Download Ford Power Stroke Diesel No-start Diagnosis

Transcript

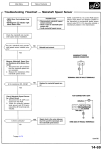

FORD POWER STROKE DIESEL NO-START DIAGNOSIS BY BOB PATTENGALE Service opportunities on diesel-powered vehicles are on the rise. If your shop is looking for additional revenue, taking on the oil-burners could be the ticket. But to be successful, you’ll need the right tools and training. H ow do you approach a familiar no-start or driveability problem? Do you jump right in, relying on past knowledge of common problems, or do you follow a set diagnostic strategy to ensure nothing is overlooked. What about when a vehicle manufacturer makes changes to the engine man- 36 November 2011 agement system? Do you take time to understand the system first or do you dive right into the diagnostic process, hoping your experience wins out? What happens if your first couple of educated guesses don’t resolve the problem? Effective and efficient repair of today’s vehicles requires an understanding of how each system operates before the diagnostic process begins. It’s Photoillustration: Harold A. Perry; images: Thinkstock & Wieck Media Don’t Start Something You Can’t Finish November 2011 37 FORD POWER STROKE DIESEL NO-START DIAGNOSIS High-Pressure Oil Rails Oil Filter Oil Reservoir for High-Pressure Pump HighPressure Oil Pump Oil Cooler IPR Sensor ICP Sensor Drain to Crankcase Fig. 1 This illustration shows the low-pressure and high-pressure oil systems for the 6.0L diesel engine. The fuel system must have the correct oil pressure to operate, so oil-related problems are common causes of hard-start/no-start issues. nice to have troubleshooter tips, but there’s no substitute for a firm grasp of how the components relate to one another and what happens when everything is working right. Many assume top driveability technicians quickly diagnose problems because they’re able to complete all the tasks in a fault tree the fastest or because they know all the common issues. The truth is they’re able to look at the symptoms, make a logical decision on where the diagnostic process 38 November 2011 should begin and then follow the best path for resolution. The opportunity to repair diesel vehicles is on the rise, and if your shop is looking for additional revenue, diesel repair can be it. To be successful you need to have the right tools and technicians who understand how diesel systems work. Ford diesel truck repair is a good opportunity. It’s also an excellent example of how things can change very quickly. In the past 10 years, Ford has offered four different platforms—7.3L, 6.0L, 6.4L and now the 6.7L—and although the basic combustion process for each is similar, how the fuel is supplied to the cylinders is very different. This article will focus on a common driveability complaint with the Ford 6.0L diesel engine, then explain how the 6.4L fuel delivery system differs from the 6.0L. Hard-start and no-start complaints are a common issue with Ford 6.0L diesel engines, and experienced techni- Courtesy Ford Motor Co. Fuel Injectors Oil Pump Photo courtesy Automotive Training Group, Inc. cians are able to determine the root cause very quickly. But they can do this only because they understand how the system operates. Technicians with limited experience will most likely begin with the “Hard Start/No Start Diagnostic Guide” developed by Ford. We don’t have the space to reproduce it here, but it can be found at http://tinyurl.com/64dvmu5. This comprehensive guide is designed to provide a logical diagnostic flow and help the technician avoid overlooking potential issues, which from Ford’s perspective will ensure that the vehicle is repaired efficiently and correctly the first time. Technicians using this guide will locate the root cause, but they may not understand why they’re performing the steps listed. One example is step 2: “Check Engine Oil Level – Check for contaminants (fuel, coolant), Correct Grade/Viscosity, Miles/Hours on oil, correct level.” Engine oil quality and level are critical for correct operation of the fuel injectors and a common cause of hard-start/no-start issues. Why is the engine oil so critical? Fig. 1 on page 38 shows a simple oil flow schematic for the 6.0L diesel engine. In order for the fuel injectors to operate, a minimum of 500 psi oil pressure is required for start-up. The highpressure oil pump can deliver up to 3600 psi, but only if the low-pressure oil system delivers the oil to the high-pressure pump. Understanding the low-pressure and high-pressure oil systems is critical for diagnosing hard-start/no-start problems, so let’s take a closer look at these systems in detail. The low-pressure oil system begins with the oil pump drawing oil from the oil pan. Oil pressure in excess of 70 psi between the pump and oil cooler is vented back to the oil pan. The oil travels from the oil pump to the oil cooler and any pressure greater than 25 psi is diverted around the oil cooler to the oil filter. The benefit is providing an alternative oil flow path during high oil flow conditions. This is what can happen when a customer skips preventive maintenance. Oil sludge builds up and can damage the reservoir filter screen. Once the screen is compromised, debris can enter the high-pressure pump. The oil travels from the oil cooler to the oil filter, and any pressure greater than 20 psi bypasses the oil filter and travels to the high-pressure reservoir. The oil filter housing contains two critical valves: One is an oil change drain valve that opens when the oil filter is Understanding the low- and high-pressure oil systems is critical for diagnosing hard-start/nostart problems. removed, allowing the oil to drain back into the pan; the other is an antidrainback valve that uses a one-way check valve to keep oil in the housing with the engine off and the filter installed. This ensures that oil is available on initial start-ups. The oil travels to the high-pressure reservoir, where approximately 1 quart of oil is stored. The high-pressure oil pump draws oil from the reservoir through a 3in. screen designed to catch debris. The photo above shows what can happen when preventive maintenance is neglected. Keep in mind that once this screen is damaged, debris will enter the highpressure pump and be carried through the high-pressure system. The high-pressure oil pump is driven by the camshaft and produces the highpressure oil needed to properly operate the fuel injectors. The pump is capable of producing more volume and pressure than is needed for normal operation, and the excess volume is controlled by the powertrain control module (PCM). Next in line is the injection control pressure (ICP) sensor, which measures the oil pressure leaving the pump and reports this to the PCM. The PCM uses November 2011 39 FORD POWER STROKE DIESEL NO-START DIAGNOSIS Here are two examples of where oil pressure may be lost in the high-pressure system. Injection pressure regulator (IPR) damage (left photo) and O-ring issues (right) are very common causes of hard-start and no-start complaints. the information from the ICP sensor to regulate the oil pressure using the injection pressure regulator (IPR). This is a duty-cycle-controlled solenoid that opens and closes to achieve the desired oil pressure. The IPR duty cycle for a normal hot idle engine is approximately 30%. In order to maintain the correct oil pressure, excess oil is diverted back to the oil pan. During engine start-up, the PCM needs to see at least 500 psi. If the pressure is too low, the PCM increases the duty cycle percentage; in other words, it closes the IPR, creating a restriction to increase the oil pressure. If the PCM command reaches 85%, the IPR is fully closed, which indicates a major problem in the oil supply chain. The photo above left shows a damaged IPR where the debris catch screen is almost completely gone. IPRs are common failure items and will normally point to additional problems. For example, if you find the high-pressure oil reservoir screen is damaged, then the IPR will likely have debris present, and if the IPR screen is damaged or 40 November 2011 clogged, the high-pressure oil reservoir screen is likely damaged as well. After leaving the high-pressure oil pump, the oil travels through a series of branch tubes, standpipes, passages, During engine start-up, the PCM must see at least 500 psi. If the pressure is too low, the PCM closes the IPR. high-pressure oil rails and finally the fuel injectors. Keep in mind that these connection points will have O-rings sealing the system. Fig. 1 cannot properly demonstrate all the possibilities, but if you look at where the lines connect to the components described, each point would likely have an O-ring. O-rings should never be reused under any circumstance. We’ll discuss how to check for leaks later in the article. Steps 1 through 6 in the “Ford Hard Start/No Start Diagnostic Guide” deal with visual inspection, engine oil quality, intake/exhaust restrictions, fuel quality and fuel pump pressure and volume. Steps 7 through 9 cover checking for diagnostic trouble codes (DTCs) and performing KOEO tests. Experienced technicians will check for DTCs first. If the following DTCs are present—P1378, Fuel Injection Control Module (FICM) voltage circuit low; P0611, FICM Internal Failure; P0261, P0264, P0267, P0270, P0273, P0276, P0279 and P0282, All Fuel Injector Circuits are low; and/or U0105, Lost communication with FICM—the most likely FORD POWER STROKE DIESEL NO-START DIAGNOSIS cause will be a faulty FICM. Powers, grounds and connections between the FICM and PCM should be checked prior to replacement of the FICM. In cases where the FICM connections test okay, it’s always a good idea to check for newer PCM/FICM calibrations. It’s not uncommon to find TSBs where the only fix is updating the controller software. If no DTCs are present or if the DTCs do not relate to a no-start condition, continue to step 10, Scan Tool – Data List Monitoring. This is the step where you really get to see what’s happening with the engine management system. It lists eight specific parameters that should be monitored while cranking the engine. Fig. 2 These screen captures show the critical parameters that should be watched while cranking the engine. The capture on the top is from a knowngood vehicle, while the one above is from a defective vehicle. 42 November 2011 The two screen captures in Fig. 2 show the parameters that should be monitored while cranking the engine. Keep in mind that if the battery voltage drops below 9.5 volts, the scan tool might reset. If this occurs, correct the battery issue before continuing. In this example, Engine Oil Temperature (EOT) is included but is not a parameter that needs to be monitored while cranking. The initial note on the Diagnostic Guide is checking EOT. If it’s below 60°F and the vehicle will not start, and the recommendation is to check the Glow Plug System Operation first. A – V PWR. Module Voltage B – FICMLPWR. FICM Logic Power C – FICMVPWR. FICM Vehicle Power. The Guide specifies 8 volts minimum for all three (A, B and C), but above 9.5 is a real-world value. If the voltage values are below the recommended specification, this should be corrected first. D – RPM. The form states 100 rpm minimum, but a real-world value is above 120 rpm. Low rpm can be caused by electrical issues. If the value is 0, check the crankshaft position sensor (CKP). E – ICP. ICP Pressure. A minimum of 500 psi is required for injector operation. As detailed earlier, there are many possible causes for low ICP pressure. The possible causes could be located in the low-pressure or high-pressure section. F – ICP V. ICP Voltage. Minimum voltage is specified as .80 volt while cranking. Zero volts might indicate wiring or connector issues. G – Fuel PW. Injector pulse width defaults to 0 without a CKP signal. Range 500µS to 2mS. H – FICMSYNC. No sync from the FICM could be caused by camshaft position sensor (CMP) or CKP faults. The value should be YES after 120 rpm is reached. The Diagnostic Guide does not reference IPR % = Inj Press Reg, but this is a critical parameter for checking the state of oil system health. As discussed earlier, IPR should be approximately 30% idling FORD POWER STROKE DIESEL NO-START DIAGNOSIS hot. If the value is higher or has reached 85%, there’s an issue with the oil system, and it’s only a matter of time before a hard-start or no-start issue develops. If you service vehicles equipped with this shows the vehicle running after warm restart with the ICP pressure high. But the pressure will continue to lower to the desired level. The Inj Press Reg percentage will continue to decrease until the ICP desired pressure is reached. The screen capture on the bottom shows that the vehicle will not start. The voltage values are normal, rpm is greater than 120, sync from the FICM is normal. The ICP is below 500 psi and the Inj Press Reg has reached 85%, which means there’s an issue in the oil system. Fig. 3 graphically displays two vehicles while cranking. The recording at the top shows a vehicle that will not start. The red vertical lines relate to the values below the graph. In this case rpm is good but ICP is not capable of reaching 500 psi and the IPR is fully closed. The bottom recording shows a vehicle that’s operating properly. The timeline shows that it takes less than 4 seconds to start and stabilize the injection control pressure. By now you should start to see a trend. After a quick glance at the other parameters, the primary focus should be the ICP and the IPR percentage. If the ICP is unable to reach 500 psi, you need to determine why. Step 1: Check the lowside oil pump pressure. Also, pay close attention to the oil filter and related check valves. Step 2: Using a scan tool with IPR bidirectional conFig. 3 These are graphical examples of how the ICP, IPR and rpm work together. The screen trol, open and close the IPR capture on top is from a known-bad vehicle that will not start, which had an oil pressure to see if any pressure change leak; the screen capture above is from a known-good vehicle. occurs. If nothing hap- 44 November 2011 engine on a regular basis, it’s not a bad idea to check these values. Now let’s take a closer look at the two scan tool examples. In Fig. 2 on page 42, the screen capture on the top FORD POWER STROKE DIESEL NO-START DIAGNOSIS pens, the IPR will need to be checked. Step 3: The photo below shows an adapter used to check for leaks at the ICP port. The ICP is removed and the adapter/air hose are installed. The shop air pushes the oil out of the high- pressure system through the IPR into the oil pan. Once you hear the air flowing easily, use a scan tool to command the IPR to 85%, which closes off the high-pressure system. If the airflow does not decrease, check the IPR. Now Here are two test devices for diagnosing a no-start condition on a Ford 6.0L Power Stroke diesel engine you cannot live without. The adapter with hose attached (top photo) is used to check for high-pressure leaks at the ICP. The two block-off tools above check the high-pressure pump’s deadhead pressure. 46 November 2011 use a stethoscope and listen for leaks. Step 4: If no leaks are found, use the high-pressure deadhead isolation tools to determine if the high-pressure pump can produce sufficient pressure. Follow the manufacturer’s recommendations for the proper test sequence. The pump should be able to produce 1500 psi while cranking and IPR over 60%. One quick check to determine if ICP is above 500 psi and the vehicle will not start is to verify that the ICP is accurate. Simply disconnect the IPR; if the vehicle starts, the ICP is out of calibration and should be replaced. If vehicle does not start, continue with other non-oil-related issues. If you skipped Steps 4 through 6 on the “Hard Start/No Start Diagnostic Guide,” now would be a good time to review the fuelrelated items. Check fuel quality, electric fuel pump pressure and fuel pump inlet restriction. Keep in mind that one bad injector will not create a no-start, so if the oil-related systems test good, the likely cause is fuel-related. Unfortunately, we cannot cover all possible causes and test sequences in detail here, so it’s important to follow all manufacturer recommendations. As for the 6.4L diesel engine, one critical difference between it and the 6.0 is that the 6.4L engine does not use a high-pressure oil system for fuel injector operation. It uses a high-pressure pump, but it’s pressurizing diesel fuel, not oil. If you decided to connect a scan tool looking for ICP, IPR or FICMSYNC, you won’t find these parameters. You’ll be monitoring parameters like pressure control valve, volume control valve and fuel rail pressure sensor. In order to be accurate and efficient when diagnosing Ford’s 6.0L diesel, you need to understand the system you’re diagnosing. The most successful driveability technicians do not rely on troubleshooting tips; they use a logical process based on how the system functions. This article can be found online at www.motormagazine.com.