Download Mitsubishi 2408f Product manual

Transcript

(8527+(50

'5,9(6

3URILEXV0'3

&RPPXQLFDWLRQV

,QWHUIDFH

7HFKQLFDO#0DQXDO

+$7968948334##,VVXH#4

&RPSDWLEOH#ZLWK#9HUVLRQ#51[#6RIWZDUH

#&RS\ULJKW#(XURWKHUP#'ULYHV#/LPLWHG#5333

All rights strictly reserved. No part of this document may be stored in a retrieval system, or transmitted in any form or

by any means to persons not employed by a Eurotherm group company without written permission from Eurotherm

Drives Ltd.

Although every effort has been taken to ensure the accuracy of this document it may be necessary, without notice, to

make amendments or correct omissions. Eurotherm Drives cannot accept responsibility for damage, injury, or expenses

resulting therefrom.

6DIHW\#,QIRUPDWLRQ

Please read this information BEFORE installing the equipment.

$

,QWHQGHG#8VHUV

This manual is to be made available to all persons who are required to install, configure or

service equipment described herein, or any other associated operation.

The information given is intended to highlight safety issues, and to enable the user to obtain

maximum benefit from the equipment.

$SSOLFDWLRQ#$UHD

The equipment described is intended for industrial motor speed control.

3HUVRQQHO

Installation, operation and maintenance of the equipment should be carried out by qualified

personnel. A qualified person is someone who is technically competent and familiar with all

safety information and established safety practices; with the installation process, operation and

maintenance of this equipment; and with all the hazards involved.

5()(5#72#<285#0$,1#352'8&7#0$18$/#)25#63(&,),$)(7<

,1)250$7,21#$%287#7+(#'(9,&(#<28#$5(#&21752//,1*

&RQW16

&RQW17

&RQWHQWV

&RQWHQWV##############################################################################################################3DJH

352),%860'3#&20081,&$7,216#,17(5)$&(

4

$#6\VWHP#2YHUYLHZ1111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111 4

7KH#352),%86#3URWRFRO1111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111 4

3ULQFLSOHV#RI#2SHUDWLRQ 1111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111 5

• ,22#'DWD#([FKDQJH 111111111111111111111111111111111111111111111111111111111111111111111111111111111111 5

3URGXFW#)HDWXUHV11111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111 6

3URGXFW#&RGH#DQG#&RQWHQWV 111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111 6

,QVWDOODWLRQ 1111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111 7

:LULQJ#WKH#6\VWHP111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111 7

• &DEOH#6SHFLILFDWLRQ 111111111111111111111111111111111111111111111111111111111111111111111111111111111111 7

• (DUWKLQJ#WKH#6KLHOG1111111111111111111111111111111111111111111111111111111111111111111111111111111111111 8

• 8VHU#&RQQHFWLRQV#WR#WKH#0DLQ#6HULDO#3RUW#+34, 111111111111111111111111111111111111111111111 8

• 7HUPLQDWRUV 11111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111 8

• 7HUPLQDO#%ORFN#+7%4,#&RQQHFWLRQV 11111111111111111111111111111111111111111111111111111111111111 9

• 5HSHDWHUV 11111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111 9

)LWWLQJ#DQG#&RQQHFWLQJ#WR#WKH#7HFKQRORJ\#%R[1111111111111111111111111111111111111111111111111111111111111111 9

&RQQHFWLQJ#WR#WKH#7HFKQRORJ\#&DUG#+8;769#RQO\, 1111111111111111111111111111111111111111111111111111111111 :

• 8;769#7\SHV#7/#8#)#9 11111111111111111111111111111111111111111111111111111111111111111111111111111111 :

• 8;769#7\SHV#:/#;/#<#)#43 11111111111111111111111111111111111111111111111111111111111111111111111111 :

:LULQJ#'LDJUDP 11111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111 ;

,QLWLDO#&KHFN#IRU#&RQQHFWLRQ111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111 ;

8QGHUVWDQGLQJ#WKH#/('#,QGLFDWLRQV 11111111111111111111111111111111111111111111111111111111111111111111111111111111 <

• 1HWZRUN#DQG#0RGXOH#/('#,QGLFDWLRQV 111111111111111111111111111111111111111111111111111111111 <

,QLWLDO#6HW0XS#IRU#3URILEXV1111111111111111111111111111111111111111111111111111111111111111111111111111111 43

&RQILJXULQJ#WKH#'ULYH 1111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111 43

&RQILJXULQJ#WKH#3/&26&$'$#6XSHUYLVRU 1111111111111111111111111111111111111111111111111111111111111111111111 45

*6'#)LOHV 1111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111 48

&RQILJXUDWLRQ#'DWD#+&IJB'DWD, 11111111111111111111111111111111111111111111111111111111111111111111111111111111111 48

• 'HPDQG#'DWD#3URWRFRO 1111111111111111111111111111111111111111111111111111111111111111111111111111 4;

'DWD#(QFRGLQJ 11111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111 4<

352),%86#'LDJQRVWLFV 111111111111111111111111111111111111111111111111111111111111111111111111111111111111 53

7URXEOHVKRRWLQJ 111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111 54

,QWHUQDO#'LDJQRVWLFV 1111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111 55

• ,17#',$*#6(/(&7#3DUDPHWHU#9DOXHV111111111111111111111111111111111111111111111111111111111 55

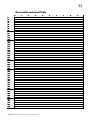

'HFLPDO2+H[DGHFLPDO#7DEOH 111111111111111111111111111111111111111111111111111111111111111111111111111111111111111 56

&RQW18

&RQWHQWV

&RQWHQWV##############################################################################################################3DJH

&RQW19

4

352),%860'3#&20081,&$7,216#,17(5)$&(

$#6\VWHP#2YHUYLHZ

Area

Computer

Factory

Level

MMS, TCP/IP Backbone

CNC

Cell

Level

PC/VME

Host

PROFIBUS-FMS

PLC

PC

Field

Level

DCS

PROFIBUS-DP

Motor

Drives

I/O

Temp

Controller

PROFIBUS-PA

Field

Device

Transmitter

Field

Device

Figure 1 PROFIBUS Application Areas

The PROFIBUS Option supports the PROFIBUS-DP variant of the PROFIBUS protocol which

is designed especially for communication between automatic control systems and distributed I/O

at the device level. It is most often used to allow a central Programmable Logic Controller or PC

based control system to use external ‘slave’ devices for I/O or specialised functions. The

principal advantage is that these devices may be distributed around a machine, thereby saving on

the cost of point to point wiring. The ‘open’ nature of the network also permits equipment from

different manufacturers to be mixed on the same bus. Additionally, the off-loading of complex

and specialised tasks such as PID temperature control lessens the processing load on the central

PLC so that its other functions may be carried out more efficiently and require less CPU

memory.

7KH#352),%86#3URWRFRO

PROFIBUS is a vendor independent, open fieldbus standard for a wide range of applications in

manufacturing, process and building automation. Vendor independence and openness are

guaranteed by the PROFIBUS standard EN50170. With PROFIBUS, devices from different

manufacturers can inter-communicate. Suitable interfaces exist for PLCs, which include the

Siemens, Mitsubishi and Allen Bradley range.

PROFIBUS-DP (De-central Periphery) is described in DIN 19245 Part 3, and forms part of EN

50170 with P-Net and WorldFIP. However it is important to note that P-Net and WorldFIP are

wholly incompatible with PROFIBUS, using different wiring and transmission technologies.

The PROFIBUS-DP network uses a high speed version of the RS485 standard, permitting baud

rates of up to 12Mbaud. A table of network speed against segment length is given in Chapter 3.

A maximum of 32 PROFIBUS-DP stations (nodes) may be contained within a single network

segment. Use of RS485 repeaters allows a total of up to 126 stations.

PROFIBUS-DP is a multimaster, master-slave, token passing network. More detailed

information, including a detailed guide to products available, may be obtained from the various

world-wide PROFIBUS user organisations. You will find contact information in trade magazines

or by reference to http://www.profibus.com on the World Wide Web.

PROFIBUS is available in two other types, aimed at different application areas, as follows:

1. PROFIBUS-PA is designed especially for process automation. It permits sensors and

actuators to be connected on one common bus line even in intrinsically safe areas.

PROFIBUS PA permits data communication and power over the bus, using intrinsically safe,

2-wire technology according to the international standard IEC 1158-2, but may also be used

on the standard RS485 cabling for non-intrinsically safe applications.

2. PROFIBUS-FMS is the general purpose solution for communication tasks at the cell level.

352),%860'3#&RPPXQLFDWLRQV#,QWHUIDFH#0#+$7968948334

5

3ULQFLSOHV#RI#2SHUDWLRQ

Physical

Actuator 1

PLC I/O Mapping

Input

I/O

Output

PLC

Ladder

Program

Modules

Physical

Actuator 2

Physical

Actuator 3

Physical

Actuator 4

Figure 2-1a: Plant wiring

conventional comms. systems

I/O scanning

Physical I/O

Input

Input

Output

Output

Slave 1

Slave 2

Slave 3

Slave 4

Figure 2 PROFIBUS compared with convetional comms. systems

PROFIBUS-DP distinguishes between master devices and slave devices. It allows slave devices

to be connected on a single bus thus eliminating considerable plant wiring typical with

conventional communications systems. The Figure above compares the two systems.

Master devices determine the data communication on the bus. A master can send messages

without an external request when it holds the bus access rights (the token). Masters are also

called active stations in the PROFIBUS protocol.

Slave devices are peripheral devices. Typical slave devices include input/output devices, valves,

motor drives and measuring transmitters. The 2408f and 2404f series Temperature Controllers

are intelligent slaves. This means they will only respond to a master when requested to do so.

PROFIBUS-DP is based around the idea of a ‘cyclical scan’ of devices on the network, during

which ‘input’ and ‘output’ data for each device is exchanged.

,22#'DWD#([FKDQJH

The process of reading the inputs and writing to the outputs is known as an I/O data exchange.

Typically, the parameters from each slave device will be mapped to an area of PLC input and

output registers, or a single function block, so that the controlling ladder logic or program

interfaces with the device as if it were an internally fitted module. It is NOT necessary,

therefore, for the programmer to know anything about the physical network. The process of

network configuration is usually performed using a PC based program which allows the devices

on the network to be defined and device parameters to be mapped into the PLC registers or

function blocks.

The cyclical scan occurs in the following order:

1. Values from each slave device, ‘Input Data’, are first scanned over the network into a predefined set of input registers in the master controller. Such values might be a set of digital

input readings for a digital input unit, or the measured temperature and alarm status from a

PID controller.

2. The master then runs its control program, (such as a ladder logic program) using the input

data read from the slave devices.

3. The master writes output values (output data) into a pre-defined set of output registers. For

example, one of the digital inputs read in the input data might be used to select one of a set of

setpoints to be sent to the PID controller.

4. These outputs are then written to each slave device, and the scan-process-write cycle repeats.

Typically no more than 32 bytes of input data and 32 bytes of output data are exchanged for each

device during the data exchange. Some PLC masters allow no more than this, although the

352),%860'3#&RPPXQLFDWLRQV#,QWHUIDFH#0#+$7968948334

6

PROFIBUS-DP standard provides the possibility of transferring 236 bytes in each direction.

The input and output data lengths for a given device are variable and it is possible to have

devices with only input data, only output data, or both.

The input and output data mixture used by a given slave device is defined by what is known as a

GSD file. See Chapter 5 for more details. For simple devices such as digital or analogue I/O

blocks, this is fixed. However, since more complex devices often have a much wider choice of

possible values to send, it is usually possible to edit the GSD file to change the mapping of

device parameters onto Profibus inputs or outputs. This is the case with most Eurotherm

implementations, which also allow access to parameter data not in the GSD Input/Output data

file. This is called Demand Data and is described further in Chapter 7.

The GSD file is imported into the PROFIBUS Master Network Configuration software before

the network is created.

NB:

PROFIBUS Input Data = Values sent from a device to a master controller or PLC,

PROFIBUS Output Data = Values sent from a master controller or PLC to a device.

3URGXFW#)HDWXUHV

• Suitable for use with:

584SV

590+

590+DRV

605A & B

605C

•

•

•

•

•

•

•

•

software version 4.x onwards

software version 5.x onwards

software version 5.x onwards

software version 4.x onwards

software version 4.x onwards

Hardware self-test

Connection using shielded, twisted-pair cable

LEDs to indicate board and communications status

Configured using Function Block inputs

Diagnostics using Function Block outputs

Automatic Baud Rate selection

Software-selectable Slave Address

Direct tag access for all drive parameters

3URGXFW#&RGH#DQG#&RQWHQWV

The Eurotherm Drives’ product is fully identified using an alphanumeric code which records

how the product was assembled, and its various settings when despatched from the factory.

The Technology Option can be supplied with the drive product, or supplied separately:

3URGXFW

3URGXFW#&RGH#ZKHQ

VXSSOLHG#ZLWK#WKH#'ULYH

3URGXFW#&RGH#ZKHQ

VXSSOLHG#VHSDUDWHO\

8;769

8;7692[[[[2[[[2[[[[2[[2[[[2352)

352)2[[2[[[2[[[

8;769

352)

$+7967:38334#0#SOXJ0LQ#7HFKQRORJ\#&DUG

8<3.

8<332[[[[2[[[2[[[[2[[2[[[2352)

352)2[[[2[[[

8<33

352)

93882352)233#0#SOXJ0LQ#7HFKQRORJ\#%R[

8<3.'59

<88.2[2[2[[[[2[[[

<88.

93882352)233#0#SOXJ0LQ#7HFKQRORJ\#%R[

938$#)#%

9382[[[2[[[2[2[2[[[6

62[[2[[[

938

93862352)233#0#SOXJ0LQ#7HFKQRORJ\#%R[

938&

938&2[[[[2[[[2[[[[2[[2[[[2352)

352)2[[2[[[2[[[

938&

352)

93882352)233#0#SOXJ0LQ#7HFKQRORJ\#%R[

352),%860'3#&RPPXQLFDWLRQV#,QWHUIDFH#0#+$7968948334

7

,QVWDOODWLRQ

:LULQJ#WKH#6\VWHP

:$51,1*$#

%HIRUH#LQVWDOOLQJ/#HQVXUH#WKDW#WKH#GULYH#DQG#DOO#ZLULQJ#LV#HOHFWULFDOO\#LVRODWHG#DQG

FDQQRW#EH#PDGH#´OLYHµ#XQLQWHQWLRQDOO\#E\#RWKHU#SHUVRQQHO1

:DLW#8#PLQXWHV#DIWHU#GLVFRQQHFWLQJ#SRZHU#EHIRUH#ZRUNLQJ#RQ#DQ\#SDUW#RI#WKH#V\VWHP#RU

UHPRYLQJ#WKH#FRYHUV#IURP#WKH#'ULYH1

The Profibus Technology Option is provided in one of two forms:

1. A plug-in Technology Box

2. A board-mounted Technology Card (584SV only)

It is operated as a 2-wire system:

• A 2-wire system can only be used in a network in which all devices use their tri-state

capability. Data flow is restricted, i.e. transmit and receive cannot be simultaneous (half

duplex).

1RWH=# ,W#LV#SRVVLEOH#WR#PDNH#VHULDO#FRPPXQLFDWLRQV#RSHUDWH#ZLWKRXW#DGKHULQJ#WR#WKH#IROORZLQJ

UHFRPPHQGDWLRQV/#KRZHYHU/#WKH#UHFRPPHQGDWLRQV#ZLOO#SURPRWH#JUHDWHU#UHOLDELOLW\1

&DEOH#6SHFLILFDWLRQ

Either of the two cable types detailed below can be used but we recommend Type A as it allows

higher speed and longer cable length.

7\SH#$#FDEOH

7\SH#%#FDEOH

&KDUDFWHULVWLF

,PSHGDQFH=

468#WR#498Ω#DW#D#IUHTXHQF\#RI#6#WR#530+]1

468#WR#498Ω#DW#D#IUHTXHQF\#RI

!433N+]

&DEOH

FDSDFLWDQFH=

?#63S)#SHU#PHWUH

W\SLFDOO\#?93S)#SHU#PHWUH

&RUH#GLDPHWHU=

PD[1#3167#PPò/#FRUUHVSRQGV#WR#$:*#55

PD[LPXP#3155PPò/

FRUUHVSRQGV#WR#$:*57

&DEOH#W\SH=

WZLVWHG#SDLU#FDEOH1#4[5#RU#5[5#RU#4[7#OLQHV

WZLVWHG#SDLU#FDEOH1#4[5#RU#5[5

RU#4[7#OLQHV

5HVLVWDQFH=

?#443Ω#SHU#NP

0

6KLHOGLQJ=

&RSSHU#VKLHOGLQJ#EUDLG#RU#VKLHOGLQJ#EUDLG

DQG#VKLHOGLQJ#IRLO

&RSSHU#VKLHOGLQJ#EUDLG#RU

VKLHOGLQJ#EUDLG#DQG#VKLHOGLQJ

IRLO

1RWH=# %HOGHQ#%63:<$#FDEOH#PHHWV#WKH#DERYH#VSHFLILFDWLRQ#IRU#7\SH#$/#EXW#WKHUH#DUH#RWKHUV1

0D[LPXP#/LQH#/HQJWK#3HU#6HJPHQW

%DXG#UDWH#+NELW2VHF,

%DXG#UDWH

<19

4<15

<61:8

4;:18

833

4833

7\SH#$#FDEOH

4533P

4533P

4533P

4333P

733P

533P

7\SH#%#FDEOH

4533P

4533P

4533P

933P

533P

0

352),%860'3#&RPPXQLFDWLRQV#,QWHUIDFH#0#+$7968948334

8

(DUWKLQJ#WKH#6KLHOG

The PROFIBUS standard suggests that both ends of the transmission line should be connected to

safety earth. If you do this, ensure that differences in local earth potential do not allow

circulating currents to flow, as not only can these induce large common mode signals in the data

lines, but they can also produce potentially dangerous heating in the cable. If in doubt, earth the

shield at only one section of the network.

8VHU#&RQQHFWLRQV#WR#WKH#0DLQ#6HULDO#3RUW#+34,

The serial port on the Option allows the following Profibus links to be made.

3URILEXV

(OHFWULFDO#&RQQHFWLRQV

1XPEHU#RI#WUDQVPLWWHUV#DQG#WUDQVFHLYHUV

DOORZHG#SHU#GLIIHUHQWLDO#SDLU#RI#ZLUHV

0D[LPXP#FDEOH#OHQJWK

605A&B

Technology Box

50ZLUH#GLIIHUHQWLDO

65#WUDQVFHLYHUV

7333IW24533#PHWUHV

605C, 590+ and 590+DRV

Technology Box

TB1

584SV Technology Card

TB1

TB1

Terminal Block TB1

1 2 3 4 5 6

Figure 3 Option showing TB1

7HUPLQDWRUV

0Vext (1)

• If the drive is at the end of the network it

must have terminating resistors.

• All other drives in the system should not

have terminators.

Connect terminating resistors to the last drive

as shown opposite. (All resistors ±5%,

minimum ¼ Watt).

+5VDCext (2)

390 Ω

B-B' (3)

220 Ω

A-A' (4)

352),%860'3#&RPPXQLFDWLRQV#,QWHUIDFH#0#+$7968948334

390 Ω

9

7HUPLQDO#%ORFN#+7%4,#&RQQHFWLRQV

7%4#7HUPLQDO

5HIHUHQFH

0HDQLQJ

4

39H[W

6LJQDO#UHIHUHQFH#IRU#352),%86

5

.89'&H[W

.89'&H[W283P$#VXSSO\#IRU#352),%86

6

%0%·

5HFHLYH27UDQVPLW#'DWD#3RVLWLYH

7

$0$·

5HFHLYH27UDQVPLW#'DWD#1HJDWLYH

8

576

)RU#FRQQHFWLQJ#UHSHDWHU#+77/,

9

*1'

*URXQG#FRQQHFWLRQ#IRU#(0&

5HSHDWHUV

RTS (Pin 5 , TB1) is a TTL level signal that can be connected to a repeater. Most repeaters

automatically switch between transmitting and receiving and so do not need this connection.

)LWWLQJ#DQG#&RQQHFWLQJ#WR#WKH#7HFKQRORJ\#%R[

Technology

Box

screen connections

605A & B

Captive Screw

Technology

Box

605C, 590+, 590+DRV (590+ 15A unit illustrated)

Figure 4 Plug-in Technology Boxes

:$51,1*$#

(QVXUH#WKDW#DOO#ZLULQJ#LV#LVRODWHG1

,03257$17=# 5HPHPEHU#WR#VHW#WKH#VZLWFK#SRVLWLRQV#RQ#WKH#',/#VZLWFK/#6:41

The Technology Option plugs into the right-hand position on the front of the drive, or in place of

the Operator Station/blank cover (605A & B only).

It can be used with the Operator Station fitted, but for the 605A & B unit you must mount the

Operator Station remotely using the Panel Mounting Kit with connecting lead (6052). The

connecting lead enters the 605 A & B drive through the gland plate.

• Remove the terminal cover and screws.

• On the 605A & B unit, plug the ribbon cable into the back of the Technology Box and into

the socket on the drive.

352),%860'3#&RPPXQLFDWLRQV#,QWHUIDFH#0#+$7968948334

:

• Click the Technology Box into place in the recess on the front of the drive. If provided,

secure in position by tightening the captive screw on the bottom right hand corner of the

Option.

• Make all user wiring connections. Refer to the Wiring Diagram.

• Re-fit the terminal cover securely with the screws.

&RQQHFWLQJ#WR#WKH#7HFKQRORJ\#&DUG#+8;769#RQO\,

The option is supplied as a “Technology Card”. This is factory-fitted to the control board inside

the drive.

When connecting to the Technology Card,

observe static control precautions.

:$51,1*$#

(QVXUH#WKDW#DOO#ZLULQJ#LV#LVRODWHG1

8;769#7\SHV#7/#8#)#9

Technology

Card

• Remove the terminal cover and screws.

,03257$17=# 5HPHPEHU#WR#VHW#WKH#VZLWFK#SRVLWLRQV

RQ#WKH#',/#VZLWFK/#6:41

Control Board

• Make all user wiring connections.

Refer to the Wiring Diagram.

• Re-fit the terminal cover securely with

the screws.

Terminal Cover

8;769#7\SHV#:/#;/#<#)#43

• Remove the bottom front cover.

,03257$17=# 5HPHPEHU#WR#VHW#WKH#VZLWFK#SRVLWLRQV#RQ

WKH#',/#VZLWFK/#6:41

• Make all user wiring connections. Refer

to the Wiring Diagram.

• Re-fit the terminal cover securely with

the screws.

Technology

Card

Control Board

Bottom Front Cover

352),%860'3#&RPPXQLFDWLRQV#,QWHUIDFH#0#+$7968948334

;

:LULQJ#'LDJUDP

DRIVE

(slave)

DRIVE

(slave)

last drive in chain

PLC/SCADA

(master)

TRANSMIT

A-A'

1

B-B'

GND

0V

2

+5V

0Vext DCext

3

4

5

6

B-B'

A-A'

RTS

GND

1

2

+5V

0Vext DCext

3

4

5

6

B-B'

A-A'

RTS

GND

390 W 220 W

605A & B

screen

connection

to earth screw

screen

connection

390W

Figure 5 Typical Wiring Diagram

1RWH=# 7KH#GLDJUDP#DERYH#VKRZV#WKH#WHUPLQDO#EORFN#RULHQWDWLRQ#IRU#WKH#%$&.09,(:#

%$&.09,(:#RI#WKH

%$&.09,(:#

938#$#)#%#7HFKQRORJ\#%R[1#:KHQ#WKH#7HFKQRORJ\#%R[#LV#LQ0VLWX/#WKH#WHUPLQDO#RUGHU#LV

HIIHFWLYHO\#UHYHUVHG#0#UHPHPEHU#WKLV#ZKHQ#PDNLQJ#XVHU0FRQQHFWLRQV1

UHPHPEHU#WKLV#ZKHQ#PDNLQJ#XVHU0FRQQHFWLRQV1#1RWH#WKDW#WKH#VFUHHQ

UHPHPEHU#WKLV#ZKHQ#PDNLQJ#XVHU0FRQQHFWLRQV1

FRQQHFWLRQV#IRU#WKH#938$#)#%#WHUPLQDWH#DW#DQ#HDUWKLQJ#SLOODU#SURYLGHG#RQ#WKH#FDVLQJ1

,QLWLDO#&KHFN#IRU#&RQQHFWLRQ

With the correct connections to the active

PLC/SCADA supervisor, the MODULE

LED will be ON continuously and the

NETWORK LED will indicate the Idle

state with a short flash.

21

02'8/(#/('

6+257#)/$6+

1(7:25.#/('

352),%860'3#&RPPXQLFDWLRQV#,QWHUIDFH#0#+$7968948334

<

8QGHUVWDQGLQJ#WKH#/('#,QGLFDWLRQV

605A&B

Technology Box

605C, 590+ and 590+DRV

Technology Box

584SV Technology Card

RUN

HEALTH

MODULE

NETWORK

MODULE

TB1

NETWORK

NETWORK

MODULE

TB1

Figure 6 Technology Option LEDs

HINT:

The general rule for LED indications is

“ON IS GOOD, OFF IS BAD”

+HDOWK#DQG#5XQ#/('V

938$#)#%#7HFKQRORJ\#%R[

These LEDs reproduce the indications of the LEDs on the drive that are hidden by the fitting of

the Technology Box.

8;769#7HFKQRORJ\#&DUG#DQG#938&/#8<3./#8<3.'59#7HFKQRORJ\#%R[

The board does not have its own Health or Run LEDs. The LEDs are either on the Operator

Station or blank cover.

1HWZRUN#DQG#0RGXOH#/('#,QGLFDWLRQV

1HWZRUN#/('

0RGXOH#/('

,QGLFDWHV#WKH#VWDWH#RI#WKH

FRQQHFWHG#QHWZRUN1

,QGLFDWHV#WKH#VHW0XS#VWDWH#RI#WKH#7HFKQRORJ\#%R[22SWLRQ1

7KH#VWDWHV#LQGLFDWHG#DUH#WKRVH#SURGXFHG#E\#WKH#)$8/7

SDUDPHWHU#RI#WKH#7(í,21#IXQFWLRQ#EORFN1

/('#,QGLFDWLRQ

'HVFULSWLRQ

)$8/7#3DUDPHWHU

'HVFULSWLRQ

2))

'LVDEOHG#RU#%DXG#VHDUFK

+$5':$5(

+DUGZDUH#)DXOW#0#H[WHUQDO

6+257#)/$6+

:DLW#3DUDPHWHULVDWLRQ

6(/)#7(67

+DUGZDUH#IDXOW#0#LQWHUQDO

)/$6+

:DLW#&RQILJXUDWLRQ

7<3(#0,60$7&+

:URQJ#W\SH#RU#GLVDEOHG

/21*#)/$6+

'DWD#H[FKDQJH#ZLWK#HUURU

3$5$0(7(5

6HW0XS#IDXOW/#SDUDPHWHU#YDOXHV#RXW0

RI0UDQJH

21

'DWD#H[FKDQJH

121(

9DOLG#VHW0XS/#UHDG\#IRU#H[WHUQDO

FRPPXQLFDWLRQV

1RWH=# 7KH#1(7:25.#/('#LV#DOZD\V#LQ#WKH#2))#VWDWH#ZKHQ#WKH#02'8/(#/('#LV#QRW

QRW#21

QRW

FRQWLQXRXVO\/#LQGLFDWLQJ#WKDW#WKH#2SWLRQ#LV#QRW#UHDG\#IRU#H[WHUQDO#FRPPXQLFDWLRQV1

352),%860'3#&RPPXQLFDWLRQV#,QWHUIDFH#0#+$7968948334

43

,QLWLDO#6HW0XS#IRU#3URILEXV

&RQILJXULQJ#WKH#'ULYH

00,#0HQX#0DS

1RQ0VSHFLILF#00,#YLHZ

4

SETUP PARAMETERS

5

FUNCTION BLOCKS

6

SERIAL LINKS

7

TEC OPTION

TEC OPTION TYPE

TEC OPTION IN 1

TEC OPTION IN 2

TEC OPTION IN 3

TEC OPTION IN 4

TEC OPTION IN 5

TEC OPTION FAULT

TEC OPTION VER

TEC OPTION OUT 1

TEC OPTION OUT 2

00,#0HQX#0DS

352),%86#'3#YLHZ

Using the Operator Station (MMI) or

other suitable PC programming tool,

the TEC OPTION function block

requires configuring before the

PROFIBUS option can be used.

The parameter names/functions in this

function block are inter-dependant and

will change with different parameter

values and the various Options that can

be fitted.

The top Function Block diagram shows

the ConfigEd Lite parameter names,

which are also displayed on the MMI if

no Option is fitted or an incorrect TYPE

is selected for the fitted Option.

ConfigEd Lite is Eurotherm Drives’

Windows-based block programming

software.

TEC OPTION

FAULT

VERSION

OUTPUT 1

OUTPUT 2

NONE

0

0

0

0

0

–

–

–

–

–

–

[750]

[751]

[752]

[753]

[754]

[755]

[756]

[757]

[758]

[759]

TYPE

INPUT 1

INPUT 2

INPUT 3

INPUT 4

INPUT 5

–

–

–

–

–

–

–

–

–

–

NONE

0000

0000

0000

Non-specific ConfigEd-Lite view

TEC OPTION

PROFIBUS DP

0

0

0

0

0

–

–

–

–

–

–

FAULT [756]

VERSION [757]

NETWORK STATE [758]

INT DIAGNOSTIC [759]

[750] TYPE

[751] ADDRESS

[752] EXT DIAGNOSTIC

[753] INT DIAG SELECT

[754] UNUSED 1

[755] UNUSED 2

– NONE

– 0101

– DISABLED

– 0000

–

–

–

–

–

–

When the TYPE parameter is set to

PROFIBUS DP ConfigEdLite view

display PROFIBUS, the function block

parameters take on new identities, as shown in the lower Function Block diagram.

4

SETUP PARAMETERS

5

FUNCTION BLOCKS

6

SERIAL LINKS

6HOHFWLQJ#352),%86#'3

7

TEC OPTION

(Select Advanced view level on the Operator Station and view the TEC OPTION function

block).

TYPE

ADDRESS

EXT DIAGNOSTIC

INT DIAG SELECT

UNUSED 1

UNUSED 2

FAULT

VERSION

NETWORK STATE

INT DIAGNOSTIC

SERIAL LINKS is at

Menu Level 1 for the

590+ and 590+DRV.

• Select PROFIBUS DP in the TYPE parameter

• Enter a slave ADDRESS

• Check the FAULT parameter for error messages, rectify if necessary

When setting values for parameters from ConfigEd Lite (or other suitable PC programming tool)

you are able to select any value in the parameter’s range, i.e. -32768 to 32767. If the value is

incorrect, i.e. it doesn’t correspond to a value that can be set using the MMI, then the FAULT

output parameter will be set to PARAMETER.

00,#3DUDPHWHU#'HVFULSWLRQV#IRU#(,#%,6<1&+

Range: Enumerated - see below

TYPE

Selects the type of Technology Option card.

Enumerated Value : Technology Option

3#=#121(

4#=#567;8

5#=#352),%86#'3

6#=#/,1.

7#=#'(9,&(1(7

8#=#&$123(1

9#=#/21:25.6

:#=#7<3(#:

Range: 0 to 125

ADDRESS

The PROFIBUS slave address. Note that addresses 0, 1 and 2 are usually reserved for

PROFIBUS Masters and so should be avoided.

352),%860'3#&RPPXQLFDWLRQV#,QWHUIDFH#0#+$7968948334

44

Range: 0 to FFFF

EXT DIAGNOSTIC

(External Diagnostic) The value of this parameter appears as the 2nd and 3rd bytes of the

application specific diagnostics to the master. Refer to “PROFIBUS Diagnostics”, page 20. This

provides a simple way to implement user defined trips or exceptions.

Range: 0 to 29999

INT DIAG SELECT

(Internal Diagnostic Select) Refer to “Internal Diagnostics”, page 22.

UNUSED 1

Reserved for future use.

Range: 0 to FFFF

UNUSED 2

Reserved for future use.

Range: 0 to FFFF

FAULT

The fault state of the Technology Option.

Range: Enumerated - see below

0 : NONE

1 : PARAMETER

2 : TYPE MISMATCH

3 : SELF TEST

4 : HARDWARE

5 : MISSING

no faults

parameter out-of-range

TYPE parameter not set to PROFIBUS DP

hardware fault - internal

hardware fault - external

no option fitted

Also refer to Network and Module LED Indications, page 9.

Range: 0000 to FFFF

VERSION

The version of the Technology Option card. If no option is fitted then the version is reset to zero.

Range: Enumerated - see below

NETWORK STATE

The network state of the Technology Option card. Refer to “Network and Module LED

Indications” page 9 for further information.

Enumerated Value : Fault State

0 : DATA EXCHANGE

1 : DATA EX ERROR

2 : WAIT CONFIG

3 : WAIT PARAM

4 : BAUD SEARCH

5 : DISABLED

DATA EXCHANGE

Data Exchange mode. The parameterisation and configuration have been accepted and the slave

is exchanging user data with the master.

DATA EX ERROR

Data Exchange mode, as above, but with read/write error(s). This indicates that at least one of the

parameters being read or written is failing, for example writing a value out of range.

WAIT CONFIG

Waiting for configuration. The parameterisation from the master has been accepted and is now

waiting for the Master to send valid configuration data.

WAIT PARAM

Waiting for parameterisation. The slave has detected communications at a valid baud rate and is

waiting for the master to send valid parametrisation data.

BAUD SEARCH

The slave has not detected valid communications.

DISABLED

The interface is disabled. The reason for this is given by the FAULT parameter.

Range: 0000 to FFFF

INT DIAGNOSTIC

Refer to “Internal Diagnostics”, page 22.

352),%860'3#&RPPXQLFDWLRQV#,QWHUIDFH#0#+$7968948334

45

&RQILJXULQJ#WKH#3/&26&$'$#6XSHUYLVRU

Other than setting the TEC OPTION TYPE and ADDRESS within the Drive, as described

earlier, all configuration is done via the Profibus-DP-Master.

During the start-up phase, the Profibus-DP-Master will check that the Profibus-DP-Slave at the

requested address is of the required type. If it is, Configuration Data and User Parameter Data

are downloaded.

The way the Profibus-DP-Master is configured depends on the manufacturer, but typically the

following steps must be followed as shown in the following diagrams.

1RWH=# 7KH#H[DPSOH#XVHV#6LHPHQV#&20#352),%86#FRQILJXUDWLRQ#WRRO1

Start PROFIBUS software

and install / import the supplied

GSD file

Select the Master Station

Type from the list and

click on the OK button

To add a Drive

to the System

click on the

DRIVES button

and position the

special cursor

where the Drive

is to be added

From the pop-up menu

select the PROFIBUS

Address for the Drive

you are adding to match

the Drive's configured

address and then

click on the OK button

next diagram

Figure 7 Typical Configuration Tool Procedure

352),%860'3#&RPPXQLFDWLRQV#,QWHUIDFH#0#+$7968948334

46

With the 605

selection made

as shown

click on the

Configure button

continued

Click on the Order No.

button to display the

pop-up menu

Select from this list

by clicking on Accept

to make an entry in the

Configure menu

Repeat this process

until the list is complete

and click on Close

The ID column is now

completed automatically

(I Addr and O Addr.

columns can also be set

to do this)

Fill in the Remarks column

for information and then

click on the OK button

Click on the

Parameterize button

next diagram

Figure 8 Typical Configuration Tool Procedure

352),%860'3#&RPPXQLFDWLRQV#,QWHUIDFH#0#+$7968948334

47

Alternative view of menu below

taken from another configuration tool

Enter the Tag No's in Hex

They are entered in pairs

i.e. 3 & 4, 5 & 6 etc.

Note that leading zeros

are omitted in the menu

thus the entry for 4 is actually

continued

`0F' and not `F' as shown, e.g.

0, 1 & 2 are

reserved

(always 00)

3&4

= 01 0F

=

271

5&6

= 01 0D

=

269

7&8

= 01 10

=

272

9 & 10

= 00 FF

=

255

Click on the OK button

Click on the OK button

to see the System menu

with the added Drive

Click on DRIVES to repeat the process

and add another Drive to the System

Figure 9 Typical Configuration Tool Procedure

352),%860'3#&RPPXQLFDWLRQV#,QWHUIDFH#0#+$7968948334

48

By referring to the Parameter Specification Table in the main Product Manual, you can enter

the parameter information you require.

The Parameter Specification Table provides the information in the following way:

7DJ

+00,,#1DPH

%ORFN

7\SH

5DQJH

,'

47

$,1#4#6&$/(

$1$/2*#,1387#4

,17

0633133#WR#633133#(

3H

48

$,1#4#2))6(7

$1$/2*#,1387#4

,17

0633133#WR#633133#(

3I

49

$,1#4#9$/8(

$1$/2*#,1387#4

,17

[[[1[[#(

3J

4:

$,1#4#%5($.#9$/

$1$/2*#,1387#4

,17

0633133#WR#633133#(

3K

4;

$,1#4#%5($.

$1$/2*#,1387#4

%22/

)$/6(#2#758(

3L

54

$,1#5#%5($.#(1%/

$1$/2*#,1387#5

%22/

)$/6(#2#758(

3O

55

$,1#5#7<3(

$1$/2*#,1387#5

(180

6DPH#DV#WDJ#46

3P

56

$,1#5#6&$/(

$1$/2*#,1387#5

,17

0633133#WR#633133#(

3Q

1RWHV

2XWSXW

2XWSXW

:

Example only

7DJ

The Tag column provides the unique parameter tag number.

7\SH

All parameter Types are supported, except STRING.

5DQJH

The Range column provides information on scaling.

*6'#)LOHV

Three GSD files are provided for use with this option. These are available on request or can be

downloaded from the Profibus Interne site (http://www.profibus.com).

1RWH=# 7KH#UHJLVWHUHG#LGHQWLILFDWLRQ#QXPEHU#IRU#WKH#RSWLRQ#LV#497<#+KH[DGHFLPDO,1

'HYLFH#GHVFULSWLRQ#IRU#WKH#938$/#%#)#&

HXUR497<1JVG

'HYLFH#GHVFULSWLRQ#IRU#WKH#8;769

HXU[497<1JVG

'HYLFH#GHVFULSWLRQ#IRU#WKH#8<3.#DQG#8<3.'59

HXU\497<1JVG

The contents of the above files are the same except for the Model Name. This is to allow the

correct description to appear on the Profibus configuration tool.

&RQILJXUDWLRQ#'DWD#+&IJB'DWD,

The Configuration Data (Cfg_Data) is used to specify the number of parameters that are to be

read and written as part of the cyclic Data Exchange.

The Data Exchange either consists of just Process Data, or Demand Data and Process Data.

• Process Data is the

fixed set of parameters

that are to be transferred

each cycle.

• Demand Data is 8

reserved bytes (octets)

to support a messaging

system, allowing

random access to any

parameter within the

drive.

352),%860'3#&RPPXQLFDWLRQV#,QWHUIDFH#0#+$7968948334

Demand Data

Process Data (2 Parameters)

0

3

8

11

OR

0

7

49

To enable the Demand Data feature, the first byte of Cfg_Data is set to 0x73 (115 decimal). The

number of Inputs and Outputs in the Process Data is defined by setting bytes to either 0x50 (80

decimal), 0x60 (96 decimal) or 0x70 (112 decimal). The maximum number of Process Data

parameters is 30.

,QGH[

+1R#'HPDQG#'DWD,

,QGH[

+:LWK#'HPDQG#'DWD,

,GHQWLILHU#%\WH

++H[DGHFLPDO,

$FWLRQ

0

3

3[:6

(QDEOH#'HPDQG#'DWD

3

4

3[83

5HDG#4VW#3DUDPHWHU

3[93

:ULWH#4VW#3DUDPHWHU

3[:3

5HDG2:ULWH#4VW

3DUDPHWHU

3[83

5HDG#5QG#3DUDPHWHU

3[93

:ULWH#5QG#3DUDPHWHU

3[:3

5HDG#DQG#:ULWH#5QG

3DUDPHWHU

4

5

HWF

HWF

HWF

HWF

5<

63

3[83

5HDG#63WK#3DUDPHWHU

3[93

:ULWH#63WK#3DUDPHWHU

3[:3

5HDG#DQG#:ULWH#63WK

3DUDPHWHU

For example:

,QGH[

'DWD

0HDQLQJ

3

3[93

4VW#3DUDPHWHU#2XWSXW##+1R#'HPDQG#'DWD,

4

3[93

5QG#3DUDPHWHU#2XWSXW

5

3[83

6UG#3DUDPHWHU#,QSXW

6

3[83

7WK#3DUDPHWHU#,QSXW

The supported Identifier Byte formats are defined by the Profibus Standard to have the following

meaning:

,GHQWLILHU

,QSXW22XWSXW

/HQJWK

)RUPDW

&RQVLVWHQF\

3[83

,QSXW

4

:RUG

1RQH

3[93

2XWSXW

4

:RUG

1RQH

3[:3

,QSXW02XWSXW

4

:RUG

1RQH

3[:6

,Q#DQG#2XW

7

:RUG

1RQH

1RWH=# $OO#SDUDPHWHU#YDOXHV#DUH#WUDQVIHUUHG#DV#:RUGV#+5#RFWHWV,1

352),%860'3#&RPPXQLFDWLRQV#,QWHUIDFH#0#+$7968948334

4:

8VHU#3DUDPHWHU#'DWD#+8VUB3UPB'DWD,

The Usr_Prm_Data is used to specify the Tag numbers of the parameters that are to be read or

written as Process Data. Each parameter is represented by 2 bytes in the Usr_Prm_Data, these

specify the Tag number in High-Byte/Low-Byte order.

The first 3 bytes of the Usr_Prm_Data are reserved for the future implementation on the DPV1

Profibus extensions. These must be set to zero. The High-Byte of the first Tag number must be in

the 4th byte.

The Usr_Prm_Data may be up to 63 Bytes long. If less than 63 Bytes are sent, the length must be

3 x 2n, where n is a number between 0 and 30. Unused Bytes must be set to zero and must be at

the end of the Tag declarations.

The number of Tags declared must match the number of Inputs, Outputs and Input-Outputs

declared to be in the Process Data by the Cfg_Data.

,QGH[

'DWD

3DUDPHWHU

3

5HVHUYHG#IRU#'394

4

5HVHUYHG#IRU#'394

5

5HVHUYHG#IRU#'394

6

+LJK0%\WH

7

/RZ0%\WH

8

+LJK0%\WH

9

/RZ0%\WH

:

+LJK0%\WH

;

/RZ0%\WH

HWF

HWF

HWF

94

+LJK0%\WH

63WK

95

/RZ0%\WH

4VW

5QG

6UG

For example:

,QGH[

'DWD#++H[DGHFLPDO,

3DUDPHWHU

3

3[33

5HVHUYHG

4

3[33

5

3[33

6

3[34

7

3[3)

8

3[34

9

3[3'

:

3[34

;

3[43

<

3[33

43

3[))

352),%860'3#&RPPXQLFDWLRQV#,QWHUIDFH#0#+$7968948334

7DJ#1XPEHU#5:4

7DJ#1XPEHU#59<

7DJ#1XPEHU#5:5

7DJ#1XPEHU#588

4;

When entered using a Profibus configuration tool, the above example would typically be

displayed as:

00,00,00,01,0F,01,0D,01,10,00,FF

Some configuration tools will alway display the number of bytes declared in the supplied GSD,

in this case 63. So the above example will appear as:

00,00,00,01,0F,01,0D,01,10,00,FF,00,00,00,00,00,00,00.....

'HPDQG#'DWD#3URWRFRO

Demand Data is a sub-protocol using the first 8 bytes (octets) in both the request and response

message of the cyclic Data Exchange. It allows random read/write access to any parameter within

the Drive. It is enabled by the Profibus-DP- Master setting the first byte of the Cfg_Data to 0x73.

(See Chapter 6, Configuration.)

The sub-protocol consists of 3 parts:

• Command

• Parameter Reference (Tag Number)

• Parameter Value or Error Code

Byte

0

1

2

Cmd / Tag

Bit

15

3

4

5

7

Value

Reserved

12

6

10

11

0

Parameter Tag Number

Command

Reserved

&RPPDQG

The Command field in the request message selects the required operation. This is either None,

Read or Write.

The Command field in the response message either confirms that no operation has been

requested, indicates that a Read or Write request has been completed successfully or indicates

that a Read or Write request has failed.

Valid values for the Command field are:

&RPPDQG

5HTXHVW#+0DVWHU#WR#6ODYH,

5HVSRQVH#+6ODYH#WR#0DVWHU,

3

1R#&RPPDQG

$FNQRZOHGJH#1R#&RPPDQG

4

5HDG#5HTXHVW

$FNQRZOHGJH#7UDQVIHU

5

:ULWH#5HTXHVW

00

:

00

5HMHFW#5HTXHVW

352),%860'3#&RPPXQLFDWLRQV#,QWHUIDFH#0#+$7968948334

4<

The valid Request/Response Command pairs are:

5HTXHVW#&RPPDQG

5HVSRQVH#&RPPDQG

3

3

4

4#RU#:

5

4#RU#:

3DUDPHWHU#5HIHUHQFH#+7DJ#1XPEHU,

The Parameter Tag Number is the unique reference to a parameter within the Drive. These are

listed in the Product Manual.

3DUDPHWHU#9DOXH#RU#(UURU#&RGH

The Value/Error Code field is used to receive a Read value, send a Write value or receive an

error code.

The Value is a signed or unsigned 16-bit integer. The scaling for each parameter is described in

the Product Manual for the host Drive.

If the Response Command is 7, i.e. the request has been rejected, this field contains the error

code. These are:

(UURU#&RGH

0HDQLQJ

3

,QYDOLG#7DJ#1XPEHU

4

5HDG#2QO\#3DUDPHWHU

5

9DOXH#8QGHU22YHU05DQJH

'DWD#(QFRGLQJ

All parameter values are transferred in the Data Exchange telegram as Words (2 octets). The

most significant octet is transmitted first, e.g.

7\SH

9DOXH

+GHFLPDO,

7UDQVPLWWHG#9DOXH

+KH[DGHFLPDO,

,17

633133

:863

,17

0633133

;$'3

%22/

)$/6(

3333

%22/

758(

3334

1RWH=# 7KH#GHFLPDO#SRLQW#SRVLWLRQ#LV#QRW#WUDQVPLWWHG1#5HIHU#WR#WKH#3URGXFW#PDQXDO#IRU#WKH#FRUUHFW

VFDOLQJ1

352),%860'3#&RPPXQLFDWLRQV#,QWHUIDFH#0#+$7968948334

53

352),%86#'LDJQRVWLFV

Profibus DP provides diagnostic information for each slave unit. The Profibus Technology

Option uses the 'ExtDiagData' of the diagnostic telegram (bytes 7, 8 and 9) to provide Trip status

and user specified events. The Profibus master is notified whenever any of the monitored events

change state. The documentation supplied with the master should provide details on how to

access diagnostic information.

An example 605A & B diagnostic response telegram:

Octet 1

Octet 2

Octet 3

Octet 4

Octet 5

Octet 6

Octet 7

Octet 8

00

0C

00

01

16

49

04

01

Octet 9 Octet 10

6A

B5

Octet 7 signifies 4 bytes of information is included.

Octet 8 indicates a "Link Overvolts" Trip

Octets 9 and 10 indicate that the EXT DIAGNOSTIC parameter is set to 6AB5.

938$#)#%/#938&/#8;769=

Octet 8, bits 0 to 4, contain the reason why the drive has tripped. (Bits 5 to 7 are reserved for

future use.) The value contained in bits 0 to 4 have the following meaning:

0 = No Trip

9 = I*t

1 = Link Overvolts

10 = Brake Resistor

2 = Link Undervolts

11 = Brake Switch

3 = Link Overcurrent

12 = Operator Station

4 = Heatsink Temperature

13 = Lost Communications

5 = External Trip

17 = Motor Temperature

6 = Input 1 Break

18 = Current Limit

7 = Input 2 Break

20 = 24V Failure

8 = Motor Stalled

21 = Low Speed Current

Octets 9 and 10 are the most significant byte and least significant byte of the EXT

DIAGNOSTIC input parameter of the TEC OPTION Function Block.

8<3./#8<3.'59=

The interface cannot distinguish the reason why the drive has tripped. The value contained in bits

0 to 4 have the following meaning:

0 = No Trip

31 = Tripped

352),%860'3#&RPPXQLFDWLRQV#,QWHUIDFH#0#+$7968948334

54

7URXEOHVKRRWLQJ

1(7:25.

02'8/(

&DXVH26\PSWRP

1R#SRZHU#DW#WKH#GULYH1

5HPHG\

&KHFN#DQG#DSSO\#SRZHU#WR#WKH#GULYH1

+2)),

7HFKQRORJ\#%R[22SWLRQ#QRW#LQVWDOOHG &KHFN#FRQQHFWLRQV#EHWZHHQ#7HFKQRORJ\

FRUUHFWO\1

%R[22SWLRQ#DQG#GULYH1#2Q#938$#)#%/#FKHFN#WKH

ULEERQ#FDEOH1

+DUGZDUH#IDXOW1

,I#+($/7+#DQG#581#/('6#DUH#2))/#UHSODFH#WKH

938$#)#%#:$51,1*=#5HPRYH#WKH GULYH/#HOVH#UHSODFH#WKH#7HFKQRORJ\#%R[22SWLRQ1

WHUPLQDO#FRYHU#DQG#WKH#7HFKQRORJ\

%R[#ZKLOVW#FRQQHFWHG#WR#VHH#WKH

GULYH·V#+($/7+#DQG#581#/('V1

%(:$5(#2)#(/(&75,+2&.1

7KH#VHOI0WHVW#KDV#IDLOHG1

5HSODFH#WKH#7HFKQRORJ\#%R[22SWLRQ1

,QFRUUHFW#7HFKQRORJ\#%R[22SWLRQ

ILWWHG#RU#VHOHFWHG1

)LW#WKH#FRUUHFW#7HFKQRORJ\#%R[22SWLRQ#RU#VHOHFW#WKH

PDWFKLQJ#YDOXH#IRU#WKH#7<3(#SDUDPHWHU#LQ#WKH#7(&

237,21#IXQFWLRQ#EORFN1#+7<3(# #352),%86#'3,1

6HW0XS#IDXOW1#$#7(í,21

SDUDPHWHU#LV#RXW0RI0UDQJH1

6HOHFW#WKH#FRUUHFW#YDOXH#IRU#WKH#SDUDPHWHU#LQ#WKH

7(í,21#IXQFWLRQ#EORFN1

1R#FRPPXQLFDWLRQV#RU#LQWHUPLWWHQW

IDLOXUH

&KHFN#ZLULQJ/#YHULI\LQJ#WKH#FRQWLQXLW\#RI#$#DQG#%

FRQQHFWLRQV#WR#WKH#PDVWHU/#DQG#HQVXUH#WKDW#WKH

FRUUHFW#WHUPLQDOV#KDYH#EHHQ#XVHG1#3D\#SDUWLFXODU

DWWHQWLRQ#WR#WKH#LQWHJULW\#RI#WKH#VFUHHQLQJ1

1R#FRPPXQLFDWLRQV#RU#LQWHUPLWWHQW

IDLOXUH

(QVXUH#WKDW#WKH#PD[LPXP#OLQH#OHQJWK#RI

WUDQVPLVVLRQ#OLQH#KDV#QRW#EHHQ#H[FHHGHG#IRU#WKH

%DXG#UDWH#LQ#XVH1#5HIHU#WR#´0D[LPXP#/LQH#/HQJWK

3HU#6HJPHQWµ/#SDJH#71

1R#FRPPXQLFDWLRQV#RU#LQWHUPLWWHQW

IDLOXUH

(QVXUH#WKDW#WKH#ODVW#XQLW#RQ#WKH#WUDQVPLVVLRQ#OLQH#LV

WHUPLQDWHG#FRUUHFWO\1#1RWH#WKDW#VRPH#HTXLSPHQW

KDV#EXLOW0LQ#UHVLVWRUV##ZKLFK#PD\#EH#VZWLFKHG#LQ#DQG

RXW#RI#FLUFXLW1

:DLWQJ#IRU#YDOLG#3DUDPHWHULVDWLRQ

GDWD

&KHFN#WKH#VODYH#$''5(661#&KHFN#WKDW#LW#LV#XQLTXH1

:DLWQJ#IRU#YDOLG#3DUDPHWHULVDWLRQ

GDWD

(QVXUH#WKDW#WKH#QHWZRUN#KDV#EHHQ#FRUUHFWO\

FRQILJXUHG#DQG#WKDW#WKH#FRQILJXUDWLRQ#KDV#EHHQ

FRUUHFWO\#GRZQORDGHG#WR#WKH#PDVWHU1

:DLWQJ#IRU#YDOLG#3DUDPHWHULVDWLRQ

GDWD

9HULI\#WKDW#WKH#*6'#ILOH#EHLQJ#XVHG#LV#FRUUHFW#E\

ORDGLQJ#LW#LQWR#WKH#*6'#ILOH#FRQILJXUDWRU#WR#FKHFN

WKH#IRUPDW1

:DLWLQJ#IRU#YDOLG#&RQILJXUDWLRQ#GDWD 5HIHU#WR#´,QWHUQDO#'LDJQRVWLFVµ/#SDJH#551

5HDG2:ULWH#IDLOXUH

5HIHU#WR#´,QWHUQDO#'LDJQRVWLFVµ/#SDJH#551

7KH#XQLW#VKRXOG#QRZ#EH#ZRUNLQJ1

,I#WKHUH#LV#VWLOO#D#SUREOHP/#SOHDVH#FKHFN#\RXU#7DJ

QXPEHUV1

352),%860'3#&RPPXQLFDWLRQV#,QWHUIDFH#0#+$7968948334

55

,QWHUQDO#'LDJQRVWLFV

Two parameters of the TEC OPTION function block provide diagnostic information:

1. The NETWORK STATE parameter (and the Technology Option’s LEDs) indicates the area

the problem is in.

2. The INT DIAGNOSTIC parameter allows access to internal network diagnostic information.

(The INT DIAG SELECT parameter selects what information will be output as the INT

DIAGNOSTIC parameter).

,17#',$*#6(/(&7#3DUDPHWHU#9DOXHV

3

6ODYH#&RQILJXUDWLRQ#HUURU1#8VHG#ZKHQ#VWXFN#LQ#WKH#:$,7#3$5$0#RU#:$,7#&21),*#VWDWHV1

3333

1R#HUURU1

3345

3DUDPHWHULVDWLRQ#WHOHJUDP#WRR#ORQJ1

3346

3DUDPHWHULVDWLRQ#WHOHJUDP#LV#D#EDG#OHQJWK1#,I#8VHUB3UPB'DWD#LV#SUHVHQW/#LW#PXVW#EH#RI

OHQJWK#6#.5Q/#ZKHUH#Q#LV#D#YDOXH#3#WR#631

3347

7KH#OLVW#RI#WDJ#QXPEHUV#LQ#WKH#8VU03UPBGDWD#FRQWDLQV#D#]HUR1#=HUR#7DJ#QXPEHUV#DUH#RQO\

DOORZHG#DW#WKH#HQG#RI#WKH#OLVW1

3354

7KH#&RQILJXUDWLRQ#WHOHJUDP#LV#RI#]HUR#OHQJWK1

3355

7KH#&RQILJXUDWLRQ#WHOHJUDP#LV#WRR#ORQJ1#7KH#PD[LPXP#OHQJWK#LV#64/#L1H1#FRQILJXUDWLRQ#IRU

63#LQSXWV/#RXWSXWV#RU#LQSXW0RXWSXWV/#SOXV#'HPDQG#'DWD1

3356

7KH#&RQILJXUDWLRQ#WHOHJUDP#FRQWDLQV#DQ#XQVXSSRUWHG#LGHQWLILHU#E\WH1#6HH#&RQILJXUDWLRQ

'DWD#VHFWLRQ1

3357

7KH#&RQILJXUDWLRQ#WHOHJUDP#FRQWDLQV#WRR#IHZ#LGHQWLILHU#E\WHV1#([FOXGLQJ#WKH#'HPDQG#'DWD

LGHQWLILHU#E\WH/#LI#SUHVHQW/#WKH\#PXVW#PDWFK#WKH#TXDQWLW\#RI#7DJV#GHFODUHG#LQ#WKH

3DUDPHWHULVDWLRQ#WHOHJUDP1

3358

7KH#&RQILJXUDWLRQ#WHOHJUDP#FRQWDLQV#WRR#PDQ\#LGHQWLILHU#E\WHV1#6HH#DERYH1

433#WR#45<

'LVSOD\V#7DJ#QXPEHU#+LQ#KH[DGHFLPDO,#RI#SDUDPHWHU#3#WR#5</#H1J1#VHWWLQJ#,17#',$*#6(/(&7#WR#434

ZLOO#VKRZ#WKH#7DJ#QXPEHU#RI#WKH#5QG#SDUDPHWHU1

533#WR#55<

'LVSOD\V#DFFHVV#PRGH#IRU#SDUDPHWHU#3#WR#5<1

633#WR#65<

3334

,QSXW#WR#PDVWHU/#L1H1#UHDG1

3335

2XWSXW#IURP#PDVWHU/#L1H1#ZULWH1

3336

,QSXW#DQG#RXWSXW/#L1H1#ERWK#UHDG#DQG#ZULWH1

'LVSOD\V#DFFHVV#HUURU#IRU#SDUDPHWHU#3#WR#5<1

3333

1R#HUURU1

3334

'DWD#RXW#RI#UDQJH1#7KH#YDOXH#EHLQJ#ZULWWHQ#E\#WKH#PDVWHU#LV#HLWKHU#OHVV#WKDQ#WKH#ORZ#OLPLW#RU

JUHDWHU#WKDQ#WKH#KLJK#OLPLW#IRU#WKH#VSHFLILHG#SDUDPHWHU1

3335

5HDG#RQO\1#7KH#PDVWHU#LV#DWWHPSWLQJ#WR#ZULWH#WR#D#UHDG0RQO\#SDUDPHWHU1

3336

1RW#6WRS#PRGH1#7KH#PDVWHU#LV#DWWHPSWLQJ#WR#ZULWH#WR#D#SDUDPHWHU#ZKLFK#FDQ#RQO\#EH

XSGDWHG#ZKHQ#WKH#GULYH#LV#LQ#WKH#6WRS#PRGH/#EXW#LW#LV#LQ#WKH#5XQ#PRGH1

3337

1RW#&RQILJXUDWLRQ#PRGH1#7KH#PDVWHU#LV#DWWHPSWLQJ#WR#ZULWH#WR#D#SDUDPHWHU#ZKLFK#FDQ#RQO\

EH#XSGDWHG#ZKHQ#WKH#GULYH#LV#LQ#WKH#&RQILJXUDWLRQ#PRGH/#EXW#LW#LV#LQ#WKH#QRUPDO#RSHUDWLQJ

PRGH1

3338

8QVXSSRUWHG#W\SH1#7KH#PDVWHU#LV#DWWHPSWLQJ#WR#UHDG#RU#ZULWH#D#SDUDPHWHU#RI#D#W\SH#ZKLFK

LV#QRW#VXSSRUWHG#E\#WKLV#LPSOHPHQWDWLRQ#RI#WKH#3URILEXV/#L1H1#W\SH#675,1*1

3339

,QYDOLG#7DJ#QXPEHU1#7KH#PDVWHU#LV#DWWHPSWLQJ#WR#UHDG#RU#ZULWH#D#SDUDPHWHU#WKDW#GRHV#QRW

H[LVW1

733#WR#75<

'LVSOD\V#ODVW#UHDG#YDOXH#+LQ#KH[DGHFLPDO,#IRU#SDUDPHWHU#3#WR#5<1

833#WR#85<

'LVSOD\V#ODVW#ZULWH#YDOXH#+LQ#KH[DGHFLPDO,#IRU#SDUDPHWHU#3#WR#5<1#1RWH#0#3333#LI#QHYHU#ZULWWHQ#WR#E\

PDVWHU1

352),%860'3#&RPPXQLFDWLRQV#,QWHUIDFH#0#+$7968948334

56

'HFLPDO2+H[DGHFLPDO#7DEOH

3

43

53

63

73

83

93

:3

;3

<3

433

443

453

463

473

483

493

4:3

4;3

4<3

533

543

553

563

573

583

593

5:3

5;3

5<3

633

643

653

663

673

683

693

6:3

6;3

6<3

733

743

753

763

773

783

793

7:3

7;3

7<3

3

3333

333$

3347

334(

335;

3365

336&

3379

3383

338$

3397

339(

33:;

33;5

33;&

33<9

33$3

33$$

33%7

33%(

33&;

33'5

33'&

33(9

33)3

33)$

3437

343(

344;

3455

345&

3469

3473

347$

3487

348(

349;

34:5

34:&

34;9

34<3

34<$

34$7

34$(

34%;

34&5

34&&

34'9

34(3

34($

4

3334

333%

3348

334)

335<

3366

336'

337:

3384

338%

3398

339)

33:<

33;6

33;'

33<:

33$4

33$%

33%8

33%)

33&<

33'6

33''

33(:

33)4

33)%

3438

343)

344<

3456

345'

346:

3474

347%

3488

348)

349<

34:6

34:'

34;:

34<4

34<%

34$8

34$)

34%<

34&6

34&'

34':

34(4

34(%

5

3335

333&

3349

3353

335$

3367

336(

337;

3385

338&

3399

33:3

33:$

33;7

33;(

33<;

33$5

33$&

33%9

33&3

33&$

33'7

33'(

33(;

33)5

33)&

3439

3443

344$

3457

345(

346;

3475

347&

3489

3493

349$

34:7

34:(

34;;

34<5

34<&

34$9

34%3

34%$

34&7

34&(

34';

34(5

34(&

6

3336

333'

334:

3354

335%

3368

336)

337<

3386

338'

339:

33:4

33:%

33;8

33;)

33<<

33$6

33$'

33%:

33&4

33&%

33'8

33')

33(<

33)6

33)'

343:

3444

344%

3458

345)

346<

3476

347'

348:

3494

349%

34:8

34:)

34;<

34<6

34<'

34$:

34%4

34%%

34&8

34&)

34'<

34(6

34('

352),%860'3#&RPPXQLFDWLRQV#,QWHUIDFH#0#+$7968948334

7

3337

333(

334;

3355

335&

3369

3373

337$

3387

338(

339;

33:5

33:&

33;9

33<3

33<$

33$7

33$(

33%;

33&5

33&&

33'9

33(3

33($

33)7

33)(

343;

3445

344&

3459

3463

346$

3477

347(

348;

3495

349&

34:9

34;3

34;$

34<7

34<(

34$;

34%5

34%&

34&9

34'3

34'$

34(7

34((

8

3338

333)

334<

3356

335'

336:

3374

337%

3388

338)

339<

33:6

33:'

33;:

33<4

33<%

33$8

33$)

33%<

33&6

33&'

33':

33(4

33(%

33)8

33))

343<

3446

344'

345:

3464

346%

3478

347)

348<

3496

349'

34::

34;4

34;%

34<8

34<)

34$<

34%6

34%'

34&:

34'4

34'%

34(8

34()

9

3339

3343

334$

3357

335(

336;

3375

337&

3389

3393

339$

33:7

33:(

33;;

33<5

33<&

33$9

33%3

33%$

33&7

33&(

33';

33(5

33(&

33)9

3433

343$

3447

344(

345;

3465

346&

3479

3483

348$

3497

349(

34:;

34;5

34;&

34<9

34$3

34$$

34%7

34%(

34&;

34'5

34'&

34(9

34)3

:

333:

3344

334%

3358

335)

336<

3376

337'

338:

3394

339%

33:8

33:)

33;<

33<6

33<'

33$:

33%4

33%%

33&8

33&)

33'<

33(6

33('

33):

3434

343%

3448

344)

345<

3466

346'

347:

3484

348%

3498

349)

34:<

34;6

34;'

34<:

34$4

34$%

34%8

34%)

34&<

34'6

34''

34(:

34)4

;

333;

3345

334&

3359

3363

336$

3377

337(

338;

3395

339&

33:9

33;3

33;$

33<7

33<(

33$;

33%5

33%&

33&9

33'3

33'$

33(7

33((

33);

3435

343&

3449

3453

345$

3467

346(

347;

3485

348&

3499

34:3

34:$

34;7

34;(

34<;

34$5

34$&

34%9

34&3

34&$

34'7

34'(

34(;

34)5

<

333<

3346

334'

335:

3364

336%

3378

337)

338<

3396

339'

33::

33;4

33;%

33<8

33<)

33$<

33%6

33%'

33&:

33'4

33'%

33(8

33()

33)<

3436

343'

344:

3454

345%

3468

346)

347<

3486

348'

349:

34:4

34:%

34;8

34;)

34<<

34$6

34$'

34%:

34&4

34&%

34'8

34')

34(<

34)6

57

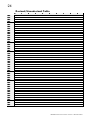

'HFLPDO2+H[DGHFLPDO#7DEOH

833

843

853

863

873

883

893

8:3

8;3

8<3

933

943

953

963

973

983

993

9:3

9;3

9<3

:33

:43

:53

:63

:73

:83

:93

::3

:;3

:<3

;33

;43

;53

;63

;73

;83

;93

;:3

;;3

;<3

<33

<43

<53

<63

<73

<83

<93

<:3

<;3

<<3

3

34)7

34)(

353;

3545

354&

3559

3563

356$

3577

357(

358;

3595

359&

35:9

35;3

35;$

35<7

35<(

35$;

35%5

35%&

35&9

35'3

35'$

35(7

35((

35);

3635

363&

3649

3653

365$

3667

366(

367;

3685

368&

3699

36:3

36:$

36;7

36;(

36<;

36$5

36$&

36%9

36&3

36&$

36'7

36'(

4

34)8

34))

353<

3546

354'

355:

3564

356%

3578

357)

358<

3596

359'

35::

35;4

35;%

35<8

35<)

35$<

35%6

35%'

35&:

35'4

35'%

35(8

35()

35)<

3636

363'

364:

3654

365%

3668

366)

367<

3686

368'

369:

36:4

36:%

36;8

36;)

36<<

36$6

36$'

36%:

36&4

36&%

36'8

36')

5

34)9

3533

353$

3547

354(

355;

3565

356&

3579

3583

358$

3597

359(

35:;

35;5

35;&

35<9

35$3

35$$

35%7

35%(

35&;

35'5

35'&

35(9

35)3

35)$

3637

363(

364;

3655

365&

3669

3673

367$

3687

368(

369;

36:5

36:&

36;9

36<3

36<$

36$7

36$(

36%;

36&5

36&&

36'9

36(3

6

34):

3534

353%

3548

354)

355<

3566

356'

357:

3584

358%

3598

359)

35:<

35;6

35;'

35<:

35$4

35$%

35%8

35%)

35&<

35'6

35''

35(:

35)4

35)%

3638

363)

364<

3656

365'

366:

3674

367%

3688

368)

369<

36:6

36:'

36;:

36<4

36<%

36$8

36$)

36%<

36&6

36&'

36':

36(4

7

34);

3535

353&

3549

3553

355$

3567

356(

357;

3585

358&

3599

35:3

35:$

35;7

35;(

35<;

35$5

35$&

35%9

35&3

35&$

35'7

35'(

35(;

35)5

35)&

3639

3643

364$

3657

365(

366;

3675

367&

3689

3693

369$

36:7

36:(

36;;

36<5

36<&

36$9

36%3

36%$

36&7

36&(

36';

36(5

8

34)<

3536

353'

354:

3554

355%

3568

356)

357<

3586

358'

359:

35:4

35:%

35;8

35;)

35<<

35$6

35$'

35%:

35&4

35&%

35'8

35')

35(<

35)6

35)'

363:

3644

364%

3658

365)

366<

3676

367'

368:

3694

369%

36:8

36:)

36;<

36<6

36<'

36$:

36%4

36%%

36&8

36&)

36'<

36(6

9

34)$

3537

353(

354;

3555

355&

3569

3573

357$

3587

358(

359;

35:5

35:&

35;9

35<3

35<$

35$7

35$(

35%;

35&5

35&&

35'9

35(3

35($

35)7

35)(

363;

3645

364&

3659

3663

366$

3677

367(

368;

3695

369&

36:9

36;3

36;$

36<7

36<(

36$;

36%5

36%&

36&9

36'3

36'$

36(7

:

34)%

3538

353)

354<

3556

355'

356:

3574

357%

3588

358)

359<

35:6

35:'

35;:

35<4

35<%

35$8

35$)

35%<

35&6

35&'

35':

35(4

35(%

35)8

35))

363<

3646

364'

365:

3664

366%

3678

367)

368<

3696

369'

36::

36;4

36;%

36<8

36<)

36$<

36%6

36%'

36&:

36'4

36'%

36(8

;

34)&

3539

3543

354$

3557

355(

356;

3575

357&

3589

3593

359$

35:7

35:(

35;;

35<5

35<&

35$9

35%3

35%$

35&7

35&(

35';

35(5

35(&

35)9

3633

363$

3647

364(

365;

3665

366&

3679

3683

368$

3697

369(

36:;

36;5

36;&

36<9

36$3

36$$

36%7

36%(

36&;

36'5

36'&

36(9

<

34)'

353:

3544

354%

3558

355)

356<

3576

357'

358:

3594

359%

35:8

35:)

35;<

35<6

35<'

35$:

35%4

35%%

35&8

35&)

35'<

35(6

35('

35):

3634

363%

3648

364)

365<

3666

366'

367:

3684

368%

3698

369)

36:<

36;6

36;'

36<:

36$4

36$%

36%8

36%)

36&<

36'6

36''

36(:

352),%860'3#&RPPXQLFDWLRQV#,QWHUIDFH#0#+$7968948334