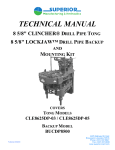

Download CLE8625DP-06-13 - McCoy Global Inc.

Transcript