Download User Manual

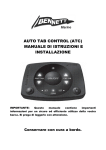

Transcript