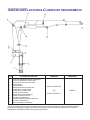

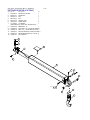

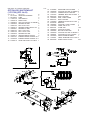

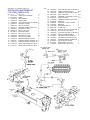

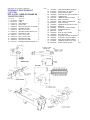

Download Parts & Specifications Volume 2 for IMT Articulating Crane Truck

Transcript