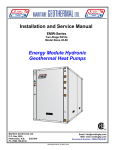

Download TF-Series - Nordic Geothermal Heat Pump

Transcript