Download Common Rail System for ISUZU SERVICE MANUAL OPERATION

Transcript

Diesel Injection Pump

SERVICE MANUAL

Common Rail System for ISUZU

4HK1 / 6HK1 Type Engine

OPERATION

February, 2004

00400056E

FORWARD

To meet the high pressurization requirements for the engine to deliver cleaner exhaust gas emissions, lower fuel

consumption and reduced noise, advanced electronic control technology is being adopted in the fuel injection system.

This manual covers the electronic control model Common Rail system with HP3/HP4 pump for the ISUZU 4HK1/6HK1

type engines which are used to ELF and GM 560 series respectively. Complex theories, special functions and

components made by manufacturers other than DENSO are omitted from this manual.

This manual will help the reader develop an understanding of the basic construction, operation and system configuration

of the DENSO manufactured components and brief diagnostic information.

TABLE OF CONTENTS

1. Product Application . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1-1. Application . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1-2. System Components Parts Numbers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

2. Outline . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

2-1. Outline of System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

2-2. Outline of System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2-3. Fuel System and Control System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

3. Construction and Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

3-1. Description of Main Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

3-2. Description of Control System Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

3-3. Various Types of Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

3-4. Engine ECU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

1.

Product Application

1-1. Application

Vehicle Name

Engine Model

Vehicle model

Exhaust Volume

Reference

ELF

4HK1

N series

5.2L

Direct-Injection

C560 Series

6HK1

GM 560

7.8L

Direct-Injection

1-2. System Components Parts Numbers

Parts Name

Supply Pump

Injector

Rail

Engine ECU

Car Manufacturer Parts

DENSO Parts Number

Reference

Number

294000-0260

8973288860

4HK1

294050-0021

9876020491

6HK1

095000-5351

8976011561

6HK1

095000-5361

8976028031

095000-5471

8973297031

4HK1

095440-0351

8973060632

4HK1

095440-0470

8973230190

6HK1

275800-2801

8151794773

6HK1

275800-2812

8973750190

4HK1

275800-2822

8973750200

-1-

2.

Outline

2-1. Outline of System

•

The common rail system was developed primarily to cope with exhaust gas regulations for diesel engines, and aimed for

1. further improved fuel economy; 2. noise reduction; and 3. high power output.

A. System Characteristics

• The common rail system uses a type of accumulation chamber called a rail to store pressurized fuel, and injectors that

contain electronically controlled solenoid valves to spray the pressurized fuel into the cylinders.

• Because the engine ECU controls the injection system (including the injection pressure, injection rate, and injection timing), the injection system is unaffected by the engine speed or load.

• This ensures a stable injection pressure at all times, particularly in the low engine speed range, and dramatically decreases the amount of black smoke ordinarily emitted by a diesel engine during start-up and acceleration.

• As a result, exhaust gas emissions are cleaner and reduced, and higher power output is achieved.

a.

Injection Pressure Control

• Enables high-pressure injection even at low engine speeds.

• Optimizes control to minimize particulate matter and NOx emissions.

b.

Injection Timing Control

Enables finely tuned optimized control in accordance with driving conditions.

c.

Injection Rate Control

Pilot injection control sprays a small amount of fuel before the main injection.

Common Rail System

Optimization, High Pressurization

Optimization

Common Rail System

Speed

Injection Timing

NOx

Conventional

Pump

Particulate

Injection Pressure

Common Rail System

Injection

Pressure

Injection Rate Control

Injection Rate

Injection Timing Control

Pilot Injection

Main

injection

Crankshaft Angle

Injection Quantity Control

Conventional

Pump

Speed

Cylinder Injection

Volume Correction

Speed

Injection Pressure Control

㧝 㧟 㧠 㧞

QD0734E

d.

EGR (Exhaust Gas Recirculation) Control

By recirculating the exhaust gas into the intake side of the engine, the combustion temperature is reduced and NOx is

decreased.

-2-

B. Comparison to the Conventional System

Common Rail System

In-line, VE Pump

High-pressure Pipe

Rail

Momentary High Pressure

Timer

TWV

Nozzle

Supply Pump

Usually High Pressure

Delivery Valve

Governor

System

In-line Pump

Feed Pump SCV (Suction Control Valve)

Injector

Fuel Tank

VE Pump

Injection Quantity Control

Pump (Governor)

Engine ECU, Injector (TWV)*1

Injection Timing Control

Rising Pressure

Distributor

Pump (Timer)

Engine ECU, Injector (TWV)*1

Engine ECU, Supply Pump

Injection Pressure Control

Pump

Pump

Dependent upon Speed and Injection Quantity

Engine ECU, Rail

Engine ECU, Supply Pump (SCV)*2

*1 TWV: Two Way Valve *2 SCVSuction Control Valve

-3-

QD2341E

2-2. Outline of System

A. Composition

The common rail system consists primarily of a supply pump, rail, injectors, and engine ECU.

a.

4HK1

Fuel temperature sensor

Vehicle speed

Accelerator opening

Intake air pressure

Intake air temperature

Coolant temperature

Crankshaft position

Cylinder recognition sensor

Engine ECU

Intake airflow rate

Rail

Pressure

limiter

Injector

Rail pressure

sensor

Fuel temperature

sensor

Supply pump

SCV (suction

control valve)

Fuel tank

Q000737E

b.

6HK1

Fuel temperature sensor

Vehicle speed

Accelerator opening

Intake air pressure

Intake air temperature

Coolant temperature

Crankshaft position

Cylinder recognition sensor

Engine ECU

Intake airflow rate

Rail

Pressure

limiter

Injector

Rail pressure

sensor

Fuel temperature

sensor

Supply pump

SCV (suction

control valve)

Fuel tank

Q000523E

-4-

B. Operation

a.

Supply pump (HP3/HP4)

The supply pump draws fuel from the fuel tank, and pumps the high pressure fuel to the rail. The quantity of fuel discharged from the supply pump controls the pressure in the rail. The SCV (Suction Control Valve) in the supply pump

effects this control in accordance with the command received from the ECU.

b.

Rail

The rail is mounted between the supply pump and the injector, and stores the high pressure fuel.

c.

Injector (G2 type)

• This injector replaces the conventional injection nozzle, and achieves optimal injection by effecting control in accordance

with signals from the ECU. Signals from the ECU determine the length of time and the timing in which current is applied

to the injector.

• This in turn, determines the quantity, rate and timing of the fuel that is injected from the injector.

d.

Engine ECU

The engine ECU calculates data received from the sensors to comprehensively control the injection quantity, timing and

pressure, as well as the EGR (exhaust gas recirculation).

2-3. Fuel System and Control System

A. Fuel System

This system comprises the route through which diesel fuel flows from the fuel tank to the supply pump, via the rail, and

is injected through the injector, as well as the route through which the fuel returns to the tank via the overflow pipe.

B. Control System

In this system, the engine ECU controls the fuel injection system in accordance with the signals received from various

sensors. The components of this system can be broadly divided into the following three types: (a.) Sensors; (b.) Engine

ECU; and (c.) Actuators.

a.

Sensors

Detect the engine and driving conditions, and convert them into electrical signals.

b.

Engine ECU

Performs calculations based on the electrical signals received from the sensors, and sends them to the actuators in order

to achieve optimal conditions.

c.

Actuators

Operate in accordance with electrical signals received from the ECU. Injection system control is undertaken by electronically controlling the actuators. The injection quantity and timing are determined by controlling the length of time and the

timing in which the current is applied to the TWV (Two-Way Valve) in the injector. The injection pressure is determined

by controlling the SCV (Suction Control Valve) in the supply pump.

Sensor (*1 : DENSO products)

Actuator

EGR is produced

by other manufactures.

Engine Speed

Crankshaft Position Sensor NE

Injector

Cylinder Recognition

•Injection Quantity Control

•Injection Timing Control

Cylider Recognition Sensor G

Accelerator Position Sensor

Load

Engine

ECU

Supply Pump (SCV)

•Injection Pressure Control

Rail Pressure Sensor (*1)

EGR, Engine Warning Light

Other Sensors and Switches

Q000524E

-5-

3.

Construction and Operation

3-1. Description of Main Components

A. Supply Pump (HP3, HP4)

a.

Outline

The supply pump consists primarily of the pump body (cam shaft, ring cam, and plungers), SCV (Suction Control Valve),

fuel temperature sensor, and feed pump.

HP3

SCV

Fuel Temperature Sensor

Q000525E

HP4

Fuel Temperature Sensor

SCV

Q000526E

• The two plungers for HP3 or the three plungers for HP4 are positioned vertically on the outer ring cam for compactness.

• The engine drives the supply pump at a ratio of 1:1. The supply pump has a built-in feed pump (trochoid type), and draws

the fuel from the fuel tank, sending it to the plunger chamber.

-6-

• The internal camshaft drives the two plungers, and they pressurize the fuel sent to the plunger chamber and send it to

the rail. The quantity of fuel supplied to the rail is controlled by the SCV, using signals from the engine ECU. The SCV is

a normally opened type (the intake valve opens during de-energization).

Injector

Discharge Valve

Rail

Intake Pressure

Feed Pressure

High Pressure

Return Pressure

Intake Valve

Plunger

Return Spring

Return

SCV

Fuel Overflow

Regulating Valve

Feed Pump

Filter

Fuel Inlet

Camshaft

Intake

Fuel Filter (with Priming Pump)

Fuel Tank

QD0704E

-7-

• Development: HP3

SCV

Plunger

Feed Pump

Pump Body

Fuel Temperature

Sensor

Ring Cam

Regulating

Valve

Drive Shaft

Filter

Plunger

Q000527E

-8-

• Development: HP4

SCV

Plunger

Fuel Temperature

Sensor

Filter

Feed Pump

Ring Cam

Regulating

Valve

Pump Body

Drive Shaft

Plunger

Q000528E

-9-

b.

Supply Pump Internal Fuel Flow

The fuel that is drawn from the fuel tank passes through the route in the supply pump as illustrated, and is fed into the rail.

Supply Pump Interior

Regulating Valve

Feed Pump

Overflow

SCV (Suction Control Valve)

Pumping Portion (Plunger)

Rail

Intake Valve

Fuel Tank

Q000283E

c.

Construction of Supply Pump (in case of HP3 pump)

• The eccentric cam is attached to the cam shaft. The eccentric cam is connected to the ring cam.

Cam Shaft

Eccentric Cam

Ring Cam

QD0706E

• As the cam shaft rotates, the eccentric cam rotates eccentrically, and the ring cam moves up and down while rotating.

Plunger

Eccentric Cam

Ring Cam

Cam Shaft

QD0727E

-10-

• The plunger and the suction valve are attached to the ring cam. The feed pump is connected to the rear of the cam shaft.

Plunger A

Ring Cam

Feed Pump

Plunger B

-11-

QD0728E

d.

Operation of the Supply Pump

• As shown in the illustration below (in case of HP3 pump), the rotation of the eccentric cam causes the ring cam to push

Plunger A upwards. Due to the spring force, Plunger B is pulled in the opposite direction to Plunger A.

• As a result, Plunger B draws in fuel, while Plunger A pumps it to the rail. In the case of the 4-cylinder engine used with

the HP3 pump, each plunger pumps fuel in a reciprocal movement during the 360° cam rotation.

• Conversely, in the case of the 6-cylinder engine used with the HP4 pump, 3 plungers pump fuel in a reciprocal movement

for each one rotation of the cam.

Suction Valve

Delivery Valve

Plunger A

Eccentric Cam

Ring Cam

SCV

Plunger B

Plunger B: Complete Intake

Plunger A: Begin Intake

Plunger B: Begin Compression

Plunger A: Begin Compression

Plunger B: Begin Intake

Plunger A: Complete Intake

Plunger B: Complete Compression

Plunger A: Complete Compression

QD0707E

< NOTE >

• There are 3 plungers for the HP4.

-12-

B. Description of Supply Pump Components

a.

Feed Pump

• The trochoid type feed pump, which is integrated in the supply pump, draws fuel from the fuel tank and feeds it to the

two plungers via the fuel filter and the SCV (Suction Control Valve).

• The feed pump is driven by the drive shaft. With the rotation of the inner rotor, the feed pump draws fuel from its suction

port and pumps it out through the discharge port.

• This is done in accordance with the space that increases and decreases with the movement of the outer and inner rotors.

Quantity Decrease

Outer Rotor

to Pump Chamber

Quantity Decrease (Fuel Discharge)

Inner Rotor

Intake Port

from Fuel Tank

b.

Discharge

Port

Quantity Increase

Quantity Increase (Fuel Intake)

QD0708E

SCV: Suction Control Valve (Normally open type)

• A linear solenoid type valve has been adopted. The ECU controls the duty ratio (the duration in which current is applied

to the SCV), in order to control the quantity of fuel that is supplied to the high-pressure plunger.

• Because only the quantity of fuel that is required for achieving the target rail pressure is drawn in, the actuating load of

the supply pump decreases.

• When current flows to the SCV, variable electromotive force is created in accordance with the duty ratio, moving the armature to the left side. The armature moves the cylinder to the left side, changing the opening of the fuel passage and

thus regulating the fuel quantity.

• With the SCV OFF, the return spring contracts, completely opening the fuel passage and supplying fuel to the plungers.

(Full quantity intake and full quantity discharge)

• When the SCV is ON, the force of the return spring moves the cylinder to the right, closing the fuel passage (normally

opened).

• By turning the SCV ON/OFF, fuel is supplied in an amount corresponding to the actuation duty ratio, and fuel is discharged by the plungers.

Exterior View of SCV

Cross-section of SCV

SCV

Return Spring

Pump Body

Cylinder

Q000270E

(1)

In case of short time ON duty

-13-

Short time ON duty => large valve opening => maximum intake quantity

Feed Pump

Plunger

SCV

Cylinder

Large Opening

Cylinder

Q000051E

-14-

(2)

In case of long time ON duty

Long time ON duty => small valve opening => minimum intake quantity

Feed Pump

Plunger

SCV

Cylinder

Small Opening

Cylinder

Q000052E

-15-

C. Rail

a.

Outline

• Stores pressurized fuel (0 to 160 MPa {0 to 1631.6 kg/cm2}) that has been delivered from the supply pump and distributes

the fuel to each cylinder injector. A rail pressure sensor and a pressure limiter are adopted in the rail.

• The rail pressure sensor (Pc sensor) detects the fuel pressure in the rail and sends a signal to the engine ECU, the pressure limiter prevents the rail pressure from being abnormally high. This ensures optimum combustion and reduces combustion noise.

For 4HK1

Pressure Sensor

Pressure Limiter

Q000529E

For 6HK1

Pressure Limiter

Pressure Sensor

Q000530E

-16-

b.

Pressure Limiter

• The pressure limiter opens to release the pressure if an abnormally high pressure is generated.

• When the rail pressure reaches approximately 200 MPa (2038 kg/cm2), it trips the pressure limiter (the valve opens).

When the pressure drops to approximately 50 MPa (509.5 kg/cm2), the pressure limiter returns to its normal state (the

valve closes) in order to maintain the proper pressure.

: 4HK1 200 ± 9 MPa

(2038 ± 92 kg/cm2)

: 6HK1 221 ± 9 MPa

(2254 ± 92 kg/cm2)

Valve Open

Valve Close

50 MPa (509.5 kg/cm2)

Q000531E

c.

Pressure Sensor

• The rail pressure sensor (Pc sensor) is attached to the rail in order to detect the fuel pressure.

• It is a semiconductor type pressure sensor that utilizes the characteristics of silicon, whereby the electrical resistance

changes when pressure is applied to it.

4.2 V

VC

VOUT

1.0 V

GND

0

200 MPa (2038 kg/cm2)

Q000532E

< NOTE >

• It is necessary to reset the ECU default value using the ISUZU diagnosis tool at the time of supply pump service replacement. In addition, the ECU has a function enabling it to learn the performance of the supply pump at the time of ECU

service replacement, so ensure sufficient time (several minutes) is available.

-17-

d.

Flow Damper

• The flow dampers are installed at the outlet of rail to damp a pulsation of fuel pressure inside the rail or to cut off the fuel

supply when the fuel leaks in the downstream of flow damper. The fuel is supplied to the injectors through an orifice of

the piston. The pressure pulsation occurring in the rail is damped by a resistive force of the return spring (5) and a passing

resistance of the orifice (2), wherein the piston (4) acts as a damper. (Refer to the picture B)

• Also, the leading end of piston (4) closes an fuel supply port to cut off the fuel supply, if the fuel leak occurs in the injection

pipe or injectors, and the fuel pressure on the downstream side of flow damper supplied through an orifice (2) + resistive

force of return spring (5) do not balance with the fuel pressure applied on the piston (4) surface prior to the orifice (2).

(Refer to the picture C)

• The piston (4) will return when the fuel pressure inside the rail less than 1.0 MPa (10.2 kgf/cm2).

(2) Orifice (3) Slit

(4) Piston

(6) Housing

(5) Return Spring

(1) From Rail

A

B

(7) To Injector

C

Q000742E

-18-

D. Injector (G2 Type)

a.

Outline

The injectors inject the high-pressure fuel from the rail into the combustion chambers at the optimum injection timing,

rate, and spray condition, in accordance with commands received from the ECU.

b.

Characteristics

• A compact, energy-saving solenoid-control type TWV (Two-Way Valve) injector has been adopted.

• QR codes displaying various injector characteristics and the ID codes showing these in numeric form (30 base 16 characters) are engraved on the injector head. The 4HK1/6HK1 engine common rail system optimizes injection volume control using this information. When an injector is newly installed in a vehicle, it is necessary to enter the ID codes in the

engine ECU using the ISUZU Diagnostic tool.

c.

Construction

QR Codes

30 base 16 characters

Solenoid Valve

Control Chamber

Pressurized Fuel

(from Rail)

Command Piston

Nozzle Spring

Pressure Pin

Nozzle Needle

Q000533E

-19-

d.

QR Codes

• In order to minimize performance tolerance of injectors at replacing them, QR*1 (Quick Response) codes have been

adopted to enhance correction precision.

• Using QR codes has resulted in a substantial increase in the number of fuel injection quantity correction points, and thus

the injection quantity control precision has improved. The characteristics of the engine cylinders have been further unified, contributing to improvements in combustion efficiency, reductions in exhaust gas emissions and so on.

< NOTE >

• QR code correction points

Injection quantity Q

Pressure Parameter

QR code on the injector connector

Actuating pulse width TQ

Q000670E

•

Location of QR codes

QR Codes (

9.9mm)

ID Codes

(30 alphanumeric figures)

Base 16 characters noting fuel

injection quantity correction

information for market service use.

Q000534E

e.

Repair Procedure Changes

• Differences in comparison with the conventional method of replacing injectors assembly are as shown below.

< NOTE >

• When replacing injectors with QR codes, or the engine ECU, it is necessary to record the ID codes (QR codes) in the

ECU. (If the ID codes of the installed injector are not registered correctly, engine failure such as rough idling and noise

will result.)

• New (Injector with QR Codes)

30 base 16 characters noting fuel injection quantity correction

information displaed for market service use

ID Code

Q000535E

-20-

• Replacing the Injector

"No correction resistance, so no electrical recognition capability"

Spare Injector

Engine ECU

* Necessary to record the injector ID codes in Engine ECU

QD1536E

• Replacing the Engine ECU

"No correction resistance, so no electrical recognition capability"

Vehicle-side Injector

Spare Engine ECU

* Necessary to record the injector ID codes in the engine ECU

QD1537E

E. Engine ECU (Electronic Control Unit)

a.

Outline

This is the command center that controls the fuel injection system and engine operation in general.

Outline Diagram

Sensor

Engine ECU

Actuator

Detection

Calculation

Actuation

QD2352E

-21-

3-2. Description of Control System Components

A. Engine Control System Diagram

Intake Air Temperature Sensor

Intake Air Pressure Sensor

Mass Airflow Meter

Inter-Cooler

G2 Injector

EGR Cooler

EGR

Valve

VNT

Controller

VNT Actuator

Coolant

Oxidation Catalyst

Q000536E

a.

Fuel Temperature Sensor (THL)

• The fuel temperature sensor detects the fuel temperature and outputs it to the ECU. The sensor uses a thermistor, which

varies resistance according to temperature.

• As the ECU applies voltage to the thermistor, it uses a voltage resulting from the division of the computer internal resistance and the thermistor resistance to detect the temperature.

VTHL (V)

ECU

5

+5V

4

VTHL

3

Output Voltage

2

1

A-GND

0

THL

-40 -20

-40 -4

0

32

20 40 60 80 100 120 (°C)

68 104 140 176 212 248 (°F)

Fuel Temperature

-22-

Q000106E

b.

Atmospheric Air Pressure Sensor (Built-in ECU)

This sensor converts the atmospheric air pressure into an electrical signal to correct full load injection volume.

VPATM

Output Voltage (V)

3.8

107 {1.09}

Atmospheric Air Pressure (kPa {kg/cm2})

-23-

Q000278E

3-3. Various Types of Control

•

This system controls the fuel injection quantity and injection timing more optimally than the mechanical governor or timer

used in conventional injection pumps.

•

For system control, the ECU makes the necessary calculations based on signals received from sensors located in the

engine and on the vehicle in order to control the timing and duration in which current is applied to the injectors, thus realizing optimal injection timing.

A. Fuel Injection Rate Control Function

The fuel injection rate control function controls the ratio of the quantity of fuel that is injected through the nozzle hole

during a specified period.

B. Fuel Injection Quantity Control Function

The fuel injection quantity control function, replaces the conventional governor function, and controls fuel injection to

achieve an optimal injection quantity based on the engine speed and the accelerator opening.

C. Fuel Injection Timing Control Function

The fuel injection timing control function, replaces the conventional timer function, and controls the fuel injection to

achieve an optimal injection timing according to the engine speed and the injection quantity.

D. Fuel Injection Pressure Control Function (Rail Pressure Control Function)

• The fuel injection pressure control function (rail pressure control function) uses a rail pressure sensor to measure fuel

pressure, and feeds this data to the ECU to control the pump discharge quantity.

• Pressure feedback control is implemented to match the optimal quantity (command quantity) set according to the engine

speed and the fuel injection quantity.

Input Signal (*1 : DENSO products)

Control Output

Accelerator sensor

Fuel Injection Rate Control

NE Sensor

(Crankshaft Position Sensor)

Fuel Injection Quantity Control

TDC Sensor

(Cylinder Recognition Sensor)

Fuel Control Computer

(ECU)

Fuel Injection Timing Control

Rail Pressure Sensor (*1)

Fuel Injection Pressure Control

Various Sensors (*1)

·Water Temperature Sensor

·Fuel Temperature Sensor

·Atmospheric Air Temperature

Sensor etc.

Atmospheric Air

Pressure Sensor

Diagnosis

Q000537E

-24-

E. Fuel Injection Rate Control

a.

Main Injection

Same as conventional fuel injection.

b.

Pilot Injection

• Pilot injection is the injection of a small amount of fuel prior to the main injection.

Main Injection

Pilot Injection

Q000110E

• While the adoption of higher pressure fuel injection is associated with an increase in the injection rate, the lag (injection

lag) that occurs from the time fuel is injected until combustion starts cannot be reduced below a certain value. As a result,

the quantity of fuel injected before ignition increases, resulting in explosive combustion together with ignition, and an increase in the amount of NOx and noise. Therefore, by providing a pilot injection, the initial injection rate is kept to the

minimum required level dampening, the explosive first-period combustion and reducing NOx emissions.

TDC

Combustion

Process

Small Injection Amount

Prior to Ignition

High Injection

Rate

Pilot Injection

Improvement

Injection Rate

Large Pre-mixture

Combustion

(NOx, Noise)

Small Pre-mixture

Combustion

Heat Generation

Rate

Ignition Delay

Q000111E

-25-

F. Fuel Injection Quantity Control

a.

Starting Injection Quantity

The injection quantity is determined based on the engine speed (NE) and water temperature while starting.

Starting Injection Quantity

Water Temperature

Engine Speed

Q000127E

b.

Transient Injection Quantity Correction

When the changes in the accelerator opening are great during acceleration, the increase in fuel volume is delayed to

inhibit the discharge of black smoke.

Injection Quantity

Change in Accelerator Opening

Injection Quantity after Correction

Delay Time

Time

Q000128E

c.

Basic Injection Quantity

• This quantity is determined in accordance with the engine speed (NE) and the accelerator opening.

• Increasing the accelerator opening while the engine speed remains constant causes the injection quantity to increase.

Basic Injection Quantity

Accelerator Opening

Engine Speed

Q000129E

-26-

d.

Injection Quantity for Maximum Speed Setting

The injection quantity is regulated by a value that is determined in accordance with the engine speed.

Injection Quantity for Maximum Speed Setting

Engine Speed

Q000130E

e.

Maximum Injection Quantity

Is determined in accordance with the engine speed and corrected by the coolant temperature signal.

Basic Maximum Injection Quantity

Engine Speed

Q000131E

f.

Amount of Injection Quantity Intake Pressure Correction

Limits the maximum injection quantity in accordance with the intake pressure, in order to minimize the discharge of

smoke when the intake air pressure is low.

Amount of Intake Air Pressure Correction

Engine Speed

-27-

Q000133E

g.

Amount of Injection Quantity by Atmospheric Air Pressure Correction

With using atmospheric air pressure sensor signal, the maximum injection quantity curve is corrected as shown in the

figure below.

Amount of Atmospheric Air Pressure Correction

Engine Speed

h.

Q000134E

Idle Speed Control System (ISC)

Controls the idle speed by regulating the injection quantity in order to match the target speed, which has been calculated

by the computer, with the actual speed. The functions of the ISC can be broadly divided into the following two items:

(1)

Auto ISC

Controls the idle speed in accordance with the water temperature.

Target Speed

Water Temperature

Q000135E

(2)

Manual ISC

Controls the idle speed in accordance with the idle speed indicated on the manual idle setting knob provided at the driver's seat.

Target Speed

ISC Knob Terminal Voltage

Q000136E

-28-

(3)

Air Conditioner Idle-up Control

When the conditions shown in the chart on the right are realized, bring the idle-up speed to constant rpm.

Conditions

Air Conditioning SW = "ON"

Clutch SW = "ON" (Clutch Connection)

Neutral SW = "ON" (Neutral)

Q000137E

i.

Auto Cruise Control

• Controls the actual vehicle speed by regulating the injection quantity in order to match the target speed that has been

calculated by the computer with the actual speed.

• The CRS ECU controls the injection quantity in accordance with signals from the cruise control computer.

-29-

G. Fuel Injection Timing Control

The characteristics of the fuel injection timing vary depending on whether it is the main injection or the pilot injection.

Although either the NE sensor or the auxiliary NE sensor is the reference for controlling the injection timing, the NE sensor is ordinarily used for this purpose.

a.

Main Injection Timing

• The basic injection timing is calculated in accordance with the final injection quantity, the engine speed, and the water

temperature (with map correction).

• While starting, it is calculated in accordance with the water temperature and the engine speed.

Basic Injection Timing

Final Injection Quantity

Engine Speed

Q000138E

b.

Pilot Injection timing (Pilot Interval)

• The pilot injection timing is controlled by adding the pilot interval to the main injection timing.

• The pilot interval is calculated in accordance with the final injection quantity, the engine speed, and the water temperature

(with map correction).

• While starting, it is calculated in accordance with the water temperature and the engine speed.

Pilot Interval

Final Injection Quantity

Engine Speed

Q000139E

c.

Fuel Injection Pressure

• A value is calculated as determined in accordance with the final injection quantity and the engine speed.

• While starting, it is calculated in accordance with the water temperature and the engine speed.

Rail Pressure

Final Injection Quantity

Engine Speed

Q000140E

-30-

3-4. Engine ECU

A. Diagnosis Codes

a.

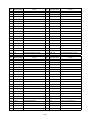

4HK1

DTC Code

Code Description

P0643

Analog Sensor Reference Voltage Output No.1 Too High

P0642

Analog Sensor Reference Voltage Output No.1 Too Low

P0653

Analog Sensor Reference Voltage Output No.2 Too High

P0652

Analog Sensor Reference Voltage Output No.2 Too Low

P0699

Analog Sensor Reference Voltage Output No.3 Too High

P0698

Analog Sensor Reference Voltage Output No.3 Too Low

P0118

Coolant Temp. Sensor Signal Too High

P0117

Coolant Temp. Sensor Signal Too Low

P0113

Intake Air Temp. Sensor Signal Too High

P0112

Intake Air Temp. Sensor Signal Too Low

P0183

Fuel Leak Temp. Sensor Signal Too High

P0182

Fuel Leak Temp. Sensor Signal Too Low

P0113

ATM Temp. Sensor Signal Too High

P0112

ATM Temp. Sensor Signal Too Low

P0193

C/Rail Press. Sensor Signal Too High

P0192

C/Rail Press. Sensor Signal Too Low

P2229

Atom Press. Sensor Signal Too High

P2228

Atom Press. Sensor Signal Too Low

P0238

Boost Pressure Sensor Signal Too High

P0237

Boost Pressure Sensor Signal Too Low

P0563

Ignition1 Voltage Too High

P0562

Ignition1 Voltage Too Low

P0103

MAF Sensor Signal Too High

P0102

MAF Sensor Signal Too Low

P1597

PTO Accelerator Sensor Signal Too High

P1594

Idleup Signal Too High

P1593

Idleup Signal Too Low

P0406

EGR Position Signal Too High

P0405

EGR Position Signal Too Low

P0571

Cruise / Brake Switch Circuit Malfunction

P0567

Cruise Resume / Accelerator Signal

P0568

Cruise Set / Coast Signal Malfunction

P0335

Crank Sensor No Pulse

P0340

Cam Sensor No Pulse

P0092

SCV (+) output short to BATT

SCV (-) output short to BATT

-31-

DTC Code

P0091

Code Description

SCV (+) output open Load / short to GND

SCV (-) output open Load / short to GND

SCV coil open

P1264

COM1 output short to BATT;

TWV1 or 3 (or 5) output short to BATT

P1263

COM1 output short to GND;

TWV1 or 3 (or 5) output short to GND

P2152

COM1 output open load;

Both TWV1 or 3 (or 5) output open load

P1266

COM2 output short to BATT;

TWV2 or 4 (or 6) output short to BATT

P1265

COM2 output short to GND;

TWV2 or 4 (or 6) output short to GND

P2155

COM2 output open load;

Both TWV2 or 4 (or 6) output open load

P0201

TWV1 output open load

Injector#1 coil open

P0202

TWV2 output open load

Injector#3 coil open

P0203

TWV3 output open load

Injector#4 coil open

P0204

TWV4 output open load

Injector#2 coil open

P1261

Capacitor charge-up circuit malfunction (insufficient charge)

P1261

Capacitor charge-up circuit malfunction (excessive charge)

P0088

Common rail pressure exceeds upper

P0088

Common rail pressure exceeds hi upper limit

P0382

Glow Controller Command Line Short to BATT

P0382

Glow Controller Command Line Open Load / Short to GND

P1094

C/Rail Press. Sensor Performance Invalid included fuel leak

P0087

P/L (pressure limiter) activated

P1404

EGR Position Error

P0400

EGR Duty Error

P0500

Vehicle Speed Sensor Malfunction

P0606

CPU fault;

-Main CPU fault

P0606

CPU fault;

-Watchdog IC fault

P0602

EEPROM/EERPOM Emulation via Flash EPROM Write Error

P0219

Engine overrun

P0512

Starter Switch Short to BATT

-32-

DTC Code

P0686

Code Description

Main relay diagnostics;

Main relay stuck closed

P0089

Supply pump control valve (suction control valve) stuck

P0299

Boost Pressure Sensor exceeds lower limit

P0234

Boost Pressure Sensor exceeds upper limit

P2293

Supply pump protection

P2294

Supply pump exchange

P1093

Supply pump malfunction

P2122

Accelerator Pedal Position Sensor 1 Low Voltage

P2123

Accelerator Pedal Position Sensor 1 High Voltage

P2127

Accelerator Pedal Position Sensor 2 Low Voltage

P2128

Accelerator Pedal Position Sensor 2 High Voltage

P2132

Accelerator Pedal Position Sensor 3 Low Voltage

P2133

Accelerator Pedal Position Sensor 3 High Voltage

P1125

Pedal Position Sensor Circuit Intermittent

P2138

Accelerator Pedal Position Sensor 1, 2 Correlation Error

P2140

Accelerator Pedal Position Sensor 2, 3 Correlation Error

P2139

Accelerator Pedal Position Sensor 1, 3 Correlation Error

U2104

CAN Bus Error

U2106

CAN TCM SOH Diagnostic

P0602

QR Code Not Programmed

P0602

QR Code ERROR

-33-

b.

6HK1

DTC Code

Code Description

P0641

Analog Sensor Reference Voltage Output No.1 Too High

P0641

Analog Sensor Reference Voltage Output No.1 Too Low

P0651

Analog Sensor Reference Voltage Output No.2 Too High

P0651

Analog Sensor Reference Voltage Output No.2 Too Low

P1646

Analog Sensor Reference Voltage Output No.3 Too High

P1646

Analog Sensor Reference Voltage Output No.3 Too Low

P0118

Coolant Temp. Sensor Signal Too High

P0117

Coolant Temp. Sensor Signal Too Low

P0113

Intake Air Temp. Sensor Signal Too High

P0112

Intake Air Temp. Sensor Signal Too Low

P0183

Fuel Leak Temp. Sensor Signal Too High

P0182

Fuel Leak Temp. Sensor Signal Too Low

P0523

Oil Press. Sensor Signal Too High

P0522

Oil Press. Sensor Signal Too Low

P0463

Fuel Level Sensor1 Signal Too High

P0462

Fuel Level Sensor1 Signal Too Low

P1433

Fuel Level Sensor2 Signal Too High

P1432

Fuel Level Sensor2 Signal Too Low

P0193

C/Rail Press. Sensor Signal Too High

P0192

C/Rail Press. Sensor Signal Too Low

P0190

C/Rail Press. Sensor Signal keeping the middle range

P0108

Atom Press. Sensor Signal Too High

P0107

Atom Press. Sensor Signal Too Low

P0238

Boost Pressure Sensor Signal Too High

P0237

Boost Pressure Sensor Signal Too Low

P0563

Ignition1 Voltage Too High

P0562

Ignition1 Voltage Too Low

P2003

MAF Sensor Signal Too High

P2004

MAF Sensor Signal Too Low

P2005

PTO Accelerator Sensor Signal Too High

P2007

VNT Current Too High

P2008

VNT Current Too Low

P0704

Clutch Pedal Switch Circuit

P0571

Cruise / Brake Switch Circuit Malfunction

P0571

Cruise / Brake Switch Circuit Malfunction

P0567

Cruise Resume / Accelerator Signal

P0568

Cruise Set / Coast Signal Malfunction

P0335

Crank Sensor No Pulse

P0385

Cam Sensor No Pulse

-34-

DTC Code

P0092

Code Description

SCV (+) output short to BATT

SCV (-) output short to BATT

P0091

SCV (+) output open Load / short to GND

SCV (-) output open Load / short to GND

SCV coil open

P1264

COM1 output short to BATT;

TWV1 or 3 (or 5) output short to BATT

P1263

COM1 output short to GND;

TWV1 or 3 (or 5) output short to GND

P2011

COM1 output open load;

Both TWV1 or 3 (or 5) output open load

P1266

COM2 output short to BATT;

TWV2 or 4 (or 6) output short to BATT

P1265

COM2 output short to GND;

TWV2 or 4 (or 6) output short to GND

P2012

COM2 output open load;

Both TWV2 or 4 (or 6) output open load

P0201

TWV1 output open load

Injector#1 coil open

P0202

TWV2 output open load

Injector#5 coil open

P0203

TWV3 output open load

Injector#3 coil open

P0204

TWV4 output open load

Injector#6 coil open

P0205

TWV5 output open load

Injector#2 coil open

P0206

TWV6 output open load

Injector#4 coil open

P1261

Capacitor charge-up circuit malfunction (insufficient charge)

P1261

Capacitor charge-up circuit malfunction (excessive charge)

P1088

Common rail pressure exceeds hi upper limit

P0382

Glow Controller Command Line Short to BATT

P0382

Glow Controller Command Line Open Load / Short to GND

P0500

Vehicle Speed Sensor Malfunction

P0087

C/Rail Press. Sensor Performance Invalid included fuel leak

P1087

P/L (pressure limiter) activated

P2565

VNT Position Signal Too high

P2564

VNT Position Signal Too low

P2900

VNT Position Stick

P2901

EGR Brushless motor Position Sensor Signal Invalid

P2902

EGR Brushless motor Performance Error

-35-

DTC Code

Code Description

P2903

EGR Valve open/Close Stick

P0606

CPU fault;

-Main CPU fault

P0606

CPU fault;

-Watchdog IC fault

P1621

EEPROM/EERPOM Emulation via Flash EPROM Write Error

P0219

Engine overrun

P0512

Starter Switch Short to BATT

P2920

Main relay diagnostics;

Main relay stuck closed

P0088

Supply pump control valve (suction control valve) stuck

P0234

Boost Pressure Sensor exceeds upper limit

P0234

Boost Pressure Sensor exceeds upper limit (Long time)

P2921

Supply pump protection

P2922

Supply pump exchange

P2923

Supply pump malfunction

P1277

Accelerator Pedal Position Sensor 1 Low Voltage

P1278

Accelerator Pedal Position Sensor 1 High Voltage

P1282

Accelerator Pedal Position Sensor 2 Low Voltage

P1283

Accelerator Pedal Position Sensor 2 High Voltage

P1287

Accelerator Pedal Position Sensor 3 Low Voltage

P1288

Accelerator Pedal Position Sensor 3 High Voltage

P1125

Pedal Position Sensor Circuit Intermittent

P1271

Accelerator Pedal Position Sensor 1, 2 Correlation Error

P1272

Accelerator Pedal Position Sensor 2, 3 Correlation Error

P1273

Accelerator Pedal Position Sensor 1, 3 Correlation Error

U1300

Class2 Bus Short to Ground

U1301

Class2 Bus Short to Battery

U2104

CAN Bus Error

P0461

Fuel Level Sensor Circuit Performance

P0602

QR Code Not Programmed

P0602

QR Code ERROR

-36-

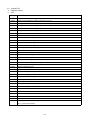

B. ECU External Wiring Diagram

a.

4HK1 Diagram (1)

STARTER RELAY

START

KEY SW

A

ON

STA-SW

IG1-SW

ACC

LOCK

A

STAEN-REL

MAIN-RELAY

C

STARTER CUT RELAY

M-REL

ECU

M-REL

+B

SCVHI

+B

B

+B

SCVHI

SCV

C

A

SCVLO

GL-CONT

+

SCVLO

GLOW-RELAY

BATTERY

-

(GM1-FB)

CRANK

POSITION

SENSOR

NE+

(GM2-FB)

NE-

(GM3-FB)

NE-SLD

(GM4-FB)

SPEED

SENSOR

SPD

AT

BATT

A

METER

BK1-SW

A

G-VB

BK2-SW

G

CRM-SW

G-SLD

PB-VCC

CRR-SW

PBOOST

PB-GND

CRS-SW

TAP DOWN

CAM ANGLE

SENSOR

(HALL)

BOOST

PRESSURE

SENSOR

TAP UP

PFUEL-VCC

PFUEL

PFUEL

RAIL

PRESSURE

SENSOR

PFUEL-GND

PTOEN-SW

APS1-VCC

PTO SW

PTOEN-REL

APS1

APS1

APS1-GND

PTOFB-SW

PTO ENABLE RELAY

APS2-VCC

OPTION

APS2

APS2

APS2-GND

PTODIS-SW

APS3-VCC

SHUTDOWN-SW

APS3

APS3

APS3-GND

RSET-SW

IDLUP-VCC

RRES-SW

IDLUP

IDLUP-GND

IDLE UP

VOLUME

SSPA-SW

SSPB-SW

CCDIS-SW

PACL-VCC

PACL

PACL-GND

PTO ACCEL

SENSOR

(TQLIM-SW)

(SP2)

IGBC-SW

(SP2-GND)

CL-SW

(TQCUT-SW)

FUEL-SW *1

(SP1-VCC)

(SP1)

(SP1-GND)

Q000538E

-37-

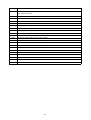

4HK1 Diagram (2)

DIAG CLEAR-SW (LOL-SW)

(POIL-VCC)

REF-SW

(POIL)

POIL-GND

AC-SW

ECU

(FQ1)

THF1

FUEL TEMP

(THF2)

INTAKE AIR TEMP

B

(INCA-BAT)

MAF

(INCA-GND)

MAF

MAF-GND

THWOUT

(SP3-GND)

TACHO

(SP3)

(ATMT-GND)

TWISTED PAIR

CAN1H

(ATMT)

CAN1L

AT

CONTROLLER

COOLANT TEMP

THA

(FQ3)

METER

THW

(THO)

(FQ2)

(ACGL-SW)

(CAN1-SLD)

(ACG-F)

AT-TACHO

COMMON1

COMMON1

CYL1

CRSET-L

TWV-A

CYL4

MIL

TWV-C

CRM-L

COMMON2

COMMON2

CYL3

TWV-B

GL-L

ATM

PRESSURE

b.

METER

ABS

(EXB-L)

AT

CLASS2

TOOL

CLASS2

TOOL

KWP2000

CYL2

TWV-D

A

EXB-SW

EXHAUST

BRAKE

RELAY

EXHAUST BRAKE

CUT RELAY

C

AT

M+

EXB-REL

EBM1

EGR DC

BRUSH MOTOR

EBM2

M-

ABS

EXHAUST BRAKE

RELAY (CHARGE)

EGR-VCC

EGR POSITION

SENSOR

EGP-POS

EGR-GND

P-GND

(EBM-W)

(EGR-UPOS)

(EGR-VPOS)

(EGR-WPOS)

P-GND

P-GND

P-GND

(IDM1)

(IDM2)

GND

GND

INT-VCC

CASE-GND

INT

INT-GND

Q000539E

-38-

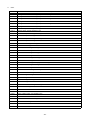

c.

6HK1 Diagram (1)

STARTER

SW

STA-SW

BATT

SCVHI

IG0-SW

SCVHI

IG1-SW

IGN A

ECU

IGN B

SCV

SCVLO

SCVLO

A

B

NE+

CRANK

POSITION

SENSOR

NE-

GLOW RELAY

NE-SLD

GL-REL

LCT TCM

TWISTED PAIR

VSS+

VSSGLOW

PLUG

C

ENGINE

BLOCK

POWER

MAINTAIN

RELAY

VSS-SLD

(+B) *1

+B

G-VB

+B

G

M-REL

G-SLD

M-REL

PBOOST

PB-VCC

GL-L

PB-GND

PFUEL

PFUEL

FIDL-L

IGNITION3

BK1-SW

PFUEL-VCC

BK2-SW

PFUEL-GND

CRM-SW

CAM ANGLE

SENSOR

(HALL)

BOOST

SENSOR

PRESSURE

PRESSURE

SENSOR

COMMON RAIL

APS1-VCC

APS1

CRR-SW

APS1

APS1-GND

CRS-SW

TOP DOWN

VEHICLE

SPEED

SENSOR

APS2-VCC

TOP UP

APS2

APS2

APS2-GND

APS3-VCC

PTO SW

(UPFTR SUP)

(UPFTR SUP)

PTOEN-SW

PTOEN-REL

APS3

APS3

APS3-GND

PACL-VCC

B

PTOFB-SW

PTO ENABLE RELAY

PACL

PACL-GND

POIL-VCC

PTODIS-SW

RSET-SW

RRES-SW

RRPA-SW

RRPB-SW

CCDIS-SW

POIL

POIL-GND

PTO ACCEL

SENSOR

ENGINE OIL

PRESSURE

SENSOR

THW

COOLANT TEMP

THF1

FUEL TEMP#1

*2 THF2

FUEL TEMP#2

THD

THA

ENGINE OIL TEMP

INTAKE AIR TEMP

IGBC-SW

CL-SW

FAXLE-SW

C

MAF

MAF

MAF-GND

A

*1: In case of connecting to outside wiring, note that this termonal is connected to +B inside ECU.

*2: This terminal is unused.

-39-

Q000540E

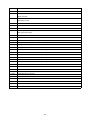

d.

6HK1 Diagram (2)

REV-SW

A/C REQUEST SW AC HI-PRESS SW

LOL-SW

FIDL-SW

AC-SW

COM-GND

LFUEL1

4WD-SW

LCL-SW

ACGL-SW

ACG

ACG-F

ACG

LFUEL2

WIF-SW

AIR 2SPD. AXLE SENSOR

FUEL LEVEL#1

N-SW

FUEL LEVEL#2

IGN (CRANK)

STARTER R/L

VB

STAEN-REL

CLUTCH SW

ELECTRIC 2SPD. AXLE

SW AUTOMATC

ECU

COMMON1

COMMON1

2SAXLE-SW

CYL1

TWV-A

IGN3

MANUAL

IGN3

CYL2

TWV-E

2SPD.

AXLE

MOTER

CYL3

TWV-C

COMMON2

COMMON2

ATM

PRESSURE

CYL4

TWV-F

CYL5

TWV-B

A/C RELAY LOW PRESSURE SW

CYL6

BATT

TWV-D

A/C CLUTCH

ACCL-REL

CLUSTER

EXB-SW

MIL

TACHO

VSOUT1

EXHT Telltail-TTM

B

EXHT BRK SOLENOID

TWISTED PAIR

CAN1H

TCM

EXB-REL

ABS

CAN1L

CAN1-SLD

CHASSIS

BUILDER

TECH II

W/ABS

NO ABS

P-GND

VSOUT2

P-GND

CLASS2

CLASS2

TCM

LCT

WTERC

P-GND

P-GND

GND

GND

DIAGCL-SW

CASE-GND

EGR-VCC

EGR-UPOS

EBM-U

EGR-VPOS

EGR VALVE

DRIVE DC BRUSH-LESS

MOTOER

EBM-V

EGR-WPOS

EBM-W

EGR-GND

C

AVNT

NOTE:

Un lock

Run

Crank

Lock/Accessory

IGN0 IGN1 CRANK IGN3

1

0

0

0

1

1

0

1

1

1

1

0

0

0

0

0

AVNT

VNTPOS-VCC

VNTPOS-SIG

AVNT POSITION

SENSOR

VNTPOS-GND

Q000541E

-40-

C. ECU Connector Diagram

a.

4HK1 ECU Connector Terminal Layout

ECU CONNECTOR PIN ASSIGNMENT : 154PIN

㪘㪄㪎㪊

㪘㪄㪎㪏

㪂㪙

㪞㪣㩷

㪄㪚㪦㪥㪫

㪧㪫㪦㪜㪥㩷 㪪㪫㪘㪜㪥㩷

㪄㪩㪜㪣

㪄㪩㪜㪣

㪂㪙

㪂㪙

㪙㪘㪫㪫

㪤㪄㪩㪜㪣

㪜㪯㪙㩷

㪄㪩㪜㪣

㪤㪄㪩㪜㪣

㪘㪄㪋㪐

㪘㪄㪉㪌

㪚㪘㪪㪜㩷

㪄㪞㪥㪛

㪘㪄㪈

㪧㪄㪞㪥㪛

㪧㪄㪞㪥㪛 㪫㪘㪚㪟㪦

㪧㪄㪞㪥㪛

㪧㪄㪞㪥㪛

㪞㪥㪛

㪘㪫㪄㩷

㪚㪩㪪㪜㪫㩷

㪤㪠㪣 㪚㪩㪤㩷

㪄㪣

㪫㪘㪚㪟㪦

㪄㪣

㪘㪧㪪㪈㩷 㪘㪧㪪㪉㩷 㪘㪧㪪㪊㩷

㪧㪘㪚㪣㩷 㪠㪛㪣㪬㪧

㪄㪭㪚㪚 㪄㪭㪚㪚 㪄㪭㪚㪚

㪄㪭㪚㪚 㪄㪭㪚㪚

㪘㪄㪌㪋

㪘㪄㪊㪇

㪠㪞㪙㪚㩷

㪄㪪㪮

㪙㪢㪈㩷

㪄㪪㪮

㪞㪣㪄㪣

㪚㪚㪛㪠㪪㩷

㪄㪪㪮

㪙㪢㪉㩷 㪚㪣㩷

㪄㪪㪮 㪄㪪㪮

㪪㪪㪧㪙

㪄㪪㪮

㪛㪠㪘㪞㩷

㪚㪣㪜㪘㪩㩷

㪄㪪㪮

㪩㪪㪜㪫㩷 㪩㪩㪜㪪㩷 㪧㪫㪦㪜㪥 㪧㪫㪦㪛㪠㪪㩷 㪧㪫㪦㪝㪙㩷

㪄㪪㪮 㪄㪪㪮 㪄㪪㪮 㪄㪪㪮 㪄㪪㪮

㪜㪯㪙㩷

㪩㪜㪝

㪄㪪㪮

㪄㪪㪮

㪪㪧㪛

㪘㪧㪪㪈 㪘㪧㪪㪉 㪘㪧㪪㪊 㪧㪘㪚㪣 㪠㪛㪣㪬㪧

㪚㪘㪥㪈㩷 㪚㪘㪥㩷

㪄㪪㪣㪛 㪈㪥

㪘㪧㪪㪈㩷 㪘㪧㪪㪉㩷 㪘㪧㪪㪊㩷 㪧㪘㪚㪣㩷 㪠㪛㪣㪬㪧

㪄㪞㪥㪛 㪄㪞㪥㪛 㪄㪞㪥㪛 㪄㪞㪥㪛 㪄㪞㪥㪛

㪞㪥㪛

㪪㪪㪧㪘

㪄㪪㪮

㪪㪟㪬㪫㩷

㪛㪦㪮㪥㩷

㪄㪪㪮

㪚㪘㪥㩷 㪢㪮㪧㩷

㪈㪣 㪉㪇㪇㪇

㪚㪣㪘㩷

㪪㪪㪉

㪘㪚㩷 㪚㪩㪤㩷 㪚㪩㪩㩷

㪄㪪㪮 㪄㪪㪮 㪄㪪㪮

㪚㪣㪘㩷

㪠㪞㪠㪄㪪㪮

㪪㪪㪉

㪘㪄㪍

㪘㪄㪐㪍

㪪㪫㪘㩷

㪄㪪㪮

㪘㪄㪎㪉

㪘㪄㪋㪏

㪚㪩㪪㩷

㪄㪪㪮

㪫㪟㪮㩷

㪦㪬㪫

㪙㪄㪌

㪙㪄㪍

㪙㪄㪋㪍

㪚㪦㪤㪤㪦㪥㪈

㪚㪦㪤㪤㪦㪥㪉

㪧㪙㩷

㪄㪭㪚㪚

㪧㪝㪬㪜㪣㩷 㪧㪦㪠㩷㪣㩷 㪜㪞㪩㩷 㪠㩷㪥㪫㩷 㪞㩷

㪄㪭㪚㪚 㪄㪭㪚㪚 㪄㪭㪚㪚 㪄㪭㪚㪚 㪄㪭㪙

㪪㪚㪭㪟㪠 㪫㪟㪮

㪙㪄㪊

㪙㪄㪋

㪪㪚㪭㪟㪠

㪚㪦㪤㪤㪦㪥㪈

㪚㪦㪤㪤㪦㪥㪉

㪙㪄㪊㪊

㪙㪄㪉㪇

㪙㪄㪈

㪙㪄㪉

㪙㪄㪌㪏

㪜㪞㪩㩷

㪄㪧㪦㪪

㪫㪟㪘

㪫㪟㪝㪈

㪫㪮㪭㪄㪦

㪫㪮㪭㪄㪘

㪫㪮㪭㪄㪛

㪫㪮㪭㪄㪙

㪙㪄㪋㪌

㪙㪄㪊㪉

㪪㪚㪭㪣㪦

㪪㪚㪭㪣㪦

㪜㪙㪤㪈

㪜㪙㪤㪉

㪧㪙㪦㪦㪪㪫 㪧㪝㪬㪜㪣 㪧㪝㪬㪜㪣

㪤㪘㪝

㪠㩷㪥㪫

㪞

㪥㪜㪂

㪙㪄㪎

㪘㪄㪉㪋

㪥㪜㪄

㪧㪙㩷

㪧㪝㪬㪜㪣㩷 㪧㪦㪠㩷㪣㩷 㪤㪘㪝㩷 㪠㩷㪥㪫㩷 㪜㪞㪩㩷 㪞㩷

㪥㪜㩷

㪄㪞㪥㪛 㪄㪞㪥㪛 㪄㪞㪥㪛 㪄㪞㪥㪛 㪄㪞㪥㪛 㪄㪞㪥㪛 㪄㪪㪣㪛 㪄㪪㪣㪛

㪙㪄㪈㪐㩷

Q000542E

b.

4HK1 Terminal Connections

No.

Terminal Name

Content

No.

A-1

CASE-GND

CASE GND

A-31 APS1

ACCEL POSITION 1 SIG

A-2

P-GND

POWER GND

A-32 APS2

ACCEL POSITION 2 SIG

A-3

P-GND

POWER GND

A-33 APS3

ACCEL POSITION 3 SIG

A-4

GND

ECU SENSOR GND

A-34 PACL

PTO ACCEL SIG

A-5

GND

ECU SENSOR GND

A-35 IDLUP

IDLE UP SIG

A-6

N/A

(Q CONTROL RESISTOR 3)

A-36 N/A

(SP1)

A-7

APS1-GND

V5RTN1

A-37 N/A

(SP2)

A-8

APS2-GND

V5RTN2

A-38 N/A

(ATM TEMP SIG)

A-9

APS3-GND

V5RTN3

A-39 SPD

SPEED INPUT

A-10 PACL-GND

PTO ACCEL GND

A-40 —

—

A-11 IDLUP-GND

IDLE UP GND

A-41 N/A

(ACG-F PULSE INPUT)

A-12 N/A

(SP3 GND)

A-42 —

—

A-13 N/A

(ATM TEMP GND)

A-43 N/A

(GLOW MONITOR2 FEEDBACK)

A-14 —

—

A-44 N/A

(GLOW MONITOR3 FEEDBACK)

A-15 N/A

(SP1-GND)

A-45 AC-SW

A/C CLUTCH REQUEST SW

A-16 CAN1-SLD

CAN1 SHIELD GND

A-46 CRM-SW

RUISE ENABLE (ON/OFF) SW

A-17 CAN1H

CAN1 HIGH

A-47 CRR-SW

CRUISE RESUME/ACCEL SW

A-18 CAN1L

CAN1 LOW

A-48 CRS-SW

CRUISE SET/COAST SW

A-19 KWP2000

ISO14230

A-49 +B

POWER

A-20 CLASS2

J1850

A-50 +B

POWER

A-21 CLASS2

J1850

A-51 BATT

BATTERY

A-22 —

—

A-52 M-REL

POWER MAINTAIN RELAY

A-23 IG1-SW

IGNITION 1

A-53 M-REL

POWER MAINTAIN RELAY

A-24 THWOUT

THW PWM OUTPUT

A-54 APS1-VCC

VBREF1

A-25 —

—

A-55 APS2-VCC

VBREF2

A-26 P-GND

POWER GND

A-56 APS3-VCC

VBREF3

A-27 P-GND

POWER GND

A-57 —

—

A-28 TACHO

TACHO

A-58 PACL-VCC

PTO ACCEL VCC

A-29 N/A

(Q CONTROL RESISTOR 1)

A-59 IDLUP-VCC

IDLE UP VCC

A-30 N/A

(Q CONTROL RESISTOR 2)

A-60 N/A

(SP1 VCC)

-41-

Terminal Name

Content

No.

Terminal Name

Content

No.

Terminal Name

Content

A-61 N/A

(ACG-L INPUT)

A-79 GL-L

GLOW LAMP

A-62 BK1-SW

BRAKE 1 SW

A-80 MIL

CHECK ENGINE LAMP

A-63 BK2-SW

BRAKE 2 SW

A-81 CRM-L

CRUISE MAIN LAMP

A-64 CL-SW

CLUTCH SW

A-82 AT-TACHO

AT-TACHO

A-65 SHUTDOWN-SW ENGINE SHUTDOWN SW

A-83 N/A

(SP2 GND)

A-66 DIAG CLEAR-SW DIAG CLEAR SW

A-84 CRSET-L

CRUISE SET LAMP

A-67 EXB-SW

EXHAUST BRAKE SW

A-85 N/A

(SP2)

A-68 —

—

A-86 IGBC-SW

IGNORE BRAKE/CLUTCH SW

A-69 REF-SW

REFRIGERATOR SW

A-87 N/A

(TORQUE LIMIT SW)

A-70 N/A

(GLOW MONITOR1 FEEDBACK)

A-88 CCDIS-SW

CAB CONTROL DISABLE SW

A-71 N/A

(TORQUE CUT SW)

A-89 SSPA-SW

SET SPEED A SW

A-72 N/A

(GLOW MONITOR4 FEEDBACK)

A-90 SSPB-SW

SET SPEED B SW

A-73 +B

POWER

A-91 RSET-SW

REMOTE SET SW

A-74 GL-CONT

GLOW CONTOROLLER

A-92 RRES-SW

REMOTE RESUME SW

A-75 PTOEN-REL

PTO ENGAGE RELAY

A-93 PTOEN-SW

PTO ENGAGE SW

A-76 STAEN-REL

STARTER ENABLE RELAY

A-94 PTODIS-SW

PTO DISABLE SW

A-77 EXB-REL

EXHAUST BRAKE RELAY

A-95 PTOFB-SW

PTO FEEDBACK SW

A-78 N/A

(EXHAUST BRAKE LAMP)

A-96 STA-SW

CRANKING REQUEST SW

No.

Terminal Name

Content

No.

B-1

N/A

(INTAKE DC MOTOR1)

B-22 —

—

B-2

N/A

(INTAKE DC MOTOR2)

B-23 N/A

(INCA-BAT)

B-3

COMMON1

INJECTOR POWER1

B-24 PBOOST

BOOST PRESSURE SIG.

B-4

COMMON2

INJECTOR POWER2

B-25 PFUEL

RAIL PRESSURE SIG.

B-5

COMMON1

INJECTOR POWER1

B-26 PFUEL

RAIL PRESSURE SIG.

B-6

COMMON2

INJECTOR POWER2

B-27 N/A

(OIL PRESSURE SIG.)

B-7

EBM1

EGR DC MOTOR 1

B-28 MAF

MAF SIGNAL

B-8

EBM2

EGR DC MOTOR 2

B-29 INT

INTAKE POSITION SIG.

B-9

N/A

(EGR BRUSHLESS MOTOR W)

B-30 G

CAM ANGLE

B-10 —

—

B-31 NE+

CRANK POSITION+

B-11 N/A

(INCA-GND)

B-32 NE-

CRANK POSITION-

B-12 PB-GND

BOOST PRESSURE GND

B-33 SCVHI

SCV HIGH SIDE

B-13 PFUEL-GND

RAIL PRESSURE GND

B-34 SCVHI

SCV HIGH SIDE

B-14 POIL-GND

OIL PRESSURE GND

B-35 THW

COOLANT TEMP.

B-15 MAF-GND

MAF GND

B-36 N/A

(ENGINE OIL TEMP.)

B-16 INT-GND

INTAKE POSITION GND

B-37 THA

INTAKE AIR TEMP.

B-17 EGR-GND

EGR POSITION GND

B-38 N/A

(EGR-U POSITION SIG.)

B-18 G-SLD

CAM ANGLE GND

B-39 N/A

(EGR-V POSITION SIG.)

B-19 NE-SLD

CRANK POSITION GND

B-40 N/A

(EGR-W POSITION SIG.)

B-20 SCVLO

SCV LOW SIDE

B-41 THF1

FUEL TEMP

B-21 SCVLO

SCV LOW SIDE

B-42 N/A

(FUEL TEMP. #2)

-42-

Terminal Name

Content

No.

Terminal Name

Content

No.

Terminal Name

Content

B-43 TWV-D

INJECTOR D(CYL2)

B-51 G-VB

CAM ANGLE VB

B-44 —

—

B-52 N/A

(LOW OIL LEVEL SW)

B-45 TWV-B

INJECTOR B(CYL3)

B-53 EGR-POS

EGR-POSITION SIG. (DC MOTOR)

B-46 PB-VCC

BOOST PRESSURE VCC

B-54 —

—

B-47 PFUEL-VCC

RAIL PRESSURE VCC

B-55 —

—

B-48 POIL-VCC

OIL PRESSURE VCC

B-56 TWV-C

INJECTOR C(CYL4)

B-49 EGR-VCC

EGR POSITION VCC

B-57 —

—

B-50 INT-VCC

INTAKE POSITION VCC

B-58 TWV-A

INJECTOR A(CYL1)

< NOTE >

• N/A: Component is not mounted (circuit pattern only). Note that the VCC and GND and pin No. A-78 for sensors are

connected inside ECU.

-43-

c.

6HK1 ECU Connector Terminal Layout

ECU CONNECTOR PIN ASSIGNMENT : 154PIN

㪘㪄㪎㪊

㩿㪂㪙㪀 㪞㪣㩷

㪄㪩㪜㪣

㪂㪙

㪂㪙

㪧㪫㪦㪜㪥㩷 㪪㪫㪘㪜㪥㩷

㪄㪩㪜㪣

㪄㪩㪜㪣

㪜㪯㪙㩷

㪄㪩㪜㪣

㪙㪘㪫㪫

㪤㪄㪩㪜㪣

㪤㪄㪩㪜㪣

㪘㪄㪋㪐

㪘㪄㪉㪌

㪚㪘㪪㪜㩷

㪄㪞㪥㪛

㪘㪄㪈

㪧㪄㪞㪥㪛

㪧㪄㪞㪥㪛 㪫㪘㪚㪟㪦

㪧㪄㪞㪥㪛

㪧㪄㪞㪥㪛

㪞㪥㪛

㪘㪄㪎㪏

㪝㩷㪠㩷㪛㪣㩷

㪞㪣㪄㪣

㪄㪣

㪭㪪㩷 㪭㪪㩷

㪤㩷㪠㩷㪣 㪦㪬㪫㪈 㪦㪬㪫㪉

㪘㪧㪪㪈㩷 㪘㪧㪪㪉㩷 㪘㪧㪪㪊㩷

㪄㪭㪚㪚 㪄㪭㪚㪚 㪄㪭㪚㪚

㪘㪄㪌㪋

㪘㪄㪊㪇

㪚㪩㪪㪜㪫㩷

㪄㪣

㪙㪢㪈㩷

㪄㪪㪮

㪧㪘㪚㪣㩷

㪄㪭㪚㪚

㪚㪚㪛㪠㪪㩷 㪪㪪㪧㪘 㪪㪪㪧㪙

㪄㪪㪮 㪄㪪㪮 㪄㪪㪮

㪛㪠㪘㪞㩷

㪙㪢㪉㩷 㪚㪣㩷 㪪㪟㪬㪫㩷

㪛㪦㪮㪥㩷 㪚㪣㪜㪘㪩㩷

㪄㪪㪮 㪄㪪㪮 㪄㪪㪮 㪄㪪㪮

㪣㪝㪬㪜㪣㪈 㪣㪝㪬㪜㪣㪉 㪭㪪㪪㪂 㪭㪪㪪㪄 㪘㪚㪞㪄㪝

㪘㪧㪪㪈 㪘㪧㪪㪉 㪘㪧㪪㪊 㪧㪘㪚㪣

㪘㪧㪪㪈㩷 㪘㪧㪪㪉㩷 㪘㪧㪪㪊㩷 㪧㪘㪚㪣㩷

㪄㪞㪥㪛 㪄㪞㪥㪛 㪄㪞㪥㪛 㪄㪞㪥㪛

㪞㪥㪛

㪠㪞㪙㪚㩷

㪄㪪㪮

㪚㪦㪤㩷

㪄㪞㪥㪛

㪭㪪㪪㩷

㪄㪪㪣㪛

㪩㪪㪜㪫㩷 㪩㪩㪜㪪㩷 㪧㪫㪦㪜㪥 㪧㪫㪦㪛㪠㪪㩷 㪧㪫㪦㪝㪙㩷

㪄㪪㪮 㪄㪪㪮 㪄㪪㪮 㪄㪪㪮 㪄㪪㪮

㪜㪯㪙㩷 㪝㪬㪜㪣

㪄㪪㪮 㪄㪪㪮

㪩㪜㪝

㪄㪪㪮

㪉㪪㪘㪯㪣㪜㩷 㪋㪮㪛㩷 㪘㪚㩷

㪄㪪㪮

㪄㪪㪮 㪄㪪㪮

㪚㪘㪥㪈㩷 㪚㪘㪥㪈㪟 㪚㪘㪥㪈㪣

㪄㪪㪣㪛

㪚㪣㪘㩷

㪪㪪㪉

㪣㪚㪣㩷 㪩㪜㪭㩷

㪄㪪㪮 㪄㪪㪮

㪚㪩㪤㩷 㪚㪩㪩㩷

㪄㪪㪮 㪄㪪㪮

㪘㪄㪐㪍

㪪㪫㪘㩷

㪄㪪㪮

㪮㩷㪠㩷㪝㩷

㪄㪪㪮

㪘㪄㪎㪉

㪘㪄㪋㪏

㪚㪩㪪㩷

㪄㪪㪮

㪚㪣㪘㩷 㪠㪞㪦㪄㪪㪮 㪠㪞㪠㪄㪪㪮

㪪㪪㪉

㪙㪄㪌

㪙㪄㪍

㪙㪄㪋㪍

㪚㪦㪤㪤㪦㪥㪈

㪚㪦㪤㪤㪦㪥㪉

㪧㪙㩷

㪄㪭㪚㪚

㪧㪝㪬㪜㪣㩷 㪧㪦㩷㪠㩷㪣㩷 㪜㪞㪩㩷 㪠㩷㪥㪫㩷 㪞㩷

㪄㪭㪚㪚 㪄㪭㪚㪚 㪄㪭㪚㪚 㪄㪭㪚㪚 㪄㪭㪙

㪪㪚㪭㪟㪠 㪫㪟㪮

㪙㪄㪊

㪙㪄㪋

㪪㪚㪭㪟㪠

㪚㪦㪤㪤㪦㪥㪈

㪚㪦㪤㪤㪦㪥㪉

㪙㪄㪊㪊

㪙㪄㪉㪇

㪙㪄㪈

㪙㪄㪉

㪪㪚㪭㪣㪦

㪪㪚㪭㪣㪦

㪜㪙㪤㩷

㪄㪬

㪙㪄㪎

㪜㪙㪤㩷 㪜㪙㪤㩷

㪄㪭

㪄㪮

㪘㪭㪥㪫

㪘㪄㪉㪋

㪘㪄㪍

㪙㪄㪌㪏

㪫㪟㪦

㪣㪦㪣㩷

㪄㪪㪮

㪫㪮㪭㪄㪦 㪫㪮㪭㪄㪜 㪫㪮㪭㪄㪘

㪜㪞㪩㩷 㪜㪞㪩㩷

㪫㪟㪘 㪜㪞㪩㩷

㪄㪬㪧㪦㪪 㪄㪭㪧㪦㪪 㪄㪮㪧㪦㪪 㪫㪟㪝㪈 㪫㪟㪝㪉 㪫㪮㪭㪄㪛 㪫㪮㪭㪄㪝 㪫㪮㪭㪄㪙

㪙㪄㪋㪌

㪙㪄㪊㪉

㪞 㪥㪜㪂 㪥㪜㪄

㪧㪙㪦㪦㪪㪫 㪧㪝㪬㪜㪣 㪧㪝㪬㪜㪣 㪧㪦㩷㪠㩷㪣㩷 㪤㪘㪝 㪭㪥㪫㪧㪦㪪㩷

㪄㪪㪠㪞

㪥㪜㩷

㪧㪙㩷

㪧㪝㪬㪜㪣㩷 㪧㪦㩷㪠㩷㪣㩷 㪤㪘㪝㩷 㪭㪥㪫㪧㪦㪪㩷 㪜㪞㪩㩷 㪞㩷

㪄㪞㪥㪛 㪄㪞㪥㪛 㪄㪞㪥㪛 㪄㪞㪥㪛 㪄㪞㪥㪛 㪄㪞㪥㪛 㪄㪪㪣㪛 㪄㪪㪣㪛

㪙㪄㪈㪐㩷

Q000543E

d.

No.

6HK1 Terminal Connections

Terminal Name

Content

No.

Terminal Name

Content

A-1

CASE-GND

CASE GND

A-32 APS2

ACCEL POSITION 2 SIG

A-2

P-GND

POWER GND

A-33 APS3

ACCEL POSITION 3 SIG

A-3

P-GND

POWER GND

A-34 PACL

PTO ACCEL SIG

A-4

GND

ECU SENSOR GND

A-35 —

—

A-5

GND

ECU SENSOR GND

A-36 —

—

A-6

N/A

(Q CONTROL RESISTOR 3)

A-37 LFUEL1

FUEL LEVEL 1 SIG

A-7

APS1-GND

V5RTN1

A-38 LFUEL2

FUEL LEVEL 2 SIG (ATM TEMP)

A-8

APS2-GND

V5RTN2

A-39 VSS+

VEHICLE SPEED SENSOR+

A-9

APS3-GND

V5RTN3

A-40 VSS-

VEHICLE SPEED SENSOR-

A-10 PACL-GND

PTO ACCEL GND

A-41 ACG-F

ACG-F PULSE INPUT

A-11

—

A-42 —

—

A-12 COM-GND

COMMON SENSOR GND

A-43 2SAXLE-SW

2SPEED AXLE SW

A-13 —

—

A-44 4WD-SW

FOUR WHEEL DRIVE HIGH/LOW SW

A-14 VSS-SLD

VSS GND

A-45 AC-SW

A/C CLUTCH REQUEST SW

A-15 —

—

A-46 CRM-SW

CRUISE ENABLE (ON/OFF) SW

A-16 CAN1-SLD

CAN1 SHIELD GND

A-47 CRR-SW

CRUISE RESUME/ACCEL SW

A-17 CAN1H

CAN1 HIGH

A-48 CRS-SW

CRUISE SET/COAST SW

A-18 CAN1L

CAN1 LOW

A-49 +B

POWER

A-19 N/A

(ISO14230)

A-50 +B

POWER

A-20 CLASS2

J1850

A-51 BATT

BATTERY

A-21 CLASS2

J1850

A-52 M-REL

POWER MAINTAIN RELAY

A-22 IG0-SW

IGNITION 0 (KEY-SW)

A-53 M-REL

POWER MAINTAIN RELAY

A-23 IG1-SW

IGNITION 1

A-54 APS1-VCC

VBREF1

A-24 —

—

A-55 APS2-VCC

VBREF2

A-25 —

—

A-56 APS3-VCC

VBREF3

A-26 P-GND

POWER GND

A-57 —

—

A-27 P-GND

POWER GND

A-58 PACL-VCC

PTO ACCEL VCC

A-28 TACHO

TACHO

A-59 —

—

A-29 N/A

(Q CONTROL RESISTOR 1)

A-60 —

—

A-30 N/A

(Q CONTROL RESISTOR 2)

A-61 ACGL-SW

ACG-L INPUT

A-31 APS1

ACCEL POSITION 1 SIG

A-62 BK1-SW

BRAKE 1 SW

—

-44-

No.

Terminal Name

Content

No.

Terminal Name

Content

A-63 BK2-SW

BRAKE 2 SW

A-80 MIL

SERVICE ENGINE SOON LAMP

A-64 CL-SW

CLUTCH SW

A-81 VSOUT1

4KPPM

A-65 N-SW

NEUTRAL SW

A-82 VSOUT2

4KPPM (128KPPM)

A-66 DIAG CLEAR-SW DIAG CLEAR SW

A-83 —

—

A-67 EXB-SW

EXHAUST BRAKE SW

A-84 ACCL-REL

A/C CLUTCH RELAY

A-68 FIDL-SW

FAST IDLE SW

A-85 —

—

A-69 FAXLE-SW

FRONT AXLE SW

A-86 IGBC-SW

IGNORE BRAKE/CLUTCH SW

A-70 LCL-SW

LOW COOLANT LEVEL SW

A-87 N/A

(TORQUE LIMIT SW)

A-71 REV-SW

REVERSE SW

A-88 CCDIS-SW

CAB CONTROL DISABLE SW

A-72 WIF-SW

WATER IN FUEL SW

A-89 SSPA-SW

SET SPEED A SW

A-73 (+B) *1

(POWER)

A-90 SSPB-SW

SET SPEED B SW

A-74 GL-REL

GLOW PLUG RELAY

A-91 RSET-SW

REMOTE SET SW

A-75 PTOEN-REL

PTO ENGAGE RELAY

A-92 RRES-SW

REMOTE RESUME SW

A-76 STAEN-REL

STARTER ENABLE RELAY

A-93 PTOEN-SW

PTO ENGAGE SW

A-77 EXB-REL

EXHAUST BRAKE RELAY

A-94 PTODIS-SW

PTO DISABLE SW

A-78 FIDL-L

FAST IDLE ENGAGE LAMP

A-95 PTOFB-SW

PTO FEEDBACK SW

A-79 GL-L

GLOW LAMP

A-96 STA-SW

CRANKING REQUEST SW

No.

Terminal Name

Content

No.

Terminal Name

Content

B-1

AVNT

AVNT DRIVE

B-23 N/A

(INCA-BAT)

B-2

—

—

B-24 PBOOST

BOOST PRESSURE SIG.

B-3

COMMON1

INJECTOR POWER1

B-25 PFUEL

RAIL PRESSURE SIG.

B-4

COMMON2

INJECTOR POWER2

B-26 PFUEL

RAIL PRESSURE SIG.

B-5

COMMON1

INJECTOR POWER1

B-27 POIL

OIL PRESSURE SIG.

B-6

COMMON2

INJECTOR POWER2

B-28 MAF

MAF SIGNAL

B-7

EBM-U

EGR BRUSHLESS MOTOR U

B-29 VNTPOS-SIG

VNT POSITION SIG.

B-8

EBM-V

EGR BRUSHLESS MOTOR V

B-30 G

CAM ANGLE

B-9

EBM-W

EGR BRUSHLESS MOTOR W

B-31 NE+

CRANK POSITION+

B-10 —

—

B-32 NE-

CRANK POSITION-

B-11

(INCA-GND)

B-33 SCVHI

SCV HIGH SIDE

B-12 PB-GND

BOOST PRESSURE GND

B-34 SCVHI

SCV HIGH SIDE

B-13 PFUEL-GND

RAIL PRESSURE GND

B-35 THW

COOLANT TEMP.

B-14 POIL-GND

OIL PRESSURE GND

B-36 THO

ENGINE OIL TEMP.

B-15 MAF-GND

MAF GND

B-37 THA

INTAKE AIR TEMP.

B-16 VNTPOS-GND

VNT POSITION GND

B-38 EGR-UPOS

EGR-U POSITION SIG.

B-17 EGR-GND

EGR POSITION GND

B-39 EGR-VPOS

EGR-V POSITION SIG.

B-18 G-SLD

CAM ANGLE SHIELD GND

B-40 EGR-WPOS

EGR-W POSITION SIG.

B-19 NE-SLD

CRANK POSITION SHIELD GND

B-41 THF1

FUEL TEMP

B-20 SCVLO

SCV LOW SIDE

B-42 THF2 *2

FUEL TEMP. #2

B-21 SCVLO

SCV LOW SIDE

B-43 TWV-D

INJECTOR D

B-22 —

—

B-44 TWV-F

INJECTOR F

N/A

-45-

No.

Terminal Name

Content

No.

Terminal Name

Content

B-45 TWV-B

INJECTOR B

B-52 LOL-SW

LOW OIL LEVEL SW

B-46 PB-VCC

BOOST PRESSURE VCC

B-53 —

—

B-47 PFUEL-VCC

RAIL PRESSURE VCC

B-54 —

—

B-48 POIL-VCC

OIL PRESSURE VCC

B-55 —

—

B-49 EGR-VCC

EGR POSITION VCC

B-56 TWV-C

INJECTOR C

B-50 VNTPOS-VCC

VNT POSITION VCC

B-57 TWV-E

INJECTOR E

B-51 G-VB

CAM ANGLE VB

B-58 TWV-A

INJECTOR A

< NOTE >

• *1: In case of connecting to outside wiring, note that this terminal is connected to +B inside ECU.

•

*2: This terminal is unused.

•

N/A: Component is not mounted (circuit pattern only).

-46-