Download User's Manual

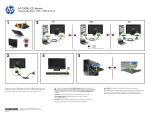

Transcript