Download INOmax® DS Troubleshooting

Transcript

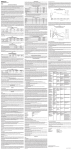

INOmax® DSIR Troubleshooting Warning: Use caution when troubleshooting the INOmax DSIR while in use for a patient. When possible replace the unit in question, and perform troubleshooting procedure once the unit is removed from the patient. If the system fails to operate properly: 1. Check the patient condition and take appropriate action. 2. Verify that the system is set up as detailed in Section 2/ Setup of the Operation and Maintenance Manual. 3. Use the INOblender® (see INOblender Operation Manual) or backup mode if necessary (see page 29 of manual). 4. Find a symptom or alarm condition in the troubleshooting table which best describes the problem and follow the recommended actions to resolve the problem. If the problem can’t be corrected: Contact Customer Service on 1300 198 565. Troubleshooting Guide High Priority Alarms Symptom/Alarm 1. High NO Alarm High NO Possible Cause Recommended Action A.Note: A newly installed NO sensor will give high readings until fully conditioned (about 5 hours) and calibrated. a. After installation of the NO sensor perform a low and high calibration. B.The High NO alarm level may be inappropriately set. a. Make sure the High NO alarm is set greater than the Set NO value. C.The NO calibration may have drifted. a. Perform a low and high range calibration of the NO sensor. b. Wait 5 hours and repeat both the low and high calibration. b. Check calibration sample tee for leaks. D.Circuit setup incorrect. a. Check circuit setup for correct use of adapters and/or check valves. High Priority Alarms Symptom/Alarm 2.LowNOAlarm Low NO Possible Cause Recommended Action A.ThePatientGasSamplelinemaybe disconnected. a. ReconnectthePatientGasSampleline. B.TheLowNOalarmsettingmaybe inappropriatelyset. a. MakesuretheLowNOalarmissetlessthan theSetNOvalue. C.TheNOcalibrationmayhavedrifted. a. Performalowandhighrangecalibration oftheNOsensor. D.TheNOsensormaynotbeproperlyseated. a. Makesurethesensorsarecorrectly seatedwiththeO-ringsandthesensor coverisfullyclosed. E. LossofNOdelivery. a. IftheINOblender®isavailable,manually ventilatethepatient(seeINOblender OperationManual). or b. TurnthebackupmodeON(seepage29of OperationandMaintenanceManual). 3. HighNO2Alarm A.Incompletesystempurge. a. Performasystempurge. SeeSection3/ Pre-UseCheckout. B.Ventilatorflowstopped. a. AllowtheventilatorgastoflushNOandNO2 fromthebreathingcircuitbeforeconnecting tothepatient. C.Twocylindervalvesareopen. a. Closeoneofthecylindervalves. D.TheNO2alarmlimitmaybesettoolow. a. MakesuretheNO2alarmlimitisappropriate fortheSetNOlevel. E. TheNO2calibrationmayhavedrifted. a. Performalowandhighrangecalibrationof theNO2sensor. High NO2 b. Checkcalibrationsampleteeforleaks. F. Outofdateorthewrongcalibration gaswasused. a. Verifythecalibrationgasexpirationdate. G.Thepatientcircuitsetupmaybeincorrect. a. Makesurethepatientcircuithosesandlengths arecorrect(seeSection4/PatientApplication ofOperationandMaintenanceManual). b. Ifneededreplacethecalibrationgasand performalowandhighrangecalibration oftheNO2sensor. b. Verifythehumidifierchamberisless than480mL. H.Samplelineocclusion. Inthiscase,thisalarmmayoccurwith aSampleLineBlockalarm. I. TheINOmax®DSIRmayhavefailed. a. ConfirmwhethertheHighNO2alarmoccurs concurrentlywithasamplelineblockalarm. b. Ifso,thisalarmwillclearwithin10seconds afterthesamplelinefaultisremedied. a. ContactCustomerService. b. Replacethedeliverysystemifinuse. c. Donotusethedeliverysystemuntilserviced. High Priority Alarms Symptom/Alarm 4. HighO2Alarm Possible Cause Recommended Action A.TheO2alarmsettingmaybeinappropriate. a. MakesuretheHighO2alarmisset appropriatelyfortheO2settingbeingused ontheventilator. B.TheO2calibrationmayhavedrifted. a. Performalowandhighrangecalibration oftheO2sensor. High O2 b. ChangetheO2sensorifthemonitorfails tocalibrate. c. ContactCustomerService. d. Replacethedeliverysystemifinuse. e. Donotusethedeliverysystemuntilservice. 5.LowO2Alarm Low O2 A.TheO2concentrationsettingattheventilator wasreduced. a. MakesuretheO2alarmsettingiscorrectfor thesettingattheventilator. B.TheO2alarmsettingmaybeinappropriate. a. TheINOmaxDSIRcandilutetheO2 concentrationsetattheventilatorby upto10%. b. Verifythatthealarmissetappropriatelyfor theO2settingbeingusedontheventilator. C.TheO2sensormaynotbeproperlyseated. a. Makesurethesensorsarecorrectlyseated andthesensorcoverisfullyclosed. D.TheO2calibrationmayhavedrifted. a. Performalowandhighrangecalibration oftheO2sensor. b. ContactCustomerService. 6.CylinderNotDetected INOmax INOmax 20 10 5 40 NO 60 (ppm) 1 80 0 or CylinderValveClosed INOmax 20 10 5 40 NO 60 (ppm) 1 0 80 a. RemoveobstructionbetweentheINOMAX A.InterferencewiththeInfraredcommunication linkbetweentheINOMAXcylinderandthe cylinderandtheINOmaxDSIR . INOmaxDSIR.(DeliveryStoppedwilloccur b. Movetheinterferinglightorthecartto onehourfromthepointwhencommunication reducethehighintensitylightintheareaof islost). theINOmeter®. B.INOMAXcylindervalveisclosed.(Delivery Stoppedwilloccuronehourfromthepoint whenthecylindervalveisclosed). a. OpenINOMAXcylindervalve. C.TransportCapnotconnectedtotheINOmeter. a. AttachtheTransportCaptotheINOmeter (DeliveryStoppedwilloccuronehourfromthe ontheINOMAXcylinder. pointwhencommunicationislost). b. ConnecttheTransportRegulator/Cap Assemblycabletotheinfraredconnectoron thebackoftheINOmaxDSIR . D.INOMAXcylindernotpresentonthe INOmaxDSIR .(DeliveryStoppedwill occuronehourfromthepointwhen communicationislost). a. LoadanINOMAXcylinderontothe INOmaxDSIRcart. E. INOmetermayhavefailed. a. ReplacetheINOMAXcylinderonthe INOmaxDSIRcart. F. INOmaxDSIRinfraredcartcableisnot connectedorhasfailed. a. Connectinfraredcartcabletotheinfrared connectoronthebackoftheINOmaxDSIR . b. ReplacetheINOmaxDSIR . High Priority Alarms Symptom/Alarm 7. DeliveryFailure Possible Cause A.MonitoredNOlevels≥100ppm or 20 40 10 5 B.TheINOmaxDSIRhasfailed. 60 a. IftheINOblenderisavailable,manually ventilatethepatient(seeINOblender OperationManual). or b. TurnthebackupmodeON(seepage29 ofOperationandMaintenanceManual). 1 0 Recommended Action 80 c. PowertheINOmaxDSIRtoSTANDBYand thenbackONtoresetthedeliverysystem.If thisdoesnotworkcontactCustomerService. d. Replacethedeliverysystemifinuse. e. Donotusethedeliverysystemuntilserviced. 8.DeliveryStopped INOmax INOmax 20 10 5 40 NO 60 (ppm) 1 0 A.Infraredcommunicationlinkbetweenthe INOMAXcylinderandtheINOmaxDSIR hasbeenlostforonehour. a. RemoveobstructionbetweentheINOMAX cylinderandtheINOmaxDSIR . b. Movetheinterferinglightorthecartto reducethehighintensitylightintheareaof theINOmeter. c. IftheINOblenderisavailable,manually ventilatethepatient(seeINOblender OperationManual). 80 or d. TurnthebackupmodeON(seepage29 ofOperationandMaintenanceManual). B.INOMAXcylinderisexpiredandcylinder valvehasbeenopenfortwominutes. a. RemovetheINOMAXcylinderfromthe INOmaxDSIRcart. b. ConnectanINOMAXcylindertothe INOmaxDSIRwithavalidexpirationdate. C.INOMAXcylinderisthewrong concentrationandcylindervalvehas beenopenfortwominutes. a. RemovetheINOMAXcylinder withthewrongconcentrationfromthe INOmaxDSIRcart. b. ConnectanINOMAXcylindertothe INOmaxDSIRwithavalidconcentration. D.INOmetermayhavefailed. a. ReplacetheINOMAXcylinderonthe INOmaxDSIRcart. E. INOMAXcylindervalveisclosed. a. OpenINOMAXcylindervalve. b. IftheINOblenderisavailable,manually ventilatethepatient(seeINOblender OperationManual). or c. TurnthebackupmodeON(seepage29 ofOperationandMaintenanceManual). F. INOMAXcylindernotpresentonthe INOmaxDSIR . a. LoadanINOMAXcylinderontothe INOmaxDSIRcart. b. IftheINOblenderisavailable,manually ventilatethepatient(seeINOblender OperationManual). or c. TurnthebackupmodeON(seepage29 ofOperationandMaintenanceManual). High Priority Alarms Symptom/Alarm 9. DrugPastExpiryDate or DrugConcentrationMismatch Possible Cause A.INOMAXcylinderisexpired(Delivery Stoppedwilloccurtwominutesfromthe pointwhenthecylindervalveisopened). Recommended Action a. Closethecylindervalve. b. RemoveexpiredINOMAXcylinderfrom theINOmaxDSIRcart. c. ReplacetheexpiredINOMAXcylinderon theINOmaxDSIRcart. INOmax INOmax 20 10 5 40 NO 60 (ppm) 1 0 80 B.INOMAXcylinderisthewrong concentration.(DeliveryStoppedwill occurtwominutesfromthepointwhen thecylindervalveisopened). a. Closethecylindervalve. b. RemovetheINOMAXcylinderwiththe wrongconcentrationfromtheINOmax DSIRcart. c. ReplacetheexpiredINOMAXcylinder withthewrongconcentrationonthe INOmaxDSIRcart. 10. InjectorModuleFail A.TheInjectorModuleelectricalcable maybedisconnected. a. ReconnecttheInjectorModuleelectrical cable. b. TurnOFFtheINOmaxDSIRsetdoseto silencethealarm. c. IftheINOblenderisavailable,manually ventilatethepatient(seeINOblender OperationManual). or d. TurnthebackupmodeON(seepage29 ofOperationandMaintenanceManual). B.TheInjectorModulemayhavefailed. a. TurnOFFtheINOmaxDSIRsetdoseto silencethealarm. b. IftheINOblenderisavailable,manually ventilatethepatient(seeINOblender OperationManual). or c. TurnthebackupmodeON(seepage29 ofOperationandMaintenanceManual) d. ReplacetheInjectorModule. e. SetthedelivereddoseandturnOFFthe INOblenderorthebackupmode. C.TheInjectorModuleelectricalcable mayhavefailed. a. TurnOFFtheINOmaxDSIRsetdoseto silencethealarm. b. IftheINOblenderisavailable,manually ventilatethepatient(seeINOblender OperationManual). or c. TurnthebackupmodeON(seepage29 ofOperationandMaintenanceManual). d. ReplacetheInjectorModuleelectrical cable. e. ResetthedelivereddoseandturnOFF theINOblenderorthebackupmode. High Priority Alarms Symptom/Alarm 11.LowBatteryAlarm Possible Cause A.Batteryisrunninglow(approximately 10minutesorlessuntilbatterydepletion). Recommended Action a. Checkmainpowerindicator. b. ConnecttoACmainpowersource. c. Makesurethepowercordisfullyinsertedinto thePowerCordInletandthatthepowercord clampissecure. d. Checkandreplacefuseifnecessary. e. ContactCustomerService. 12. LowNO/N2Pressure A.TheNOcylindersupplymaybelow. a. MakesuretheNOcylinderisturnedON. b. Ifthehighpressurecylindergaugereadsless than200psig,changethecylinder. INOmax INOmax 20 10 5 NO 60 (ppm) 1 c. IftheINOblenderisavailable,manually ventilatethepatient(seeINOblender OperationManual). 40 0 or 80 d. TurnthebackupmodeON(seepage29 ofOperationandMaintenanceManual). B.Thesupplylinemaynotbeconnected. a. Ifthecylindergaugereadsgreaterthan 200psig. b. Verifythelowpressurehosesareconnected correctlytothebackoftheINOmaxDSIR. c. IftheINOblenderisavailable,manually ventilatethepatient(seeINOblender OperationManual). or d. TurnthebackupmodeON(seepage29 ofOperationandMaintenanceManual). 13.ServiceRequired A.TheINOmaxDSIRhasfailed. Service Required a. IftheINOblenderisavailable,manually ventilatethepatient(seeINOblender OperationManual). or b. TurnthebackupmodeON(seepage29 ofOperationandMaintenanceManual). Manual Delivery Available c. TurntheINOmaxDSIRtoSTANDBYand thenbackONtorestthedeliverysystem. PleasecontactCustomerServiceandreplace thedeliverysystemassoonaspossible. Utilize the INOblender or Backup Delivery 14. SetNOandBackupOn INOmax INOmax 20 10 5 60 (ppm) 0 80 a. TurntheINOmaxDSIRsetdosetozero. b. Correctthereasonforinitiatingthe backupmode. c. TurnONtheINOmaxDSIRsetdose. 40 NO 1 A.ThebackupmodehasbeenturnedON andthesetdoseisstillset. d. TurnthebackupmodeOFF. e. IfthisdoesnotworkcontactCustomerService. Low Priority Alarms Symptom/Alarm Possible Cause A.ThebackupmodehasbeenturnedON andthesetdoseiszero. 15. BackupOn 250ml/min INOmax INOmax 20 10 5 c. TurnthebackupmodeOFF. 40 60 (ppm) 0 a. Correctthereasonforinitiatingthe backupmode. b. TurnONtheINOmaxDSIRsetdose. NO 1 Recommended Action 80 16. FailedNOSensor A.Thewrongcalibrationgasmayhavebeenused. a. Makesurethecorrectcalibrationgasisused andensuresampletubingconnectionsare secureanddonotleak. B.Thereisaleakaroundthesensors. a. Makesurethesensorsarecorrectly seatedwiththeO-ringsandthesensor coverisfullyclosed. C.NOsensorabsentorfailed. a. Completealowcalibrationfirst,andthen repeatthehighcalibration. b. Sensorneedstobereplaced. c. Replacethedeliverysystemifinuse. d. ContactCustomerService. 17. FailedNO2Sensor A.Thewrongcalibrationgasmayhavebeenused. a. Makesurethecorrectcalibrationgasis usedandensuresampletubingconnections aresecureanddonotleak. B.Thereisaleakaroundthesensors. a. Makesurethesensorsarecorrectly seatedwiththeO-ringsandthesensor coverisfullyclosed. C.NO2sensorabsentorfailed. a. Completealowcalibrationfirst,andthen repeatthehighcalibration. b. Sensorneedstobereplaced. c. Replacethedeliverysystemifinuse. d. ContactCustomerService. 18. FailedNO2Sensor A.Thewrongcalibrationgasmayhavebeenused. a. Makesurethecorrectcalibrationgasisused andensuresampletubingconnectionsare secureanddonotleak. B.Thereisaleakaroundthesensors. a. Makesurethesensorsarecorrectlyseated andthesensorcoverisfullyclosed. C.O2sensorabsentorfailed. a. Completealowcalibrationfirst,andthen repeatthehighcalibration. b. Sensorneedstobereplaced. c. Replacethedeliverysystemifinuse. d. ContactCustomerService. Low Priority Alarms Symptom/Alarm A.Monitorisfailingtocommunicatecorrectly orisreportingafault. 19. MonitoringFailure O (%) 2 21 NO (ppm) 2 3.0 NO Possible Cause a. DoesnotstopdeliveryofINOMAXto thepatient. b. ContactCustomerService. 5 (ppm) 20.SampleLine/FilterBlock Recommended Action A.Thesamplelinemaybeblocked. a. Makesurethesampleinletlineandoutlet portsarenotobstructed. b. Changethesampleline. 21. TwoCylindersOpen INOmax INOmax 20 10 5 A.Twocylindervalvesareopen. a. Closeoneofthecylindervalves. A.Thewatertrapbottleonthesideofthe INOmaxDSIRisfull. a. Emptythewatertrapbottle. B.Watertrapbottleisemptybutthemessage remainsinthealarmmessagebox. a. Removethewatertrapbottleandclean theopticalsensorlevelindicatorwithan alcoholswab. C.TheINOmaxDSIRmayhavefailed. a. ContactCustomerService. 60 (ppm) 0 a. Replacethewater separatorcartridge. 40 NO 1 B.Thewaterseparatorcartridgemaybeblocked. 80 22.WaterTrapBottleFull b. Replacethedeliverysystemifinuse. Indicators Symptom/Indicator 23.PatientInfoIncomplete Possible Cause Recommended Action A.Patientidentifierhasnotbeenentered. a. Enterpatientidentifier. A.Thesetdosehasbeensettozeroandthe INOMAXcylindervalveisstillopen. a. ClosetheINOMAXcylindervalveif treatmenthasbeenstopped. A.Deviceisoperatingonthebattery. a. ConnecttoACmainpowersource whenavailable. Patient Info Incomplete 24. SetDoseisZero,Close CylinderValve Set Dose is Zero, Close Cylinder Valve 25.RunningonBattery b. Checkmainpowerindicator. c. Makesurethepowercordisfully insertedintothePowerCordInlet andthatthepowercordclampissecure.