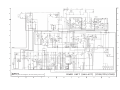

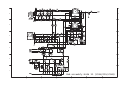

Download Multimedia LCD Projector SM0547 SERVICE MANUAL

Transcript