Download Coopra 40C Service manual

Transcript

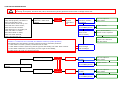

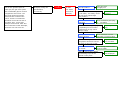

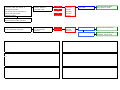

Advanced Heating Technologies b.v. Wall hung, fan flue, room sealed, high efficiency gas boiler TROUBLE SHOOTING MANUAL EN Models: 15B 15C 30B 30C 30K 40C TWIN80C (partly) COOPRA Advanced Heating Technologies b.v. Vierlinghstraat 14 NL 3316 EL, Dordrecht Tel: +31 (0) 78 – 653 08 30 Fax: +31 (0) 78 – 653 08 33 2006 E000129004 Trouble shooting manual EN E000129004 Table of contents 1. Overall information 1.1. 1.2. 1.3. 1.4. 1.5. 1.6. 1.7. 1.8. Overall view……………………………………..………………. 3 Hydraulic diagram Nomenclature……………………………………….………….. 4 Cover removal Emptying the main circuit Emptying the d.h.w. circuit Control panel Condensate trap route…………………………………….. 5 3.12. 1 1 1. 2 2 2. 3 4 4 4. 5 6 7 8 9 9 A A A/C. A/d. A/b. b/r 2. Checks, servicing and replacement of components 2.1. 2.2. 2.3. 2.4. 2.5. 2.6. 2.7. 2.8. 2.9. 2.10. 2.11. 2.12. 2.13. Fan, gas valve and venturi assembly……….…….. 6 Burner……………………………………………………..………… 7 Pump Main circuit pressure sensor……………………..…….. 8 Flow water temperature sensor Return water temperature sensor……………….…. 9 D.h.w. heat exchanger sensor Three-way diverter valve……………………………..….. 10 C.h. pressure relief valve…………………………….…… 12 Electronic control p.c.b. Display Glow plug and ionisation rod…………………………... 13 D.h.w. heat exchanger………………………………….... 13 3. FAULT FINDING 3.1. 3.2. 3.3. 3.4. 3.5. 3.6. 3.7. 3.8. 3.9. 3.10. 3.11. Burner states Pump test (each boiler start) Temperature test (each boiler start) Pump monitoring (during operation) System water pressure monitoring (operation) Stand-by Pre-rinse Ignition In operation Post-rinse Pump afterrun Burner is on Burner is off Display Blocking Lock-out STATUS INDICATIONS All known indications listed: ……………………………….….. flashing ………………………………..…. continuous …..(1+dot) ……...…. continuous …………………...………....… flashing ………………………………..…. continuous …..(2+dot) ……..…. continuous ……………………………………. flashing ……………….…...........…… flashing ………………..……………..…. continuous …..(4+dot) …….….. continuous ……………..…….…………….. flashing ……………..….…………..…… flashing ……………....…..........….. flashing …………….….…………..……. flashing …………….….…………….….. flashing ……….………..…………..…… continuous …..(large A) ……….… flashing …..(large A) ……..…. continuous …..(large A/C+dot) continuous …..(large A/d+dot) continuous …..(large A/b+dot) continuous …..(small b/r)…………..… continuous Chimney sweeper function C …..(large C) …….…… flashing C d b J C C. d. b. c E E F H H h nc O O o o. P P P P/C. P/d. P/b. U 2 …..(large C) …….…… continuous …..(small d) …………. continuous …..(small b) ……...…. continuous …..(large J) …….….. continuous (TWIN) …..(large C) ……...... continuous (5x) …..(large C+dot) continuous …..(small d+dot) continuous …..(small b+dot) continuous …..(small c) ……..….. continuous …..(large E) ……..….. flashing …..(large E) …………. continuous (TWIN) …..(large F) …….…… flashing …..(large H) ……..….. flashing …..(large H) ……..….. continuous …..(small h) ……..….. continuous …..(small nc) ……..….. continuous …..(large O) ……….… flashing …..(large O) ……….… continuous …..(small o) ……….… continuous .....(small o+dot) ………. continuous …..(large P) ……...…. continuous …..(large P+pump test) continuous …..(large P) …………….... continuous (2x) …..(large P/large C+dot) continuous …..(large P/small d+dot) continuous …..(large P/small b+dot) continuous …..(large U) ……….… continuous Trouble shooting manual EN E000129004 Chapter 1: Overall information 1.1. Boiler types 80C, 40C, 30K, 30B, 30C, 15B, 15C Combi boiler 30K TWIN80C 1.2. Hydraulic diagram of Combi boiler Heating operation Hot water operation 3 Trouble shooting manual EN E000129004 1.3. Nomenclature 2. Pull the bottom of the cover until the control panel is completely out of the cover, than lift the cover and free it from the hooks G (fig 4) placed on the top of the boiler. 3. Re-assemble in reverse order. 1 2 4 3 Fig 4 Fig 2 1 2 3 4 1.5. Emptying the main circuit Frame Cover Control panel Control panel cover 1.4. Cover removal 1. Open the c.h. flow and return valves. 2. Open the control valve used for the filling of the c.h. circuit drain cock and drain the boiler. 3. Drain completely the boiler by turning the knob of the fill and relief valve. Warning: isolate the boiler from the mains electricity supply before removing any covering or component. 1.6. Emptying the direct hot water circuit For all the checks and maintenance operations it is necessary to remove the cover. Turn off the d.h.w. inlet isolating valve; turn on the hot water taps and any drain cocks. To remove the cover: 1. Turn the hexagonal nut F (fig 3) counter-clockwise and free the hook from the boiler frame. 1.7. Control panel Warning: isolate the boiler from the mains electricity supply before removing any covering or component. To gain access to the parts located behind the control panel proceed as follows: 1 Remove the cover (section 1.3). 2 Remove the screw H (fig 5) and lower the control panel. Fig 3 Fig 5 3 Service manual E000129004 To gain access to the parts located inside the control panel proceed with steps 1 and 2 than: 3 Remove the screws I (fig 6). 4 Remove the lid J 5 Re-assemble in reverse order. Fig 6 1.8. Condensate trap route The plastic pipe K (fig 7) that connects the condensate collector with the condensate drain pipe has also the function of condensate trap. For this reason, if the pipe K needs to be removed during service operations, it is very important to re-install routing it as shown in figure 7. Fig 7 3 Service manual E000129004 Chapter 2: Checks, servicing and replacement of components 2.1. Fan, gas valve and venturi assembly The function of the fan is to force the mixture of air and gas into the burner. The flow rate of the air-gas mixture and consequently the input power of the boiler is proportional to the speed of the fan that is controlled by the electronic control p.c.b. The venturi assembly A placed on the inlet port of the fan allows the mixing of gas and air in the right proportion. The gas-air ratio can be adjusted by the venturi screw B (fig 8). Fig 9 7 Remove the fan with the venturi assembly and the gas valve. 8 To separate the fan from the venturi assembly and gas valve unscrew the screws I (fig 10). 9 To separate the gas valve from the venturi assembly unscrew the screws J. 10 Re-assemble the parts following the removal procedures in the reverse order. Replacing the parts replace also the gaskets that ensure the gas circuit tightness. If the venturi assembly has been replaced, before to start the boiler ensure that the venturi screw B (Fig. 8) is completely tighten (clockwise) than carry out a complete adjustment as explained in the installation manual. Warning: After cleaning or replacement as detailed above refer to section Combustion adjustment check in the chapter Commissioning of the installation instructions manual. Fig 8 F Removal of the assembly Warning: isolate the boiler from the mains electricity supply before removing any covering or component. 1 Remove the cover (section 1.4. 2 Close the gas inlet valve. 3 Lower the control panel (section 1.7). 4 Disconnect the wirings from the fan C and gas valve D (fig 9). 5 Unscrew the Allen key screws E and separate the gas connection F from the gas valve. 6 Unscrew the Allen key screws G and the bracket H. Fig. 10 4 Service manual E000129004 2.2. Burner F Removal of internal turbulators To remove the turbulators placed inside the burner remove the burner as explained in the previous section and unscrew the screw E (Fig. 13). F Removal of the burner assembly Warning: isolate the boiler from the mains electricity supply before removing any covering or component. E 1 2 1 Remove the cover (section 1.4 2 Close the gas inlet gas cock. 3 Remove the fan, gas valve and venturi assembly (section 2.1). 4 Remove the condensate connection pipe A (Fig. 11). 5 Unscrew the five Allen key screws B and lower the condensate collector C that holds the burner. 6 To remove the burner from the condensate collector unscrew the Allen Key screws D (Fig. 12). 7 Re- assemble the parts following the removal procedures in the reverse order. 4 6 8 Fig 13 Follow the indications given in Fig. 13 and Fig. 14 to reassemble correctly the turbulators. 9 8 7 6 5 4 3 2 1 E Fig 14 The disk 6 is thinner than the disk 1. All the spacers (3, 5, 7 and 9 in Fig. 14) have the same length. Fig. 11 Warning: After cleaning or replacement as detailed above refer to section Combustion adjustment check in the chapter Commissioning of the installation instructions manual. 2.3. Pump The pump has the function of making the water in the main circuit circulate through the main heat exchanger and therefore through the c.h. system (during the c.h. function) or through the d.h.w. heat exchanger (during the d.h.w. function). F Removal 1 Warning: isolate the boiler from the mains electricity supply before removing any covering or component. 1 Remove the cover (section 1.4) 2 Empty the main circuit (section 1.5) 3 Lower the control panel (section 1.7) 4 Disconnect the connector A (Fig. 15). 5 Unscrew the Allen screws B and remove the pump. 6 Re- assemble the parts following the removal procedures in the reverse order. Fig 12 5 Service manual E000129004 2.5. Flow water temperature sensor The flow temperature sensor has the function of converting the temperature of the water flowing in the outlet pipe of the main heat exchanger into an electric signal (resistance). F Check Warning: isolate the boiler from the mains electricity supply before removing any covering or component. 1 Remove the cover (section 1.4). 2 Disconnect the connectors A (Fig. 17). 3 Measure the resistance between the leads of the sensor. At a normal temperature of 25 °C the resistance should be about 12 kOhm. Fig. 15 F Removal Warning: isolate the boiler from the mains electricity supply before removing any covering or component. 2.4. Main circuit pressure sensor The main circuit pressure sensor is connected to the outlet port of the pump and translates the pressure of the main circuit to an electrical signal. 1 Remove the cover (section 1.4). 2 Disconnect the connectors A (Fig. 17). 3 Remove the temperature sensor 4 Re-assemble the sensor following the removal procedures in the reverse order. F Removal Warning: isolate the boiler from the mains electricity supply before removing any covering or component. 1 Remove the cover (section 1.4) 2 Empty the main circuit (section 1.5 3 Lower the control panel (section 1.7 4 Disconnect the connector A (Fig. 16). 5 Unscrew the sensor B. 6 Re-assemble the parts following the removal procedures in the reverse order. Fig. 17 Fig. 16 6 Service manual E000129004 2.6. Return water temperature sensor The return temperature sensor has the function of converting the temperature of the water flowing in the inlet pipe of the main heat exchanger into an electric signal (resistance). 2.7. D.h.w. heat exchanger temperature sensor The d.h.w. heat exchanger temperature sensor is placed in the domestic cold water inlet pipe of the exchanger. It has two functions: 1 when there is no d.h.w. draw off it senses the temperature of the exchanger and operates the boiler in order to keep the water at the desired temperature (d.h.w. hold temperature). 2 when there is d.h.w. draw off it senses the temperature change of the exchanger and operates the boiler in d.h.w. mode. F Check Warning: isolate the boiler from the mains electricity supply before removing any covering or component. 1 Remove the cover (section 1.4). 2 Disconnect the connector A (Fig. 18). 3 Measure the resistance between the leads of the sensor. At a normal temperature of 25 °C the resistance should be about 12 kOhm. F Removal Warning: isolate the boiler from the mains electricity supply before removing any covering or component. The sensor is not in direct contact with the water so it isn’t necessary to empty the d.h.w. circuit. 1 Remove the cover (section 1.4) 2 Unscrew the screws A and move away the plate B (Fig. 19). F Removal Warning: isolate the boiler from the mains electricity supply before removing any covering or component. 1 Remove the cover (section 1.4). 2 Empty the main circuit (section 1.5) 3 Lower the control panel (section 1.7) 4 Disconnect the connector A (Fig. 18). 5 Unscrew and remove the temperature sensor. 6 Re-assemble the sensor following the removal procedures in the reverse order. 3 Disconnect the sensor from the control panel wiring. 4 Remove the holder spring C (Fig. 20) and extract the sensor. 5 Re-assemble the sensor following the removal procedures in the reverse order. Fig. 18 Fig. 20 Re-assembling the sensor use an adequate quantity of thermal conductive grease and insert the sensor in the jacket until it reaches the top. 7 Service manual E000129004 2.8. Three-way diverter valve The three-way valve has the function of modifying the hydraulic circuit of the boiler by means of an electric command given by the electronic control p.c.b. in order to send the water that comes from the c.h. system or from the d.h.w. heat exchanger towards the pump and the main heat exchanger. Heating position Hot water position 30K Fig. 23 If the valve is complete the resistance measured will be approx. 8 kOhm. Fig. 21 On the motor body an indicator is visible with which it is possible to know the position of the diverter valve. F Removal of the motor Warning: isolate the boiler from the mains electricity supply before removing any covering or component. Fig. 21 and Fig. 22 indicate the relationship between the positions of the indicator A and the consequent hydraulic function. 1 Remove the cover (section 1.4). 2 Release the electrical connector from the motor body. 3 Press the push-button B placed in the rear side of the motor body (Fig. 24) and rotate the motor anti-clockwise, releasing it from the hydraulic group. 30K 30K Fig. 22 F Check of electrical completeness Fig. 24 Warning: isolate the boiler from the mains electricity supply before removing any covering or component. 4 Reassemble the motor carrying out the removal operations in reverse order. Fig. 23 demonstrates the relationship between the position of the indicator and the electrical resistance of the motor. 8 Service manual E000129004 F Check the diverter mechanism Warning: isolate the boiler from the mains electricity supply before removing any covering or component. 1 Remove the cover (section 1.4) and remove the three way valve motor (see section Removal of the motor). 2 Push the stem of the diverter mechanism (Fig. 25) checking that there are no mechanical impediments. Type 30K coopra Fig. 26 7 Remove the motor (see section Removal of the motor). 8 Disconnect the pipe I and remove the automatic air vent J (Fig. 27). 9 Remove the pin K and remove the valve body L. 10 Re-assemble the parts carrying out the removal operations in reverse order. Fig. 25 F Removal of the diverter mechanism Warning: isolate the boiler from the mains electricity supply before removing any covering or component. 1 Remove the cover (section 1.4) and remove the motor (see section Removal of the motor). 2 Empty the main circuit (section 1.5) 3 Unscrew the diverter mechanism D (Fig. 25) by means of the tool provided with the spare part and replace. 4 Re-assemble the mechanism carrying out the removal operations in reverse order. Fig. 27 F Removal of the three way valve body Warning: isolate the boiler from the mains electricity supply before removing any covering or component. 1 Remove the cover (section 1.4). 2 Empty the main circuit (section 1.5) 3 Lower the control panel (section 1.7) 4 Disconnect the wirings of the diverter valve, pump, return water temperature sensor and main circuit pressure sensor. 5 Disconnect the pipe E (fig 26). 6 Completely unscrew the connections F, G and H (Fig. 26) and remove the complete hydraulic group. 9 Service manual E000129004 2.9. C.h. pressure relief valve F Removal F Removal Warning: isolate the boiler from the mains electricity supply before removing any covering or component. Warning: isolate the boiler from the mains electricity supply before removing any covering or component. 1 Remove the cover (section 1.4). 2 Lower the control panel (section 1.7) 3 Disconnect all the wirings connected to the p.c.b. 4 Unscrew the screws A (Fig. 29) and remove the electronic control p.c.b. 5 Re-assemble the electronic control p.c.b. carrying out the removal operations in reverse order. 1 Remove the cover (section 1.4). 2 Empty the main circuit (section 1.5) 3 Lower the control panel (section 1.7) 4 By means of a suitable spanner unscrew and remove the valve A (Fig. 28). 5 Re-assemble the sensor following the removal procedures in the reverse order. Fig. 29 2.11. Display p.c.b. Fig. 28 F Removal Warning: isolate the boiler from the mains electricity supply before removing any covering or component. 2.10. Electronic control p.c.b. The fundamental function of the electronic control p.c.b. is that of controlling the boiler in relation to the external needs (i.e. heating the dwelling or heating the water for d.h.w. use) and operating in order to keep the room temperature and the domestic hot water to the desired value. 1 Remove the cover (section 1.4). 2 Lower and open the control panel (section 1.7). 3 Remove the electronic control p.c.b. as explained in the section 2.10 4 Unscrew the screws A (Fig. 30) and remove the display p.c.b. 5 Re-assemble the display p.c.b. carrying out the removal operations in reverse order. This is obviously possible within the useful power and maximum working temperature limits foreseen. The electronic control p.c.b. does also a sequence of operations (ignition cycle) which lead to the ignition of the gas at the burner and checks the presence of the flame during the entire period in which it is activated Generally, the electronic control p.c.b. receives inlet information coming from the boiler (the sensors) or from the outside (user settings, room thermostat, etc.), processes it and consequently acts with outlet commands on other components of the boiler. Fig. 30 10 Service manual E000129004 2.12. Glow plug and ionisation rod F Removal Warning: isolate the boiler from the mains electricity supply before removing any covering or component. 1 Remove the cover (section 1.4). 2 Disconnect the connector A (glow plug) or B (ionisation rod) (Fig. 31). 3 To remove the glow plug unscrew the screw C. 4 To remove the ionisation rod unscrew the screws D. 5 Re-assemble the component carrying out the removal operations in reverse order. Fig. 32 7 Lower the control panel (section 1.7). 8 Disconnect the wirings of the diverter valve, pump, return water temperature sensor and main circuit pressure sensor. 9 Disconnect the pipe D (Fig. 33). 10 Completely unscrew the connections E, F and G (Fig. 33) and remove the complete hydraulic group. 11 Unscrew and remove the automatic air vent H. Fig. 31 2.13. D.h.w. heat exchanger Type 30K During a d.h.w. draw off the d.h.w heat exchanger allows the instantaneous transfer of heat from the main circuit to the water destined for d.h.w use. When there is no draw off, the exchanger works as a small d.h.w. tank and it is kept at the desired temperature (d.h.w. hold temperature) by means of the electronic control system. F Removal Warning: isolate the boiler from the mains electricity supply before removing any covering or component. Fig. 33 1 Remove the cover (section 1.4). 2 Empty the main circuit (section 1.5) 3 Empty the d.h.w. circuit (section 1.6) 4 Unscrew the screws A and move away the plate B (Fig. 32). 5 Remove the d.h.w. heat exchanger temperature sensor (section 2.7). 6 Unscrew the inlet and outlet domestic water connections C. 12 Move the lower part of the exchanger towards the front of the boiler and lower it until its top is free from the frame of the boiler. 13 Move the top of the exchanger towards the front of the boiler, lift and remove it. 14 Re-assemble the exchanger and the other parts carrying out the removal operations in reverse order. 11 Chapter 3: FAULT FINDING Burner state stand-by pre-rinse/pre-heat glowpluignition in operation 0 sec 12 sec post-rinse pump afterrun stand-by heat demand fan gas valve glow plug ionisation pump 3 sec 7 sec 22 sec end of heat demand 0 sec 6 sec Pump test program (each boiler start) At each new heat demand the pump is switched, the pre-rinse starts, the glowplug pre-heats, and the static water pressure is measured. After 3 seconds the pump is switched to high speed and the active water pressure is measured and stored in the software. If the difference between the active water pressure and the static water pressure is between 0.05 and 0.54 bar (0.64 bar for type 40 and TWIN) a correct water flow through the primary heat exchanger is present and the ignition time starts. 22 sec Temperature test (each boiler start) After ignition the water flow through the heat exchanger is secured by a temperature test of flow / return sensor. The temperature rise between flow sensor and return sensor must rise more than 3°C within 10 seconds. If so the regulation is released. 12 sec end of heat demand Pressure monitoring (during operation) If the system water pressure changes by more than ± 0.1 bar ( and ± 0,3 bar with changing pump speed) within 4 seconds, the regulation blocks and switches over to the pump test program, with a continuous P on the status display. 12 sec Pump speed regulation (high/low during heating operation) When the temperature difference between flow and return is greater than 30°C, the pump switches to high speed. When the temperature difference drops below 10°C, the pump switches back to low speed. end of heat demand Trouble shooting manual EN E000129004 12 sec Static pressure monitoring The boiler is in working mode when the system water pressure is between 0,5 and 3 bar. With a water pressure between 0,5 and 0,2 bar, the burner is limited to low load. If the water pressure is less than 0.2 bar, the regulation locks with a ‘P’ + ‘pressure’ on the display. If the water pressure is greater than 3.0 bar, the regulation locks with a ‘P’ + ‘pressure’ on the display. 3.1 Stand-by (Fan off - Gas valve off - Glow plug off - Ionisation off) 3.2 Pre-rinse / pre-heat glowplug (Fan on - Gas valve off - Glow plug on - Ionisation off) Heat demand: During the standby, a check is made to see if there is heat demand. If so the boiler will go over to pre-rise. Fan: The fan switches over to the purging speed (1350 rpm). Glow plug: The glow plug is switched on at full power. Pump test: After the pump test program is met, ignition state starts. 3.3 Ignition (Fan on - Gas valve on - Glow plug on/off - Ionisation off/on) 3.4 In operation (Fan on - Gas valve on - Glow plug off - Ionisation on) The ignition sequence of the burner is initiated. conditions burner on: - when the room thermostat is closed (heat demand), - and when the actual flow temperature is 5°C below the set point, - and after 3 minutes anti-cycling time, if applicable. conditions burner off: - when the room thermostat is open (end of heat demand), - or when the actual flow temperature is 3°C above the set point, - or when the actual flow temperature is 3°C above the 3.5 Post-rinse (Fan on - Gas valve off - Glow plug off - Ionisation off) 3.6 Pump afterrun (heating) (Fan off - Gas valve off - Glow plug off - Ionisation off) Combustion chamber is being post-ventilated with air. At end of heat demand the regulation runs into post-rinse. The fan runs at the last demanded speed for 20 seconds. The pump continues to run over the heating circuit. The time is adjustable (minimum of 1 minute with a maximum of CO=24 hours). Trouble shooting manual EN E000129004 Fan: The fan is running at the ignition speed (2900 rpm). Gas valve: The gas valve coil is activated and opens the safety valves. Glow plug: The glow plug ignites the gas/air mixture from the burner. Ionisation: As soon as an ionisation signal is measured, the glow plug is switched off and the boiler will go over to in operation. If there is no ionisation signal at the end of the safety time, a new start attempt is made. After four failed start attempts the boiler runs into lock-out. 3.7 Display The left segment indicates the Status (or the parameter when being in the menu option) A dot on the status display indicates that the burner is on. The two right segments indicate the flow sensor temperature or the system water pressure (or the value of the parameter when being in the menu option). A = Status B = Reading C = “+” button D = “-“ button E = Set/Reset F = Flame This boiler is in stand-by mode, waiting for heat demand. The Status shows a continuous 0, no dot (thus the burner is off). The two right segments indicate the actual flow sensor temperature of 19‘C. 3.8 Blocking The STATUS display shows a continuous indication (not flashing). The boiler operation is stopped due to a minor incorrect operation of the boiler or faulty component. Most blocking actions restore automatically in time when the conditions return within certain requirements. Some blocking operations need a reset of the 230V supply power or must be repaired. Note that each blocking operation will stay at least with 3 minutes anti-cycling time. The STATUS display shows a flashing indication. The boiler operation is stopped due to a major incorrect operation of the boiler or faulty component The pump runs over the heating circuit (24 hours). At some lock-outs, the fan runs post-rinse for 1 minute. Most lock-out operations can be restored by pressing the ‘Set/Reset’ button once. Note that some lock-out operations need a reset of the 230V supply power. Trouble shooting manual EN E000129004 3.9 Lock-out 3.10 STATUS INDICATIONS High voltage! The wiring of the pump, the three-way valve, fan and wiring of the gas block can be under a voltage of 230 VAC each burner start (after the pump test program), the boiler is doing a temperature test. The flow sensor must rise by 3°C more than the return sensor, within the first 20 seconds. if the difference is not made, the boiler will make a re-start. After three failed re-starts, within one heat demand, boiler runs into lock-out mostly, this lock-out is related to a water flow problem 1 flashing boiler does not pass temperature test flow sensor open circuit 1 continuous flow sensor broken flow sensor, or wiring problem flow sensor short circuit 1. continuous flow sensor use view option in menu mode test sensor (R=12 kOhm@25°C) replace sensor obstruction in water water circuit (flow or return) open (thermostatic) valves or zone systems install a differential bypass valve between flow and return check flow of water through heat exchanger check flow sensor function use view option in menu mode test sensor (R=12 kOhm@25°C) replace sensor check flow sensor function use view option in menu mode test sensor (R=12 kOhm@25°C) replace sensor Trouble shooting manual EN E000129004 Reset the appliance. Press the “+” button for 5-10 seconds, the status 8 comes up (water pressure) Start demand for heat with the chimney sweeper function. Read the pressures. a). if the delta P is under 0,05 bar, the boiler has no water. b). if the delta P is above 0,54 bar (0,64 for type 40 and TWIN), the water does not flow. c). If the delta is between 0,05 and 0,54 (0,64 for type 40 and TWIN), the water flow is all right, the pump test ends. check both flow and return sensors for function if during operation the ionisation fails, the gas valve shuts off, and restart is made. If this failure causes a third restart within one burner demand, the boiler runs into lock-out. during operation, the boiler may not have ionisation interruption 2 flashing too many restarts during operation check flame stability display reading can give indication of flame function check ionisation current on low load (3-13 microAmp DC) clean ionisation probe with fine sandpaper re-adjust gas/air mixture, check gas valve function 2 continuous return sensor broken return sensor, or wiring problem return sensor short circuit 2. continuous return sensor repair shorted wiring of ionisation probe to earth blocked condensation discharge clean siphon and condensate tray discharge check gas valve coil resistance on the two outermost terminals (R = about 4,1 kOhm) replace gas valve check return sensor function use view option in menu mode test sensor (R=12 kOhm@25°C) replace sensor check return sensor function use view option in menu mode test sensor (R=12 kOhm@25°C) replace sensor Trouble shooting manual EN E000129004 return sensor open circuit check ionisation wiring mostly, a printed circuit board component is broken. internal communication error 3 flashing internal error internal regulation fault software problem interrupt the supply power hard-ware component broken replace printed circuit board software problem check wiring and connections hard-ware component broken check why frost protection fails and repair this. check flue gas sensor function use view option in menu mode test sensor (R=12 kOhm@25°C) replace sensor check flue gas sensor function use view option in menu mode test sensor (R=12 kOhm@25°C) replace sensor check flue gas sensor function use view option in menu mode test sensor (R=12 kOhm@25°C) replace sensor Analog/Digital conversion error hard-ware component broken If the flue gas sensor measures a temperature below - 25°C, the boiler runs into lock-out, because the frost protection failed function. extreme low flue gas temperature (< - 25°C below zero) 4 continuous flue gas sensor flue gas sensor broken flue gas sensor, or wiring problem flue gas sensor short circuit 4. continuous flue gas sensor Trouble shooting manual EN E000129004 flue gas sensor open circuit 4 flashing If the measured fan speed, during initialising, exceeds the maximum fan speed, the regulation blocks. After 1 minute the boiler runs into lock-out. If the measured fan speed, in operation, deviates from the desired fan speed, the burner will be switched off, and post-purge will start. If this blocking action lasts for more than 1 minute, the boiler runs into lock-out. communication fault, heavy running fan rotor, fan motor broken, PCB failure 5 flashing fan speed malfunction If the gas valve circuit is disrupted, the boiler runs into lock-out. broken gas valve coils, PCB failure, interrupted wiring 6 continuous 7 flashing heavy running fan rotor, or equal problem replace fan check the fan coil resistance on the two outermost terminals (R =115-120 Ohm) replace fan check the printed circuit board for function replace PCB hot water sensor check internal tank sensor connection adjust in the menu the correct type of appliance, use parameter H gas valve malfunction software problem check wiring and connections hard-ware component broken PCB power supply to the gas valve: The voltage supplied by the board onto the two outermost contacts to open the gas valve is about 210 VDC. check gas valve coil resistance on the two outermost terminals (R = about 4,1 kOhm) replace gas valve check the printed circuit board for function replace PCB Trouble shooting manual EN E000129004 printed circuit board is not recognising the hot water sensor push reset button hard-ware component broken PCB power supply to the fan: The voltage supplied by the board onto the two outermost contacts of the fan plug varies (modulation). In chimney sweeper function: high load = approx 230 VAC low load = approx 125 VAC If the hot watwer sensor is disrupted, the boiler runs into blocking mode software communication fault (hall sensor) If a false flame signal is detected with closed gas valve for more than 5 seconds, the boiler runs into lock-out. the boiler may not have an ionisation signal when burner is off. 8 flashing incorrect flame signal software problem replace printed circuit board after successful re-programming of the printed circuit board, the status code shows flashing 9 successful software update 9 flashing software updating at the end of the updating session press set/reset button once A sensor with incorrect temperature indication between 97°C and 115°C, while the actual temperature differs. flow, return, internal tank or outdoor sensor sensor malfunction find the sensor involved replace that sensor test sensor (R=12 kOhm@25°C) replace sensor If a false flame signal is detected during pre-rinse / post-rinse, the regulation blocks. If the false flame signal lasts for more than 5 sec, the boiler runs into lock-out. 9 continuous Trouble shooting manual EN E000129004 If the flue gas sensor exceeds a temperature of 105°C, the boiler runs into lock-out extreme high flue gas temperature A flashing flue gas limiter lock-out ( 105°C) Find the cause of this flue gas limiter lock-out, because previously: a). The burner was off at 100°C b). The burner was on low load at 90°C interrupt the supply power The powering up of the supply voltage makes the flue gas sensor active. If the flue gas sensor exceeds a temperature of 100°C, the burner is blocked. high flue gas temperature A continuous A/C. or A/d. or A/b. continuous burner blocked, caused by high flue gas temperature ( 100°C) Find the cause of this flue gas limiter lock-out, because previously the burner was on low load at 90°C burner limited to low load, caused by high flue gas temperature ( 90°C) blocking action restores automatically burner action restores when the temperature descends 70°C check flue gas sensor function use view option in menu mode test sensor (R=12 kOhm@25°C) replace sensor Reset the appliance. Press the “+” button for 5-10 seconds, the status 8 comes up (water pressure) Start demand for heat with the chimney sweeper function. Read the pressures. a). if the delta P is under 0,05 bar, the boiler has no water. b). if the delta P is above 0,54 bar (0,64 for type 40 and TWIN), the water does not flow. c). If the delta is between 0,05 and 0,54 (0,64 for type 40 and TWIN), the water flow is all right, the pump test ends. burner action restores when the temperature descends 70°C check function of burner check flow of water through heat exchanger Trouble shooting manual EN E000129004 If the flue gas sensor exceeds a temperature of 90°C, the burner is blocked. The display shows alternately a code A and the actual boiler status extreme high flue gas temperature b/r continuous TWIN HWS right unit Chimney sweeper function Start the chimney sweeper fuction by pressing the + and - buttons of the display simultaneously for at least 5 to 10 seconds. The chimney sweeper function overruns the central heating regulation (not hot water regulation). The status shows a flashing C and the two right segments show the ionisation current in microamperes DC. temporarily display for service purposes C flashing chimney sweeper function press the “+” or “-” button for high or low load chimney sweeper function removes automatically after 10 minutes or by pressing the "-" button = high load = low load The two right segments show the actual ionisation current in micro Amps DC Trouble shooting manual EN E000129004 Enter the chimney sweeper function by pressing both the “+” and “-” buttons simultaneously for 5 - 10 seconds C = heat demand heating d = heat demand for hot water combi-boiler b = heat demand for hot water external cylinder heat demand No dot indication, burner is off C or d or b continuous burner is off caused by 3 minutes anti-cycling counter burner starts automatically Pump is on Fan is on Burner is off J continuous TWIN heat demand C continuous high flow or return sensor temperature ( 93°C) burner is off, blocked by maximum flow- or return temperature block removes automatically when the flow temperature drops 5°C below set point If the flow sensor temperature is 3'C above set point, the burner is switched off. heat demand C continuous flow temperature above set point burner is off, blocked by set point block removes automatically when the flow temperature drops 5°C below set point if the temperature difference between flowand return sensor becomes less than - 5'C, the boiler start is blocked. heat demand C continuous flow/return temperature difference is less than - 5'C burner is off, blocked by sensor temperatures block removes automatically when the temperature difference between flow and return sensor becomes within - 5'C if the temperature difference between flowand return sensor becomes more than 45'C, the boiler start is blocked. heat demand C continuous flow/return temperature difference is > 45'C burner is off, blocked by sensor temperatures block removes automatically when the temperature difference between flow and return sensor becomes less than 20'C at each start the glow plug protection counter is incremented 1 step. If the counter is too high ( xxx steps), the boiler start is blocked. heat demand C continuous glow plug protection counter glow plug counter is decremented 1 step per minute boiler restores automatically in time before each burner start, the difference between flow- and return temperature must be less than 20°C. Trouble shooting manual EN E000129004 If either the flow sensor or return sensor exceeds a temperature of 93'C, the burner is switched off. C. = heat demand heating d. = heat demand for hot water combi-boiler b. = heat demand for hot water external cylinder heat demand The dot indicates the burner is on. at the end of heat demand, the contacts of the green connector, ports 1 and 2, are open. end of heat demand ( Heating) software or hard-ware problem, the boiler runs into lock-out for safety reasons internal interlock fault C. or d. or b. continuous boiler is in heating mode burner modulates, depending the amount of heat required. Pump on, Fan on, Burner on c continuous pump afterrun heating post-rinse time is adjustable in menu ( Letter O) pump stops automatically after post-rinse time. internal lock-out software problem interrupt the supply power hard-ware component broken replace printed circuit board E flashing no slave recognised Trouble shooting manual EN E000129004 E continuous TWIN At each burner start, while the fan runs on the ignition speed of 2700 rpm, the gas valve opens and a flammable gas/air mixture is supplied to the burner. The glow plug ignites the gas/air mixture at the surface of the burner. If there is insufficient ionisation current at the end of the safety time, a new start attempt will be made. After four failed consecutive start attempts, the boiler runs into lock-out. too many start attempts, during one heat demand, successively F flashing boiler does not start (four failed consecutive attempts) NO GAS SUPPLY gas valve failure open gas cocks in supply line gas inlet pressure is too high, (> 60 mbar). The safety valves can not open against high inlet pressure NO IGNITION glow plug check resistance glow plug (1 - 1,4 kOhm) the life time of the glow plug is depending on the number of starts and on high mains voltage supply NO FLAME gas/air mixture replace glow plug check ionisation current (low load 3-13 micro Amp) No flame building. The gas/air mixture is not set correctly for the type of gas adjustment full / low load check wiring, remove short circuit to earth with high temperature flame, an insulating layer can be formed on the probe remove dirt with fine sandpaper Trouble shooting manual EN E000129004 NO IONISATION no current reduce gas inlet pressure If the flow sensor exceeds a temperature of 105°C, the boiler runs into lock-out high flow temperature H flashing flow sensor limiter ( 105°C) burner on test sensor (R=12 kOhm@25°C) replace flow sensor check water pressure replace pressure sensor flow sensor high temperature ( 105°C) burner off test sensor (R=12 kOhm@25°C) replace flow sensor check water pressure replace pressure sensor burner has to be restored by interrupting supply power If the flow sensor exceeds a temperature of 105°C, while the burner was off, the boiler blocks. high flow temperature H continuous burner action restores when the actual flow temperature becomes 5°C below the set point. end of heat demand ( Hot water) h continuous pump afterrun hot water post-rinse time hot water is non-adjustable pump stops automatically after 30 seconds the software was interrupted in the middle of a sequence software blocking nc continuous software problem unexpected failure interrupt the 230 volt supply power open bridge of connector of printed circuit board causes this lock-out gas valve circuit has open bridge on connector X4 gas valve connector X4 check wiring check bridge check contact of plug and terminal of PCB O flashing Trouble shooting manual EN E000129004 at the end of heat demand of the combi-boiler, the pump post-rinse for 30 seconds over the hot water circuit. once per hour is tested the difference between flow and return temperatures. If the flow sensor temperature becomes below 8°C, the regulation starts the pump waiting for heat demand O continuous stand-by the difference between flow and return temperatures must be less than 5°C if not, pump is started if needed, turn on heating ( room thermostat) frost protection 8°C o continuous frost protection check heat demand ( room thermostat) repair heat demand on the green connector ( contacts 1 and 2) frost protection 3°C o. continuous frost protection check heat demand ( room thermostat) repair heat demand on the green connector ( contacts 1 and 2) pump wiring open P continuous pump wiring disconnected check wiring repair pump wiring, connector or connection frost protection is finished, when the temperature of return sensor is above 15°C. If the flow sensor temperature becomes below 3°C, the regulation starts the burner If the pump is not connected the boiler will not start-up. Trouble shooting manual EN E000129004 frost protection is finished, when the temperature of return sensor is above 15°C. after each burner start the boiler is doing a pump test. The boiler is starting and stopping the pump and measuring both the dynamic and static system water pressures. water flow problem P continuous boiler does not pass pump test check water flow pump test repeating each 15 seconds The two right segments show the actual flow temperature install a differential bypass valve between flow and return Press the “+” button for 5-10 seconds, the status 8 comes up (water pressure) Read the pressures. a). if the delta P is under 0,05 bar, the boiler has no water. b). if the delta P is above 0,54 bar (0,64 for type 40 and TWIN), the water does not flow. c). If the delta is between 0,05 and 0,54 (0,64 for type 40 and TWIN), the water flow is all right, the pump test ends. high system water, pressure > 3,0 bar P continuous have at least one radiator always open high water pressure vent the air bleed cocks one at a time check pump function vent pump, accelerate pump shaft check pressure sensor function use view option in menu mode drain water from the system blocking mode releases after draining under 2,9 bar combo-boiler in hot water open at least one thermostat a combo-boiler makes valve to create contact, via the flow pipe to the return pipe and expansion vessel. check the expansion vessel pre-pressure pre-pressure depends on the installation height above the expansion vessel 5 meter - 0,5 bar 10 meter - 1,0 bar 15 meter - 1,5 bar fill the system with water blocking mode releases after filling above 1,3 bar Advised is to fill the system with a water pressure between 1,5 to 2 bar. low system water pressure < 0,2 bar P continuous low water pressure Trouble shooting manual EN E000129004 with water pressure above 3,0 bar (high pressure) or under 0,2 bar (low pressure), the regulation blocks. The two right segments show the actual water pressure The boiler is operational with a water pressure between 0,5 and 3,0 bar. vent the system (boiler/radiators) with water pressure between 0,2 and 0,5 bar, the burner is reduced to low load. The display shows alternately a code P with the actual operating status. low system water, pressure between 0,2 and 0,5 bar P/C. or P/d. or P/b. continuous burner limited to low load, caused by low water pressure fill the system with water low load releases after filling above 0,5 bar 230 VAC supply Line and Neutral reversed U continuous incorrect electrical connection check supply reverse Line and Neutral check Earth without proper Earth, the ionisation cannot work The two right segments show the actual water pressure Line and Neutral are exchanged or no good Earth is present Reading water pressure Filling Emtying Air Venting Trouble shooting manual EN E000129004 Water pressure Trouble shooting manual EN E000129004 Trouble shooting manual EN E000129004 2006 Coopra Advanced Heating Technologies b.v. All rights reserved. Nothing from this document may be duplicated and/or made public by means of printing, photocopy, microfilm or in any other way without prior written permission from the manufacturer. This also applies to the appropriate drawings and/or diagrams. The information supplied in this document is based on general data with regard to constructions, material characteristics and working methods known at the time of going to print. Therefore, we reserve the right to make changes without notification. For this reason, the instructions given serve only as a guideline for the installation, use and maintenance of the unit shown on the cover of this document. This document is valid for the unit in its standard version. Therefore, the manufacturer cannot be held liable for any damage arising from specifications that deviate from the standard version of the unit delivered to you. This document has been compiled with all possible care. However, the manufacturer cannot be held liable for any mistakes in this document or for any consequences. Take the time to read this document carefully before installing or using the unit. Always keep this document near the unit. E000129004-4 Trouble shooting manual EN - MV040506 (org) COOPRA Advanced Heating Technologies b.v. Vierlinghstraat 14 NL 3316 EL Dordrecht Tel: +31 (0) 78 – 653 08 30 Fax: +31 (0) 78 – 653 08 33