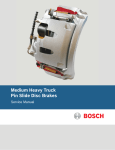

Download 2006 Section 5 - Brakes.indd - Oemys

Transcript