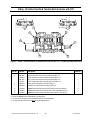

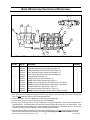

Download Model V20

Transcript