Download SERVICE-MANUAL HM5011/5010 - Frank`s Hospital Workshop

Transcript

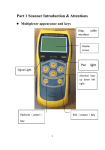

ENGLISH ® Instruments Spectrum analyzer HM5011 HM5010 4S-5010-0010 09 JUN 1998 SERVICE-MANUAL HM5011/5010 Service Manual Adjustment Procedure Circuit Diagrams 5 Alignment Procedure for HM5010/HM 5011 ......... A Control and Adjustment of Supply Voltages ............................................... B Final Alignment - Tuner ..................................... C Alignment - IF-Unit ........................................... D Linearity of Frequency Display ......................... HM5010 XY-board ........................................... Tuner ............................................................... Tracking-Generator .......................................... E Alignment of HM5011 Tracking Generator ...... 5 6 6 7 10 11 12 13 Tracking-Generator ................................................. Tuner RA-Board ...................................................... Tuner RB-Board ...................................................... IF-Amplifier ............................................................. Main board ............................................................. X-Y Board ............................................................... FC-Board ................................................................ PA-Board ................................................................ CRT-Board .............................................................. Power supply Board ............................................... RA-Board ................................................................ Tracking-Generator ................................................. RB-Board ................................................................ Main board ............................................................. Main board ............................................................. XY-Board ................................................................. XY-Board ................................................................. FC-Board ................................................................ FC-Board ................................................................ PA-Board ................................................................ CRT-Board .............................................................. PS-Board ................................................................ PS-Board ................................................................ PS-Board ................................................................ Block Diagram HM5010/HM5011 .......................... 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 Subject to change without notice HM5010/5011 2 SPECTRUM ANALYZER Specifications Frequency Frequency range: 0.15MHz to 1050MHz (-3dB) Center frequency display accuracy: ±100kHz Marker accuracy: ±(0.1% span + 100kHz) Frequency display res.: 100kHz (4½ digit LED) Frequency scanwidth: 100kHz/div. to 100MHz/div. in 1-2-5 steps and 0Hz/div. (Zero Scan) Frequency scanwidth accuracy: ±10% Frequency stability: better than 150kHz / hour IF Bandwidth (-3dB): Resolution: 400kHz and 20kHz; Video-Filter on: 4kHz Sweep rate: 43Hz Amplitude Amplitude range: -100dBm to +13dBm Screen display range: 80dB (10dB / div.) Reference level: -27dBm to +13dBm (in 10dB steps) Reference level accuracy: ±2dB Average noise level: -99dBm (20kHz BW) Distortion: <-75dBc; 2nd and 3rd harmonic 3rd order intermod.: -70dBc (two signals >3MHz apart) Sensitivity: <5dB above average noise level Log scale fidelity: ±2dB (without attn.) Ref.: 250MHz IF gain: 10dB adjustment range Spectrum Analyzer HM5010 / HM5011 Input Input impedance: 50Ω Input connector: BNC Input attenuator: 0 to 40 dB (4 x 10dB steps) Input attenuator accuracy: ±1dB/10dB step Max. input level: +10dBm, ±25VDC (0dB attenuation) +20dBm (40dB attenuation) Tracking Generator Output level range: -50dBm to +1dBm (in 10dB steps and var.) Output attenuator: 0 to 40dB (4 x 10dB steps) Output attenuator accuracy: ±1dB Output impedance: 50Ω (BNC) Frequency range: 0.15MHz to 1050MHz Frequency response: ±1.5dB Radio Frequency Interference (RFI): <20dBc Divers AM-Demodulator output for head-sets. Permissible load impedance >8Ω General Display: CRT. 6 inch, 8 x 10 div. intern. graticule Trace rotation: Adjustable on front panel Line voltage: 115 / 230V ±10%, 50-60Hz Power consumption: approx. 20W Operating ambient temperature: 0°C..+40°C Protective system: Safety Class I (IEC 1010-1) Weight: approx. 7kg Cabinet: W 285, H 125, D 380 mm Subject to change without notice 5/96 Frequency Range 0.15MHz - 1050MHz. 4½ Digit Display (Center & Marker Frequency, 0.1MHz resolution) –100 to +13dBm Amplitude Range, 20kHz, 400kHz and Video-Filter Tracking-Generator (HM5011 only): Frequency range: 0.15MHz - 1050MHz. Ω). Output Voltage: +1dBm to –50dBm (50Ω Evolution of the original HM5005/HM5006 has led to the new HM5010/ HM5011 Spectrum Analyzer/Tracking Generator which now extends operation over 1 GHz (frequency range 0.15 to 1050 MHz). Both fine and coarse center frequency controls, combined with a scanwidth selector provide simple frequency domain measurements from 100 kHz/div. to 100 MHz/Div.. Both models include a 4½digit numeric LED readout that can selectively display either the center or marker frequency. The HM5011 includes a tracking generator. The HM5010/5011 offer the same operation modes as the HM5005/5006. The instruments are suitable for pre-compliance testing during development prior to third party testing. A near-field sniffer probe set, HZ530, can be used to locate cable and PC board emission "hot spots" and evaluate EMC problems at the breadboard and prototype level. The combination of HM5010 / 5011 with the HZ530 is an excellent solution for RF leakage/radiation detection, CATV/ MATV system troubleshooting, cellular telephone/pocket pager test and EMC diagnostics. There is an optional measurement output for a PC which makes documentation of results easy and affordable with the HO500 Interface. Accessories supplied: Line Cord, Operators Manual. Optional accessories, 50Ω Ω-feedthrough termination HZ22 Viewing Hood HZ47, Near Field Probe Set HZ530, Carrying Case HZ96-2, Transient Limiter HZ560 HO500 Computer Interface for HAMEG Spectrum Analyzer This HO500 computer interface offers the facility to transfer a calibrated frequency spectrum from any HAMEG spectrum analyzer to a PC. The HO500 interface is a 8 bit ISA BUS card installed in the PC, which transfers data via an interface cable. The software supplied allows a hard copy print out (including parameters) of the frequency spectrum, in Windows Format. Signal aquisition occurs 2 to 3 times per second. The picture consists of 10 bit vertical by approx 3600 point horizontal display. The PC monitor display is in SVGA Format with 800 x 600 pixels. For comparison measurements, a previosly stored reference curve can be recalled. The software supplied works under Windows 3.1, 3.11 and WIN95. A simple XY analog output is required to connect the HO500 to the spectrum analyzer. 3 Subject to change without notice EMC-MEASUREMENT EQUIPMENT Specifications Frequency Frequency range: 0.1MHz to 1000MHz (lower frequency limit depends on probe type) Output impedance: 50 Ω Output connector: BNC-jack Input capacitance: 2pF (high imped. probe) Max. Input Level: +10dBm (without destruction) 1dB-compression point: -2dBm (frequency range dependent) DC-input voltage: 20V max. Supply Voltage: 6V DC 4 AA size batteries Supply-power of HM5010/5011 Supply Current: 8mA (H-Field Probe) 15mA (E-FieldProbe) 24mA(High imp.Probe) Probe Dimensions: 40x19x195mm (WxDxL) Housing: Plastic; (electrically shielded internally) Package contents: Carrying case 1 H-Field Probe 1 E-Field Probe 1 High Impedance Probe 1 BNC cable (1.5m) 1 Power Supply Cable (Batteries or Ni-Cads are not included) Near Field Sniffer Probes HZ 530 SCALE = 10dB/DIV. The H-Field probe provides a voltage to Frequency Response E-Field Probe (typical) Subject to change without notice The High-Impedance Probe The high-impedance probe (Hi-Z) permits the determination of the radio frequency interference (RFI) on individual contacts or printed circuit traces. It is a direct-contact probe. The probe is of very high impedance (near the insulation resistance of the printed circuit material) and is loading the test point with only 2 pF (80Ω at 1 GHz). Thereby one can measure directly in a circuit without significantly influencing the relationships in the circuit with the probe. One can, for example, measure the quantitative effectiveness of filters or other blocking measures. Individual pins of ICs can be identified as RFI sources. On printed circuit boards, individual problem tracks can be identified. With this Hi-Z probe individual test points of a circuit can be connected to the 50Ω impedance of a spectrum analyzer. The E-Field Monopole Probe The E-field monopole probe has the highest sensitivity of the three probes. It is sensitive enough to be used as an antenna for radio or TV reception. With this probe the entire radiation from a circuit or an equipment can be measured. It is used, to determine the effectiveness of shielding measures. With this probe, the entire effectiveness of filters can be measured by measuring the RFI which is conducted along cables that leave the equipment and may influence the total radiation. In addition, the E-field probe may be used to perform relative measurements for certification tests. This makes it possible to apply remedial suppresion measures so that any requalification results will be positive. In addition, pre-testing for certification tests may be performed so that no surprises are encountered during the certification tests. SCALE = 10dB/DIV. The H-Field Near-Field Probe the connected measurement system which is proportional to the magnetic radio frequency (RF) field strength existing at the probe location. With this probe, circuit RF sources may be localized in close proximity of each other. The H-field will decrease as the cube of the distance from the source. A doubling of the distance will reduce the Hfield by a factor of eight (H = 1/d³); where d is the distance. In the actual use of the H-field sensor one observes therefore a rapid increase of the probe’s output voltage as the interference source is approached. While investigating a circuit board, the sources are immediately obvious. It is easily noticed which component (i.e. IC) causes interference and which does not. In addition, by use of a spectrum analyzer, the maximum amplitude as a function of frequency is easily identified. Therefore, one can eliminate early in the development components which are not suitable for EMC purposes. The effectiveness of countermeasures can be judged easily. One can investigate shields for "leaking" areas and cables or wires for conducted interference. SCALE = 10dB/DIV. The HZ530 is the ideal toolkit for the investigation of RF electromagnetic fields. It is indispensable for EMI precompliance testing during product development, prior to third party testing. The set includes 3 hand-held probes with a built-in pre-amplifier covering the frequency range from 100kHz to over 1000 MHz. The probes - one magnetic field probe, one electric field probe, and one high impedance probe - are all matched to the 50Ω inputs of spectrum analyzers or RFreceivers. The power can be supplied either from batteries, Ni-Cads or through a power cord directly connected to an HM5010/HM5011 series spectrum analyzer. Signal feed is via a 1.5m BNC-cable. When used in conjuction with a spectrum analyzer or a measuring receiver, the probes can be used to locate and qualify EMI sources, as well as evaluate EMC problems at the breadboard and prototype level. They enable the user to evaluate radiated fields and perform shield effectiveness comparisons. Mechanical screening performance and immunity tests on cables and components are easily performed. Frequency Response H-Field Probe (typical) Frequency Response High Impedance Probe (typical) 4 Alignment Procedure for HM5010/HM 5011 Attention! The opening of covers or removal of parts is likely to expose live parts and accessible terminals which can be dangerous to life. Maintenance, service and alignment should be carried out by qualified personnel only, which is acquainted with the danger involved. When aligning the HM5010/5011 it is assumed that all sub-assemblies of the instrument are completely pretested and working correctly. The tuner, IF-unit, and tracking generator should be pre-aligned. When aligning a HM5010, a separate tracking generator unit must be available and connected to the HM5010 for some specific adjustments. Prior to the alignment procedure, the instrument must warm up for 60 minutes. All adjustments are carried out by means of a plastic screw driver or a ceramic adjustment tool. The alignment is divided into the following steps: A Checking of supply voltages D Linearity alignment B Alignment of the tuner E Tracking generator alignment C Alignment of the IF-unit F Check of overall adjustment The numbering system is related to the respective pictures. Screen shots are designated as PIC 1 HF-Synthesizer 100 kHz to 1000 MHz, i.e. HM 8133 2 BNC cable, BNC T-connector, 2 x 10dB attenuator 50 Ohm 1 Voltmeter i.e. HM 8011-3 Control and Adjustment of Supply Voltages adjust: adjust: adjust: adjust: 12V to an accuracy of ±0.1V via Trimpot 4 PIC 1 minimum brightness via Trimpot 2 PIC 1 maximum brightness via Trimpot 3 PIC 1 astigmatism via Trimpot 1 PIC 1 check: check: check: check: check: check: – 12V +12V +5V –5V +38V +138V tolerance ± 0.2V tolerance ± 0.1V tolerance ± 0.2V tolerance ± 0.2V tolerance ± 1V tolerance ± 1V 1 1 2 3 4 5 6 The corresponding voltage test points to check direct voltage can be measured at the measuring connector strip (see PIC 2). +138V +38V GND +5V +12V -12V Basic adjustment: When Y-pos. knob is snapped in on front board, adjust beam approx. 2 mm below bottom graticule line via R801. 4 PIC 1. PS-Board 5 Instrument Rear Side 1 A PIC 2. XYF-Board (partial) 3 1 2 CRT-Board Subject to change without notice B Final Adjustment - Tuner The tuner is already aligned by the factory. When changing the 1st mixer, it might be necessary to realign cavity filter: Set signal to 500MHz -27dBm to input, center frequency to 500MHz, Scanwidth to 0.5MHz, turn all three M3 screws to max. amplitude. In case curve is not uniform, coils L1, L2, and L3 can be adjusted to maximum uniformity (fig. 22) by slightly bending them. In case signal in frequency range is shacky, 2nd local oscillator might not be snapped in correctly. The correct snapin of the PLL is visible via the lock detect LED (D2), which has to be lit constantly without flickering if PLL is snappedin correctly. The oscillator signal has to be fixed (crystal dependent) at 1.32GHz, it may not drift. The PLL is snapped-in when the tuning voltage VT (measure at PAD1) is between 0.5 and 4.5V. The alignment will bring the tuning voltage to the center of the tuning range. VT of the 2nd LO has to be between 2V and 2.5V. Constantly check tuning voltage while aligning tuner. Alignment is necessary in two cases: VT<2.0V and VT>2.5V. • Case 1 VT<2.0V Correction: a ) Solder all adjustment areas to connect trace from C1 to C2. b ) Remove excess solder at center conductor of resonator pad. • Case 2 VT>2.5V Correction: a ) Adjustment areas may not be soldered to connect trace from C1 to C2. b ) Add solder to resonator pad. C Alignment of IF-Unit fig. 22 for HM5010 Measurement setup: Apply two different signals to the input of the HM5011 via BNC T-connector and 10dB attenuators. Adjust HM5010/5011: Center frequency to 500MHz; all attenuators on (–40 dB) Bandwidth 400kHz; video filter off; scanwidth 0.5MHz/div.; marker off. Adjust Tracking Generator: Attenuator –20dB; level max. (HM5011 only) RF-generator: frequency 500MHz; level –5dBm The output voltage of the tracking generator is visible on the screen by an overlay of the fixed frequency. A "zero" point fig. 23 is visible within the signal to the right or to the left of the 500MHz spectral line (fig. 23) (5011 only). IF Filter Curve at 400kHz Bandwidth align: Step 1 Align (with plastic screw driver) Coil L1 (PIC 5) to maximum output amplitude and symmetry to Y-axis. Step 2 Align (with plastic screw driver) Coils 3 + 4 + 13 + 14 (PIC 5) to symmetrie to Y-axis. The "zero" fig. 23). point must be at the maximum (at 500MHz) (fig. Stept 3 If necessary, repeat step 1 and 2. align: align: VR 3 VR 1 L 10 L7 L 11 L8 L4 L 12 L9 L 13 L 14 L3 L1 fig. 23 for HM5011 VR 4 Subject to change without notice VR 2 PIC 5 IF-Amp Board 6 IF Filter Curve at 20kHz Bandwidth (HM5010) align: Step 1 Align (with plastic screw driver) Coils L7+8+9+10+11+12 until "zero" point is exactly centered at 500MHz (as with 400kHz Bandwidth). Watch for symmetry of Filter Curve. IF Filter Curve at 20kHz Bandwidth (HM5011) Pre-Alignment: Remove T-connector. Connect tracking generator module directly to the input of the HM5011. Turn off attenuators on tracking generator module and on HM5011 (0 dB). The output voltage of the tracking generator module is now visible as horizontal line (with slight ripple). adjust: Step 1 adjust: Step 2 Adjust (with plastic screw driver) Coils 7 + 8 + 9 + 10 + 11 + 12 to maximum screen height of displayed output voltage. Add attenuators of HM5010/5011 as soon as "line" has reached the middle of the screen (–30 dB). This alignment has to be performed repeatedly in order to optimize settings. Fine Alignment: Connect BNC-T-connector again as in the beginning of the IF alignment. Set attenuator of tracking generator module to –20dB, scanwidth to 0.5 MHz/div. If necessary, re-adjust center frequency (adjust 500MHz spectral line to screen center). "Zero" point is now visible to the right or to the fig. 24). left of screen center (amplitude maximum) (fig. adjust: Step 1 adjust: Step 2 Align (with plastic screw driver) Coils L7+8+9+10+11+12 until "zero" point reaches maximum. Watch for symmetry of Filter Curve. This alignment has to be performed repeatedly in order to optimize settings. fig. 24 IF Gain - Adjustment of different Bandwidths Set scanwidth to 0.2MHz/div. Switch bandwidth repeatedly between 400kHz and 20kHz. The distance between the output voltage (line) of the tracking generator and tge 400MHz amplitude may not vary. If the amplitude values do not match exactly, adjust by means of R-trimmer VR2 (PIC5) (PIC5). Linearity of IF-Amplifier Gain The linearity of the IF-amplifier gain has to be checked through the entire display range. Apply a 400MHz (-27dBm) signal directly to the input of the HM5010/5011. Adjust scanwidth to 5MHz/div, release attenuator switched (0 dB), select filter bandwidth of 400kHz. The spectral line should reach the upper screen edge. Use attenuators to reduce signal in 10db steps, whereby each individual attenuation step has to reduce the level by 10dB ±1dB. In case deviation is as follows: - A the drop of the individual attenuation steps is larger than 10dB ± 1dB, or - B the drop of the individual attenuation steps is smaller than 10dB ±1dB, the linearity of the attenuators has to be adjusted as follows: Set attenuator to -40dB. Adjust spectral line exactly to -40dB (center line) via VR1, VR3, VR4. Then set attenuators back to 0dB und adjust spectral line by means of trimpots VR802A and VR801 (XY board) to zero point and base line to bottom graticule line. This procedure has to be repeated until the settings at -40dB and 0dB are correct. D Linearity of Frequency Display Settings for HM5010/5011: Center frequency at 500MHz; all attenuator switches released; filter bandwidth 400kHz; video filter off; scanwidth to 100MHz/div.; marker off. Measurement Setup: Apply signal of 500MHz –27dBm to input of HM 5010/5011. Check: Check: 7 Basic setting: The HM5010/5011 has to be adjusted that the noise level touches the bottom graticule line. The spectral line of 500MHz -27dBm reaches the top graticule line and is situated in the center of the screen. Adjust 500MHz spectral line exactly to screen center via X-pos knob (on front of the unit). Upper frequency limit: Check if frequency of minimum 1050 can be set as center frequency. Subject to change without notice Adjust HM5010/5011 to basic setting (see above). Apply input signal of 100MHz, level +7dBm fig. 7) Overriding the input allows for the harmonics of the input signal to become visible (fig. 7). This simplifies the adjustment of individual spectral lines in horizontal direction. adjust: Spectral line at 400MHz Turn X-ampl. knob on front of instrument to have the 4 spectral lines matched with fig. 8 the corresponding graticule lines on the screen(fig. 8). adjust: Spectral line at 100MHz With Trimpot RV171 align to match this spectral line with the corresponding fig. 9 graticule line on the screen (fig. 9). adjust: Zero Peak With Trimpot RV173 align to match this spectral line with the corresponding fig. 9 graticule line on the screen (fig. 9). adjust: Spectral line at 600-1000MHz With Trimpot RV186 adjust to match 700MHz to the correct graticule line. adjust: Spectral line at 800 MHz; With Trimpots RV181 + RV183 for 900MHz and RV197 for 1000MHz (PIC 3) adjust to match this spectral line with the corresponding graticule line on the screen. fig. 7 fig. 8 fig. 9 adjust: Beam length With Trimpot RV101 adjust beam to end approx. 1mm beyond the right CRT Fig. 11 - base line too short) boundary (graticule) (Fig. Fig. 10 - 300 to 1000MHz spectral lines not correct ) (Fig. fig. 10 RV 112 RV113 fig. 11 RV 149 RV 101 RV 183 RV 181 RV 186 RV 197 RV 171 RV 173 PIC 3 - MB-Board Set Trimpot RV113 that frequency will not display below 990MHz when center frequency is set to lowest frequency Subject to change without notice 8 Adjust Marker. Settings on HM5010/5011: Center frequency to 500MHz, all attenuators in off position, filter bandwidth to 400kHz, video filter off. Scanwidth to 100MHz, Marker on. Signal 100MHz +7dBm. Adjust Marker to 500MHz display and set to 500MHz mark on screen via RV149 (PIC 4). Turn Marker left to max. and adjust to 990MHz via RV112. VR 2 VR 3 L 10 L7 L 13 L 11 L8 L4 L 12 L9 L 14 VR 4 RV 112 L3 VR 1 L1 RV 113 RV 149 RV 183 RV 101 RV 181 RV 186 RV 197 RV 171 RV 173 PIC 3 - Main-Board 9 Subject to change without notice RV 801 RV 802A XY-Board 1 1 2 3 4 5 6 Subject to change without notice +138V +38V GND +5V +12V -12V 10 1st Mixer 11 M3 Screws Cavity - Filter M3 Screws Cavity - Filter C1 C2 MPAD1 Tuner Subject to change without notice RV4 RV3 C68 C69 MPAD2 Tracking-Generator Subject to change without notice 12 E Alignment of HM5011 Tracking Generator 1. Required Instruments: 1.1 1.2 1.3 1.4 1.5 Spectrum Analyzer - minimum 1000MHz Completely assembled HM5011 Multimeter to measure DC voltage Oscilloscope, i.e. HM303 Coax cabel 2. Preparation: 2.1 2.2 2.3 2.4 2.5 Assemble Spectrum Analyzer completely (without case). All sub-assemblies have to be pre-checked. HM5011 has to be warmed up. Connect VCO output of RA board to VCO input (MCX connector). Connect 12MHz reference clock of TG board to RCA connector ST1 on RB board. 3. Check Signalling Lines Cable connection W1 Pin Nr. 1 2 3 4. Signal Supply OP Supply Supply PLL Check Supply and Bias Voltages Comp.Nr. C1 C2 C11 C6 C9 C12 5. Description -12V +12V +5V Pin Nr. 1 1 3 5 3 3 Description 1. VCO Amp. 2. VCO Amp. fix LO Amp. Var. Amp. 1. Power Amp. 2. Power Amp. Voltage +5.8 V +5.8 V +5.9 V +5.6 V +3.6 V +4.8 V Alignment of fixed LO 5.1 The 2nd LO oscillates at a frequency of 1.35 GHz. The level at the mixer input IC3 Pin2 is -17dBm. Oscillation of the 2nd LO can also be measured with the H or E-Field Probe (HZ530). 5.2 Lock-Detect LED (D4) will confirm the correct PLL lock when lighting up without flickering or going out. The oscillator signal has to remain fixed crystal dependent) at 1.35GHz and may not drift. PLL is locked if tuning voltage VT (measure at PAD2) is between 0.5 and 4.5V. Align tuning voltage to medium tuning range. VT of fixed LO should be between 2 and 2.5V. The tuning volage has to be check constantly during alignment. Place coax resonator CR2 bottom side to the edge of soldermask next to center conductor, and solder on the left and the right side. 5.3 Alignment is necessary in two cases: VT<2.0V and VT>2.5V. • Case 1 VT<2.0V Correction: a ) Solder all adjustment areas to connect trace from C1 to C2. b ) Remove excess solder at center conductor of resonator pad. • Case 2 VT>2.5V Correction: a ) Adjustment areas may not be soldered to connect trace from C1 to C2. b ) Add solder to resonator pad. 13 Subject to change without notice 6. Control of fixed LO-Level 6.1 To check 2nd LO-level, cap C20 (22pF) has to be removed and 50Ohm Coax-cable has to be connected to 13dB attenuator of output. Connect other end of coax cable with adequate test analyzer. Adjust test analyzer to 1.35 GHz center frequency; the LO-level to be measured has to be -17dBm (±1 dB) (consider attenuation of cable). If cap is not removed and coax cable is connected parallel to mixer to the VCO-branch, a level of approx. -24 dBm (±1dB) should be measured due to decreased load resistance. 6.2 6.3 7. Check of VCO 7.1 7.2 7.3 Adjust HM5011 to Zero Scan, center frequency to 500MHz. Remove Cap C14 (22pF), connect one side to attenuator output, other side stand up in the air. Connect Cap side sticking up in the air to center conductor of 50 Ohm cable. Solder shielding of cable directly next to Cap to ground. Connect other end of Cap to Analyzer input (i.e. Advantest R3361A). Start 1.35GHz Stop 2.35GHz reference level: 0dBm. VCO signal which can be observed on the test analyzer has to shift according to center frequency (tuning voltage). Tuning range has to be at least from 1350 to 2350 Mhz. continuously and without interruption. It should not go under absolute level of +7dBm (coax cable of 1 mtr. has 1-2 dB of attenuation at 2GHz). Level has to be between +7 dBm and +10 dBm. Connect coax cable parallel to 1st mixer to VCO-branch. A level of +5 dBm to +8 dBm due to decreased load resistance over frequency band. 7.4 7.5 8. Check of Attenuators: 8.1 8.2 8.3 8.4 8.5 Set -30dB attenuation to Tuner and to 0dB attenuation to TG. Set Center Frequency to 500MHz, 100MHz/Div. span. Connect tracking generator to tuner input. TG-line has to be visible. Switch on additional attenuators. Attenuation for each attenuator switch has to be 10dB (±1 dB) 9. TG Level Adjustment: 9.1 9.2 9.3 9.4 9.5 9.6 9.7 Connect TG to reference analyzer. Set HM5011 to Zero Scan and 500MHz Center Frequency. Release all attenuator buttons of TG (0-dBm) and turn TG-level to maximum. Adjust amplitude to +1dBm with Pot RV4 on TG. turn TG-level to minimum. Adjust amplitude to -10dBm with Pot RV3 on TG. Amplitude has to be adjustable now between +1dB and -10dB. 10. Final Check 10.1 Position of TG-level has to align in both bandwidths (400kHz and 20kHz). If necessary, align with IF-Amp. 10.2 TG-level knob has to be adjustable from +1 to -10dBm. Subject to change without notice 14 Tracking-Generator 15 Subject to change without notice Tuner RA-Board Subject to change without notice 16 Tuner RB-Board 17 Subject to change without notice Subject to change without notice IF 2 +12V CD1 1nF IF IN IF AMP C2 47p C1 8p2 C17 0.1u R19 4K75 T3 BC557 1 30.0 MHz 22p C3 CD2 1nF R40 2K21 R21 100k 1N4148 D2 D1 1N4148 500mVpp BW FROM TUNER 2nd IF OUT C4 8p2 RF2 F19 R11 4K75 C15 22p 2.2k R10 +12V 250mV +8V(12.5 kHz) 0V(250 kHz) C18 120p C19 1p8 VR1 200R TUNER GAIN COMP. F1 RF3 R1 100k C10 10n C9 0.1u C16 0.1u C20 270p RF2 F9 T2 BF961 RF2 F3 R9 3K32 R8 221R C21 270p C23 120p C22 1p8 VR2 50K C13 220p RF2 F4 C12 33p C24 10n C25 10n F7 RF2 R7 10K0 R2 47R5 R18 470k C14 220p C11 82p C5 39p R17 47R5 C27 10n R16 181R R13 100k 221R R15 XT1 27.125MHz R3 2K21 L2 0.82u R6 10K0 T4 BF961 11V= 0.7Vpp RF2 F10 NTC R14 220R C29 1p8 82p C6 C33 120p C28 120p 33p C7 4.7V= C32 1p8 R22 4K75 RF2 F11 C34 10n C30 270p RF2 F12 R4 470R T1 BC547 R5 220R D3 D4 CD3 1nF 1N4148 IF GAIN BC547 T5 C39 10n C37 0.1u C26 0.1u L5 15u FROM ATTEN. RF UNIT S.1 R20 47K5 R23 22K1 1N4148 C31 270p C8 10n IF GAIN RANGE VR4 100K R27 150k C36 330p R29 47R5 C38 180p R30 3K32 VID BW L1102 L1101 400mVpp R28 470K RF2 F13 R32 100R IF GAIN +12V +5V R24 100R T6 BF961 >2Vpp 100u 100u VIDEO SIGNAL VID CD4 1nF R25 180R R26 100K +5V +12V IF PCB Date: B Size Title C35 10n RF2 F14 6 5 4 3 2 1 NTC R39 2K21 200mVpp VR3 500R NTC R34 2K2 +8.8V R37 3K92 8 9 7 6 G VCC May 5, 1994 IF5005.SCH IF AMP HM5005/6 Sheet 1 4 U F 2 C44 22p C41 22u IC1 MC3356P HAMEG INSTRUMENTS GERMANY 22K R38 C42 10n C43 0.1u 7.6V= R36 332R OVERALL GAIN R31 4K75 R35 2K21 Document Number C40 180p R33 180R GND IF GAIN +12V +5V +12V GND +5V GND VIDEO SIGNAL BW TO AL (RF UNIT) KA901 S.1 1 2 3 4 KA1102 TO XYF PCB P803 S.3 6 5 4 3 2 1 KA1101 1 2 3 4 5 11 12 13 15 16 17 18 19 20 of 8 REV IF-Amplifier 31 32 -6V2 1k0 3 C206 0.1u C205 0.1u C204 0.1u C203 0.1u C202 0.1u 0.1u 1k00 R169 C169 0.1u +5V RV112 1K0 R129 6k19 /10turns 10K 2 RV110 14k3 R128 3 RV113 R177 2k74 RV111 10K /10turns 2 C201 2 1 3 1 2 1 3 1 1 2 3 4 5 6 1 2 3 4 5 6 DIGITAL SECTION MK-MIN MKR +VREF CF-MIN CF +VREF MOLEX6 P107 G D C B A T N V D C TO FC PCB W304 S.5 ANALOG SECTION R199 1k00 +5V INH 2 P201 MOLEX6 R216 51R1 QA QB QC QD 1 2 3 4 5 6 P108 + V T G G P 2 T V N N S 0 C D D V 1 2 3 4 5 6 IC201A 74HC390 CLR CKA CKB C119 0.1u 3 5 6 7 T108 BC850C TO FC PCB W305 S.5 R112 10k0 6 11 10 9 13 14 15 12 1 5 2 4 6 11 10 9 13 14 15 12 1 5 2 4 X1 MPOS MOFF GND UREF CF FINE A B C X0 X1 X2 X3 X4 X5 X6 X7 INH 1 4 C199 0.1u X A B C X0 X1 X2 X3 X4 X5 X6 X7 IC102 HEF4051 X TO AL PCB W1203 S.1 C216 10nF C117 22u /35V C118 22u /35V R111 33k2 3 3 IC103 HEF4051 C253 27p %2 R116 100k C108 1nF 13 12 2 3 1k00 R152 1 1 4 14 15 12 C254 56p R253 10k0 3 4 100R 100R 301R 499R 1k00 3k01 4k99 10k0 30k1 49k9 R252 51R1 2 1 8 9 J201 COAX R255 51R1 * 2 3 R10c 6M8 10 R262 51R1 9 51R1 R257 T102 BC850C T101 BC860C R123 274k RV101 100K SW-AMPL R142 15k0 IC106A LM324 C116 0.1u 1 * 13 12 9 8 1 0 R143 10k0 8 11 10 CLR IC202B 74HC390 14 15 12 IC204D HEF4011 HEF4011 IC204C CKA CKB x100V IC206C 74HC02 C136 0.1uF 8 +28V 2 3 C143 470p R194 * R172 2k74 5K0 RV171 L-A1 R171 1k50 IC101C TL074 R120 22k1 R118 4k75 R117 22k1 R10d 6M8 C107 9 10 R186 221k R193 61k9 R185 * R191 30k0 R184 0R R192 20k0 +28V 1 L-B RV186 10K R222 51R1 IC205E 74HCU04 11 3n3 C138 R125 8k25 R126 10k0 1 1 4 3 D181 BAW56 R183 10k0 RV183 100K L-C2 R187 3k32 R188 D109 BAS16 +VREF R119 22k1 IC205D 74HCU04 2 -6V2 R141 9k09 RT101 2k2 RT102 * R267 1k00 R221 51R1 %10 TO TG J402 S.6 8 MHz OUT 13 13 11 10 9 C255 1nF IC205F 74HCU04 R254 2k21 12 QA QB QC QD R133 56k2 -6V2 +VREF R140 562R 0R R189 R182 4k75 L-C1 RV181 5K0 R181 0R +VREF R10b 8k25 R115 10k0 R10a 10k0 C105 22nF R114 5k11 R113 6M8 IC201B 74HC390 CLR CKA CKB IC101D TL074 14 IC101A TL074 1 0.1u C115 R251 51R1 XT254 8MHz IC205B 74HCU04 3 R211 51R1 R151 18k2 VREF -6V2 +28V R109 R108 R110 R101 R102 R103 R104 R107 R106 R105 IC204A R224 51R1 QA QB QC QD 13 11 10 9 HEF4011 1 2 * 1 %2 R148 10k0 6M8 R190 R154 22k1 1 2 1 R S T 1 1 (PS) 1 0 C L K 1 %8 3 3 R223 51R1 D225B BAW56 D225A 5 %1k 6 5 4 UNC R225 2k21 IC205C 74HCU04 IC204B HEF4011 1 1 1 1 3 2 1 5 4 2 3 6 4 5 7 9 6 IC205A 74HCU04 2 R149 10k0 5 6 7 R127 150k 3 2 4 IC206D 74HC02 1 R265 4k75 9 10 6 5 C262 4n7 PE BAS16 D263 13 12 1 2 3 5 9 10 11 6 R261 51R1 R161 51R1 R266 51R1 R122 68k1 R264 51R1 11 12 IC206A 74HC02 -6V2 R121 221R 22k1 R167 D103 BAS16 R157 8k25 -6V2 0.1u C109 +5V SAWTH C265 0.1u D265 BAS16 R258 51R1 74HC02 IC206B 6 5 13 R259 51R1 +VREF R160 100R R158 1M00 D110 BAS16 8 IC106C LM324 7 IC106B LM324 R137 1M5 R138 1M5 C110 10nF (VT) R179 * IC104B LM393/M R198 56k2 D180 * R180 * RV180 * R156 221k R250 22k1 RV149 10K MKR-Offs. 3 R159 1k50 C130 4n7 R170 * Q Q Q Q Q 1 1 1 1 1 Q Q Q Q Q Q Q 4 3 2 1 0 9 8 7 6 5 4 1 IC203 HEF4020 %4 2 %10k %2k R233 51R1 1 LM393/M R146 * R155 47k5 14 IC106D LM324 +VREF R197 47k5 R196 10k0 RV197 2k5 D144 * R144 * 12 13 D197 BAS16 R175 * IC104A C129 0.1u 8 4 0.1u C120 L-D RV176 * R195 0R R145 * 110...210ns -12V C121 220p R153 * 3 2 R124 1k50 -5V +5V -6V2 R249 51R1 R150 47k5 R147 * 3 R176 D171 BAV70 R173 47k5 RV173 500K L-A2 R174 * R178 * 7 R135 R134 47k5 2 1 4 LE 4 14 15 IC202A R263 100k 74HC390 CLR CKA CKB 5 6 D102 BAS16 X Y C L P U G G L E E N N N K C D D 1 2 3 P111 C141 0.1u TO FC PCB W303 S.5 P202 MOLEX6 +5V R256 51R1 3 5 6 7 -5V +5V 1 2 3 Subject to change without notice Date: C Size Title R212 51R1 0.1u D128 BAV99 (+13V) 1 2 LM 317 0.1u C133 3 -6V2 R164 221R 1 R139 39R R166 * 1 C K 3 E 2 MMS0204 / 0.25W / 5% 3 B A 1 MB50101B.SCH MB PCB HM5010/11 November 6, 1995 C135 0.1u /35V Sheet 6 5 4 3 2 1 P109 4 BC860 BC850 BAS16 BAW56 BAV70 2 1 LM 7805 0.1u C137 0.1u of 3 0.1u C103 C134 * -12V (+12V) GND (-5V) +5V +32V C123 22u /35V C101 R163 2k05 R165 * TO PS P1006 S.8 C122 22u /35V C124 22u C127 0.1u IC107 * * C125 C132 * 6 5 4 3 2 1 TOP VIEW 2 O U I N ADJ 3 2 O U I N ADJ HAMEG INSTRUMENTS GERMANY 0.1u C111 R162 100R IC108 LM317 R131 39R R130 39R R100 0R +VREF +28V * C139 0.1u Document Number 0.1u C104 R132 39R GND BLANK GND C142 22u /35V C102 P110 C L k %4 MK GND XF +20V 60mA 1 2 3 PCB 3 R168 C126 1000u /16V 1 2 1 G OU N IN D IC128 LM79L05 3 C140 * 2 TO CRT W701 S.7 +5V C131 0.1u TO XY PCB W801 S.3 QA QB QC QD 1 2 3 +5V C128 1000u /16V -6V2 1 2 3 4 5 6 IC101B TL074 C112 1nF -6V2 X1 X0 Y1 Y0 Z1 Z0 Z IC105 HEF4053 8k25 R136 301k C B A INH +28V REV Main board Subject to change without notice A K nc C805 0,1uF R835 12K1 R834 12K1 R826 * BAS16 Top View SOT23 22p C807 R836 10K0 T806 BC860C R841 100R 100R R825 B C R837 10K0 R833 100K R804 2K21 E -12V BFS20 BC860 BC850 R838 2K74 1K50 R808 R831 10R 1 2 3 R802 1K0 T801 BC847B 1K50 R809 T812 BF422 R806 100R R866 30K1 1W +73V 3-Pol 1 2 3 W802 R832 22K1 T805 BC850C T804 BC850C R807 100R T803 BFS20 2.0mA R814 100R TO CRT PCB P701 S.7 YF1 NC YF2 +12V R840 * 10K0 R852 R853 10R C801 0.1u D801 BAS16 1 R811 1K50 R812 1K50 T811 BF422 R824 100R 3 SXA 0411 Met. Fi. 1% 1W R-Chip 5% 1206 R-Chip 1% 1206 C808 22p R839 1K50 C806 0.1u R830 10R RV802A 4K7 Y AMPL +133V +73V R865 30K1 1W R827 2K21 C824 0.1u/250V XF GND MK C896 0.1uF C822 FROM RB PCB KA??? S.? 1 2 3 4 5 6 P807 1 2 3 4 5 6 R863 100K T810 BD850 C818 10n FROM MB PCB P111 S.4 3 2 1 P801 R803 2k74 -12V YPOS GND nc +5V +12V R851 6K81 3 2 1 R801 4K75 BFS20 T802 10u/25V R813 100R R810 100R R 0R R 0R R 0R 1 2 1 2 3 4 5 6 1 2 3 4 5 6 P804 FROM TG UNIT KA501 S.6 GND GND GND +5V +12V -12V -12V 1 2 3 4 5 6 1 2 3 4 5 6 R896 * C821 * C819 0.1u -12V R898 22k1 -12V R864 10R * C815 C816 * 0.1u C814 C820 * C828 +12V 0.1u C813 6 5 4 3 2 1 C817 0.1u 10u/25V R897 20k0 VIDEO SIGNAL FROM IF-AMP 0R R R828 10R0 C897 * +12VY -12VA C823 10u/25V R822 2k74 RV801 10K YP-sym R823 100R R829 10R P802 * FROM FC PCB KA301 S.5 VF BW +12V +5V GND -12V R895 100k 0.1u 3 R816 1K82 R815 +140V C803 C802 0.1uF R805 100k R805A 100R 0.1u C804 Y AMP R845 22K1 R850 10R0 6 5 4 3 2 1 3 1 C871 2n2 2 6 5 4 3 2 1 +140V +32V GND +5V +12V -12V FROM PS P1008 S.8 P805 FROM IF AMP KA1101 S.2 (P803A / 5005) P803 +12V 6 GND 5 +5V 4 GND 3 VS 2 BW 1 +12V R847 10R R846 22K1 RV804 4K7 A X POS C826 47u/250V +140V C809 0.1u R871 221k 100R R859 C811 0.1u 0.1u C810 C893 0.1uF 3 R872 182k 5 6 (221K) R874 * R842 4K75 1 1 0R R892 221R 2 1 R875 RV872 4k7 A VOLUME R873 2M2 D874B * (BAV99) D874A 2 R862 1K50 C891 0.1uF IC891 LM317 A IN D OU J +32V 1K82 R819 T807 BC847B IC875B TL082 7 2 1 R843 100R 2 R891 4K75 3 1 2 3 D802 1 R856 1K82 R855 1K82 R858 100R 47K5 1W R868 +73V 1 2 3 4 5 6 W801 6-Pol BAS16 1 2 3 4 5 6 C892 0.1uF C878 10u/25V R876 0R R881 10k0 C812 0.1u X AMPL RV803 4K7 A +140V +20V...+125V R867 47K5 1W 10R R817 T813 BF422 +73V R818 1K82 C873 100p R821 100R +140V R820 100R T808 BFS20 10u/25V C827 C825 0.1u/250V X AMP R 0R i.r. R880 332k 2 3 -12VA 4 8 +12VY R861 3K01 R870 4K75 R889 1K00 C889 0.1uF 3 R879 1K00 6 5 4 3 2 1 R844 0R R860 4K75 R848 22K1 T809 BFS20 FROM MB PCB W??? S.? MOLEX6 6 5 4 3 2 1 P808 AUDIO - AMPL. R882 68k1 IC875A TL082 1 R877 0R C879 0.1uF R857 100R T814 BF422 1.5mA R854 100R TO CRT PCB P702 S.7 GND GND NC XF1 +140V XF2 Date: C Size Title -12V nc GND nc +5V +28V R884 100R R887 332R R883 100R R849 100R 1 1 +12V R888 0R R889 0R 3 2 1 November 6, 1995 XY50101B.SCH XYF PCB HM5010 Sheet 3-Pol 3 2 1 P870 3 NF GND +12V FROM PA PCB W??? S.? P810 2.5MB6 1 2 3 4 5 6 CHECK-PTS. HAMEG INSTRUMENTS GERMANY R886 51R1 T886 BC860 220uF/16V C882 T885 BC850 R885 51R1 Document Number 3 2 2 3 +5V +140V +32V GND +5V +12V -12V of REV XY Board 33 34 3 TO MB PCB P202 S.4 C L P U L E E N K C G G N N D D /65mm 2 R317 100K 3 R318 100K D307 1 4 BANDWIDTH 12.5kHz 2 5 ALPS 3 1 2 D306 6 BAW56 3 SW301 T304 BC850 10K0 R309 D304 BAS16 +5V 4K75 R301 IC300 ICM7217N BAV70 1 R323 82K5 LED301 RED UNCAL R314 33K2 T303 BC860 C302 0.1u T305 BC850 R311 182R W303 6pol 2 1 D305 BAV99 1 2 3 4 5 6 C301 220u /16V L302 100uH +5V 2 250kHz 12.5kHz R336 * R316 221R R315 221R R310 221R R302 10K0 12 9 8 19 24 14 10 7 6 5 4 1 BAV70 D301 3 15 14 13 1 1 2 5 T306 BC860 3 ALPS SW302 VIDEOFILTER OFF 4 5 6 12 3 2 4 7 10 1 5 6 9 11 D302 BAV70 R330 10K0 ZERO 0.1 0.2 0.5 10 20 50 100 20 23 27 25 28 22 26 21 18 17 16 15 2 CO Q0 Q1 Q2 Q3 Q4 Q5 Q6 Q7 Q8 Q9 R304 10K0 RST CLK ENA IC320 HEF4017 1 2 3 OFF ON R329 * R319 33K2 LED315 LED314 LED313 LED312 LED311 LED310 LED309 LED308 LED307 LED306 LED305 D303 BAS16 1 VF BW +12V +5V +5V 1 2 3 4 5 6 7 9 10 11 IC301 HP3603 1000MHz 1 1 3 C L P R 1 0 1 C L Q Q Q Q R335 4k75 0 1 2 3 4 5 6 7 8 9 74HC42 IC308 C339 * 4 P R 10 9 8 5 4 2 3 7 CLK D CLK D R340 475R +5V 6 11 12 +5V IC321B 74HC74 3 2 IC321A 74HC74 +5V A B C D 8 9 R338 * R339 * 15 14 13 12 6 2 1 3 1 10 9 8 5 4 2 3 7 2K21 R342 TO MB PCB P107 S.4 B A B C D T W V Z C 1 2 3 4 5 6 IC302 HP3603 100MHz R341 475R BAW56 D340 6 5 2 3 6pol 6 A B C D 10 9 8 5 4 2 3 7 CI CLK PE B/D U/D R331 33K2 +5V IC306C MC14011 10 CO QA QB QC QD T331 BC850 1 IC307 +5V 1 1 MC14029 /70mm R332 1K00 W304 9 8 7 6 11 14 2 D341 BAV70 IC303 HP3603 10MHz 3 221K R344 2 1 R343 10K0 3 2 5 15 1 9 10 4 12 13 3 C308 0.1u T340 BC850 4 5 6 1 SW304 R321 33K2 UP 10 9 8 5 4 2 3 7 1 2 3 2 3 +5V R312 1M00 R322 1K00 +5V C305 0.1u R336 39R2 6 4 5 6 IC305 HP3603 0.1MHz SCANWIDTH IC306A MC14011 1 R335 39R2 IC304 HP3603 1MHz 6 11 SW303 R320 33K2 1 2 3 MC14011 IC306D 5 6 IC306B MC14011 R313 22K1 10 9 8 5 4 2 3 7 DOWN 12 13 4 1 C307 0.1u C306 22n 1 BW VF C310 0.1u MARKER OFF 2 ALPS 4 3 5 6 SW305 TO XYF PCB P802 S.3 C311 0.1u 3K32 R308 T302 BC860 T301 BC850 RV310 10K A 2 Subject to change without notice Date: C Size /300mm R327 100R R324 100R C303 220u /16V MKR LED303 GREEN R303 150R CTR LED304 GREEN TR 5K0 RV301 TO MB PCB P108 S.4 X1 MPOS MOFF GND UREF CF FINE /60mm November 22, 1995 FC50101A.sch FC-PCB HM 5010/11 P301 +5V 1 5 P302 TRACE ROTATION COIL 1 Sheet HAMEG INSTRUMENTS, GERMANY W301 6pol R326 100R R325 100R C304 0.1u +5V CF FINE Document Number - G + + B V 1 N 5 1 WF 2 D V 2 V V 1 2 3 4 5 6 Title L301 100uH C309 0.1u R307 10K0 R306 10K0 R359 100R 3 1 1 2 3 4 5 6 W305 6pol of REV FC-Board PA-Board Subject to change without notice 22 23 1 2 3 4 5 6 KA702 6 5 4 3 2 1 P702 TO PS P1002 S.8 TO XYF PCB KA801 S.3 XF2 150V XF1 NC GND GND BLV FCD G1 -1925V H1 H14 6 5 4 3 2 1 1 2 3 4 5 6 0.1u/100 C703 C701 0.1u LL4151 D701 4 2 R704 1k0 5 1 R707 51k1 R708 47k5 IC701 6 CNY17 R701 681R R702 68k1 20k0 VR701 R703 47k5 D703 TLSG5101 10K0 R705 D702 LL4151 1 2 3 51R1 0.1u/250 C702 T701 BC850 R710 GND BLANC GND R706 10K0 TO MB PCB P110 S.4 1 2 3 KA701 Date: A Size Title 3 2 4 12 13 9 1 1 4 1 2 3 March 14, 1994 CRT5005.SCH CRT PCB HM5005/6 1 2 3 P701 Sheet 7 TO XYF PCB KA802 S.3 HAMEG INSTRUMENTS GERMANY 11 7 6 Document Number D14-364 YF1 NC YF2 of 8 REV CRT-Board Subject to change without notice Power Supply Board Subject to change without notice 24 RA-Board 25 Subject to change without notice Tracking-Generator Subject to change without notice 26 TO RB-Board 27 Subject to change without notice Main Board Subject to change without notice 28 Main board 29 Subject to change without notice XY-Board Subject to change without notice 30 XY-Board 31 Subject to change without notice FC-Board Subject to change without notice 32 FC-Board 33 Subject to change without notice PA-Board Subject to change without notice 34 CRT-Board 35 Subject to change without notice PS-Board Subject to change without notice 36 PS-Board 37 Subject to change without notice PS-Board Subject to change without notice 38 Block Diagram HM5010/HM5011 39 Subject to change without notice Oscilloscopes Multimeters Counters Frequency Synthesizers Generators R- and LC-Meters Spectrum Analyzers Power Supplies Curve Tracers 4S-5010-0010 Time Standards HAMEG GmbH Industriestraße 6 D-63533 Mainhausen Telefon: +49 (0) 6182 / 800-0 Telefax: +49 (0) 6182 / 800-100 E-mail: [email protected] [email protected] Internet: www.hameg.de Printed in Germany