Download Original instructions centrifugalpump JCE

Transcript

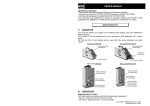

Original instructions centrifugalpump JCE Original instructions Doc no.: BA-014 2014-03-07 sid 2 Index 1. Health and Safety_________________ 3 1.1. Note on safety 1.2. Warning devices 1.3.Warnings 2.Safety of machinery_________________ 4 2.1. Rebuilding of machine 2.2. Personnel requirements 2.3. The manufacturer 2.4.Marking 2.5.Noice 2.6. Safety notes 3.Components______________________ 5 4.Preparing for start_______________ 6 4.1. Filling the pump 4.2.Running 4.3. Emergency stop 4.4. Recovering after Emergency 4.5. Operator's maintenance 5.Maintenance Instructions_________ 7 6.Spareparts_______________________ 8 7.DECLARATION OF CONFORMANCE_______ 9 Doc.no. BA-014 | Original instructions centrifugalpump J-C-E | 2014-03-07 | Revision 0 sid 3 1. Health and Safety This user manual contains instructions for the daily work of the equipment to be operated and used by the operator. Operator's manual should always be available to the person or operators of the equipment. It is important to: • Operator Manual and other applicable documents are preserved throughout the life of the equipment. • Operator Manual and other applicable documents included as part of the equipment. • This user manual is forwarded to other users of the equipment. • Operator's Manual must be updated at any additions or changes to the equipment. • Operator's Manual describes the methods used in the use of the equipment.. 1.1 Note on safety Before you start using the equipment and performing maintenance or servicing this equipment, please read the relevant parts of the instruction. Take into account all Danger, Prohibition, Obligation and notes signs mentioned in the manual. Serious personal injury and machine damage can occur unless the information noted. The machinery is designed for use by a singel operator. Consider all electrical equipment energized. Consider all the hoses and pipelines under pressure. Service and maintenance of equipment / machine, make sure the electricity supply and hydraulics are broken and that the fuses are broken. The machine must be vented and the safety switch be locked. Service and maintenance should only be performed by qualified service and maintenance personnel. Follow the instructions regarding maximum load, see the decal on the equipment and technical data. 1.2 Warning devices Annual inspection of warning devices and protective devices shall be performed, ie. control of its function, and status. 1.3 Warnings Danger, Warning, Precautionary and NOTE have the following meaning in this manual (see photos below). DANGER! Ignoring this information will result in immediate danger to life! BAN! Prohibited action that is associated with death or serious injury! IMPOSITION! Correct use of personal protective equipment or other aids. NOTE Information that requires extra attention! Doc.no. BA-014 | Original instructions centrifugalpump J-C-E | 2014-03-07 | Revision 0 sid 4 2. Safety of machinery The machine is labeled with a CE mark, see 2.4, meaning that it is designed, manufactured and described in accordance with the EU Machinery Directive 2006/4/EC. 2.1 Rebuilding of machine If the machine is rebuilt or supplemented with other parts that the manufacturer does not approve, do not apply the CE mark for the parts that change the machine's function. Warning labels and CE mark on machine must be clearly visible. If the machinery with warning label is replaced, then the new warning labels installed in the same place as before. Damaged decals and CE mark must be replaced immediately. If the machine is rebuilt or added to it is very important that this instruction immediately completes/ adjusted with the necessary illustrations, photographs and texts. 2.2 Personnel requirements To avoid injury and machine damage operations staff shall be especially instructed or trained according to the manufacturer's instructions. Operators and operating personnel may only administer the parts they have been instructed or trained. All controls and keys shall only be operated with hands, that they should never be activated by means of any kind, unless otherwise provided. 2.3 The manufacturer 2.4 Marking This machine is made by: Pumpteknik AB Box 9034 SE-400 91 Göteborg Sweden This machine is equipped with the following marking: 2.5 Noice This machine has a continuous A-weighted sound pressure level below 70 dB (A). 2.6 Safety notes • The machine may only be used by trained professionals, and may only be used when the user has read and understood the contents of the current user description. • Use the machine to the predetermined purposes and only with the installed protection devices. All applicable safety regulations must be observed. • The daily maintenance work must be performed by trained personnel. • Electrical work must be performed by a trained professional. • Work on energized or pressurized parts is not allowed. • Rebuilds, repairs, and modifications to the machine may only be performed under the applicable safety regulations. • When replacing spare parts use original spare parts. • Safety instructions concerning the hydraulic unit please see its documentation. • The pump should always be filled with the media before start! Doc.no. BA-014 | Original instructions centrifugalpump J-C-E | 2014-03-07 | Revision 0 sid 5 3. Components 2 1 4 1 Filling cap 2 Outlet 3 Inlet 4 Hydraulic engine Doc.no. BA-014 | Original instructions centrifugalpump J-C-E | 2014-03-07 | Revision 0 3 sid 6 4. Preparing for start Install suction and discharge hose Verify that the pump is filled with water or other medium to be pumped (see 4.1). NOTE! The pump is filled with water before commissioning. Check that the hydraulic connections are properly connected. 4.1 Filling the pump NOTE! The pump is filled with water before commissioning. Read the manual before using the machine. Eye protection must be used! Wear gloves! • Check that the pump is not in operation. • Open the filler plug . • Fill the water / fluid so that the entire pump casing is filled. • Refit the filler plug. 4.2 Running For operation of the pump, refer to the hydraulic system documentation. 4.3 Emergency stop For emergency stop of the pump, refer to the hydraulic system documentation. Controlle that the pump and all its parts are intact, in good shape before restart, see point 4. 4.4 Recovering after Emergency To reset the emergency stop, please refer to the hydraulic system documentation. 4.5 Operator's maintenance See JCE Maintenance instructions Appendix 1 of this manual. Doc.no. BA-014 | Original instructions centrifugalpump J-C-E | 2014-03-07 | Revision 0 sid 7 5. Maintenance Instructions Before starting the motor make sure that • the casing is filled with water. • the hoses are intact. • the connections are tight and properly connected. • the suction strainer is mounted and thoroughly. Note! The pressure outlet can be set in the desired direction. After finishing pumping drain the pump and hoses from water, ensure that clay and sludge not remain in the connections, valve or casing. Hardened clay or similar can cause stoppages. Slow evacuation may be due to: 1.Too little water in the casing. 2.Untight connections. 3.Broken suction hose. 4.Untight check valve. 5.Worn impeller. A clean and maintained pump malfunctions rarely. Note! Do not disassemble the hydraulic motor, send it to Pumpteknik for action. Doc.no. BA-014 | Original instructions centrifugalpump J-C-E | 2014-03-07 | Revision 0 sid 8 6. Spareparts Pump: 3” and 3”/4” 19 18 17 16 14 9 10 23 1 2 3 11 12 Pos.no. Description 10 24 4 15 5 Quantity 6 Order no. 1 Connection 1 3”- C1 2 Intermediate part 1 3”- C2 Non Return Valve 1 3”- C3 3 4 Suction Casing 1 3”- C4 3”/4”- C4 5 Gasket 3 3”- C5 6 Impeller 1 3”- C6 3”/4”- C6 7 Mechanical seal 1 3”- C7 8 Casing 1 3”- C8 9 Bolt 2 3”- C9 10 Washer 6 3”- C10 11 Bolt 6 3”- C11 7 13 8 22 Pos.no. Description 12 Washer 13 20 21 Quantity 25 Order no. 12 3”- C12 Drain plug 1 3”- C13 14 Bolt 2 3”- C14 15 Lock 2 3”- C15 16 Gasket 1 3”- C16 17 Pressure pipe incl. connection 1 3”- C17 18 Gasket 1 3”- C18 19 Filling plug 1 3”- C19 20 Stub shaft 1 3”- C20 21 Support frame 1 3”- C21 22 Plate incl. rivets 1 3”- C22 23 Bolt 1 3”- C23 24 Washer 1 3”- C24 25 Hydraulic motor 1 3”- C25 Doc.no. BA-014 | Original instructions centrifugalpump J-C-E | 2014-03-07 | Revision 0 sid 9 7. DECLARATION OF CONFORMANCE Acc. to annex 2:1A The manufacturer: Pumpteknik AB Box 9034 SE-400 91 Göteborg Sweden declares that the following product: Serial no: Year of manufacturing: is manufactured in accordance with the following product directives: 2006/42/EG And in conformity with the following harmonized standards: SS-EN-ISO 12100-2010 and in accordance with the following national standards and specifications. Machine according to Annex 4: Notified Body number: Notified Body: Machine EX class: Place: Askim Date: 2014-03-07 Bo Svensk Responsible for the compilation of documentation within the EU: Roger Gustafsson The manufacturer: Pumpteknik AB Box 9034 SE-400 91 Göteborg Sweden Phone: +46 31 89 48 80 E-mail: [email protected] Website: www.pumpteknik.com Doc.no. BA-014 | Original instructions centrifugalpump J-C-E | 2014-03-07 | Revision 0 Pumpteknik AB Askims Verkstadsväg 1 SE-436 34 Askim Sweden Tel: +46 31 45 02 30 Fax: +46 31 45 42 63 www.pumpteknik.com Pumpteknik AB Pajalagatan 56 SE-162 65 Vällingby Sweden Tel: +46 730 72 71 10 www.bana1.se – PUM-0214 – April 2014 Original instructions centrifugalpump