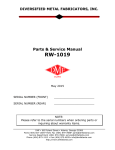

Download Installation and Parts & Service Manual ROTO 180

Transcript