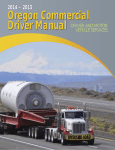

Download Commercial driver`s guide to operation, safety and licensing

Transcript