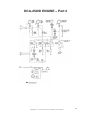

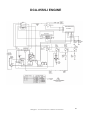

Download DCA25-150 Service Manual - Multiquip Service & Support Center

Transcript