Download J Series Gas IOM

Transcript

INSTALLATION, OPERATION, MAINTENANCE

AND PARTS MANUAL

'J' SERIES - GAS FIRED

STEAM BOILERS (6J - 60J)

This Manual must be available to the boiler operator at all times.

JGAS-E-10 2008

In case of Emergency

This boiler has been designed and constructed to meet all of the essential requirements of the applicable

European Directives and subject to proper maintenance should not give occasion to any hazardous

conditions. If such a condition should occur during commissioning or during subsequent operation of

this product, what so ever the cause, then the fuel supply to the boiler should be isolated immediately,

until such time that the fault has been investigated by a competent person and rectified.

For Your Safety!

The following WARNINGS, CAUTIONS and NOTES appear in various sections of this manual.

It is the responsibility and duty of all personnel involved in

the operation and maintenance of this equipment to

fully understand the WARNINGS, CAUTIONS and

NOTES by which hazards are to be eliminated or

reduced.

Personnel must become familiar with all aspects of

safety and equipment prior to operation or

maintenance of the equipment.

WARNINGS must be observed to prevent

serious injury or death to personnel.

CAUTIONS must be observed to prevent

damage or destruction of equipment or

loss of operating effectiveness.

NOTES must be observed for essential

and effective operating procedures,

conditions and as a statement to be

highlighted.

WARNING

Steam Boilers are a potential hazard, possibly

fatal if not properly maintained.

CAUTION

It is vitally important that the instructions given

in this manual are strictly adhered to.

Failure to carry out the routine maintenance checks could result

in a drastic reduction in the life expectancy of the boiler.

The Pressure System Safety Regulations 2000

Fulton Boilers fall within the scope of the Pressure Systems Examination Scheme.

Regular inspections are therefore required by a 'Competent Person'.

The scope of the examination and the actual intervals between examinations is at the discretion of the competent person.

It is the responsibility of the user to provide a written scheme of examination for those parts of the system in

which a defect may give rise to danger.

Instructions in this manual are provided for the safe operation and maintenance of the boiler and do not cover

periodic statutory inspections.

For further information contact:

(a)

SAFed

SAFETY ASSESSMENT FEDERATION Limited.

Nutmeg House,

60 Gainsford Street,

Butlers Wharf,

London, SE1 2NY.

(b)

Health and Safety Executive local office.

(c)

Your Competent Person.

J Gas 08 2008

LIST OF CONTENTS

TITLE

INTRODUCTION

General

Technical Data (for a full specification refer to section 5)

INSTALLATION

General

Siting

Ventilation

Flue Outlet

Water Supply (see also Water Treatment in section 5)

Blowdown Valves

Main Steam Valve

Steam Safety valves

Water Gauge Set

Gas Supply

Gas Valve, Pilot Gas (40 - 60 models & Australia)

Electrical Requirements

Steam Pressure Gauge

Commissioning the Boiler

Boiler Inspection and Initial Firing

Setting the Burner Controls for Low Fire/High Fire, Models 40-60

Multibloc Gas Valves

Cleaning Steam Lines and Pressure Vessel

Gas Supply - Propane/Butane

OPERATION

General

Boiler Controls

Control Panel - Indicator Lights

Filling the Boiler - All Models

Starting the Burner - All Models

Daily Operating Tests

Pump Check

First Low Water Level Check

Second Low Water Check Blowdown Procedures

Evaporation Checks

Troubleshooting - Boiler

Troubleshooting - Burner Control Unit LFL - 1

Troubleshooting - Burner Control Unit TMG 740-3

Draining the Boiler

Long Term Shut Down

SECTION

1

1.1

1.2

2

2.1

2.2

2.3

2.4

2.5

2.6

2.7

2.8

2.9

2.10

2.10.1

2.11

2.12

2.16

2.16.1

2.16.2

2.17

2.18

2.19

3

3.1

3.2

3.3

3.4

3.5

3.6

3.6.1

3.6.4

3.6.5

3.7

3.8

3.9

3.10

3.11

3.12

3.13

Maintenance Log

MAINTENANCE

General

Daily

Weekly

Monthly

Three Monthly Six Monthly

4

4.1

4.2

4.3

4.4

4.5

4.6

GENERAL DATA

Boiler Dimensions

Boiler Specification

Recommended Water Conditions

Probe Lengths

Wiring Diagrams

Pressure Controller

Boiler Controls Test Log

5

J Gas 08 2008

SAFETY

The instructions provided for the operation and maintenance of the boiler MUST be observed.

Failure to do so could result in damage to the boiler and serious personal injury.

WARNING

It is the responsibility of the installer to ensure all parts supplied

with the boiler are fitted in a correct and safe manner.

WARNING

Do not try to do repairs or any other maintenance

work you do not understand. Obtain a Service Manual from

Fulton or call a Fulton Service

Engineer

WARNING

Understand the electrical circuit before connecting or disconnecting an electrical component. A wrong connection can

cause injury and or damage.

WARNING

Do not change the boiler fuel without consulting the boiler

manufacturer.

WARNING

Non-approved modifications can cause injury and damage.

Contact your Fulton dealer before modifying the boiler.

WARNING

WARNING

A defective boiler can injure you or others. Do not operate

a boiler which is defective or has missing parts. Make sure

that all maintenance procedures are completed before using the boiler.

WARNING

The installation of Gas appliances including the flue system

should only be carried out by Corgi

Registered Enginee

WARNING

The importance of correct boiler water and feed water cannot be over emphasised, see the relevant section in this

manual.

WARNING

DANGER FROM INCOMPLETE COMBUSTION

The importance of correct burner adjustment to achive low

emissions, safe, clean and efficient combustion is paramount.

Poor combustion, where unburnt gas forms carbon monoxide

is both a health hazard, and the potential risk to the boiler

from overheating, caused by re-burning of the unburnt gas

in the secondary flue passes.

CAUTION

Obey all laws and local regulations which affect you and

your boiler.

CAUTION

WARNING

Only qualified persons should be allowed to

operate and maintain the boiler and its equipment. Boilers

should always be drained through an approved Blowdown

Vessel.

LOW FEED WATER TEMPERATURE

Low feed water temperature can result in thermal shock to

the boiler pressure vessel. Return the maximum amount of

condensate and if necessary pre-heat the feed water. If in

doubt consult FBW.

LIFTING EQUIPMENT

Make sure that lifting equipment complies with all local regulations and is suitable for the jobYou can be injured if you

use faulty lifting equipment. Make sure the lifting equipment

is in good condition.

WARNING

Operating the boiler beyond its design limits can

damage the boiler, it can also be dangerous.

Do not operate the boiler outside its limits.

Do not try to up grade the boiler performance by unapproved

modifications.

WARNING

DANGER FROM HOT SURFACES

Steam Boilers have high temperature surfaces, that if touched

may cause serious burns. Only

competent and qualified personnel should work on or in the

locality of a steam boiler and ancillary equipment. Always

ensure the working area and floor are clear of potential

hazards, work slowly and methodically.

Do NOT store inflammable materials near the boiler.

CAUTION

HYDRAULIC TEST - RISK OF BRITTLE FRACTURE

Hydraulic testing requires specialist equipment and is normally only required by engineering surveyors / inspectors.

The material the boiler is manufactured from, has not been

impact tested, as it is not a requirement of BS2790 (boiler

construction

standard). In order to ensure the material / pressure vessel

does not suffer from brittle fracture,

hydraulic testing should not be carried out

below 7OC.

CAUTION

WATER SOFTENER and CHEMICAL TREATMENT

The chemicals required to operate the water softeners and

chemical treatment plants are NOT SUPPLIED by Fulton.

It is the responsibility of the operator to ensure adequate

supplies of chemical are available at all times (including

commissioning).

Costly repairs could be required should the plant

operate without chemicals or the wrong dosage of

chemicals.

J Gas 08 2008

Optional Variations (where fitted)

Motorised High / Low Control B

Spirax High Integrity Level Controls C

Automatic TDS Blowdown System D

Title

Gas Fired Steam Boiler

General Arrangement

Typical Installation

Boiler Flue Connection

Boiler Feed Water Arrangement

Boiler Blowdown (20 - 60)

Boiler Blowdown (6 - 15) Water Column Blowdown Valve

Water Column Sequencing Valve

Boiler Top Components

Steam Pressure Gauge

Burner Electrode Settings

6 - 30 Gas Valve

Pressure Controller

40 - 60 Gas Valve

Gas Valve Detail Control Panel Facias

Boiler Blowdown Valve

Sequencing Blowdown Valve

Water Level Gauges

Boiler Maintenance

Removing/replacxing UV Detector

Handhole

Boiler Furnace

Ignition Electrode

Burner Plate

Burner Assembly

Flue Cleaning

Boiler Dimensions Electrical Circuits

Three Phase Supply Circuit

Three Phase Supply Circuit - Australian Boilers Only

Ancillary Control Circuit

Burner Control Circuit Burner Control Circuit, Australian Boilers Only

Burner Control Circuit, High - Low Gas

PM5 Remote Panel / Typical boiler Connections

Tank Solid State Water Level and Alarm Circuits

Standard Single Boiler and

Ancillary Skid Electrical Connections

Spirax Level Control Circuit

LC Level Control Circuit

TDS and Blowdown Control Circuit

J Gas 08 2008

Appendix

Fig. No.

1

2

3

4

5

6

7

8

8A

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

1

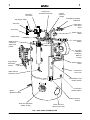

1

Monobloc

Gas Valve

Supply Gas,

Pressure Test Point

Steam

Pressure

Gauge

Feed Water Isolating

Ball Valve

Gas Supply Valve

Gas Inlet

Feed Water

Non-return

Valve

Scale Trap

Steam Supply

Valve

Safety Valve

Air Pressure

Switch

Water Column

containing

water level

probes

Air Intake

Manifold

containing

Main Air

Control

Sight Gauge

Blowdown

Valves

Boiler Control

Panel

Control Box

Door Lock

Water Column

Blowdown Valve

Feed Water Pump

Isolator Switch

Control Box

Isolator Switch

Boiler

Blowdown Valve

Steam Pressure

Control

Clean Out Handhole

(Water Jacket)

Clean Out Door

(Gas turn around)

FIG.1 GAS FIRED STEAM BOILER

1

J Gas 08 2008

1

1

INTRODUCTION

SECTION 1

1.1 General (Fig. 1)

The J Gas Service Manual is a generic publication, as such provides information on standard boiler operation and maintenance.

The Fulton J Series Gas Fired Steam Boiler is a vertical two pass boiler of simple and efficient design and construction. Every care has been taken in the manufacture of the boiler to ensure that quality and reliability standards are maintained. However, satisfactory performance can only be ensured if the installation recommendations, operating routines and maintenance schedules laid out in this manual are adhered to.

1.2

Technical Data - Boiler Output

for a full specification refer to Section 5.

BOILER MODEL

6J

8J

10J 15J 20J 30J

40J

50J 60J

Output

kg/h (F & A 100oC)

96

128 160 240 320 480

640

800 960

CAUTION

WATER SOFTENER and CHEMICAL TREATMENT

The chemicals required to operate the water softeners and chemical treatment plants are NOT SUPPLIED by Fulton.

It is the responsibility of the operator to ensure adequate supplies of chemical are available at all times (including commissioning).

Costly repairs could be required should the plant operate without chemicals

or the wrong dosage of chemicals.

J Gas 08 2008

2

2

2

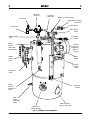

Modular

Gas Unit

Pressure

Test Point

Gas Cock

Steam Pressure Gauge

Feed Water Isolating

Ball Valve

Check Valve

Scale Trap

Main Steam

Valve

Steam Safety

Valve

Air Safety

Switch

Water

Column

with water

level probes

Blower

Housing

containing

Main Air

Control

Burner

Motor

Water

Gauge

Sets

Operator

Control

Panel

Blowdown

Valve

Water

Column

Blowdown

Valve

Pressure

Control

Main

Boiler

Blowdown

Valve

Clean Out Door

(Gas turn around)

Hand Hole

(Water Jacket)

FIG. 2 GENERAL ARRANGEMENT

3

J Gas 08 2008

2

2

INSTALLATION

SECTION 2

2.1

GENERAL

The installation of a J Series Gas Fired Steam Boiler should be carried out by competent personnel in accordance with all relevant safety regulations. It is the responsibility of the installer to ensure that these regulations are complied with.

The requirements and instructions contained in this Section generally relate to the boilers being

installed to operate on natural or manufactured gas. Where the boiler is to operate on L.P. Gas,

special reference should be made to Section 2.10 - Gas Supply, and Section 2.18 L.P. Gas Supply.

2.2

Siting ( Reference should be made to Utilization Procedures as stated in IGE/UP/10 Part 1

Communication 1676, and in particular to Section 5, Location of Appliances ).

The boiler house should be sufficiently large to allow easy and safe access to all parts of the boiler for operational and maintenance purposes.

Reference should be made to Section 5 - General Data to ascertain the relevant dimensions and weights, special note should be taken of the required vertical clearance required for maintenance.

WARNING

Maintenance on the burner assembly requires the area directly above

and to one side of the boiler must not be obstructed with pipework or

equipment which would interfere with the removal of the complete burner

unit. Care should be taken on installation of the boiler to ensure this

area remains clear of obstructions.

The flooring must be level, laid in a non-combustible material and be of sufficient strength to support the boiler.

2.3

Ventilation

Adequate fresh, clean air is necessary for safe and efficient combustion, and should be provided at high and low level in accordance with BS 6644 1991 and IGE/UP/10 Part 1 Communication 1676.

Note:

(a) Ensure there is adequate ventilation in the boiler room. Lack of ventilation will create a high temperature and cause control lockout.

(b)

Do not keep exhaust fans running with windows, doors and vents closed, this will interfere with the necessary boiler draught.

(c)

Do not store chemicals such as perclorethylene in the boiler house, the fumes may

damage the boiler and flue and cause the burner to lock out on flame failure.

Note: see section 5 for Low and High Level values.

J Gas 08 2008

4

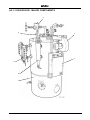

5

Water column

blowdown line

Steam Supply

J Gas 08 2008

FIG. 3 TYPICAL INSTALLATION

Boiler blowdown valve

Flanged connection

20 - 60J only

Flue spigot

Strainer

D

H = 1.5 X D

D = Diameter of flue

Flue

H

Plugged drains

Stainless steel

feed water and

condensate

return tank

F03164

Drain

Overflow to

drain

Blowdown

Separator

Vent

Make-up feed water supply

Note: A break tank may be required depending

upon Local Water Authority By-laws

Isolating gate/ball valve

Flexible link

Overflow

Standard boiler trim

supplied with boiler

Condensate return

Feed water

pump

Clean-out door

Draught stabiliser

(when fitted)

Feed water non-return valve

Feed water isolation ball valve

Pipe safety valve

to a safe area,

using unions and

drain as required.

Cowl

2

2

2

2

2.4

Flue Outlet

The boiler is supplied with a stainless steel flue spigot that should be inserted into the flue outlet in the back of the boiler and secured with the three angle clips supplied loose in the trim box.

The height and type of flue will be subject to local planning regulations and approvals. The following

information is only intended to provide assistance for the installation of a simple flue.

Where multi-boiler flues or difficulties are experienced,

specialist advice should be obtained.

The flue diameter must be the same or larger than the flue flange provided with the boiler and the outlet should be at least 1 meter higher than the

nearest ridge to avoid down draughts. Where a

chimney cowl is fitted, care should be taken to ensure that the distance between the lowest point of the cowl and the top of the flue is 1.5 X the diameter of the flue.

and that it is of the terminal cone type.

FIG. 4 BOILER FLUE CONNECTION

Note:

1.

2.

3.

2.5

If the flue layout is such that it may produce an excessive up-draught, a draught stabiliser

may be required.

Avoid fitting 90deg. elbows whenever possible, if unavoidable compensate by increasing the flue diameter.

Ensure all flue pipes from the boiler to the main flue have a rising pitch.

Water Supply

The quality of the water used in the boiler will affect the life and performance of the boiler. Feed water contains solids and dissolved gases, these may promote encrustations of scale; foaming, priming, surging; corrosion and pitting; or caustic embrittlement. To prevent this happening it is strongly

recommended that a reputable water treatment concern is consulted prior to commissioning the boiler.

Isolating

Check

Note: see Section 5 Water Treatment.

Ball Valve

Valve

Connect the feed water pump to the check valve inlet with 25 mm. bore pipe (this may be reduced to 15 mm. where the discharge pipework is shorter than 4m in total), the pump suction pipe work must remain at 25mm minimum diameter.) and insert the stop valve supplied, between the boiler and the check valve.

It is essential to protect the feedwater pump from Feed

damage by foreign matter, a strainer should

Water

therefore be fitted in the pump suction pipework

Supply

Care should be taken to ensure the pipework is properly aligned and not placing any strain upon the feed water pump.

Note: FIG. 5 BOILER FEED WATER ARRANGEMENT

1.

The boiler feedwater pump may contain an inhibitor and this should be flushed from the pump prior to fitting the pump to the boiler. Failure to do so may result in water bounce or foaming due to the inhibitor forming a seal in the boiler.

2.

If the boiler is to be operated with little or no condensate return, consideration should be given

to pre-heating the feedwater. If in doubt consult Fulton Boiler Works.

3.

The Feedwater inlet connection on some boilers is located on the left hand side of the boiler below the sight glass assembly.

J Gas 08 2008

6

2

2

2.6

BOILER Blowdown Valves

There are three blowdown valves on the boiler

(four if two water gauge sets are fitted), the boiler blowdown valve at the rear of the boiler, the water column blowdown valve and the

water gauge blowdown valve.

All of these valves must be connected to a blowdown receptacle of approved design.

Regulations exist covering such items and care must be taken to ensure compliance with these regulations. If in doubt regarding blow

down arrangements, consult your Fulton agent.

Note: 6J - 15J main blowdown connection via branch

pipe 20J - 60J main blowdown connection is integral,

via a boiler mounted flange.

FIG. 6 BOILER BLOWDOWN (models 20-60)

(skid mounted boiler shown)

FIG. 7 BOILER BLOWDOWN (models 6 - 15)

(skid mounted boiler shown)

7

J Gas 08 2008

2

2

2.6.1 WATER COLUMN Blowdown Valve

The valve on the water column should be operated

daily to blowdown the column.

Water Column

Blowdown Valve

FIG. 8 WATER COLUMN BLOWDOWN VALVE

WATER COLUMN Blowdown Valve

(Australian boilers only).

The valve is a three position isolation valve, each position is indicated on a backing

plate mounted with the valve,

(the valve is shown in the blowdown position).

FIG. 8A

J Gas 08 2008

WATER COLUMN SEQUENCING and BLOWDOWN VALVES

(Australian boilers only)

8

2

2

Flame (UV) Detector

Secondary Air Control

Secondary Air Control

Main Gas Valve

Boiler Water Level Probes

Air Proving Switch

Water Feed

with Stop Valve and

Check Valve

Gas Train

with 360O rotation

Note: Boiler illustrated is fitted with optional Self Monitoring Controls.

FIG. 9 BOILER TOP COMPONENTS

9

J Gas 08 2008

2

2.7

2

Main Steam Valve

The main steam stop valve should be inserted in the steam line approximately 12in. (305 mm) from the

top of the boiler.

2.8

Steam Safety valves

Safety Valves are factory fitted and preset, they MUST NOT be adjusted. The discharge outlet should be piped to a safe discharge point and the piping so arranged that any condensate trapped in the pipework will drain away from the valve.

Note: It is recommended that the safety valve discharge pipework is installed to the requirements of

BS806 clause 4.9.7. / BSEN 134801-1:2002

(a)

(b)

(c)

The lift pressure is indicated on the safety valve. (Do not adjust).

The safety valve fitted to the boiler is designed to prevent the boiler exceeding it's design pressure.

Any system connected to the boiler not capable of accepting boiler pressure must be protected by a separate safety valve set to the required pressure.

WARNING

Factory fitted safety valves are preset to protect the boiler only and

must not be used to protect any other items not capable of

accepting boiler pressure.

2.9

Water Gauge Set (The design may vary from that illustrated)

Numbers may vary due to individual countries regulations.

Boilers are normally supplied with two complete water gauge sets.The water gauge blowdown cock should be connected to the auxiliary blowdown line from the water column blowdown valve in soft copper tubing. The connection to the gauge cock is DN8, 6mm (1/4in. BSP).

2.10 Gas Supply

Verify that the burner is suitable for the type of gas being supplied. Ensure the piping from the meter is the correct size, and that a gas cock is inserted in the line between the boiler and the meter. To avoid pressure drops, eliminate all unnecessary bends and elbows in the pipework between the gas meter and the boiler. A scale trap is provided on the gas train and should be used.

Burners suitable for operation on natural and manufactured gas are supplied with gas trains or a modular gas head which are fitted with pressure regulating governors. A minimum pressure of 7 in.

(17.5 mb) water column at the specified flow rate, is required at the gas train for natural gas installations and a minimum pressure of 5 in. (12.5 mb) water column is required at the gas train for manufactured gas installations.

If the gas supply is in excess of 100 mbar (6 - 30) or 200 mbar (40 - 60) a suitable regulator is required before the main gas valve.

Burners arranged for operation on L.P. gas are supplied with gas trains which include a pressure regulating governor. It is essential that the MAXIMUM pressure of the gas at the gas train does not exceed 32 in. (80 mb) water column and does not fall below 20 in. (50 mb) water column. To obtain these pressures a pressure regulating device or service governor must be fitted to the supply line from the storage tank to the boiler gas train.

Careful consideration must be given to the siting of LPG storage tanks to prevent over pressure conditions arising, due to temperature rises caused by solar gain.

2.10.1 GAS VALVE, with pilot gas line.

(Models 40 - 60 and Australian boilers).

The main gas valve is fitted with a by-pass system (internal or external depending on the model)

the by-pass allows pilot pressure to be maintaned whilst the flame is verified.

J Gas 08 2008

10

2

2

2.11 Electrical Requirements

An individual wiring diagram for the boiler is located on the inside cover of the control box.

When referring to the electrical specification of the boiler, the reference number located on the rear inside wall of the control box and the wiring diagram number should be quoted.

The audible alarms provided are mounted on the side of the control panel, if not audible they should be repositioned where they can be heard by a person competent to take the appropriate action should the alarm be activated.

Unless otherwise specified, the alarms supplied will be mains voltage models. Unless otherwise specified all models are supplied with burner motors and feed water pump motors arranged for operation on a three phase supply.

The power ratings and requirements are given in Technical Data - Section 5.

Steam Pressure Gauge

Plug

Steam Cock

Test Point

Syphon

F03210

FIG. 10 STEAM PRESSURE GAUGE

2.12 Steam Pressure Gauge

The steam pressure gauge assembly should be assembled in accordance with Fig. 10 using a suitable sealant on all joints.

Screw the assembly into the top of the boiler and connect the copper tube from the pressure controller

to the nipple provided on the assembly. The gauge should be facing the electrical control box and/or the

boiler operator.

11

J Gas 08 2008

2

2

2.16 Commissioning the Boiler

It is essential that the commissioning procedures listed below are carried out by a Fulton Service

Engineer who will have the necessary experience and testing equipment to ensure that the installation

is not only correct, but is operating safely and at optimum efficiency.

FLUE COMMISSIONING

Prior to initial firing of the boiler, the flue must be checked for leaks.

This is done by BOTH of the following methods:

Visual Inspection

Check joints between all flue sections for quality of seals. Where the flue passes through the structure of the building use your judgement as to the integrity of this section of the flue.

Smoke Test

With the flue capped, the drain stabilizer pipe (if fitted) blanked and a smoke generator inserted into the flue, there should be no smoke visible from the flue.

If either of these tests fail or at any time during boiler operation, there is doubt about the integrity of the flue, shut down the boiler and contact Fulton Boiler Works Immediately.

Note: Flues that are designed to operate with positive pressure should be tested to the requirements

of IGE/UP/10 March 2001.

2.16.1BOILER INSPECTION and INITIAL FIRING

(a)

Ensure the boiler has been washed out after installation.

It is advisable to conduct a water analysis before operating the boiler.

Examine the probes in the water column and the boiler shell and record their lengths.

Replace any damaged probes.

(b) If the burner is fitted with an ultraviolet or solid state detector, remove the detector and check for damage.

Remove the burner and check that the electrodes have not been damaged and that their

setting corresponds to the appropriate drawing.

Check that the burner is the correct type for use with the gas being supplied.

(c) Main Gas Supply

Ultra-Violet Detector

Ignition Electrode

297.4mm

Primary Air

Blast Tube

12.7mm

3 mm min.

5 mm max.

50.8mm

FIG. 11 BURNER ELECTRODE SETTINGS

J Gas 08 2008

12

2

2

Main Gas Valve

Air Pressure Gauge

Feed Water

Check Valve

Safety Valve

Flue

FIG. 12 6 - 30J MODELS GAS VALVE

(d) (e) A barometric type draught stabiliser, if fitted in the flue, should be set for a draught of - 0.01 in.

to

- 0.02 in. (- 0.025 mb to - 0.05 mb) of water column pressure with the burner off.

(f)

Open all the valves in the feed water line.

Ensure that all wiring connections are correct and that all terminal screws are tight.

Close the isolating valve on the discharge side of the feed water pump. Remove the priming plug

from the pump head and slowly fill the pump with water. Replace the priming plug and tighten

secuerly.

Note the correct rotation of the pump on the motor fan cover.

Start the pump and check the direction of rotation.

Vent the pump by means of the vent valve in the pump head. At the same time, open the discharge

isolating valve a little. Continue to vent the pump. At the same time, open the discharge isolating

valve a little more. Close the vent valve when a steady stream of water runs out of it.

Completly open the discharge isolating valve.

The bypass valve located in the drain plug may be opened during the filling procedure, close the

bypass when the operation is stable.

DO NOT ALLOW THE PUMP TO RUN DRY.

13

J Gas 08 2008

2

2

(g) Open all the valves in the water feed line.

Switch on the feedwater pump motor and fill the boiler.

The operation of the pump controls should be checked by using the boiler blowdown valve (located

at the rear of the boiler). When the water sight level gauge is reading two thirds full, the pump will

stop.

Open the boiler blowdown valve and slowly drain the boiler. When the water level falls below the

pump on probe, the pump should start. If the pump does not start check the probe connections.

Close the boiler blowdown valve.

For models 40 - 60 with an external pilot gas line, see 2.16.2.

(h) After purging the gas lines of air, start the burner.

Note: For Australian boilers only:

Prove the pilot flame by placing the PILOT HOLD / NORMAL switch into the Pilot Hold position,

this will hold the gas valve in the pilot gas position until the pilot flame has been verified.

(j)

Check the Satronic burner control for a minimum of four indicator lights to verify the flame.

Adjust the gas input by reading the gas meter (if fitted).

(k)

Adjust the main air control gate located on the burner scroll, to obtain a clean combustion.

Measure the levels of CO2 CO and O2 in the exhaust gas, record the results.

See typical combustion values in section 5.

(l) Observe the flame through the peephole between the electrodes and adjust the scondary air

control located on the top of the boiler, so that the flame cannot be seen 'backing up' the blast

tube.

(m) Check the operation of the low water safety controls.

(n) If the pressure control is fitted with a differential scale:

(see OEM literature in section 5)

Adjust the steam pressure control to suit the boiler application. It should be borne in mind that

boilers are designed to operate most efficiently at their maximum operating pressure. When boilers are to be operated below a pressure of 80 psi (5.5 bar) consideration should be given to the

fitting of a pressure reducing set.

(i) Set the main scale pressure to the maximum

pressure required (system pressure).

Do not exceed the boiler operating pressure.

(ii) Set the differential scale to it's minimum pressure.

If the pressure control has a fixed differential,

i.e. no adjustable differential scale, set the main

scale to the maximum pressure required.

Note: When multiple boilers are fitted with a

sequence control:

(i)

Set the main scale and differential scale

as above.

FIG. 13

J Gas 08 2008

PRESSURE CONTROLLER

14

2

2

Main Gas Valve Assembly

Main Gas Line Isolating

Pilot Line Ball Valve

Pilot Line Governor

Pilot Line Gas Valves

Note: Australian Models are fitted

with a Gas Valve Closed Indicator

on the Main Gas Valve

FIG. 14 40 - 60J MODELS GAS VALVE

15

J Gas 08 2008

2

2

(ii)

Set the setback pressure control to the

required set back pressure.

2.16.2 SETTING THE BURNER CONTROLS FOR LOW FIRE / HIGH FIRE, MODELS 40 - 60

The correct setting for low fire/high fire operation are made by making adjustments to the two stage

solenoid

valve and the low fire steam pressure switch.

(a)

Isolate the main gas valve by closing the valve in the gas input line.

(b)

Screw the pilot gas governor fully down, (governor open).

(c)

Start the burner and where possible meter the pilot gas rate, (ideally the pilot gas rate should be

10% of the full gas rate).

(d)

Check the LED display on the Satronic control box (where fitted).

The pilot should produce a solid line of five illuminated LED's (four minimum).

Check the ignition and pilot stability several times.

Record the pilot gas pressure.

(e) Open the main gas isolating valve.

(f)

Set the gas input to the boiler for correct input on high fire. This adjustment should be done

where possible by using the gas meter.

Adjust the main and secondary air gates to obtain optimum combustion conditions.

(g)

Adjust the low fire steam pressure switch to cut-out at approximately 5 psi below the setting of

the main steam pressure control.

(h)

Adjust the two-stage solenoid valve to obtain a low fire gas input of approximately 80% of high

fire.

Leave the air gates adjustments as for high fire.

J Gas 08 2008

16

2

2

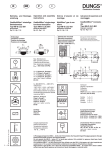

2.17 GAS MULTIBLOCS (see attached manufacturers leaflets).

BOILER SIZE

MULTIBLOC USED

6 - 30

6 - 30 Australian

MB-D(LE) 405-412 B01

MB-D(LE) 405-412 B07

40 - 60

MB-ZRD(LE) 415-420 B01

L.P.G.

Dungs:

MB-ZRD(LE) 405-412 BO1

Output pressure controller

adjusting screw

Hydraulic brake

6 - 30 Models

Main gas flow

adjustment

Operating indicator

Adjustable

pressure switch

Test point

connection

Test point

connection

downstream

of valve 1

Gas input

filter cover

Gas output

flange

Test point

connection

downstream of

valve 2

Test point

connection

upstream of

valve 1

Output pressure controller

adjusting screw

Hydraulic

brake

Main gas flow

adjustment

Operating indicator

Test point

connection

downstream of

valve 1

Adjustable pressure switch

Test point

connection

downstream of

valve 2

Gas input flange

Test point

connection

upstream of

valve 1

Gas input filter cover

FIG. 15 GAS VALVE - MAJOR COMPONENTS

17

J Gas 08 2008

2

2

2.17 GAS MULTIBLOCS (continued)

40 - 60 Models

(with pilot line fitted for Australia)

Hydraulic Brake

Main Gas Flow Adjustment

High Fire Solenoid

Output Pressure Controller

Adjusting Screw

Low Fire Flow

Adjustment

Operating Pressure Indicators

Input Gas Test Point

Adjustable Pressure

Switch

Test Point 1

Downstream

(internal leak test)

Test Point 2

Downstream

Test Point 1

Upstream

Gas Input

Mounting Flange

J Gas 08 2008

18

2

2

2.18 CLEANING STEAM LINES AND PRESSURE VESSEL

During the first week of boiler operation, clean all oil and dirt from the boiler, steam line and

condensate return line.

(a)

Disconnect the condensate return pipe adjacent to the condensate return tank.

(b)

Direct the returns to a floor drain or other safe discharge point and make safe.

(c)

Leave in this position for one week to allow all impurities to flush through.

(d)

Drain the boiler completely each day.

(e)

After the week is completed, drain and flush the condensate return tank, removing all installation sediment. Reconnect the condensate return pipe to the condensate return tank.

L.P. GAS

2.19 GAS SUPPLY - PROPANE / BUTANE

WARNING

Do not change the boiler fuel without

consulting the boiler manufacturer.

Note: LPG Boilers should be installed to the requirements of IGE/UP/10 March 2001

For PROPANE:-The boiler governor must be adjusted to give a firing pressure of 10 in. (25 mb) water column at the test point provided at the elbow on the gas train.

For BUTANE:-The boiler governor must be adjusted to give a firing pressure of 8 in. (20 mb) water column at the test point provided at the elbow on the gas train.

Gas Pressure Alarm Indicator Light

For L.P.G. applications the inlet pressure switch is used to protect the system from over pressure and should be set at 100 mbar.

19

An L.P. gas boiler is similar in design to a natural gas boiler, the main differences are important and must be taken into account when installing the boiler and ordering spare parts.

When installing an L.P. gas boiler, the feed from the bulk tank supply must be fitted with a supply governor which is set to reduce the supply feed pressure to the boiler governor to 30 in. (80 mbar) Water Column or less.

J Gas 08 2008

3

3

SECTION 3

OPERATION

3.1

GENERAL

DRYING OUT TIME

The refractory casing of the boiler is made from a material that uses a high proportion of water in the mixing process. Whilst some of the water is driven off by chemical reaction and the

initial test firing, the refractory is still 'wet' when the boiler is delivered. For a few days after the boiler is commissioned and in service, water will be seen running from the bottom of the casing and from around some branch pipes.

This is perfectly normal and part of the drying process. 3.2

BOILER CONTROLS

The following instructions are given for the guidance of the operator in the use of the J Series gas fired boiler and to provide adequate information to ensure that when the boiler is put into use it will be done safely and without risk to health. Where original equipment Service Manuals are supplied, they must be read and understood in conjunction with this manual. All Warnings and Cautions must be observed.

The following brief description of the controls used on the J Series gas fired boiler is intended to

provide the operator with a basic understanding of the operating principles, which is essential for the continued efficient operation of the boiler.

Note:All the controls are of the ‘fail-safe’ type and are wired in series; failure of any one will automatically shut down the boiler.

Low Water Relays and Feedwater Pump Relays. These relays operate in conjunction with probes

suspended in the boiler and water column to automatically maintain the level of water in the boiler

and to cut-off the burner should the water level fall to an unsafe level.

Steam Pressure Control(s). Located on the control panel box and connected to the steam pressure

gauge assembly by copper tube, the pressure regulator controls the on/off cycle of the burner,

shutting the burner off when maximum pressure is reached and switching it on when the steam

pressure falls.

Note: A set-back pressure controller is fitted when multi-boilers are fitted with a sequence control.

Burner Programmer. This is the main control in the panel box. The programmer in conjunction with

a sensing device ‘supervises’ the ignition sequence, proves the flame is satisfactory and finally

‘monitors’ the established flame. Should any fault occur, either during the ignition sequence or

during normal running, the programmer will immediately go to ‘lockout’ and the multibloc gas valve

will be closed.

Air Pressure Switch. Mounted on the burner scroll, this switch is operated by the pressure of air entering the burner through the throat of the scroll. Lack of air, or insufficient pressure, will prevent the

switch completing the circuit thus preventing the burner from operating.

Gas Head Assembly. Consists of a multibloc incorporating an integral governor, pressure switch and

gas valves or for larger boilers in addition to the internal components, an external pilot line with

it's own gas proving valves and governor.

PUMP CONTROL

Pump Interrupt/Pump Run Switch.

Fitted on the left side of the control panel, used to override (switch off) the pump controls during evaporation tests.

Australian Boilers only.

Pilot Hold/Normal switch, Mounted on the right hand side of the boiler control box, the switch is used

to hold the main gas valve at pilot pressure in order to verify the pilot flame.

J Gas 08 2008

20

3

3

6J - 30J

40J - 60J Standard and Australian

(standard boilers have the CPI

indicator blanked)

6J - 30J Australia

3.2

BOILER CONTROLS continued.

Note:

Boilers fitted on skid units and in plant rooms are interlocked with the feed water and

condensate return tank, after switching the boiler on at the boiler control box isolator switch,

the reset button on the tank control box must be reset.

FIG. 16 CONTROL PANEL FACIAS

21

J Gas 08 2008

3

3

3.3

INDICATOR LIGHTS

Indicator lights are fitted to the control panel as an additional aid to the operator. The meaning and operating sequence of these lights is as follows:

CAUTION

The control circuit live light is dirived from a single phase. It is possible that with the control phase

down or a defective bulb the other phases could be live. Always isolate the supply before investigating any fault.

Start/Low Water Reset. This switch is used to start the boiler and to reset the low water alarm. When the switch is pressed to initiate the start-up sequence, the low water alarm lamp also illuminates and the low water audible alarm sounds. Keeping the switch depressed for approximately 2 seconds

cancels the low water alarm and initiates the burner start sequence.

Illumination of this switch and sounding of the audible alarm at any other time other than at switch on indicates that the boiler has gone to a lock-out due to a low water condition. Once the water in the boiler has been restored to a safe operating level, pressing the switch will reset the controls.

Circuit On. (Circuit Energised 40J - 60J) Indicates that power is being supplied to the control panel box.

Low Water Alarm (1st. low water). This light will energise, when the boiler is switched on and the

water level is between 1st. low water and 2nd. low water. A light will illuminate and a pulsing alarm sound.

Low Water Reset (2nd low water). The 1st. low water light and alarm are replaced by the 2nd. low

water light and a continuous alarm, indicated by the low water reset switch. The second alarm must be reset, the first alarm will be automatically reset by the return to normal water level.

Ignition. Indicates that the ignition transformer has been energised. This light will only be illuminated for approximately 5 - 10 seconds during the ignition sequence.

Gas Pressure Alarm. This light will illuminate whenever the gas is off, or below minimum inlet

pressure required by the European Standard for gas burners EN676.

This switch is factory set and should not be adjusted after the boiler has been commissioned.

Start Gas. (40 - 60 models and Australian boilers)

This light indicates the gas valves in the pilot line are energised. Flame Failure / Reset. This switch will be illuminated when the burner has gone to a lock out

condition due to flame failure. The burner controller can be reset by pressing this switch.

Combustion Air. This light indicates that the burner motor contactor is energised.

Closed Position Indicator (C.P.I.). (Australian Boilers Only)

The lamp illuminates when the gas valve is in the closed (no gas) position.

ADDITIONAL INDICATOR LIGHTS ON MODELS 40J AND 60J

Low Flame.

This light indicates that the burner is operating in the low flame mode.

High Flame.

This light indicates that the burner is operating in the full firing mode.

Main Gas. This light illuminates when the Multibloc gas valve is energised.

J Gas 08 2008

22

3

3

3.4

FILLING the boiler - All Models

Carry out the following procedure on the initial start up of the boiler and on every subsequent occasion when restarting the boiler after a shut down:

(a)

Ensure the main steam stop valve is OPEN.

(b) Ensure the steam pressure gauge isolating valve is OPEN.

(c) Ensure all the valves in the main gas supply to the boiler are OPEN.

(d) Ensure all the valves in the water feed line are OPEN.

(e)

Ensure the main boiler blowdown valve is CLOSED.

(f) Ensure water level gauge isolating valve(s) is OPEN.

(g)

(h)

Ensure water level gauge blowdown valve(s) is CLOSED.

(i)

Ensure the Burner and Pump switch is in the OFF position.

(j)

Ensure all appropriate electrical isolators are switched ON.

(k)

Ensure the pump interrupt switch is switched OFF (Pump Run).

Ensure water column blowdown valve is CLOSED.

CAUTION

The feed pump seals are water cooled.

The pump must never be allowed to run whilst dry, irreparable damage may result.

Ensure the pump is fully primed before energising the motor.

(l)

Press the control switch to the PUMP ONLY position.

Note: If the boiler water level is below its correct level, the feed water pump will operate. When the water reaches the correct level (two thirds up the water level gauge sight glass), the pump will stop. If the water level is above the top of the water level gauge sight glass, drain off until the level is in the middle of the water level gauge sight glass.

23

J Gas 08 2008

3

3

3.5

STARTING THE BURNER

(a)

CLOSE the main steam stop valve.

(b)

Press the control switch to 'PUMP AND BOILER' position, the low water audible alarm will sound, the low water reset and low water alarm lights will illuminate.

(c)

Press the low water reset switch for two seconds maximum.

The alarms will stop, and the alarm lights extinguish.

The burner start sequence will commence.

After a maximum of one minute the burner should be firing, and the main gas light ON.

(d) (e)

When the boiler has achived the required (set) pressure, the main steam isolating valve

should be slowly opened allowing steam to enter the system distribution pipework.

WARNING

The system should be raised to temperature slowly to allow

for expansion and to avoid thermal shock and water hammer.

This can be achived by one of two methods.

1.

2.

Crack open the main steam valve and allow the system to heat up slowly, (minimum

15 minuets) before fully opening the main steam valve.

Open the main steam valve when starting the boiler, allowing the boiler and system to heat up together.

Note: This can lead to water logging of the steam lines until full pressure is achived.

Note: TDS Panel Mounted Controllers (BC3210 - BC3200) if fitted.

The controller must be reset after any break in electrical supply to the unit.

3.6

Daily OPERATING TESTS (3.6 - 3.7)

Visually inspect the steam and feed water pipework, valves and fittings for signs of leakage. If leaks are suspected shut the system down and evacuate the system to atmospheric pressure before

attempting to repair the leaks. The following procedure should be carried out by a competent person to ensure the correct functioning of the water level and low water safety controls. Where possible, the boiler should not be under steam pressure during these tests, (see 3.6.5.g.2.).

Note: Ensure that the water level is maintained during the pressure build up. If any part of the equipment is not operating correctly, the fault should be investigated before the boiler is used. Ensure that all blowdown pipework is safe and discharged to a blowdown receptacle.

3.6.1. Pump check

With the burner firing and the pump not running, lower the water level in the boiler by opening the main boiler blowdown valve.

As the water level falls, visible in the sight glass, and before the low water lock out position is reached the water pump should start to run. When this happens close the main boiler blowdown valve.

The water pump should continue to run and re-fill the boiler to the correct level and stop.

J Gas 08 2008

24

3

3

3.6.4 First Low Water Level

(a)

Ensure the following:

The burner is firing.

The water level is correct in the boiler.

The water pump is not running.

(b)

Switch the pump off (Pump Interrupt) at the pump interrupt/pump run switch.

(c)

OPEN the main blowdown valve.

(d)

When the water level nears the bottom of the water level gauge sight glass, the low water alarm should sound, the LOW WATER ALARM lamp should illuminate and the burner should stop

firing. When this happens, CLOSE the blowdown valve IMMEDIATELY.

(e)

Switch the pump to RUN at the main pump interrupt/pump run switch. The pump should run and refill the boiler. When the water level in the boiler rises above the first low water level, the LOW WATER LEVEL lamp should extinguish, the audible alarm should silence and the burner start sequence should commence automatically.

The pump should run until the boiler water level is correct and then stop.

3.6.5 Overriding (2nd) Low Water Check

(a)

Ensure the following:

The burner is firing.

The water level is correct in the boiler.

The water pump is not running.

(b)

Switch the pump off (Pump Interrupt) at the pump intrrupt / pump run switch.

(c)

OPEN the main blowdown valve.

(d)

When the water level nears the bottom of the water level gauge sight glass, the LOW WATER ALARM lamp should illuminate, the low water audible alarm should sound and the burner

should stop firing.

(e)

Continue to blow down the boiler. As the water level falls nearer the bottom of the water level gauge sight glass, the LOW WATER RESET switch should illuminate and the second audible low water alarm should sound.

(f)

CLOSE the main blowdown valve and switch the pump to RUN at the pump interrupt/pump run switch. The water pump should now start to run and refill the boiler. Once filled to the correct

level the pump should stop. The low water alarm should continue to sound, the LOW WATER RESET switch and LOW WATER ALARM lamp should remain illuminated and the burner should NOT start.

(g)

When the water level in the boiler is correct, the burner can be restarted by depressing the

LOW WATER RESET switch for a maximum of 2 seconds.

1.

The First and Overriding low water checks can be carried out in one operation to reduce the blowdown time and possible interruption to the steam supply.

2.

Where the water level tests are to be carried out at full pressure, evaporate the water down to 1st. low level as in 3.8, blowdown the boiler from 1st. to 2nd. low water.

The purpose of adopting this procedure is to prevent steam and water being expelled from the blowdown vessel vent because of prolonged blowdown.

25

J Gas 08 2008

3

3

3.7

BLOWDOWN PROCEDURES (DAILY TESTS)

Keep the boiler, water gauge, water column and interconnecting pipework free from sludge and scale buildup by blowing down in the following manner:

Note: Where a boiler is operating continuously at steam pressure, advice should be sort from Fulton

regarding the appropriate blowdown procedure.

(a) Start the boiler and generate not more

than 10psi of steam.

(b) Shut off both the burner and the pump.

Boiler Blowdown

(a) Fully OPEN the boiler main blowdown

valve for not more than 10 seconds.

Water Column

(b) CLOSE the valve.

Blowdown Valve

Note: Where high levels of suspended solids are produced,

longer and/or more frequent blowdown may be required.

Water Column Blowdown

Note: The water column contains the pump

on/off probe, which is not safety interlocked.

(a) OPEN the ball valve in the water column, close after 5 seconds.

Australian Boilers only

Water Column Blowdown

1. Place the sequence valve lever into the

blowdown column position A.

A

2. Open the Column blowdown valve B for

5 seconds then CLOSE.

3. Place the sequence valve lever into the

blowdown leg position C.

4. Open the Column blowdown valve B for

5 seconds then CLOSE.

5. Return the sequene lever to the working

D

C

B

A

B/DOWN COLUMN

Operating handle shown

in the closed position.

Fig. 17 BOILER BLOWDOWN VALVE

C

B/DOWN LEG

D

WORKING

POSITION

Fig. 18 SEQUENCING BLOWDOWN VALVE

J Gas 08 2008

26

3

3

Water Gauge Blowdown

(a) Blowdown the water gauge, set 1.

1. Open the gauge glass blowdown valve A

2. Close (for approx. 3 seconds) the top gauge valve B

3. Open valve B

4. Close (for approx. 3 seconds) the bottom gauge valve C

5. Open valve C

Water Level Gauge

6. Close valve A

Set 2

Repeat for gauge set 2

On completion of the blowdown procedure ensure

that all isolation valves are OPEN and all

blowdown valves CLOSED.

B

Note: Where a Boiler is operating continuously at steam

pressure, advice should be taken from a Fulton agent

as to the appropriate blowdown procedure.

WORKING

POSITION

STEAM

BLOWDOWN

WATER

BLOWDOWN

B

B

B

C

C

A

A

C

C

A

Water Level

Gauge

A

Set 1

Water Level Gauge Operating Positions

FIG. 19 WATER LEVEL GAUGES

3.8

EVAPORATION CHECKS

With the boiler running under normal load conditions, and the pump stopped having just completed a refill cycle:

(a)

Ensure that the boiler water level is correct.

(b)

Switch the pump off at the pump interrupt / pump run switch.

If it is required to check the second low water alarm, wait a further period for the LOW WATER RESET switch to illuminate.

When the check is complete, proceed as follows:

(a)

Switch the pump to RUN at the pump interruptpump run switch.

(b)

Press the LOW WATER RESET switch. The pump will start to refill the boiler.

If the pump starts to run at any time during the test then the test must be abandoned and re-started from the beginning.

27

The water level in the boiler will lower through natural evaporation. When the level nears the bottom of the water level gauge sight glass, the first low water alarm will sound, the LOW WATER ALARM lamp will illuminate and the burner will shut down.

J Gas 08 2008

3

3

3.9

TROUBLESHOOTING

Problem Cause

Ignition Failure 1. Power Supply

2. Ignition Electrodes

3. Transformer

4. Burner Control

5. Air Settings

6. Faulty Air Switch 7. Gas Valve

8. Gas supply 9. Loose wire connections

Remedy

Check fuse or Circuit breaker.

Reset or Replace as required.

Check for cracks in porcelain,if found replace the electrode. Check electrodes for carbon build-up.

Clean as required.Check settings, adjust if

required.

Check voltage between transformer leads at

terminal block to be sure transformer is live.

Check voltage between ignition terminal and

neutral, this check must be made before the

control locks out. If no power, replace the control.

Check main air adjustment and secondary air

adjustment.

Check for faulty air switch.

Check filters in the valve block. Clean as required.

Check for gas pressure and intermittent supply

problems.

Check connections to all components.

Flame Failure 1. Power Supply Check fuse or Circuit breaker.

During Start-up Reset or Replace as required.

2. Gas supply Check for gas pressure and intermittent supply

problems.

3. Air Settings Check main air adjustment and secondary air

adjustment.

4. Ignition Electrodes Check electrodes for carbon build-up.

Clean as required. Check for proper adjustment, readjust if necessary. Check for cracks in

porcelain, if found replace the electrode.

5. UV Detector

Check the detector is located correctly and clean.

6. Burner Control Check voltage between ignition terminal and

neutral, this check must be made before the

control locks out.

If no power, replace the control.

7. Loose wire at fuel valve circuit. Tighten wiring connections.

8. Contact open on

Air Switch Adjust to the correct setting.

9. UV Detector wiring

reversed at control box. Change to the correct terminals.

Flame Failure 1. Power Supply

During Normal Run 2. Gas Supply

3. UV Detector

4. Faulty Air Switch 5. Bad Combustion Check fuse or circuit, reset or replace as

necesssary.

Check gas pressure coming into the gas train,

if low contact the gas supplier.

Check the setting on the gas valve regulator,

adjust as required.

Check the detector is located correctly and clean.

Check for faulty air switch.

Check combustion readings.

J Gas 08 2008

28

3

3

3.9

TROUBLESHOOTING, continued.

Problem Cause

Burner Cut-off 6. Gas Valve

7. Weak Amplifier

(Honeywell Control Box Only)

8. Weak Pilot

9. Faulty Level Control

10.Dirty or defective

UV detector

Remedy

Check filters in the valve block. Clean as required.

Replace the amplifier.

Adjust to larger pilot by adjusting pilot gas

pressure regulator.

Test level controls, adjust or replace as required.

Clean or replace.

Poor Combustion1.Refractory Bricks Check refractories to see if they are plugged with soot or broken in pieces. Clean or replace as

necessary.

2. Stainless Steel Ring Check the ring is present (40 - 60 models) and fits tightly against the furnace wall.

3. Main Air Adjustment Check air adjustment. Air/fuel mixture may be off. Open main air gate until the flame brushes the

furnace wall.

4. Secondary Air

Adjustment Check main air adjustment, reset as required and secure in place. Check CO2 and O2 levels.

5. Draft

Check draft with a gauge. Readings will vary

between installations, if in doubt consult Fulton

for a draft value for your system.

6. Dirty Flue Check flue for carbon build-up or blockage.

Clean the flue.

7. Negative Room Pressure Ensure there are no exhaust fans running in the

boiler room.

8. Dirty Fan Check fan for obstructions, clean as required.

Burner Back Fires 1. Refractory Bricks Check refractories to see if they are plugged with soot (Delayed Ignition) or broken in pieces.

Clean or replace as necessary.

2. Ignition Electrodes Check electrodes for carbon build-up.

Clean as required. Check for proper adjustment, readjust if necessary. Check for cracks in

porcelain, if found replace the electrode.

3. UV Detector Check the detector is located correctly and clean.

4. Draft Check draft with a gauge.

Draft should be -.05 to -.10mbar with the

burner off,

or -.10 to -.15mbar when operating.

A barometric damper may need to be installed.

5. Negative Room Pressure Ensure there are no exhaust fans running in the

boiler room.

6. Air Adjustment Check Air Adjustment settings.

7. Gas Supply Check gas pressure coming into the gas train,

if low contact the gas supplier.

Check the setting on the gas valve regulator,

adjust as required.

29

J Gas 08 2008

3

3

3.9

TROUBLESHOOTING, continued.

Problem Cause

Boiler will not

maintain pressure 1. Gas Supply

2. Dirty Flue 3. Pressure Control

4. Scale build-up in boiler

5. Refractory Bricks. 6. Steam traps

blowing through.

7. Boiler size.

8. Faulty Gas Valve. Boiler is Surging 1. Steam traps

(Widely fluctuating blowing through.

water level in 2. Contamination

sight glass) in boiler. 3. Scale buildup or

lime deposits.

4. Too much compound

(water treatment

over dose). in the system.

5. High Alkalinity (high ph).

6. Load exceeds

boiler capacity.

Remedy

Check gas pressure coming into the gas train,

if low contact the gas supplier.

Check the setting on the gas valve regulator,

adjust as required. If possible meter the flow rate.

Check flue for carbon build-up or blockage.

Clean the flue.

Disconnect all power to the controller.

Disconnect the wires from the controller.

Place an OHM meter between the switch

terminals. Lower the set point of the controller,

the switch should make. Raise the set point and recheck, the switch

should break. If the controller operates improperly, replace it. Clean the pressure vessel.

Check refractories to see if they are blocked

with soot or broken in pieces. Clean or replace as necessary.

Check steam traps, clean or replace as required.

Boiler may be undersized.

Check gas flow rate.

Check steam traps, clean or replace as required.

Empty boiler and feed tank.

Flush out and refill, if system operates but progressively

deteriorates, there is probably a leak somewhere in the system.

Consult Fulton or call a water treatment specialist.

Dump contents of the return tank and flush the

system. Test the water.

Have a water treatment specialist test the water.

Check total system load against the output of the boiler. Decrease the load required at any one time.

Boiler rumbles 1. Poor Combustion

Check combustion readings.

and pulsates

2. Draft.

Check draft with a gauge.

Draft should be -.05 to -.1mbar with the burner off.

A barometric damper may need to be installed.

3. Too much main air.

Adjust main air gate.

Boiler carrying over

water with 1. Steam Traps.

Check steam traps, clean or replace as required.

the steam

2. Too much compound

(water treatment Dump contents of the return tank and flush the

over dose) in the system. system. Test the water.

3. Contamination in boiler. Empty boiler and feed tank. Flush out and refill, if

system operates but progressively deteriorates,

there is probably a leak somewhere in the system.

J Gas 08 2008

30

3

3

3.9

TROUBLESHOOTING, continued.

Problem

Cause

FEED WATER PUMP

Pump will not run

1.

2.

3.

4.

5.

6.

Motor starter

overload, trips out

1.

immediately when supply is 2.

switched on.

3.

4.

5.

6.

Motor contactor overload

trips out occasionally.

1.

2.

Supply failure.

Fuses are blown.

Motor contactor overload

has tripped out.

Contactors

not making Control circuit is defective.

Motor is defective.

One fuse/automatic circuit

breaker is blown. Contacts in motor contactor

overload are faulty.

Cable connection is

loose or faulty.

Motor winding is defective.

Pump blocked.

Overload setting too low.

Overload setting is too low.

Low voltage at peak times.

Motor contactor has not

tripped out but the pump does not run. Remedy

Connect the electricity supply.

Replace fuses.

Reactivate the motor protection.

Check, the coil is faulty or wiring loose.

Repair the control circuit.

Replace the motor.

Replace the fuse.

Replace motor starter contacts.

Tighten or replace the cable connection.

Replace the motor.

Remove the blockage.

Set the motor starter correctly.

Set the overload correctly.

Check the electricity supply.

Check :

Motor does not run when started:

items: 1, 2, 4, 5, 6,

Pump capacity

not constant. 1. Pump inlet pressure is too

low (cavitation).

Check the suction conditions.

2. Suction pipe/pump partly

blocked. Clean the pump or suction pipe.

3. Pump draws in air.

Check the suction conditions.

Pump runs but

gives no water.

1. Suction pipe/pump blocked.

Clean the pump or suction pipe.

2. Foot or non-return valve

blocked in closed position.

Repair the foot or non-return valve.

3. Leakage in suction pipe. Repair the suction pipe.

4. Air in suction pipe or pump.

Check the suction conditions.

5. Pump rotates in the

wrong direction.

Change the direction of rotation of

the motor.

6. Boiler feed water non-return

Check and clean boiler feed water

valve letting water passed non-return valve, ensure it is seating

the valve seat, (normally and not allowing water passed.

accompanied by banging in

the feed water tank).

31

J Gas 08 2008

3

3

3.9

TROUBLESHOOTING, continued.

Feed Water Pump

Problem

Cause

Pump runs backwards

when switched off. 1. Leakage in suction pipe.

2. Foot or non-return valve is

defective.

Leakage in shaft seal. 1. Shaft seal is defective.

Remedy

Repair the suction pipe.

Repair the foot or non-return valve.

Replace the shaft seal.

Noise. 1. Cavitation occurs in the pump.Check the suction conditions.

2. Pump does not rotate freely

(frictional resistance)

because of incorrect

pump shaft position. Adjust the pump shaft.

3. Frequency converter

operation.

See Grundfoss manual.

4. Boiler feed water non-return Check and clean boiler feed water

valve letting water passed non-return valve, ensure it is seating

the valve seat, (normally and not allowing water passed.

accompanied by banging in

the feed water tank).

Water pump will not 1. Scale on probes.

Check and clean probes, replace as

come on at times.

necessary.

2. Faulty pump contactor

Check the contactor has power.

Check the contactor is pulling in.

Replace if necessary.

3. Faulty pump motor.

Check the pump has power.

If the pump has power but is not running, replace it.

4. Faulty Level Control Relay

Check the relay has power and is

secure on it's base. Replace if faulty.

Low fuel pressure.

1. Gas pressure regulator

Check and replace.

Boiler flooding 1. Pump does not shut off.

2. Relay failed.

3. Earth connection.

4. Vacuum created

with boiler off.

Dirty probes. Clean or replace as necessary.

Ensure the relay is secure on its base.

If so replace the water level relay.

Clean and tighten as required.

As the boiler cools, it pulls water from the

system piping. To prevent this, add a

check valve on the steam gauge

assembly piping, which closes under

pressure and opens under vacuum.

J Gas 08 2008

32

3

3

3.10

TROUBLESHOOTING, Burner Control Unit - LFL 1 (Landis and Staefa)

Symptom and

Identification Symbol

Cause

No Start 1. No Power

2. External Interlocks

3. Air Pressure Switch

4. CPI switch 5. Air Damper 6. Burner Moter fault

Lockout 1. False flame detected

Remedy

Check all fuses.

Check for correct wiring.

Check all external interlocks are made.

Check that the switch is in 'No Air' position.

If fitted, must be made.

If fully closing damper fitted, check

relevant micro switch on damper.

Check overload.

Check for stray light (cell only).

Faulty cell or damaged flame probe.

Interruption of

start-up sequence

1. Air Damper

Check fully open microswitch is made.

Lockout

1. Air Pressure Switch

Check that switch is made.

P

2.

Lockout 3.

Note: Any air pressure

failure after this time

will cause a lockout

condition.

Flame supervision

Interruption of

start-up sequence

1. Air Damper

Lockout

1. No ignition spark

Check for stray light (cell only).

Faulty cell or damaged flame probe.

Check low fire microswitch is made.

Check supply ignitor.

1

Check electrode and HT leads

for damage.

2. No pilot flame Check gas supply.

Check electrode setting.

Check functionality of pilot gas valve(s).

Check pressure gas downstream of

pilot valve(s).

3. Pilot lights then

extinguishes Check flame stability with ignition off.

Note: Any flame signal Check air pressure at burner.

failure after this stage Check gas pressure is steady.

will cause a lockout Check the flame is being sensed, i.e.

condition

(i) Check sensor for damage.

(ii) Check sensor can view flame.

(iii) Check flame signal,

see data sht. LFL1 - 7451

33

J Gas 08 2008

3

3

3.10 TROUBLESHOOTING, Burner Control Unit - LFL 1 (Landis and Staefa)

Symptom and

Identification Symbol

Lockout

Cause

1. No main flame 2

Lockout

1. Flame failure l

Lockout on completion

of control programme 1. Extraneous light sequence

2. Faulty flame signal

2. Air pressure failure

Remedy

Check supply to main valve(s).

Check functionality of main valve(s).

Check gas pressure at burner.

Check air pressure at burner.

Check flame signal strength,

refer to LFL1 data sht. 7451

Check flame signal.

Check switch operation.

Check flame extinguished.

Check gas valves for leaks.

Check for aged/faulty UV cell.

Check flame supervision circuit.

3.11 TROUBLESHOOTING - Gas, Burner Control Unit - TMG 740-3 (Satronic)

Routine Checks.

Test the safety of the flame detection system during

commissioning and after servicing, or if the system

has not been in operation for a long period.

Test 1

1.

Bridge the gas proving switch.

2.

Close the gas isolation valve.

3.

After the first safety interval has elapsed,

the boiler should lockout.

Test 2

1. During normal boiler operation, remove the flame detector and block light from the

sensor. Lockout should occur within one second.

Fault Finding

Fault finding is considerably simplified by making use of the coloured programme indicator. Irregularities

during commissioning, normal operation or a normal shutdown pause can be localised via the programme

indicator disc. If malfunction occurs, it is useful to note the exact position of the indicator before operating

the control switch or reset button. The following list is designed to assist with fault finding.

COLOUR WHERE WHAT

Blue beginning does not start

continuous ventilation

line lockout

end continuous ventilation

anywhere lockout

Yellow end lockout

Red end lockout Green end lockout Black end lockout REASON

No power, break in control circuit, air proving switch not in resting position.

End switch 'MAX' air damper does not operate.

Air proving switch does not switch over or is too late.

End switch 'ignition position' , air damper does not operate.

Stray light

No ignition, no spark, no gas or too little gas

too much or too little air.

Flame detector selector switch set incorrectly.

No flame signal current or too weak after end of

second safety interval (double fuel feed burner).

Loss of flame during operation, air pressure too low.

Stray light due to burning on, flame detector tube reached end of life and activates shutoff, defect in flame

detector circuit.

J Gas 08 2008

34

3

3

3.12 DRAINING THE BOILER,

Boilers with manual blowdown valves

CAUTION

Your local regulations could state boiler water above 43OC must not be discharged into the drain.

ALWAYS check your local regulations.

1.

Ensure the boiler is cold.

2.

Isolate the boiler electrics at the isolator on the control box door.

3.

Isolate the feed water tank and the feed water pump.

4.

Open the main steam valve and the boiler drain valve.

5.

Open the drain valve on the blowdown vessel.

6.

Open all valves in the drain lines.

Boilers with automatic blowdown systems

1.

2.

3.

The boiler should not be under pressure.

The boiler should be cold.

Close the blowdown isolation valve.

Using a screwdriver located as shown ‘A’, push up and make a quarter turn,

this will lock the button in position and open the blowdown valve.

4.

Using the blowdown isolation valve to throttle the flow, drain the boiler.

Note: Skid units and plant rooms have internal drainage systems which require the same procedures.

A

3.13 LONG TERM SHUT DOWN

To store the boiler in a corrosion-free situation there are three practical solutions:

1.

Fully flood the boiler to exclude as much air as possible.

2.

Drain the boiler completely.

Remove all hand hole and manhole doors.

Open all gas/oil side access doors.

3.

As (2) but also introduce a form of convection heating to the gas/oil and water side.

A very effective solution is to install a string of outdoor type waterproof light bulbs distributed throughout the boiler.

35

J Gas 08 2008

3

3

This log should be completed regularly as a record of boiler maintenance.

MAINTENANCE LOG

Date

Action

J Gas 08 2008

Remarks

Sig.

36

4

4

Feed Water

Dip Pipe

Removing/replacing Water Level Probe

Safety Valve

Outlet

Water Level

Gauge Blowdown

Water Column

Blowdown

Boiler Blowdown

Handhole

FIG. 20 BOILER MAINTENANCE

37

J Gas 08 2008

Feed Water Pump

Interrupt Switch

4

4

MAINTENANCE

SECTION 4

4.1

General

Maintenance on Gas appliances should only be carried out by competent, trained personnel who are CORGI/ACS registered, and who have the necessary equipment to check combustion.

If any fault is found during these operations contact your Fulton representative.

CAUTION

It is essential that regular checks are made to ensure that scale buildup is not