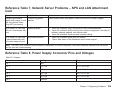

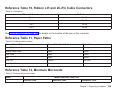

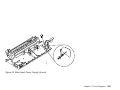

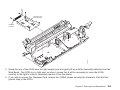

Download IBM 4247 Printer Maintenance Information

Transcript