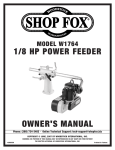

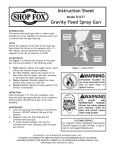

Download Woodstock Shop fox M1008 Instruction manual

Transcript