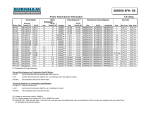

Download Boiler Company SERIES 3 Specifications

Transcript