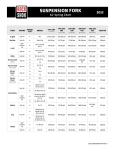

Download Specialized Demo 8 I 2014 User Manual

Transcript