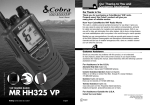

Download Service 2460-4129

Transcript