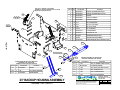

Download Technical Manual (Revision 10-09)

Transcript