Download the ultimate jem low lying fog/smoke machine service manual

Transcript

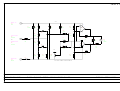

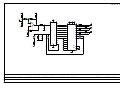

THE ULTIMATE JEM LOW LYING FOG/SMOKE MACHINE SERVICE MANUAL PLEASE READ THESE INSTRUCTION CAREFULLY JEM SMOKE PLC Version 1.0 990127 0 HEAVY FOG 6500 SERVICE MANUAL CONTENTS: Index… … … … … … … … … … … … … … … … … … … … … … … … … … … … .Page 1 Features and Specifications… … … … … … … … … … … … … … … … … … … … … ...2 Safety… … … … … … … … … … … … … … … … … … … … … … … … … … … … … ... ..3 Safety and wiring off machine… … … … … … … … … .… … … … … … … … … … … ..4 Safety and wiring off machine… … … … … … … … … .… … … … … … … … … … … ..5 Fault Finding Guide… … … … … … … … … … … … … … … … … … … … … … … … … 6 7 8 9 Fault finding guide & 22 pin socapex guide … … … … ...… … … … ..… … … … … … 10 Service and maintenance. … … … … … … … … … … … … … … … … … … … … … … ..11 12 13 14 15 16 DMX 512 Option… … … … … … … … … … … … … … … … … … … … … … … … … … 17 Part number guide… … … … … … … … … … … … … … … … … … … … .… … … … … ..18 Heavy Fog 6500 mother wiring diagram… … … … … … … … … … … … … … … … ...19 Heavy Fog 6500 trigger wiring diagram… … … … … … … … … … … … … … … … … .20 Schematics… … … … … … … … … … … … … … … … … … … … … … … … … … … … ..21 1 Heavy Fog 6500 Features and Specifications: The Heavy Fog 6500 is a dual purpose machine it can deliver Smoke or Low lying fog at continuous output 24 hours a day 7 days a week 365 days of the year. A series of vertical and horizontal louvers at the front of the machine controlled by a jot-stick mounted on the controller will direct the low lying fog wherever it is required, further more the controller has a pre-programmed louver movement to reproduce scenic effects such as Sea, Wave, Cloud, Waterfall, Curtain and volcano. The on-board 19" rack mounted controller can be removed and mounted remotely or if preferred the machine can be controlled via a lighting desk using either the 0-10v input connection through a Mono Jack plug, and the 512 DMX card Via a 5 pin XLR plus a slave socket to link the machines together. Specifications: Power requirements: 220v-240v 50hz 3 phase 20 amps per phase 208v 60hz 60 amp Single phase. Heaters: 10kw Fan speed: 0-3000rpm (1.2 amps) Smoke output: 1250mc per minute H.F output 500 square maters per minute Pumps: 2 x Piston pumps (0.7amps each) Fluid capacity: 2 x 5ltr integral tanks Fluid types: A1, B2,C3 and C4 Dimensions: 1170 x 760 x 715mm Weight: 210kg 2 Safety ? ? Always connect to the correct mains power supply. ? ? Always use genuine JEM fog fluid. ? ? Always disconnect from the mains before attempting to start work on the JEM H.F 6500. ? ? Do not suspend the machine above peoples heads. ? ? Do not stand directly at the front of the machine when firing. ? ? Do not block the airflow vent at the back of the machine. ? ? Clean the machines filters out once a month. ? ? Always install in a well-ventilated area. ? ? Ensure correct fluid is placed into specific smoke or heavy fog tanks. ? ? Never attempt to do any work on the machine if it isn't described in the manual. ? ? Consult your supplier for advice on the JEM Heavy fog 6500. 3 Safety Wiring of the machine _ Because the machine, in most cases, will be wired to a 3 phase supply, a voltage of 415volts A.C will exist across each set of phases, therefore great care must be taken when working on live apparatus. ELECTRICITY KILLS. Under no circumstances should anyone without sound electrical knowledge be permitted to work on this machine while connected to a live electrical feed. U.K AND EUROPEAN WIRING IF THE MACHINE The U.K /European model operates on 220/240 volts and may be operated on a single 220/240 volt phase, however, this causes a substantial current draw, so it is much more desirable to use three separate phases to provide better load distribution. The machine will benefit and run much more smoothly. U.S.A WIRING IF THE MACHINE The wiring connection is different in the U.S. In the U.S. 2 x 110volt phases (legs) are used to obtain 208 volts, however the same cautions apply. To obtain a voltage of 208 volts from two 110 volt legs, connect all live feeds (Hots) together on one leg, and the neutral Blue wire on the other leg. This will give you 208 volts. Note in this situation the supply neutral is not used. To those unfamiliar with use if multiple electrical phases, known as "Legs" in the USA this action may seem strange but is common in the commercial field and normal practice. As always make sure that the earth (ground wire in the USA) is properly connected. NEVER operate this machine without the earth/ground wire connected. 4 Safety Wiring of the machine _ N.B. THIS APPLIANCE MUST BE EARTHED! Wiring of Plug 240V 3 PHASE BROWN BLACK PHASE 1 PHASE 2 BLACK PHASE 3 BLUE NEUTRAL GREEN/YELLOW EARTH 208V SINGLE PHASE 5 BLACK PHASE 1 BLUE PHASE 2 GREEN/YELLOW EARTH Fault finding guide Problem Probable Cause Cure Heater, Fan and compressor fail LED's on. Condenser fan fuse blown. Condenser fan motor faulty. Fan blade jammed. Insufficient air flow to the machine. Low gas charge. Condenser coil air outlet blocked or restricted at rear of machine. Replace Fuse No7. Replace. Re-align. Clear restriction. Re-site machine. Check for leaks, purge and re-charge. Clear restriction and or re-site machine. Red LED on motherboard flashing. Overheat sensor circuit activated faulty sensor on block. O/S Triac or Opto on Trigger board. Replace sensor or sensors. Phase down. Contactor 1 faulty. Faulty capacitor. Pressure switch tripped. Compressor internal thermal overload trip activated. Check mains supply voltage. Repair or replace Contactor 1. Replace compressor capacitor. Reset and try again, if trip re-activates, check filters are clean and machine isn't in an enclosed space, reset and run again, if trips again reset and check machine for gas, when running high pressure side 200psi low pressure side 30 psi (5lb of R22 in machine) If less check for leaks. If O.K check compressor for faults. Replace. Freeze fan and solenoid switch fail lights on. Evaporator fan motor failure. Jammed fan wheel. Evaporator fan fuse blown. Solenoid failure. Evaporator coil sensor faulty. Mag valve sensor faulty. Replace motor. Rectify. Replace fuse No 8 on trigger PCB. Replace coil. Replace sensor. Replace sensor. Heavy fog smoke rising. Evaporator fan speed to high. Fan voltage on low speed should be 75 - 85 volts, check this on mother PCB. Replace, then purge and recharge. Heavy fog button pressed but does not activate after normal delay period. Faulty thermostatic expansion valve. Restriction in refrigeration circuit. Solenoid valve jammed open. Drier blocked. Lack of refrigerant. 6 Replace Triacs or Opto's No's 1,2 6 and 7 Check pipe work for ice build up at any one point and clear by applying heat. Clear or replace. Replace. Check for leaks, seal vacuum purge and recharge. Fault finding guide Timer malfunction. Damp or faulty switch. Erratic special effects. Excess voltage drop in control Try different controller or use shorter cable. control cable. Damp controller. Faulty power supply. Condenser fan runs at full speed on switch-on. Broken sensor. Wire broken or disconnected on mother PCB. Replace red sensor on condenser coil Repair or re-connect wire. No heavy fog output/ or no smoke output Tank empty. Air leak in pump or fluid line. Faulty pump. Pump fuse blown. Refill. Locate and reseal. Replace. Replace fuse No's 5 and 6. *Earlier models only* Blocked change over valve. Change over fuse blown. Change over valve faulty. Clean and test. Replace fuse No 5. Replace or modify to current spec, using two separate pumps. Repair or replace Faulty switch or broken LED. High current draw. Repair or replace. Refrigerant overcharge. Tight compressor. Compressor electrical problem. Discharge valve leak. Internal compressor leak. Purge and recharge. Run in for a few hours. Wiring problem, Check and correct. Low current draw. Low refrigerant charge. Water in system. Check for leaks and re-seal. Purge, evacuate and re-gas. Servo faulty, no servo action at all. Faulty servomotor or wiring. Repair or replace. Block heats up O.K but no heating LED on controller. Socapex line 22 (Red) broken. Repair. 7 Re-seal. Replace compressor. Fault finding guide Problem Probable cause Cure Heat fan LED & Compressor fan fail LED lights on. Socapex line21 (White) Broken. Repair. Servo appears faulty. Smoke blows low on floor or to one side. Socapex line 3 (Yellow/Blue)or 4 (Yellow/Red) broken. Repair. No variable smoke output at all. Worn or damaged slider control. Replace. Smoke output stuck on minimum. Broken + volts supply to slider. Reconnect wires on slider ensuring secure. Machine cannot be turned on or off using "Standby" or "on " buttons. Mains LED is dim. Machine works by pressing the heavy fog button only to start. Socapex line 5 (Green/Brown) Repair. broken. Machine stays in standby mode. Socapex line 7 (White/Red) broken. Repair. Smoke LED will not light and difficulty selecting heavy fog function. Socapex line 8 (Red/Brown) broken. Repair. Heavy fog LED will not light . Socapex line 9 (Red/Black) broken. Repair. Machine will not switch from Heavy fog to smoke or vice versa, machine is stuck in smoke mode. Socapex line 10 (Red/Blue) broken. Repair. 8 Fault finding guide Problem Probable cause Cure Front evaporator fan will Socapex line 11(Pink) broken or not respond to demand 4066 chip next to pink wire for smoke or heavy fog. blown. Repair connection or replace chip. No smoke or heavy fog but front fan still controllable with slider when smoke or heavy fog is in demand. Socapex line 12 (Orange) broken Repair connection or replace chip. or 4066 chip next to pink wire blown. NOTE:- 4066 chip can be damaged by plugging in the controller with the power already switched on. Standby, mains on, Smoke only works. No heavy fog. Stuck in standby from switch on. Socapex line 13 (Purple) broken. Repair. Machine will not go into Socapex line 15(Brown) broken. ready mode although heating LED goes of and front nozzle is hot. Repair. No operation of solenoid Socapex line 16 (Black) broken. switch fail Led or compressor fail LED. Repair. No operation of freeze fan fail and compressor fail LED's. Socapex line 17 (Yellow) broken. Repair. Smoke delivered when heavy fog is required, heavy fog LED is light. Socapex line 18 (Green) broken. Repair. Heavy fog LED only lights up on controller, total failure of all controls, but compressor starts up. Socapex line 19 (Light Blue) broken. Repair. 9 Fault finding guide Problem Probable cause Cure Mains on LED only lights up on controller. Total failure of all controls but pumps run. Socapex line 20 (Dark Blue) broken. Repair. Machine has failed but Socapex line 6 (White/Blue) there are no file lights on broken controller. Repair. 22 pin Socapex wiring table Pin 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 Colour ORANGE/BLUE ORANGE/GREEN YELLOW/BLUE YELLOW/RED GREEN /GROWN WHITE/BLUE WHITE/RED RED/BROWN RED/BLACK RED/BLUE PINK ORANGE PURPLE GREY BROWN BLACK YELLOW GREEN LT BLUE BLUE WHITE RED Function DMX -VOLTS DMX +VOLTS VERTICAL LOUVER HORIZONTAL LOUVER CONTROLLER LED + VE COMPRESSOR FAIL CONTROLLER ON LED -VE REFRIGERATION OFF LED REFRIGERATION ON LED SMOKE H/F SIGNAL FREEZE FAN FAIL PUMP SIGNAL STANDBY/ON DMX GROUND READY SIGNAL DEFROST VALVE SIGNAL FREEZE FAN FAIL PUMP CHANGEOVER GROUND (GND) +12VOLTS HEAT FAN FAIL HEATING SIGNAL 10 SERVICE AND MAINTENANCE Internal view of the machine Section 1 Internal view of machine For an internal view of the machine you must: 1. Unscrew all 28 screws on the outside of the machine. This includes the side panels. 2. Remove the two nylon caps and nuts on the front cover and push the fluid tanks down into the machine. 3. Line up the 2 ducting clips on the front cover so they are flat and pull the lid forward. The rear lid will slide off backwards. Ensure the controller has had its joystick removed before this is done. Section 2 view off Electronics door 1. Looking towards the front from the rear of the machine, on your left-hand side of the machine you will see a filtered side panel. 2. Unscrew all 6 (six) screws from around the edges and remove the panel. 3. There you will see a slide out electronics door, pull towards you for a view of the electronics. 4. On the electronics door you will see a Mother PCB a Trigger PCB and 2 Contactor. Section 3 Replacing the Trigger PCB After following section 2. 1. Remove all crimps on the board. 2. Unscrew the second Triac in from the left of the board. 3. Unscrew all four (4) nylocs in the corners of the board. 4. Pull out the molex connector. 5. Remove the board. 6. Reverse the procedure to replace the board. N.B. Trigger board connections are as follows, PRE MAY 1997 (JEM HEAVY FOG V1.0) N, 15,1,2,3,4,5,6,7,8,9,0,11,12,13,14. POST MAY 1997 (LVD_TRIG.PCB) N, 15,1,2,3,4,5,7,6,8,9,10,11,12,13,14. The above connections are from right to left. 11 SERVICE AND MAINTENANCE Section 4 Replacing the Mother PCB After following section 2. 7. Remove all wires on the board. Making note of the connections. 8. Remove all four-(4) nyloc in the corners of the board. 9. Pull the board forwards to reveal the back of the board. 10. Remove all soldered wire connections on the back of the motherboard by de-soldering them, making a note of the connections. 11. Remove the board. 12. Replace with new board. 13. Reverse procedure to replace the board. Section 5 Replacing a Contactor After following section 2. 1. Remove all wires on the contactor you are replacing, making note were they were removed from. 2. Remove the two- (2) nuts and bolts holding the contactor in place. 3. Remove the contactor. 4. Replace contactor and Reverse procedure. Section 6 Replacing a condenser sensor After following section 1 and removing only the back panel. 1. Cut wires as close to the red condenser sensor as possible. 2. Remove all silicone from around the old sensor, and remove sensor. 3. Strip the existing Red wires back about 3mm, ensuring the joints are staggered. 4. Place heat-shrink over the red wire connections. 5. Solder new sensor to the existing red wires. 6. Pull heat-shrink over the connections and Heatshrink. 7. Place some Heat sink past on the copper outlet pipe from the coil. 8. Place the new sensor on top of it and tiewrapp, 12 Ensuring you do not break the sensor SERVICE AND MAINTENANCE Section 7 Replacing a servo board After following section 1 and only removing the front cover. 1. The servo boxes are on either side of the machine at the front. 2. Remove the four- (4) screws holding the servo box in-place. 3. Disconnect the louver arm connector. 4. Pull the box towards you. This will give you a view of the servo PCB inside the box. 5. Disconnect the wires. 6. Unscrew the four- (4) screws on the bottom of the box that hold the servo PCB in-place. 7. Remove the PCB. 8. Replace with new PCB. 9. If the metal arm connections on the bottom of the PCB are not attached to the new PCB then disconnect the metal connections from the old PCB and fix to the new PCB. 10. When connecting, line the pot up on the bottom of the board so that it is at half way through a turn. This will give a central point on the louver when in fire mode. 11. Reverse procedure from No 7. Section 8 Replacing the vapour fan After following section 1 and removing the front cover only. 1. Remove earth from the fan. 2. Cut up the heat-shrink until you can see were the wires join; cut the wires at this point. 3. Remove all the heat-shrink from of the cable. 4. Remove all the silicone from around the vapor fan. 5. Remove the two- (2) bolts holding the vapor fan in-place. 6. Remove the vapor fan. 7. Replace with new vapor fan. 8. To the existing wires sleeve with new heatshrink. 9. Around the edge of the new vapor fan once inplace, seal with silicone sealant. 10. Join the wires together by soldering ensuring there is heat-shrink over the brown and blue 13 wire joints 11. Heat-shrink the connections and replace the SERVICE AND MAINTENANCE Section 9 Replacing the block After following section 1, taking off only the front cover make sure the machine is turned off. If you have the old style block the heating elements will only be coming out of the block 1" in length and there will be heat resistant wire attached to them. The new blocks have 7" of elements coming out of the block and are attached to the wires with crimps. 1. Remove the fluid tanks on both sides of the machine. 2. Remove the two screws that hold the sensor access plate in-place, and remove plate. 3. Remove the four- (4) screws that hold the sensor retaining plate in-place. 4. Remove the sensors, (do not cut the wires, these sensors are fragile) 5. Drill out the six (6) 1/16" rivets that hold the vapor fan plate in place, (above the block) and place plate on-top of machine, (do not cut the wires to the fan). 6. Remove the bracket that holds the block in-place, this will have an earth connection on it. 7. At the back of the block there is an 8-way dispersal cone try to pull this off, if no luck cut it off. 8. Depending on type of block, cut through or pull off the wires connected to the block elements. 9. Undo all the 4mm nuts that connect the fluid inlet pipes to the block. 10. Now you can remove the block by pulling the block in it's casing up towards you. 11. Replace with new block, ensuring that it has all the correct fittings on it and the fluid inlet pipes are bent in the right direction, the 8way dispersal cone cannot be fitted until the block is in place, You may have to cut the block shroud as shown in diagram 1 for the new block to fit. 12. Once in-place bend all 8 elements down 90 degrees. 13. Place heat-shrink over all 8 elements (3" of 12.6mm heat-shrink). 14. Cut 2"0f 6.8mm heatshrink and place it over the wires that will connect to the block elements, (pushing it to the top of the wires). 15. Cut 8 x 9" of glass fibre insulation and push it over all 8 of the wires that will connect to the elements. 16. If not already connected fit all the wires with 2.5 crimps (blue). 17. Push the crimps one at a time onto the elements. Ensure that the Brown wires are at the bottom and the blue wires are on the top. 18. Once crimps are connected, pull down over the crimp connection the heat-shrink and shrink on with a heat gun. Pull up over the whole element the Glass fibre insulation, now pull over the glass fibre insulation the last piece of heat-shrink at the bottom (so that 12 is on the heat-shrink and 1" is over the wire) now shrink on using the heat gun. 19. Spiral-wrap the wires. 20. Connect all the fluid pipe inlets back to the block. 21. Replace the vapor fan by riveting it back into place. 22. Reconnect the bracket the holds the block in-place along with the earth tag. 23. Refit the 8-way dispersal cone. 24. Refit the sensors reversing procedures 4,3 and 2. 25. Refit the tanks. 26. Test to ensure all is working, refit the cover. 14 Heavy fog 6500 controller White to Slider Green Blue Orange Yellow / Blue Yellow / Red Pink Blue to slider Red to Slider Link Red White 0 - 10v Jack Socket Blue Purple Red / Blue Red / Brown White / Red Green / Brown Red Link to pump switch Red / Black Light Blue Brown White Yellow Black White / Blue JEM LTD. +12V SERVO +VE J1c RED 5 C1 4700uF R2 820R R6 1M C2 0.1uF R3 220R OR HORIZ LOUVRE J1b ORANGE R1 22K 2 3 U1 6 R10 390K D2 VERT LOUVRE J1b ORANGE R11 4K7 R8 220R C3 0.1uF C5 1nF 7 R4 220R C6 0.1uF M 1 M1 12V 60RPM U1 D3 8 R13 47R 4W 4 R12 390K +12V c R5 680R R7 1M VR1 22K R9 4K7 C4 1nF D1 SERVO GND J1a WHITE D R A W N B Y :C P W POT SHAFT LINKED TO MOTOR SHAFT DATE: 7,3,1997 TITLE: H F 6 5 0 0 S E R V O B O A R D DWG No. CPW060 REV. JEM LTD. DEFROST VALVE J13 PIN8 +12V C40 0.1uF C37 V3 100uF R82 R88 +12V 1M +12V Q9 2M2 D10 R93 9 0.1uF 10K GND J11 R86 JMP 10K C35 14 7 1 U2 R89 10K U1 8 R87 10K D7 D8 R92 47K R94 6 D9 150K 1% V3 C38 VOUT 10uF +12V GND +12V R97 680R R77 1K R84 D11 4K7 R79 +12V +12V 12K R83 c R85 1K 220K GND V4 R90 1K VR7 200K C8 C9 0.1uF 0.1uF R80 R78 1K 33R V1 11 13 DEFROST VALVE FAIL U2 10 J6 SOLENOID J14 PIN8 SENSOR BLACK C34 R81 R95 C36 0.1uF 2K2 2K2 0.1uF GND DRAWN BY:CPW V2 C39 10uF 6VREF 5 2 U1 4 V3 R91 1K C10 0.1uF GND DATE: 10,12,1996 TITLE: HF6500/HF2500 MOTHERBOARD - PART3 DWG No. CPW049 REV. 1 HEATING SIGNAL PAD 11 RED +12V C45 10uF R41 1K HEATERS 1&2 J13 PIN10 +12V C24 0.1uF R44 4K7 c 4 VR2 2K2 R46 2K2 2 Q7 U3 +12V R38 120R C42 0.1uF C43 0.1uF C44 0.1uF C47 0.1uF C48 0.1uF C49 0.1uF 7 C51 0.1uF C52 0.1uF C53 0.1uF R45 4K7 +12V 1 8 J3 BLOCK SENSOR 14 Q8 9 SERVO GND WHITE DMX -VE +12V C28 0.1uF R53 10K 11 4 PUMP SIGNAL J14 PIN6 ORANGE R51 4K7 U5 GND 5 SERVO +VE RED J12c DMX +VE J9b VERT LOUVRE ORANGE 7 R63 390K VRAMP 6 R64 1M 1 PUMP J13 PIN5 11 U4 13 U5 +12V R65 680R +12V R60 680R +12V GND 9 +12V R61 10K VR3 200K U5 VR4 2K2 6 R52 220K C29 0.1uF C27 10uF GND R59 120R R54 22K J5 CONDENSER SENSOR R74 100K 14 U5 J4 EVAPORATOR SENSOR VR5 200K C32 0.1uF D6 R71 100K 8 c 7 1 c 9 FREEZE FAN SIGNAL J14 PIN9 PINK JMP R70 22K 8 ZD2 3V3 U4 R66 390K c R58 6K8 2 FREEZE FAN J13 PIN12 5 R73 2K2 GND R57 680R 4 J10 C33 100uF R69 56K V4 VRAMP FREEZE FAN FAIL J14 PIN5 YELLOW 10 R56 220R VRAMP ORANGE& GREEN PAD 1 ORANGE& BLUE PAD 2 J9a GND C30 0.1uF YELLOW& RED PAD 1 YELLOW& BLUE PAD 2 J12b C31 0.1uF 13 U3 10 6500 DMX GREY PAD 10 +12V R62 100K +12V R55 10K 2500 GREY PAD 10 GND +12V 2 DMX GND SERVO GND WHITE GND HEAT FAN FAIL J14 PIN4 WHITE J12a HORIZ LOUVRE ORANGE J8b READY SIGNAL J14 PIN11 BROWN GND C26 10uF J7a 6500 VERT LOUVRE PAD 3 YELLOW& BLUE R50 2K2 U3 C25 0.1uF U4 GND J14 PIN10 LT BLUE J8a 6 14 GND J13 PIN3 SERVO +VE RED 6500 HORIZ LOUVRE PAD 4 YELLOW& RED R49 4K7 R48 1M U3 HEAT FAN J13 PIN11 C50 0.1uF +12V +12V GND R47 1M +12V R43 1M R40 1K C54 4700uF J7b R42 1M R39 2K2 +12V J14 PIN7 DK BLUE GND C46 10uF HEATERS 3&4 J13 PIN9 5 +12V J13 PIN2 R67 47R SPARE - 6500 J14 PIN1 GREY +12V GND R68 1K GND R72 6K8 R75 4K7 VR6 10K GND DRAWN BY:CPW DATE: 10,12,1996 TITLE:HF6500/HF2500 MOTHERBOARD - PART2 R76 1K GND c R37 10K JEM LTD. +12V DWG No.CPW047 REV. 1 +12V +12V R116 1K R115 2M2 JEM LTD. +12V R128 22K 6VREF +12V C39 0.1uF 11 +12V R131 1K 13 9 C40 4u7F R132 100K 14 8 U11 D/A1 4 10 R114 1M GND R117 100K 2 U9 C34 10uF 3.5VREF GND U12 VJP SETTING 5 C33 2u2F 7 R133 100K 6 C41 22uF FOG CONTROL R129 22K GND GND R130 100K VERT LOUVRE YELLOW & BLUE GND +12V +12V R120 1K R119 2M2 R138 47K U12 11 10 U11 14 HJP SETTING 9 R136 100K R139 56K FOG CONTROL C36 10uF 3.5VREF R137 100K 4 12 U9 GND R135 1K 2 R121 100K 8 C35 2u2F C42 0.1uF 5 D/A2 R118 1M 6VREF +12V GND R134 100K HORIZ LOUVRE YELLOW & RED GND +12V FOG CONTROL R145 47K +12V c 13 VR10 10K +12V +12V VR7 OUTPUT LEVEL 22K R126 1K R125 2M2 +12V D/A3 10 R123 2M2 R124 2M2 D14 C37 2u2F c DMX CABLE SCREENS FOR PINK, YELLOW & BLUE, YELLOW & RED R127 100K 12 C38 10uF 3.5VREF DMX FAN SPEED PINK DRAWN BY: CPW R142 22K 9 14 U11 R140 100K GND GND 6VREF 8 U9 11 3 3 13 R148 22K 7 +12V R122 68K GND +12V C43 0.1uF R147 22K 1 12 FREEZE FAN SIGNAL PINK U12 U12 3 4 PUMP SIGNAL ORANGE GND 5 GND R141 100K 1 U11 6 R146 22K C44 0.1uF 2 R143 68K FOG CONTROL R144 100K GND DATE: 3,3,1997 TITLE: HF6500 CONTROLLER - PART5 DWG No. CPW059 REV. JEM LTD. +12V +12V R98 20K 1% R103 1K R101 2M2 3.5VREF +5V R100 2M2 +5V 16 7 R104 10K 1 R99 8K2 +V Q1 10 U9 Q2 INP 6 Q3 GND R105 10K Q4 Q5 GND R102 56K C31 1uF U8 Q6 11 Q7 R D11 GND D10 C32 3n3F Q8 R107 220K Q9 9 1 7 10 A0 6 3 Q11 R106 10K 2 6 4 5 13 4 12 3 14 GND 15 Q2 A3 Q3 12 13 15 16 A4 Q4 A5 Q5 A6 Q6 17 A7 D/A1 R108 R111 1M D/A2 R109 1M R112 1M D/A3 R110 1M R113 1M 18 D12 19 D13 1M Q7 A8 24 1 A9 U13 21 A10 A11 22 23 8 SE RESET A2 +V 25 A10 Q12 A1 7 A9 GND 11 8 A8 Q10 27 VPP P Q0 Q1 9 5 28 A12 A11 G A12 E 2 GND A13 20 26 A13 GND GND 14 GND DRAWN BY: CPW DATE: 3,3,1997 TITLE: H F 6 5 0 0 C O N T R O L L E R - P A R T 4 DWG No. CPW058 REV. JEM LTD. +12V SE SWITCHES SE SWITCHES SE RESET +12V SW10 WAVE SE U2 4 SE RESET EFFECTS FOG GO +12V SW11 SEA SE 14 +12V U2 10 R79 15K R78 220K +12V R81 47K 7 +12V 1 14 4 5 +V Q S C18 3n3F 2 9 Q D 3 R65 68K A10 6 GND Q S C19 3n3F LED12 WAVE SE YELLOW 12 Q 11 R66 120R 7 +V D 1 GND R R67 68K A11 7 SW12 CLOUD SE U3 4 R 5 +V 3 Q S C20 3n3F 2 R69 68K A9 6 7 +V Q C28 100uF LED7 TIMER OFF RED LED9 TIMER REPEAT YELLOW LED8 TIMER ONCE YELLOW R91 1M R72 120R R90 470K 7 LED15 WATERFALL SE YELLOW R92 1K LED6 TIMER ON GREEN R93 1K R94 1K C30 0.1uF TIMER FOG GO +12V 1 14 U1 6 R95 100K U1 12 4 3 R96 100K U1 GND GND 8 2 EFFECTS FOG GO Q4 9 5 VR1 PUMP TIME 470K SE RESET C29 0.1uF R97 22K 11 13 c SE RESET R87 1K 13 7 GND SE SWITCHES R86 1K R85 10K A8 GND 12 R71 68K C21 3n3F C27 10uF 12 EFFECTS FOG GO SE SWITCHES GND 14 Q S LED14 CLOUD SE YELLOW GND R 11 R70 120R SE SWITCHES +12V R83 47K 10 D 1 GND 12 +12V 9 Q D U10 5 GND SE RESET SW13 WATERFALL SE U3 14 R82 1K 2 SE RESET EFFECTS FOG GO SE SWITCHES +12V 6 R80 2K2 LED13 SEA SE YELLOW GND SE RESET C25 0.1uF GND R68 120R EFFECTS FOG GO SE SWITCHES C24 0.1uF 13 GND 12 R77 47R C26 0.1uF 3 U10 R U1 +12V SW14 VOLCANO SE 4 R 5 3 Q S R73 68K GND 2 GND 6 7 10 R 9 Q D C22 3n3F U4 14 +V A13 Q S C23 3n3F LED16 VOLCANO SE YELLOW R75 68K GND GND 12 7 A12 SW6 TIMER ONCE 13 R76 120R LED17 CURTAIN SE YELLOW EFFECTS FOG GO DRAWN BY: CPW VR2 DELAY TIME 470K 12 Q 11 R74 120R 14 +V D 1 R89 10K D8 10 c U4 +12V SW15 CURTAIN SE R84 47K EFFECTS FOG GO DATE: 28,2,1997 SW7 TIMER REPEAT D7 D9 SW5 TIMER START R88 2K2 GND TITLE: H F 6 5 0 0 C O N T R O L L E R - P A R T 3 DWG No. CPW057 REV. JEM LTD. +12V C9 0.1uF R32 10K R39 1K C10 0.1uF R35 10K R33 10K R36 2M2 C12 0.1uF +12V 7 R37 4K7 1 R45 120R 5 3 2 U5 C7 100uF LED10 HORIZ SCAN GREEN SW8 HORIZ SCAN R40 47K D3 8 14 1 U5 VR4 HORIZ SCAN 6 D4 SPEED 100K 4 12 VR3 HORIZ SCAN ARC 470K GND R38 560K R42 47K +V 14 13 Q D 11 CK R C11 3n3F 12 Q 10 R44 68K 13 7 U7 GND 2 U6 7 R46 2M2 c C8 100uF S 9 R41 47K c R34 10K R43 10K +12V HJP SETTING c GND R59 100K R60 22K DMX HORIZ LOUVRE YELLOW & BLUE HORIZONTAL JOYSTICK POT 10K GND +12V R61 100K VR8 HORIZONTAL ADJUSTMENT 10K c GND +12V C16 0.1uF R56 10K SW9 VERT SCAN D5 R50 10K R48 10K R51 2M2 9 c 14 VR6 VERT SCAN SPEED 100K 13 R49 10K C13 100uF C14 100uF 6 R62 100K 14 8 10 R52 4K7 R55 47K R53 560K S 5 VR5 VERT SCAN ARC 470K +V 3 CK R C17 3n3F R57 68K 2 14 5 Q D Q 1 7 U7 GND 4 VR9 VERTICAL ADJUSTMENT 10K GND 4 U5 DMX VERT LOUVRE YELLOW & RED VJP SETTING +12V 3 U6 7 c D6 R58 120R 11 U5 +12V LED11 VERT SCAN GREEN c R54 1K C15 0.1uF c R47 10K R63 100K R64 22K VERTICAL JOYSTICK POT 10K GND GND DRAWN BY: CPW DATE: 28,2,1997 TITLE: H F 6 5 0 0 C O N T R O L L E R - P A R T 2 DWG No. CPW056 REV. READY SIGNAL BROWN JACK INPUT +VE FOG ENABLE Q3 R1 1K LED3 READY GREEN R8 1K6 +12V FOG ENABLE R15 1K 4 5 R23 1K TIMER & EFFECTS FOG GO 9 SW18 FOG OUTPUT LED4 REFRIGERATION OFF YELLOW 3 U14 6 FOG CONTROL JACK INPUT -VE GND +12V LED1 CONTROLLER ON GREEN 8 R9 680R R149 47K LED5 REFRIGERATION ON YELLOW R24 1K REFRIG OFF LED RED & BROWN REFRIG ON LED RED & BLACK GND R5 2K2 R7 1K DMX +VE RED CONTROLLER ON LED -VE WHITE & RED Q2 R3 68K R6 22K R4 100K R10 2K2 LED2 HEATING RED TIMER FOG GO +12V +VOLTS DK BLUE +12V U15 7805 SMOKE/HF SIGNAL RED & BLUE D1 R18 220K HEATING SIGNAL RED OUT GND C5 0.1uF GND LT BLUE R19 10K GND DMX GND BLACK C1 10uF EFFECTS FOG GO R17 22K TIMER & EFFECTS FOG GO Q6 GND Q5 +12V R16 10K D MX F IRE WHITE +12V GND +12V FREEZE FAN FAIL YELLOW HEAT FAN FAIL WHITE +5V IN C4 470uF Q1 R11 1K6 R25 1K 6 U7 R2 2K2 CONTROLLER ON LED +VE GREEN & BROWN JEM LTD. +12V DEFROST VALVE FAIL BLACK LED18 HEAT FAN FAIL RED R12 1K6 LED19 FREEZE FAN FAIL RED R13 1K6 SW1 CONTROLLER OFF 13 C2 0.1uF C3 100uF SMOKE/HF SIGNAL RED & BLUE SW2 CONTROLLER ON DATE: 27,2,1997 SW3 REFRIGERATION OFF R21 120R GND R31 1K C6 10uF LED22 HF FLUID YELLOW 8 U10 10 14 U10 SW4 REFRIGERATION ON DMX REFRIG OFF BLUE STANDBY/ON PURPLE COMPRESSOR FAIL WHITE & BLUE DRAWN BY: CPW 11 R26 47K D2 LED20 DEFROST VALVE FAIL RED LED23 SMOKE FLUID YELLOW +12V R22 2K2 DMX REFRIG ON ORANGE LED21 COMPRESSOR FAIL RED R14 1K6 R29 10K +12V R20 22K R30 1K 9 R27 47K PUMP CHANGEOVER GREEN R28 220K GND DMX HF FLUID YELLOW DMX SMOKE FLUID GREEN SW16 HEAVY FOG SW17 SMOKE GND GND TITLE: H F 6 5 0 0 C O N T R O L L E R - P A R T 1 DWG No. CPW055 REV. 1 J16 Q1 PH2 g g C4 0.1uF X2 mt1 Q2 mt1 Q6 4 HEATER3 J6 U7 3041 R17 470R FS7 10A R18 330R R12 330R FS6 10A R20 120R 6 2 J5 U6 3041 HEATER2 C9 0.1uF X2 mt2 R15 120R 6 2 R1 330R FS4 10A R13 470R HEATER1 J4 U2 3041 R2 470R HEATER4 J1 PIN9 J1 PIN10 J1 PIN9 U1 R7 3041 330R R8 470R J1 PIN10 FS2 10A mt1 mt2 R9 120R 6 2 6 2 J3 PH3 g Q7 1 mt2 R4 120R C7 0.1uF X2 4 1 4 1 4 1 mt2 +12V C1 0.1uF X2 mt1 +12V +12V +12V g J1 PIN1: J1 PIN2: J1 PIN3: J1 PIN4: J1 PIN5: J1 PIN6: J1 PIN7: J1 PIN8: J1 PIN9: J1 PIN10: J1 PIN11: J1 PIN12: J2 g g R21 91K C8 0.1uF X2 Q5 FS8 1A ZD4 75V 4 FS5 3A +12V U8 D5 7812 IN L1 4mH 400W +12V J1 PIN12 +12V C11 0.1uF X2 J1 PIN2 OUT PH1 J1 PIN5 C14 0.1uF X2 C12 0.1uF X2 C13 0.1uF X2 R26 91K PH1 R27 47R PH1 R28 120R D3 0.1uF C3 C10 FS9 1A FS10 1A J10 J11 J12 C5 HF CONTACTOR 4700uF +12V 4700uF J14 D4 RL1 12V J1 PIN3 FS11 1A HEATER CONTACTOR RL2 12V J1 PIN4 D6 RL3 12V J1 PIN7 D7 GND DRAWN BY:CPW SMOKE PUMP R22 470R R25 91K PH1 D2 2 PUMP FS1 800mA T1 FS3 1A 6 1 R23 470R RAMP RESET +12V GND HF CONTACTOR PUMP PUMP CHANGEOVER HEATER CONTACTOR DEFROST VALVE HEATERS 3&4 HEATERS 1&2 HEAT FAN FREEZE FAN J7 U3 3021 GND D1 R5 1K5 ZD1 75V 4 2 FREEZE FAN C2 0.1uF X2 DATE: 15,12,1996 TITLE:HF6500 TRIGGERBOARD J13 FS12 1A DEFROST VALVE +12V J2 NEUTRAL FREEZE FAN 6 1 RAMP RESET J1 PIN1 R24 470R VAPOUR FAN LINE J17 PH1 ZD2 75V U4 3021 J1 PIN11 HEAT FAN J8 ZD3 75V 6 2 R11 47R L2 4mH 400W HEAT FAN R6 91K Q3 R3 91K J9 U5 3021 1 mt1 mt2 R10 91K R16 91K R19 1K5 L3 4mH 400W +12V C6 0.1uF X2 mt2 ZD5 75V 4 R14 91K Q4 mt2 ZD6 75V g mt1 +12V mt1 +12V PH1 JEM LTD. J15 J1 PIN8 D8 HF PUMP RL4 12V D9 PUMP CHANGEOVER J1 PIN6 DWG No.CPW050 REV. Transformer 15v O/P 20VA 15v reg 12 way molex Heater #1 Live Feed (10A Fuse) Heater Live Input From Contactor HF 6500 TRIGGER BOARD Heater #2 Live Feed (10A Fuse) MOLEX PIN-OUTS Pin 1 - Half wave output Pin 2 - Heavy-fog contactor Pin 3 - Heater contactor Pin 4 - Heaters 1 & 2 Pin 5 - +12 volts Pin 6 - Pump Pin 7 - Defrost valve Pin 8 - Condensor fan Pin 9 - Ground Pin 10 - Pump change over Pin 11 - Heaters 3 & 4 Pin 12 - Evaporator fan 6500 D.M.X WIRING 1 2 3 1 2 3 4 5 6 7 8 9 10 1=BLACK FROM P.C.B 2=YELLOW/RED FROM P.C.B 3=YELLOW/BLUE FROM P.C.B 4=PINK FROM P.C.B 5=WHITE FROM P.C.B 6=ORANGE FROM P.C.B 7=BLUE FROM P.C.B 8=GREEN FROM P.C.B 9=YELLOW FROM P.C.B 10=RED FROM P.C.B DMX FUNCTIONS CHANNEL 1 = COMPRESSOR ON 2 = FLUID TANK CHANGE OVER 3 = HORIZONTAL LOUVRE 4 = VERTICAL LOUVRE 5 = FIRE 6 = NOT USED DATE.25/02/98 6500 DMX WIRING DRAWN BY J.MARSHALL 1=ORANGE/BLUE FROM SOCAPEX 2=GREEN/BLUE FROM SOCAPEX 3=GREY FROM SOCAPEX