Download TROUBLESHOOTING

Transcript

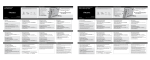

CL–1 CLUTCH – TROUBLESHOOTING TROUBLESHOOTING CL034–01 PROBLEM SYMPTOMS TABLE Use the table below to help you find the cause of the problem. The numbers indicate the priority of the likely cause of the problem. Check each part in order. If necessary, replace these parts. Symptom Suspect Area See page Clutch grabs/chatters 1. Engine mounting (Loosen) 2. Clutch disc (Runout is excessive) 3. Clutch disc (Oily) 4. Clutch disc (Worn out) 5. Clutch disc torsion rubber (Damaged) 6. Clutch disc (Glazed) 7. Diaphragm spring (Out of tip alignment) – CL–17 CL–17 CL–17 CL–17 CL 17 CL–17 CL 17 CL–19 Clutch pedal edal spongy s ongy 1. Clutch line (Air in line) 2. Master cylinder cup cu (Damaged) 3. Release cylinder cup (Damaged) – CL–4 CL 4 CL–9 Clutch noisy 1. Release bearing (Worn, 1 (Worn dirty, dirty or damaged) 2 Clutch 2. Cl h disc di torsion i rubber bb (Damaged) (D d) CL–19 CL 19 CL 17 CL–17 Cl t h slips Clutch li 1. Clutch pedal edal (Free (Freeplay lay out of adjustment) 2. Clutch disc (Oily) 3. Clutch disc (Worn out) 4. Dia Diaphragm hragm sspring ring (Damaged) 5. Pressure plate late (Distortion) 6. Flywheel (Distortion) CL–2 CL–17 CL–17 CL 17 CL–17 CL 17 CL–17 CL 17 – Cl t h does Clutch d nott disengage di 1. Clutch pedal (Freeplay out of adjustment) 1 2 Clutch line (Air in line) 2. 3 Master cylinder cup (Damaged) 3. 4 Release cylinder cup (Damaged) 4. 5 Clutch disc (out of true) 5. 6 Clutch 6. Cl tch disc (Runout (R no t is excessive) e cessi e) 7 Cl 7. Clutch t h di disc (Li (Lining i b broken) k ) 8 Clutch 8. Cl t h disc di (Dirty (Di t or burned) b d) 9. Cl Clutch h di disc (Oil (Oily)) 10. Clutch disc (Lack of spline grease) 11. Diaphragm g spring g ((Damaged) g ) 12. Diaphragm g spring g (Out ( of tip alignment) g ) 13. Pressure plate (Distortion) CL–2 – CL 4 CL–4 CL 9 CL–9 CL 17 CL–17 CL 17 CL–17 CL 17 CL–17 CL 17 CL–17 CL CL–17 CL–19 CL–17 CL–19 CL–17 Author: Date: 1780 CL–2 CLUTCH – CLUTCH PEDAL CLUTCH PEDAL CL035–01 INSPECTION 1. Pedal Height Adjust Point Push Rod Play and Freeplay Adjust Point Push Rod Play Pedal Height Q10088 CHECK THAT PEDAL HEIGHT IS CORRECT Pedal height from asphalt sheet: 1MZ–FE: 161.8 – 171.8 mm (6.370 – 6.764 in.) 5S–FE: 156.8 – 166.8 mm (6.173 – 6.567 in.) 2. IF NECESSARY, ADJUST PEDAL HEIGHT Loosen the lock nut and turn the stopper bolt until the height is correct. Tighten the lock nut. 3. CHECK THAT PEDAL FREEPLAY AND PUSH ROD PLAY ARE CORRECT Push in on the pedal until the beginning of clutch resistance is felt. Pedal freeplay: 5.0 – 15.0 mm (0.197 – 0.591 in.) Gently push the pedal until the resistance begins to increase a little. Push rod play at pedal top: 1.0 – 5.0 mm (0.039 – 0.197 in.) 4. (a) Pedal Freeplay (b) (c) (d) IF NECESSARY, ADJUST PEDAL FREEPLAY AND PUSH ROD PLAY Loosen the lock nut and turn the push rod until the freeplay and push rod play are correct. Tighten the lock nut. After adjusting the pedal freeplay, check the pedal height. Connect the air duct and install the lower finish panel. CL0042 5. (a) (b) (c) 25 mm (0.98 in. ) or more Release Point Full Stroke End Position CL0512 INSPECT CLUTCH RELEASE POINT Pull the parking brake lever and install wheel stopper. Start the engine and idle the engine. Without depressing the clutch pedal, slowly shift the shift lever into reverse position until the gears contact. (d) Gradually depress the clutch pedal and measure the stroke distance from the point the gear noise stops (release point) up to the full stroke end position. Standard distance: 25 mm (0.98 in.) or more (From pedal stroke end position to release point) If the distance not as specified, do the following operation. Inspect pedal height. Inspect push rod play and pedal freeplay. Bleed the clutch line. Inspect the clutch cover and disc. Author: Date: 1781 CL–3 CLUTCH – CLUTCH PEDAL 6. (a) CHECK CLUTCH START SYSTEM Check that the engine does not start when the clutch pedal is released. (b) Check that the engine starts when the clutch pedal is fully depressed. If necessary, replace the clutch start switch. Clutch Start Switch Q00307 5.0 ± 0.5 mm (0.197 ± 0.020 in.) 7. INSPECT CONTINUITY OF CLUTCH START SWITCH Check the continuity between terminals when the switch is ON and OFF. Switch position Condition ON (pushed) Continuity OFF (free) No continuity CL0477 Author: Date: 1782 CL–4 CLUTCH – CLUTCH MASTER CYLINDER CLUTCH MASTER CYLINDER CL036–01 COMPONENTS Filler Cap Clip Float Reservoir Tank Grommet Clevis Pin Boot Slotted Spring Pin Washer Master Cylinder Body Clevis Piston Lock Nut Clutch Line Snap Ring 15 (155, 11) Push Rod Spring 12 (120, 9) Non–reusable part N·m (kgf·cm, ft·lbf) : Specified torque Q10085 Author: Date: 1783 CL–5 CLUTCH – CLUTCH MASTER CYLINDER CL037–01 REMOVAL SST Q10094 1. DRAW OUT FLUID WITH SYRINGE 2. DISCONNECT CLUTCH LINE Using SST, disconnect the clutch line. Use a container to catch the fluid. SST 09023–00100 Torque: 15 N·m (155 kgf·cm, 11 ft·lbf) 3. REMOVE CLIP AND CLEVIS PIN 4. REMOVE 2 MOUNTING NUTS AND PULL OUT MASTER CYLINDER Torque: 12 N·m (120 kgf·cm, 9 ft·lbf) Author: Date: 1784 CL–6 CLUTCH – CLUTCH MASTER CYLINDER CL038–01 DISASSEMBLY 1. (a) (b) REMOVE RESERVOIR TANK Using a pin punch and hammer, drive out the slotted spring pin. Remove the reservoir tank and grommet. Q10083 2. REMOVE PUSH ROD Pull back the boot, and using snap ring pliers, remove the snap ring. 3. REMOVE PISTON Q05039 Author: Date: 1785 CL–7 CLUTCH – CLUTCH MASTER CYLINDER CL039–01 REASSEMBLY 1. 2. 3. COAT PARTS WITH LITHIUM SOAP BASE GLYCOL GREASE, AS SHOWN INSERT PISTON INTO CYLINDER INSTALL PUSH ROD ASSEMBLY WITH SNAP RING CL0528 4. (a) (b) INSTALL RESERVOIR TANK Install the reservoir tank and a new grommet. Using a pin punch and hammer, drive in the slotted spring pin. Protrusion 1.5 – 3.5 mm (0.059 – 0.138 in.) Q10081 Author: Date: 1786 CL–8 CLUTCH – CLUTCH MASTER CYLINDER CL03A–01 INSTALLATION Installation is in the reverse order of removal (See page CL–5). HINT: After installation, bleed system and adjust clutch pedal (See page CL–2). Author: Date: 1787 CL–9 CLUTCH – CLUTCH RELEASE CYLINDER CLUTCH RELEASE CYLINDER CL03B–01 COMPONENTS Clutch Line 15 (155, 11) Release Cylinder Body 12 (120, 9) Piston Boot Bleeder Plug 8.4 (85, 74 in.·lbf) Spring Push Rod N·m (kgf·cm, ft·lbf) : Specified torque Q10016 Author: Date: 1788 CL–10 CLUTCH – CLUTCH RELEASE CYLINDER CL03C–01 REMOVAL SST Q10077 1. DISCONNECT CLUTCH LINE Using SST, disconnect the line. Use a container to catch the fluid. SST 09023–00100 Torque: 15 N·m (155 kgf·cm, 11 ft·lbf) 2. REMOVE 2 BOLTS AND PULL OUT RELEASE CYLINDER Torque: 12 N·m (120 kgf·cm, 9 ft·lbf) Author: Date: 1789 CL–11 CLUTCH – CLUTCH RELEASE CYLINDER CL03D–01 DISASSEMBLY 1. REMOVE BLEEDER PLUG 2. PULL OUT BOOT WITH PUSH ROD 3. REMOVE PISTON Blow compressed air into the release cylinder and remove the piston with spring. Q05878 Author: Date: 1790 CL–12 CLUTCH – CLUTCH RELEASE CYLINDER CL03E–01 REASSEMBLY 1. 2. 3. 4. COAT PISTON WITH LITHIUM SOAP BASE GLYCOL GREASE, AS SHOWN INSTALL PISTON WITH SPRING INTO CYLINDER INSTALL BOOT WITH PUSH ROD TO CYLINDER INSTALL BLEEDER PLUG Torque: 8.4 N·m (85 kgf·cm, 74 in.·lbf) Q06048 Author: Date: 1791 CL–13 CLUTCH – CLUTCH RELEASE CYLINDER CL03F–01 INSTALLATION Installation is in the reverse order of removal (See page CL–10). HINT: After installation, bleed clutch system. Author: Date: 1792 CL–14 CLUTCH – CLUTCH ACCUMULATOR (1MZ–FE) CLUTCH ACCUMULATOR (1MZ–FE) CL03G–01 COMPONENTS w/ Cruise Control System : Starter 39 (400, 29) Cruise Control Actuator 21 (210, 15) Battery 27 (270, 20) 13 (130, 9) 13 (130, 9) Clutch Accumulator Bracket 15 (155, 11) N·m (kgf·cm, ft·lbf) : Specified torque Q10092 Author: Date: 1793 CL–15 CLUTCH – CLUTCH ACCUMULATOR (1MZ–FE) CL03H–01 REMOVAL 1. (a) (b) w/ Cruise Control System: REMOVE CRUISE CONTROL ACTUATOR Remove the battery. Remove the 3 bolts and cruise control actuator with bracket. Torque: 13 N·m (130 kgf·cm, 9 ft·lbf) Q10074 2. (a) (b) REMOVE STARTER Remove the nut and disconnect the connectors. Remove the 2 bolt and clamp. Torque: 39 N·m (400 kgf·cm, 29 ft·lbf) 3. (a) REMOVE CLUTCH ACCUMULATOR WITH BRACKET Using SST, disconnect the clutch lines from the clutch accumulator. Torque: 15 N·m (155 kgf·cm, 11 ft·lbf) SST 09023–00100 Remove the 2 bolts and nut. Torque: Bolt: 21 N·m (210 kgf·cm, 15 ft·lbf) Nut: 27 N·m (270 kgf·cm, 20 ft·lbf) Q10078 SST Q10076 (b) Author: Date: 1794 CL–16 CLUTCH – CLUTCH ACCUMULATOR (1MZ–FE) CL03I–01 INSTALLATION Installation is in the reverse order of removal (See page CL–15). Author: Date: 1795 CL–17 CLUTCH – CLUTCH UNIT CLUTCH UNIT CL03J–01 COMPONENTS 5S–FE : Release Fork Flywheel 39 (400, 29) 19 (195, 14) x6 Release Bearing and Hub Release Fork 47 (480, 35) 5S–FE : Clutch Disc Clutch Cover Clutch Disc Boot N·m (kgf·cm, ft·lbf) : Specified torque Q10017 Author: Date: 1796 CL–18 CLUTCH – CLUTCH UNIT CL03K–01 REMOVAL 1. Matchmarks Q10161 REMOVE TRANSAXLE FROM ENGINE (See page E153 MX–4, S51 MX–4) 2. REMOVE CLUTCH COVER AND DISC (a) Place matchmarks on the flywheel and clutch cover. (b) Loosen each set bolt one turn at a time until spring tension is released. (c) Remove the set bolts, and pull off the clutch cover with the clutch disc. NOTICE: Do not drop the clutch disc. 3. 1MZ–FE: (a) (b) REMOVE RELEASE BEARING AND FORK FROM TRANSAXLE Remove the release bearing together with the fork and then separate them. Remove the boot. 5S–FE: Z19000 Author: Date: 1797 CL–19 CLUTCH – CLUTCH UNIT CL03L–01 INSPECTION 1MZ–FE: 1. INSPECT CLUTCH DISC FOR WEAR OR DAMAGE Using calipers, measure the rivet head depth. Minimum rivet depth: 0.3 mm (0.012 in.) If necessary, replace the clutch disc. 5S–FE: Q10090 2. INSPECT CLUTCH DISC RUNOUT Using a dial indicator, check the disc runout. Maximum runout: 0.8 mm (0.031 in.) If necessary, replace the clutch disc. CL0373 3. INSPECT FLYWHEEL RUNOUT Using a dial indicator, check the flywheel runout. Maximum runout: 0.1 mm (0.004 in.) If necessary, replace the flywheel. CL0372 A 4. INSPECT DIAPHRAGM SPRING FOR WEAR Using calipers, measure the diaphragm spring for depth and width of wear. Maximum: Depth A: 0.6 mm (0.024 in.) Width B: 5.0 mm (0.197 in.) If necessary, replace the clutch cover. B Z09915 Author: Date: 1798 CL–20 CLUTCH – CLUTCH UNIT 5. INSPECT RELEASE BEARING Turn the bearing by hand while applying force in the axial direction. HINT: The bearing is permanently lubricated and requires no cleaning or lubrication. If necessary, replace the bearing. N00414 Author: Date: 1799 CL–21 CLUTCH – CLUTCH UNIT CL03M–02 INSTALLATION 1MZ–FE: 1. (a) (b) SST INSTALL CLUTCH DISC AND CLUTCH COVER ON FLYWHEEL 1MZ–FE: Insert SST in the clutch disc, and then set them. SST 09301–00220 5S–FE: Insert SST in the clutch disc, and then set them. SST 09301–00210 Flywheel Side 5S–FE: SST Q10089 3 5 (c) (d) SST 1 Align the matchmarks on the clutch cover and flywheel. Torque the bolts on the clutch cover in the order shown. Torque: 19 N·m (195 kgf·cm, 14 ft·lbf) HINT: Temporarily tighten the No.3 bolt. 6 4 2 Matchmarks Q10084 2. CHECK DIAPHRAGM SPRING TIP ALIGNMENT Using a dial indicator with roller instrument, check the diaphragm spring tip alignment. Maximum non–alignment: 0.5 mm (0.020 in.) If alignment is not as specified, using SST, adjust the diaphragm spring tip alignment. SST 09333–00013 SST Q10072 Author: Date: 1800 CL–22 CLUTCH 3. 1MZ–FE Engine: (a) (b) – CLUTCH UNIT APPLY MOLYBDENUM DISULPHIDE LITHIUM BASE GREASE (NLGI NO.2) Apply release hub grease to these parts: Release fork and hub contact point Release fork and push rod contact point Release fork pivot point Apply clutch spline grease: Clutch disc spline HINT: Recommended grease part number 08887–01706 (100 g). 4. INSTALL RELEASE BEARING AND FORK TO TRANSAXLE Install the bearing to the release fork, and then install them to the transaxle. 5. INSTALL TRANSAXLE TO ENGINE (See page E153 MX–9, S51 MX–8) 5S–FE Engine: Q10091 Author: Date: 1801