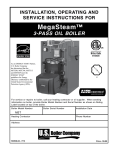

Download U.S. Boiler Company V8H SERIES Instruction manual

Transcript