Download StageFlexer® User`s Manual - Flexcell International Corp.

Transcript

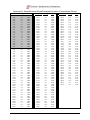

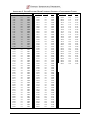

StageFlexer® User's Manual 12-22-14 Rev: 3.0 Culturing Cells in a Mechanically Active Environment™ Flexcell International Corporation 2730 Tucker Street, Suite 200 Burlington, NC 27215 800-728-3714 (919) 732-1591 FAX: (919) 732-5196 www.flexcellint.com COPYRIGHT © 2009 FLEXCELL INTERNATIONAL CORPORATION FLEXCELL® INTERNATIONAL CORPORATION TABLE OF CONTENTS Using the StageFlexer® ...................................................................................................... 1 Introduction ........................................................................................................................ 1 StageFlexer® Assembly ..................................................................................................... 1 Plating and Viewing Cells when using a Loading Station™ .............................................. 3 Using the StageFlexer with the FX-5000™ or Flex Jr.™ Tension System ......................... 3 Minimum Loading Station™ Limitation ............................................................................ 3 Appendices ........................................................................................................................... 4 Appendix 1: StageFlexer® 25 mm Loading Station™ Conversion Chart .......................... 5 Appendix 2: StageFlexer ® 28 mm Loading Station™ Conversion Chart ......................... 6 Appendix 3: StageFlexer ® 31 mm Loading Station™ Conversion Chart ......................... 7 i FLEXCELL® INTERNATIONAL CORPORATION USING THE STAGEFLEXER® INTRODUCTION The Flexcell® StageFlexer® (Fig. 1) in conjunction with the FX-5000™ or Flex Jr. ™ Tension System allows users to observe cell stretching activity under a microscope. Cells are grown on a 42 mm diameter silicone membrane (StageFlexer® Membrane) which is clamped and sealed above a small cylindrical vacuum chamber. When a vacuum is applied, the membrane is pulled downward into this chamber applying strain to the cells growing on the membrane surface (Fig. 2). The membrane can be deformed freely in an open chamber or over a loading post to supply uniform biaxial strain to the cells (Fig. 2). The loading post comes in three different diameters (25 mm, 28 mm, and 31 mm) for varied growth surface area. Figure 2. Schematic of strain application to cells in a StageFlexer® STAGEFLEXER® ASSEMBLY Assemble the eight main parts of the StageFlexer® in the following order (Fig. 3): 1. StageFlexer® body 2. Rubber gasket 3. Loading Station™ 4. Retaining ring 5. O-ring 6. Silicone membrane 7. Top ring 8. Four top screws Figure 1. Flexcell® StageFlexer® Cells in a StageFlexer® can be viewed on a standard microscope. The hole in the bottom of the StageFlexer® allows for illumination through the loading post. Figure 3. StageFlexer® assembly order 1 FLEXCELL® INTERNATIONAL CORPORATION The Loading Station™ (i.e., loading post) is a small hollow acrylic piece that is inserted into the StageFlexer® vacuum chamber. It is used with a rubber gasket and a retaining ring that effectively seal the vacuum within the unit. layer between the silicone membrane and Loading Station™ to reduce friction. Next, place the O-ring over the ridge around the main body of the StageFlexer®. Then carefully place the membrane over top of the vacuum chamber and O-ring and center it using the screw holes around the edge of the StageFlexer®. Finally place the top ring over the membrane and O-ring, put the screws in place, and tighten the assembly to clamp the membrane. To insert the Loading Station™ into the StageFlexer®: 1. Coat the rubber gasket with a thin film of silicone grease on both sides and insert it into the bottom of the StageFlexer®. Add medium to the cells as needed. Connect the 1/4" blue tubing with BioFlex® adapter to the fitting on the front of the StageFlexer®. The base of the assembly should fit onto the microscope base for proper viewing. 2. When using the 25 mm Loading Station™, place it into the StageFlexer first. Using retaining ring pliers to squeeze the retaining ring, close the ring enough to push it into the StageFlexer®. Push the ring down until it snaps into the milled ring hole at the bottom of the StageFlexer®. Getting the ring low enough may require additional vertical pressure from a regular screwdriver or similar tool. Also included with the StageFlexer® is a larger aluminum plate which can be screwed onto the microscope stage. This plate replaces the small plate that is screwed to the bottom of the StageFlexer®. Simply remove the four screws on the bottom of the StageFlexer® and then the small plate. Screw the larger plate in its place such that the long end is facing away from the fitting on the front of the StageFlexer®. The larger base will have to be drilled at the back end to fit onto your particular microscope. The stage clips on your microscope should be held in place by two screws at the back of the stage. The holes to be drilled in the back of the larger base should be distanced apart exactly to fit the two screws that hold the stage clips in place. Once the holes are dimensioned and drilled in the larger StageFlexer® base, attach the base to the stage of the microscope with the screws. This will allow you to easily adjust the position of the StageFlexer® on your microscope and keep it in place over time. 3. When using the 28 mm or 31 mm Loading Stations™, use the retaining ring tool to squeeze the retaining ring around the bottom of the Loading Station™ into the milled ring area. Place the assembly into the StageFlexer® and push the ring down until it snaps into the milled ring hole at the bottom. As before, this may require the use of a regular screwdriver or similar tool. To remove the 25 mm, 28 mm and 31 mm Loading Stations™, reverse the above process. After assembly, use the Lubri-Sil™ lubricant supplied with the post to spread a generous, even layer of lubricant on top of the Loading Station™. The idea is to create a boundary 2 FLEXCELL® INTERNATIONAL CORPORATION PLATING AND VIEWING CELLS ™ USING A LOADING STATION WHEN It should be noted that the only cells that are going to receive uniform strain are those attached to area of the membrane that is over the post when the membrane is in its fully stretched position. Therefore, it is best to attempt to plate cells only in the uniformly strained area or to view or test the cells that are in the uniformly strained area. To determine this area, the following equation can be used: To FX-5000 Diameter = (Diameter of Loading Station)/(1 + (Max%Elongation/100)) To StageFlexer Figure 4. StageFlexer® to FX-5000™ Tension Unit Tubing Adapter The "Max%Elongation" is the maximum % elongation that you plan to use in your regimen. The calculated diameter is the diameter of a circle at the center of the membrane. Any cells outside of this circle will not receive uniform strain. Also included with the system is a white PVC volume that should be used inline with the FLEX IN and FLEX OUT tubing. Because the StageFlexer® has such a low air volume, it is necessary that some extra volume be added to the system for stabilization. The PVC volume is simply added by cutting the larger clear tubing on the FX-5000™/ Flex Jr.™ tubing adapter at its midpoint, and connecting each cut end to the fitting on each end of the PVC volume. USING THE STAGEFLEXER® WITH THE FX5000™ OR FLEX JR. ™ TENSION SYSTEM Connect the front hose barb of the StageFlexer® to the FX-5000™ or Flex Jr.™ as shown in Figure 4. Connect the short blue tubing provided with the StageFlexer® to the front hose barb on the StageFlexer®. Then connect the quick disconnect at the end of the StageFlexer® to the quick disconnect at the end of the tubing shown below. MINIMUM LIMITATION LOADING STATION™ It is important to note that there is a minimum vacuum level in which static friction is overcome on the Loading Stations™. The membrane does not begin to stretch until this point. For the 25mm Loading Station™, this level is -6.0 kPa or 1.6% elongation. For the 28mm Loading Station, this level is -12.0 kPa or 1.9%. For the 31mm Loading Station™, this level is 16.0 kPa or 2.1%. Do not try stretching cells at a % elongation less than that listed for each Loading Station™ diameter. 3 FLEXCELL® INTERNATIONAL CORPORATION APPENDICES Appendix 1: StageFlexer® 25 mm Loading Station™ Conversion Chart Appendix 2: StageFlexer ® 28 mm Loading Station™ Conversion Chart Appendix 3: StageFlexer ® 31 mm Loading Station™ Conversion Chart 4 FLEXCELL® INTERNATIONAL CORPORATION APPENDIX 1: STAGEFLEXER® 25 MM LOADING STATION™ CONVERSION CHART Press (-kPa) % Elong Strain Press (-kPa) % Elong Strain Press (-kPa) % Elong Strain 0.00 0.28 0.57 0.86 1.16 1.46 1.77 2.09 2.41 2.74 3.08 3.42 3.76 4.11 4.47 4.83 5.20 5.57 5.95 6.33 6.72 7.12 7.52 7.93 8.34 8.75 9.18 9.60 10.04 10.47 10.92 11.36 11.82 12.27 12.74 13.21 13.68 14.16 14.64 15.13 15.62 16.12 16.62 17.13 17.64 18.15 18.67 19.20 19.73 20.26 20.80 21.35 21.90 22.45 0.0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1.0 1.1 1.2 1.3 1.4 1.5 1.6 1.7 1.8 1.9 2.0 2.1 2.2 2.3 2.4 2.5 2.6 2.7 2.8 2.9 3.0 3.1 3.2 3.3 3.4 3.5 3.6 3.7 3.8 3.9 4.0 4.1 4.2 4.3 4.4 4.5 4.6 4.7 4.8 4.9 5.0 5.1 5.2 5.3 0.000 0.001 0.002 0.003 0.004 0.005 0.006 0.007 0.008 0.009 0.010 0.011 0.012 0.013 0.014 0.015 0.016 0.017 0.018 0.019 0.020 0.021 0.022 0.023 0.024 0.025 0.026 0.027 0.028 0.029 0.030 0.031 0.032 0.033 0.034 0.035 0.036 0.037 0.038 0.039 0.040 0.041 0.042 0.043 0.044 0.045 0.046 0.047 0.048 0.049 0.050 0.051 0.052 0.053 23.01 23.57 24.13 24.70 25.28 25.86 26.44 27.03 27.62 28.21 28.81 29.41 30.02 30.63 31.25 31.87 32.49 33.12 33.75 34.38 35.02 35.67 36.31 36.96 37.62 38.27 38.93 39.60 40.27 40.94 41.61 42.29 42.97 43.66 44.35 45.04 45.73 46.43 47.13 47.84 48.54 49.26 49.97 50.69 51.41 52.13 52.86 53.59 54.32 55.05 55.79 56.53 57.28 58.02 5.4 5.5 5.6 5.7 5.8 5.9 6.0 6.1 6.2 6.3 6.4 6.5 6.6 6.7 6.8 6.9 7.0 7.1 7.2 7.3 7.4 7.5 7.6 7.7 7.8 7.9 8.0 8.1 8.2 8.3 8.4 8.5 8.6 8.7 8.8 8.9 9.0 9.1 9.2 9.3 9.4 9.5 9.6 9.7 9.8 9.9 10.0 10.1 10.2 10.3 10.4 10.5 10.6 10.7 0.054 0.055 0.056 0.057 0.058 0.059 0.060 0.061 0.062 0.063 0.064 0.065 0.066 0.067 0.068 0.069 0.070 0.071 0.072 0.073 0.074 0.075 0.076 0.077 0.078 0.079 0.080 0.081 0.082 0.083 0.084 0.085 0.086 0.087 0.088 0.089 0.090 0.091 0.092 0.093 0.094 0.095 0.096 0.097 0.098 0.099 0.100 0.101 0.102 0.103 0.104 0.105 0.106 0.107 58.77 59.52 60.28 61.03 61.79 62.56 63.32 64.09 64.86 65.63 66.41 67.18 67.96 68.74 69.53 70.31 71.10 71.89 72.69 73.48 74.28 75.08 75.88 76.68 77.49 78.30 79.11 79.92 80.73 81.55 82.36 83.18 84.00 84.82 85.65 86.47 87.30 88.13 88.96 89.79 90.62 10.8 10.9 11.0 11.1 11.2 11.3 11.4 11.5 11.6 11.7 11.8 11.9 12.0 12.1 12.2 12.3 12.4 12.5 12.6 12.7 12.8 12.9 13.0 13.1 13.2 13.3 13.4 13.5 13.6 13.7 13.8 13.9 14.0 14.1 14.2 14.3 14.4 14.5 14.6 14.7 14.8 0.108 0.109 0.110 0.111 0.112 0.113 0.114 0.115 0.116 0.117 0.118 0.119 0.120 0.121 0.122 0.123 0.124 0.125 0.126 0.127 0.128 0.129 0.130 0.131 0.132 0.133 0.134 0.135 0.136 0.137 0.138 0.139 0.140 0.141 0.142 0.143 0.144 0.145 0.146 0.147 0.148 5 FLEXCELL® INTERNATIONAL CORPORATION APPENDIX 2: STAGEFLEXER® 28 MM LOADING STATION™ CONVERSION CHART Press (-kPa) % Elong Strain Press (-kPa) % Elong Strain Press (-kPa) % Elong Strain 0.00 0.70 1.39 2.08 2.76 3.44 4.11 4.78 5.44 6.10 6.76 7.41 8.05 8.69 9.33 9.97 10.60 11.22 11.85 12.47 13.08 13.70 14.31 14.92 15.52 16.12 16.72 17.32 17.91 18.51 19.10 19.68 20.27 20.85 21.43 22.01 22.59 23.17 23.75 24.32 24.89 25.47 26.04 26.61 27.18 27.75 28.32 28.88 29.45 30.02 30.59 31.16 31.72 32.29 0.0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1.0 1.1 1.2 1.3 1.4 1.5 1.6 1.7 1.8 1.9 2.0 2.1 2.2 2.3 2.4 2.5 2.6 2.7 2.8 2.9 3.0 3.1 3.2 3.3 3.4 3.5 3.6 3.7 3.8 3.9 4.0 4.1 4.2 4.3 4.4 4.5 4.6 4.7 4.8 4.9 5.0 5.1 5.2 5.3 0.000 0.001 0.002 0.003 0.004 0.005 0.006 0.007 0.008 0.009 0.010 0.011 0.012 0.013 0.014 0.015 0.016 0.017 0.018 0.019 0.020 0.021 0.022 0.023 0.024 0.025 0.026 0.027 0.028 0.029 0.030 0.031 0.032 0.033 0.034 0.035 0.036 0.037 0.038 0.039 0.040 0.041 0.042 0.043 0.044 0.045 0.046 0.047 0.048 0.049 0.050 0.051 0.052 0.053 32.86 33.43 34.00 34.57 35.14 35.71 36.29 36.86 37.44 38.01 38.59 39.17 39.75 40.33 40.92 41.51 42.10 42.69 43.28 43.88 44.47 45.07 45.68 46.28 46.89 47.51 48.12 48.74 49.36 49.99 50.62 51.25 51.89 52.53 53.17 53.82 54.48 55.13 55.79 56.46 57.13 57.81 58.49 59.17 59.86 60.56 61.26 61.97 62.68 63.40 64.12 64.85 65.59 66.33 5.4 5.5 5.6 5.7 5.8 5.9 6.0 6.1 6.2 6.3 6.4 6.5 6.6 6.7 6.8 6.9 7.0 7.1 7.2 7.3 7.4 7.5 7.6 7.7 7.8 7.9 8.0 8.1 8.2 8.3 8.4 8.5 8.6 8.7 8.8 8.9 9.0 9.1 9.2 9.3 9.4 9.5 9.6 9.7 9.8 9.9 10.0 10.1 10.2 10.3 10.4 10.5 10.6 10.7 0.054 0.055 0.056 0.057 0.058 0.059 0.060 0.061 0.062 0.063 0.064 0.065 0.066 0.067 0.068 0.069 0.070 0.071 0.072 0.073 0.074 0.075 0.076 0.077 0.078 0.079 0.080 0.081 0.082 0.083 0.084 0.085 0.086 0.087 0.088 0.089 0.090 0.091 0.092 0.093 0.094 0.095 0.096 0.097 0.098 0.099 0.100 0.101 0.102 0.103 0.104 0.105 0.106 0.107 67.08 67.83 68.59 69.36 70.13 70.91 71.70 72.49 73.29 74.10 74.91 75.73 76.56 77.40 78.25 79.10 79.96 80.83 81.71 82.59 83.48 84.39 85.30 86.21 87.14 88.08 89.02 89.98 90.94 10.8 10.9 11.0 11.1 11.2 11.3 11.4 11.5 11.6 11.7 11.8 11.9 12.0 12.1 12.2 12.3 12.4 12.5 12.6 12.7 12.8 12.9 13.0 13.1 13.2 13.3 13.4 13.5 13.6 0.108 0.109 0.110 0.111 0.112 0.113 0.114 0.115 0.116 0.117 0.118 0.119 0.120 0.121 0.122 0.123 0.124 0.125 0.126 0.127 0.128 0.129 0.130 0.131 0.132 0.133 0.134 0.135 0.136 6 FLEXCELL® INTERNATIONAL CORPORATION APPENDIX 3: STAGEFLEXER® 31 MM LOADING STATION™ CONVERSION CHART Press (-kPa) % Elong Strain Press (-kPa) % Elong Strain 0.00 0.37 0.79 1.25 1.76 2.31 2.91 3.54 4.22 4.94 5.70 6.49 7.32 8.18 9.08 10.01 10.98 11.97 13.00 14.05 15.13 16.23 17.36 18.51 19.69 20.89 22.11 23.34 24.60 25.87 27.16 28.46 29.78 31.11 32.45 33.80 35.16 36.53 37.90 39.28 40.67 42.05 43.44 44.84 46.23 47.62 49.00 50.39 51.77 53.14 54.51 55.87 57.22 0.0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1.0 1.1 1.2 1.3 1.4 1.5 1.6 1.7 1.8 1.9 2.0 2.1 2.2 2.3 2.4 2.5 2.6 2.7 2.8 2.9 3.0 3.1 3.2 3.3 3.4 3.5 3.6 3.7 3.8 3.9 4.0 4.1 4.2 4.3 4.4 4.5 4.6 4.7 4.8 4.9 5.0 5.1 5.2 0.000 0.001 0.002 0.003 0.004 0.005 0.006 0.007 0.008 0.009 0.010 0.011 0.012 0.013 0.014 0.015 0.016 0.017 0.018 0.019 0.020 0.021 0.022 0.023 0.024 0.025 0.026 0.027 0.028 0.029 0.030 0.031 0.032 0.033 0.034 0.035 0.036 0.037 0.038 0.039 0.040 0.041 0.042 0.043 0.044 0.045 0.046 0.047 0.048 0.049 0.050 0.051 0.052 58.56 59.89 61.21 62.51 63.80 65.07 66.33 67.56 68.78 69.98 71.15 72.31 73.44 74.54 75.62 76.67 77.69 78.69 79.65 80.58 81.48 82.35 83.18 83.97 84.72 85.44 86.12 86.76 87.35 87.90 88.41 88.87 89.29 89.66 89.98 90.25 5.3 5.4 5.5 5.6 5.7 5.8 5.9 6.0 6.1 6.2 6.3 6.4 6.5 6.6 6.7 6.8 6.9 7.0 7.1 7.2 7.3 7.4 7.5 7.6 7.7 7.8 7.9 8.0 8.1 8.2 8.3 8.4 8.5 8.6 8.7 8.8 0.053 0.054 0.055 0.056 0.057 0.058 0.059 0.060 0.061 0.062 0.063 0.064 0.065 0.066 0.067 0.068 0.069 0.070 0.071 0.072 0.073 0.074 0.075 0.076 0.077 0.078 0.079 0.080 0.081 0.082 0.083 0.084 0.085 0.086 0.087 0.088 7