Download MICROLINE 182/183 PRINTER

Transcript

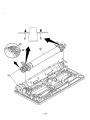

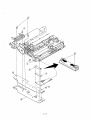

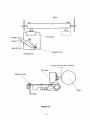

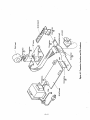

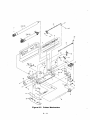

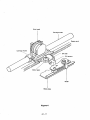

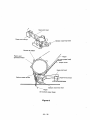

/L (ii,’’, i/ MICROLINE 182/183 PRINTER MAINTENANCE MANUAL ; .,. PREFACE This maintenance manual describes field maintenance of the Microline 182/l 83 for maintenance engineers. For performance specifications and operating procedures, refer to the “User’s Manual”. CONTENTS Page CONFIGURATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.1 Standard Printer Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.2 Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . l-l l-l 1-2 MAINTENANCE TOOLS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1 PARTS REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3.1 Precautions for Parts Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3.2 Disassembly and Reassembly Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-l 3-l 3-2 CLEANING 4-l .................................................. .............. ADJUSTMENT . ............................................................. 5-l TROUBLESHOOTING AND REPAIR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Items to be Checked Before Repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6.1 Method of Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6.2 Connection Circuit and Resistance Check for 6.3 Print Head and LF/SP Motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-l 6-1 ,6-l Cl RCUIT DIAGRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-l MAINTENANCE PARTS LIST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1 THEORY OF OPERATION SPECIFICATIONS (STANDARD MODEL) SPECIFICATIONS (IBM COMPATIBLE MODED DIP SWITCH SETTING TABLE, (STANDARD MODEL) DIP SWITCH SElTlNG TABLE (IBM COMPATIBLE MODE0 6-5 RECORDS OF CHANGES Part No. EC0 No. Printer/PCB Serial No. OKI-J Par1 No. M-52033; ISSUE 1 Page affected Description of changes i-24, 3-25,3-28, F;“;c;t;entj 1-29, i-9, 8-10, (Addition) M-5, AA-IO, :ront-cover, ‘reface, l-1, i-2, 3-34 i-2 to 8-8 IB-1, AB-2 IC-I, AC-2 Descriptions of ML183 are added. (Replacement) Circuit, diagram (Rev. 7) of SLMC-2 circuit board is added. (Addition) ‘-27 to 7-33 NML-007 NML-035 NML-053 NML-063 ML182 220 v 240 V 501 A00001 61 501A0000041 ML183 220 v 240 V 501 A0000001 501 A0000001 ML182 220 v 240 V 504AOOO9311 504A0004441 ML183 220 v 240 V I 7-43 to 7-49 - ML182 220 v 240 V 506AOO12961 506A0007001 ML183 220 v 240 V 506A0000009 506A0000003 ML1 82 220 v 240 V 508A0016961 508A0008501 ML183 220 v 240 V Circuit diagram (Rev. 8) of SLMC-2 circuit board is r-35 to 7-41 added. (Addition) 7-51 to 7-57 7-59 to 7-69 506A0000009 506A0000003 Circuit diagram (Rev. 9) of SLMC-2 circuit board is added. (Addition) Circuit diagram (Rev. 10) of SLMC-2 circuit board is added. (Addition) Circuit diagram (Rev. 11) of SLMC-2 circuit board is added. (Addition) (con.) Part No. EC0 No. Printer/PCB Serial No. >age affected Description of changes \E-1 Change of DIP switch functions LReplacement) LB-3 (Deletion) iack cover Renewal of issue (Replacement) rD1, AD2 1. CONFIGURATION ‘\._ _,. 1. CONFIGURATION 1.1 Standard Printer Configuration The standard configuration of the ML 182/l 83 is as fOllOws: tractor feed unit _ A (ML183 only) COW assembly er SUDPIY Control board ,: Figure l-1 Printer Configuration l - l assembly 1.2 Options (l), (2) ,Tractor feed unit with acoustic cover, access cover and paper separator (only ML1 82) Roll paper stand (only ML182) ‘._ .-, (3) Super-speed RS232-C serial interface board, (4) Super-speed RS422-A serial interface board (5) High-speed RS422-A serial interface board : l-3 I. CONFIGURATIO’N 1.1 Standard Printer Configuration The standard configuration of the ML 182/l 83 is as follows: y/.Power supply assembly v//Ribbbn cartridge Figure l-1 Printer Configuration 1 -,4 1.2 Options (1) Tractor f ee d unit with acoustic cover and, access cover. ,(only Mll82) __ (2) Roll paper stand (only MLJ 82) with paper row detection micro switch 1-5 2. MAINTENANCE ‘L 2. MAINTENANCE TOOLS The tools in table 2-l are necessary for replacing printed-circuit boards and unit parts. For other maintenance procedures, different tools may be necessary. Table 2-l Maintenance Tools No. Tool Quantity Purpose 1 Phillips screwdriver No. l-100 1 2- to 2.6-mm screws 2 Phillips screwdriver No. 2-200 1 3- to 5-mm screws 3 Screwdriver No. 3-100 1 4 Cutters No. 5H 1 5 Round pliers No. 1 1 6 Thickness gauge set 1 for head gap adjustment 7 Metal rod 1 for head gap. adjustment a Volt-ohm-milliammeter 1 2-l Remarks 3, PARTS REPLACEMENT .._ 3. PARTS REPLACEMENT 3.1 (1) (2) .~~ Precautions for Parts Replacement Be sure to turn OFF the AC POWER switch and remove the AC,input plug from the AC receptacle before disassembly or reassem’bly. Don not disassemble the printer as long as it is in good operating condition. (3) Be careful not to remove parts unless, necessary. Disassembly should be the minimum necessary. (4) Use only the specified maintenance tools. (5) Disassemble the printer in the specified order of disassembly procedures; otherwise, parts may be damaged. (6) In the course of disassembly, it may be agood ideato keep the removed small parts such as screws and washers by attaching them temporarily to their original places so as not to lose them. (7) KS such as the microprocessor, ROM, and RAM can easily be damaged by static electricity. Do not wear gloves that are apt to produce static electricity when handling printed-circuit boards. (8) Do not place the printed-circuit boards directly on the printer or the floor. 3 - l 3.2 Disassembly and Reassembly .Procedures 3.2.1 Upper cover (1) Turn OFF the AC POWER switch, and remove AC cable @ from the outlet, and then remove interface cable @ , remove paper. (2) Remove acoustic cover and paper separator (if installed). (3) Remove tractor feed unit @ by depressing lock lever @ and tilting backward (if it is installed). (4) Remove roll paper with paper shaft @ by lifting upward. Remove side frame @ by tilting forward (if it is installed). (5) Remove access cover @ by lifting rear, edge. (6) Pull platen knob @ out (7) Remove two screws’@. (8) Remove upper cover @ by lifting up front and pushing it backward. (9) For reassembly, reverse the disassembly procedure. 3-2 3 i3 3.2.2 Control board (1) Remove the upper cover (see 3.2.1). (2) Remove serial interface board by removing two screws locating on both sides of interface connector. Remove interface board upward (if installed). (3) Remove transformer connector @ from the, control board @ . (4) Remove three screws @ and two screws @. (5) Remove control board @ by !ifting upward (see Notes below). Observe’paper nearend lever when removing the PCB. (6) Before reassembly, secure rubber insulator @ is, installed. (7) For reassembly, reverse the disassembly procedure.. Notes: 7. Do not”fouch the terminal (contact) @for connector @directly with hand and make sure that if ,i.s clean. 2. When affachin , make sure that pa er near-end lever 0 is c/ear in the groove of phofosensor 6 8 on control board 6 1 . 3-4 3.2.3 Transformer assembly (1) Remove the upper cover (see 3.2.1). (2) Remove connector @ from the control board. (3) Remove ground strap screw @ (4) Remove two screws 0. (5) Remove transformer assembly@ with power PCB@ and AC cord receptacle @ by lifting upward. (6) For reassembly, reverse the disassembly procedure. 3-6 View A 3-7 3.2.4 Power supply board (1) Remove the upper cover (see 3.2.1). (2) Remove the transformer asssembly (see 3.2.3). (3) Remove power supply board @ from transformer @ by pulling off connection pins 0. (4) For reassembly, reverse the disassembly procedure. Note: When attaching, set the powersupplyboard @ along guide @ before assembling. 3-8 3-9 3.2.5 Operation board (1) Remove the upper cover (see 3.2.1). (2) Disengage two tabs 0. (3) Remove connector @ connecting the connection board and operation board. (4) Remove operation board 0. (5) For reassembly, reverse the disassembly procedure. Note: Be careful not to damage the cab/e connecting the switch and the connector. .- 3-10 3-11 3.2.6 0) Print head Turn OFF the AC POWER switch, and remove AC cable @ fiom the outlet. Caution: (2) Print head may be hot after printing. Remove access cover @ by lifting up rear edge of cover. (3) Remove ribbon cartridge @ by gently squeezing both sides ‘@ 2nd lifting up. (4) Raise head clamp @ by swinging right tab up (see figure). (5) Remove print head @ by lifting straight up. (6) For reassembly, reverse the disassembly procedure. ‘~. Note: heft the’print head in connect6r 0 &i/epres+ing it agztinst the carriage frame@. 3-12 3-13 3.2.7 Ribbon feed gear assembly (1) Remove the upper cover (see 3.2.1). (2) Remove ribbon cartridge @ by lifting both sides@ (3) Disengage the two front tabs @ and two rear tabs@ (total of four tabs). Then lift upward by inserting small flat screwdriver to slots. (4) Remove ribbon feed gear assembly @. (5) Remove carriage cable @ , cable holder 8, and contact pressure rubber @ from ribbon feed gear assembly @. 6) For reassembly, reverse the disassembly procedure. Notes: 1. D not touch the carriage cable @ and space motor assembly @ terminal (contact) 6B directly with hand and make sure that it is clean. 2. Make sure the carriage cab/e @ is not folded. 3. After installing ribbon feed gear assembly @, check and adjust the gap between the platen and print head (see section 5). 3-14 3 - 1.5 3.2.8 Space motor assembly (1) Remove the upper cover (see 3.2.1). (2) Remove the print head (see 3.2.6). (3) Remove the ribbon feed gear assembly (see 3.2.7). (4) Remove connector 0, and observe concave surface. (5) Remove three screws 0. 6) Remove space motor assembly 0. (7) For reassembly, reverse the disassembly procedure. Notes: 1. Do not touch the space motor assembly @ terminal (contact) @ direcfly with hand and make sure that if is clean. 2. When installing space motor assembly 0, put the @ side of the assembly close to carriage frame @, and align the @ side of the assembly with the corresponding side of the carriage frame. 3. When installing slider 0, put the @ and @parts of the slider close to space motor assembly 0. 4. Afterinstalling space motorassembly 0, checkandadjusf fhegap between fheplafen and print head (see section 5). 3-16 @*----$ i i 3-17 3r2.9 Space rack (1) Remove the upper, cover (see 3.2.1). (2) Remove the print head (see 3.2.6). (3) Remove the ribbon feed gear assembly (see 3.2.7). (4) Remove the space motor assembly (see 3.2.8). (5) Remove spring 0. (6) Disengage tab 0. (7) Remove by inserting a minus screwdriver between space rack @and base frame @ and gently pushing the space rack @ up. (8) For reassembly, reverse the disassembly procedure. Note: After installing space motor assembly, check and adjust the gap between the platen and print head (see section 5). 3-78 c.. 1 ‘. ? 3-19 32.10 Carriage cable (1) Remove the upper cover (see 3.2.1). (2) Remove the print head (see 3.2.6). (3) Remove the ribbon feed gear assembly (see 3.2.7). (4) Remove the space motor assembly (see 3.2.8). (5) Remove the space rack (see 3.2.9). (6) Unlock the two tabs @ and remove cord clamp 0. (7) Remove contact rubber 0. (8) Remove carriage cable (ZJ. (9) For reassembly, reverse the disassembly procedure. ~, Notes: 1. Do not ,tooch the carriage cable direct/y with hand and make 2. and connection board @ terminal (contact) @ Make sure the carriage cab/e @ is not folded. 3. AfterinstaNingspacemotorassembly, checkandadjusf thegap between theplatenand print head (see section 5). 3 - 20 3 - 21 3.2.11 Printer mechanism (1) Remove the upper cover (see 3.2.1). (2) Remove connector @ connecting the control board @ and transformer assembly@. (3) Remove ground ‘strap screw 0. (4) Remove the operation board (see 3.2.5). (5) Remove four screws @) and washers @. 6) Rem&e printer mechanism 0. (7) Remove three screws@, two screws 0, and control board @. (8) Foi reassembly, reverse the disassembly procedure. 3 - 22 3 - 23 3.2.12 LF motor assembly (1) (2) Remove the upper cover (see 3.2.1). Remove the printer mechanism. (See 3.2.11 step 7. The control board need not be removed.) (3) Remove two screws 0. (4) Remove LF motor assembly 0. (5) For reassembly, reverse the disassembly procedure. Notes: I. DO not touch the LFmotorassembly @ terminal(confacf) @directly with handor fold it and make sure that if is clean. 2. Move the bias ge r @ to the platen gear @ as indicated by the arrow then engage D . (The bias gear @ is differentiated by half of a tooth with respect them at portioh 6 to the tooth of platen gear @ .) 3. When assembling the Lf motor assembly 0, loosen the screw @ fastening the connection board and make a space between the base and connection board. Then inStall the LF motor whi/e pressing it against. @ and @.Then tighten the screw @ fastening the connection board. 4. After assembling, make sure that the platen gear @ is correctly engaged and the platen turns smoothly. 3-24