will maintain

constant

tension on belt.

PULLEY

CAPACITOR

COVER

20. Loosen

the two MOTOR

CLAMP

SCREWS on each

end

of

motor.

Rotate

the

motor

so that

the

CAPACITOR

COVER

is on top..,

tighten the screws.

The ventilation

holes are now facing downward

which

will help prevent sawdust from entering motor.

VENTILATION

HOLES

17

MOTOR

CLAMP SCREW

(BOTH ENDS)

SCREW

BASE

SCREWS

TWO HOLES CLOSEST

TOGETHER

INSTALLING

1.

Remove

2.

Screws furnished

screw

them into

the belt and motor

BRACKET.

3.

Position

BELT

screws

BELT GUARD

then

BELT

/

BELT GUARD

SUPPORT BRACKET

pulley.

%

with guard are "self threading"

holes iN BELT

GUARD

SUPPO'R'T

remove

SCREW

\

BELT GUARD SUPPORT

them

GUARD

SUPPORT

BRACKET

and

GUARD

SUPPORT

as shown

and install

...

make sure motor

shaft is in CENTER

the

of

BELT GUARD

f

hole in SUPPORT.

\

PIVOT

SCREW

!

CENTERED

OPENING

Insta

three CLIPS

/furnished

with guard) 90 ° apart

starting

with one cliD at the end of the guard as shown

•.. LONG END of clip facing AWAY from you.

BELT GUARD

\

LONG

5.

Reinstall

motor

aligned the belt.

pulley

the same way

6.

Place belt on SAW" PULLEY

..

through opening in END of guard.

7.

Silo belt over motor

it was when

insert

end

of

you

belt

pulley•

18

END

8°

Press guard

approximately

onto support

so that bottom

3/4 in. away from beFt°

of

guard

is

NOTE:

To remove guard, lift up on LONG TABS of

clips ...

pull guard outward.

The clips should remain

on the BELT GUARD

SUPPORT.

8/4

i

ASSEMBLING

(Included with

HOLD-DOWN

Model 113.298240)

Locate the clamp assembly, support

and two washers in loose parts bag.

Screw the support

gauge head.

rod (I)

tightly

rod, two

into

wing

screws

the hole in the miter

Position the clamp assembly (2) on the

install washers (3) and wing screws (4).

handle

LATCH

and rod...

CLAMP LOCK

NOTE:

The small knob (5) on the clamp screw must not

turn.

Check nut underneath

it ... it must be tight against

the knob. Use a 1/2 inch wrench to tighten it.

PLUGGING

1

IN MOTOR

1.

From

2.

Route motor cord along right side of cabinet and snap

ties in 1/4" hole in side of cabinet. Secure two cords in

wire ties.

among the loose parts, find

3.

Plug motor

cord

into outlet

two

wire

ties

on side of switch

box.

19

IN.

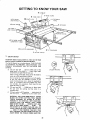

GETTING TO KNOW YOUR SAW

9 SAWBLADE

7

8

MITER

GAUGE

LOCK

HANDLE

6

MITER

|0

BLADE

GUARD

TABLE INSERT

EXACT-I-CUT

ANTIKICKBACK

PAWLS

_

GAUGE

RIP FENCE

RIP FENCE

LOCK HANDLE

4

TILT LOCK HANDLE

(UNDERNEATH TABLE)

2

ELEVATION

HANDWHEEL

3

] ON-OFF

1

TILT

HANDWHEEL

SWITCH

ON-OFF SWITCH

CAUTION:

Before turning switch on, make sure the blade

guard is correctly installed and operating properly.

@

The On-Off Switch has a locking feature. THIS FEATURE

IS INTENDED

TO PREVENT

UNAUTHORIZED

AND

POSSIBLE

HAZARDOUS

USE

BY CHILDREN

AND

OTHERS.

A.

TO

turn

saw

ON

,..

stand

to either

blade never in line with it ...

insert finger

switch lever and pul! END of lever out.

After turning switch ON, always allow

come uo to full speed before cutting.

KEY

side of the

(YELLOW PLASTIC)

under

the blade to

Do not cycle the motor

switch on and off rapidly,

as this may cause the sawblade

to loosen. !n the

event this should ever occur, allow the sawblade to

come to a complete

stop and retighten

the arbor

nut normally,

not excessively.

Never leave the saw

while the power is "'ON".

B.

TO

turn

the saw

complete

C.

saw OFF

until

stop.

TO lock switch

with one han_

the

...

PUSH

cutting

lever in. Never

tool

has

come

KEY

leave

_o

a

in OFF position

... hold switch IN

..

REMOVE

key wtl.h other hand.

WARNING:

FOR YOUR OWN SAFETY, LOWER

BLADE OR OTHER CUTTING TOOL BELOW

TABLE

SURFACE.

(IF BLADE

IS TILTED,

RETURN IT TO VERTICAL

(90 ° ) POSITIONL

ALWAYS

LOCK THE SWITCH "OFF".

WHEN

SAW IS NOT IN USE ... REMOVE KEY AND

KEEP IT IN A SAFE PLACE ... ALSO ... IN

THE EVENT OF A POWER FAILURE (ALL OF

YOUR LIGHTS GO OUT) TURN SWITCH OFF

... LOCK IT AND REMOVE THE KEY. THIS

WILL PREVENT THE SAW FROM STARTING UP

AGAIN WHEN THE POWER COMES BACK ON.

i!!,

2O

2

ELEVATION

blade, Turn

to lower.

HANDWHEEL

. . . elevates or lowers the

clockwise

to elevate ... counterclockwise

TILT

HANDWHEEL

...

tilts

the

cutting.

"_'urn clockwise

to tilt

counterclockwise

to tilt toward

right.

blade

toward

If necessary, the miter gauge head can then

slightly

to compensate

and then locked.

Slots are provided

in the miter gauge for attaching

an

AUXILIARY

FACING

to make it easier to cut long

pieces. Be positive

facing does not interfere

with the

proper operation

of the sawblade guard.

for

bevel

left

...

When the blade is tilted to the LEFT as far as it will go,

it should be at 45 ° to the table and the bevel indicator

should

point

NOTE:

There

Select a suitable piece of smooth straight wood..,

two holes through it and attach it with screws.

TILT

LOCK

are LIMIT

STOPS

inside

the saw which

HANDLE

...

locks

the

blade

in

NOTE:

When bevel crosscutting,

attach facing so that it

extends

to the right of the miter gauge and use the

miter gauge in the groove to the right of the blade.

the

desired tilt position.

To loosen, turn counterclockwise.

Push handie

in and turn

it to another

position

necessary in order to tighten or loosen.

if

IMPORTANT:

Be sure

handle

is hanging

in the

"DOWN"

position

before tilting

blade. If it is pointing

to the 1 o'clock

position

it may jam on underside

of

the table and bend the locking bolt,

RIP FENCE

...

is locked

in place by tightening

lock knob.

To move the fence, loosen the knob

grasp the fence with one hand at the front.

Holes

facing

STO I

7

Select a piece of smooth

straight

wood approx.

3/4"

thick,

at least as long as the rip fence, and at least

7-1/2"

wide (high) to permit clamping

of featherboards.

it

to

the

fence

with

three

Round

Head

the round

#10

BLADEGUARD

must always be in place and working

properly

for

all thru-sawing

cuts. That

is, all cuts

whereby

the blade

cuts

completely

through

the

workpiece.

the

DO

type cut in material

thinner

fence is positioned

over the

8

depressed area of table extension,

the facing should be

attached to the fence so that the bottom

edge touches

the top surface of the extension.

In this case, the facing

must be shorter than the fence. This will prevent thin

material from sliding under the rip fence.

WOOD

AUXILIARY FAC!NG

When replacing

the guard, make sure the PIN in the rod

engages with the NOTCH in the spreader support.

Make

sure thumbscrew

is tightened

securely.

holes.

If you are making a rip

than 3/16 in. while the

_

To remove the guard for special operations,

loosen

thumbscrew

and slide the guard off of the rod.

NOT DISTURB

THE SETTING

OF THE ROD.

Wood Screws 2 in. long. To remove the facing, loosen

the screws, slide the facing forward

and pull the screws

through

_

the

and

are provided

in the rip fence for attaching

a wood

when using the dado head, or molding head.

Attach

drill

45 ° .

prevent the blade from tilting beyond 45 ° to the LEFT

and 90 ° to the RIGHT.

(See "Adjustments"

section

"Blade Tilt, or Squareness of Blade to Table").

4

be swiveled

TABLE

INSERT

blades or other

is removable

cutting

for removing

or installing

tools.

FACING

SCREW

#I0 WOOD

6

WARNING:

FOR

SWITCH

"OFF"

POWER

SOURCE

INSERT.

SCREWS

MITER

GAUGE

...

head is locked

in position

for

crosscutting

or mitering

by tightening

the lock knob.

ALWAYS

LOOK IT SECURELY

WHEN IN USE.

There

are "_wo slots

left

for

right

_lnd

positions

Miter

Gauge to cut miters.

the

for

stop

pin

conveniently

at the 45 degree

setting

the

A.

Lower the blade below

B.

Raise blade guard.

C.

Loosen

D.

Lift

front

NOTE:

The slots for the stop pin and the graduations

are

manufactured

to very

close

tolerances

which

provide

accuracy

for average woodworking,

in some

cases where extreme

accuracy is required, when making

angle cuts, for example,

make a trial cut and then

recheck it.

YOUR

OWN

SAFETY,

TURN

AND

REMOVE

PLUG

FROM

OUTLET

BEFORE

REMOVING

the table surface.

Screw.

insert

from

front

end,

and

pull

toward

of saw.

NEVER

OPERATE

THE

SAW WITHOUT

THE

PROPER INSERT

IN PLACE.

USE THE SAW BLADE

INSERT

WHEN

SAWING

. . . USE

THE

COMBINATION

DADO

MOLDING

INSERT

WHEN

DADOING

OR MOLDING.

21

9

REMOVING

AND INSTALLING

SAWBLADE.

WARNING:

FOR YOUR OWN SAFETY,

TURN

SWITCH

"OFF"

AND REMOVE

PLUG FROM

POWER SOURCE OUTLET BEFORE REMOVING OR

INSTALLING SAWBLADE.

A Raise Blade Guard...remove

insert.

B. To REMOVE blade, olace a block of wood

against front of blade

.. PULL arbor wrench

toward you to LOOSEN arbor nut.

BLADE

GUARD

BLADE

C.

To TIGHTEN

against rear

from you.

Always

tighten

SHOWN

GUARD

NOT

FOR

SHOWN

PICTURE CLARITY

FOR

side of

the arbor

...

make sure the teeth

of the saw ... and that

and free from any burrs.

the

collar

must

are

the

be against

the

Head, it is not

ARBOR

nsert

ooening

n ............

toward

keyslot

rear of saw _o engage spr ng clip

in insert will arop over screw. Tighten

Do not

tighten

screw

to the

point

where

NUT

LOOSE

COLLAR

and until

screw.

it wil

ARBOR

_

deflect

_,-'_

d_

_'_

FRONT OF SAW

lO

CLARITY

nut securely.

NOTE: When usinc; the Dado or Molding

necessary to install the loose collar.

To replace insert.

Place nsert

into

PICTURE

arbor nut, place a block of wood

of blade

...

PUSH wrench away

When installing

the blade

pointing

toward

the front

blade and collars are clean

The HOLLOW

blade.

NOT

/

\

"_\

_ \

A_.BOR NUT

_

EXACT-I-CUT

The "yellow"

plastic disc imbedded

in the table in front

of the sawblade, is provided for marking the location of

the "'sawcut" on the workpiece.

A.

Check disc

...

if it is above table surface, place

piece of hardwood

on top of it and tap it down.

B

With blade 90 ° (square to table)

wood.

C.

Pull miter gauge back until wood is over disc. Using

very sharp pencil, mark a line on disc.

D.

With miter gauge in right hand groove, follow

procedure and mark another line on disc.

E.

These lines indicate the

made by the sawblade.

F.

When

cutting

workpiece

with

"'path"

the workpiece,

line on disc.

a

cut off a piece of

of the

line

up

cut

same

BLADE GUARD NOT SHOWN FOR PICTURE CLARITY

(kerr)

mark

on

22

BASIC SAW OPERATION

WORK HELPERS

Before

"Basic

Notice

cutting

any wood

Saw Operations".

that

in

order

on

to

your

make

AUXI

saw,

some

study

of

the

all

of the

cuts,

it

NOTE:

is

which

FENCE/WOR

Since

Fence,

necessary

to use certain devices "Work

Helpers"

like the

Push Stick,

the Push Block and the Auxiliary

Fence/Work

Support,

LIARY

K SUPPORT

Make one using a piece of 3/8 in. and 3/4

Fasten together with glue and woodscrews.

both

the

the

Push

4-3/4

Block

in, plywood.

is used with

in. dimensions

must

the

be held