Download SERVICE MANUAL

Transcript

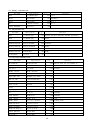

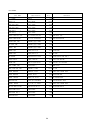

SERVICE MANUAL MODEL FG-8110 SWEEP/FUNCTION GENERATOR CONTENTS 1. PERFORMANCE CHECK PROCEDURE 2. ADJUSTMENT PROCEDURE 3. TROUBLESHOOTING PROCEDURE 4. PARTS LIST 5. CIRCUIT DIAGRAM 2 1. PERFORMANCE CHECK PROCEDURE 1-1. General This section contains the Procedures required to check and maintain specified instrument performance. The adjustments should be performed at an ambient temperature of 23°C ±5°C and a relative humidity of less than 60%. It allows the instrument to stabilize at this environment for a minimum of 30 minutes. 1-2. Equipment's required Table 1-1 is shown test equipment's required. Table 1-1 Equipment's required No . Equipment name Specification 1. Frequency Counter DC to 60 MHz 2. Oscilloscope DC to 20 MHz 3. AC Millivolt Meter Up to 30 Vrms 4. Distortion Analyzer 0.01% 100kHz 5. DC Power Supply DC 0 to 10V 6. Signal Generator 200mHz to 110 MHz 7. FEEDTHROUGH TERMINATION 50 Ω 1-3. Performance check 1-3-1. OUTPUT FREQUENCY RANGE SPECIFICATION 0.1 Hz TO 10 MHz ACCURACY +/- 5 % OF SETTING EQUIPMENT FREQUENCY COUNTER BNC CABLE FEEDTHROUGH TERMINATION 50 Ω (if necessary) PROCEDURE 2. Set 8210 as follows; 3 Remark - Function ; SINE WAVE ( ) - ATT ; 0 dB(PULL OUT) - AMPLITUDE ; CENTER - COUNT ; INT(PULL OUT) - DC OFFSET ; OFF(PUSH IN) - SYM ; OFF(PUSH IN) - SWEEP ; OFF(PUSH IN) 2. Connect the frequency counter to output terminal. 3. Set the frequency counter to frequency measurement. 4. Set the output frequency of this product by FREQUENCY RANGE and DIAL and verify counter frequency reading as follows; 8210 setting Range Frequency 1M 10.000 MHz 100.00 kHz 100k 1.0000 MHz 10.000 kHz 10k 100.00 kHz 1.0000 kHz 1k 10.000 kHz 100.00 Hz 100 1.0000 kHz 10.000 Hz 10 100.00 Hz 1.0000 Hz 1 10.000 Hz 100.00 mHz Counter reading ** For reading less than 200 mHz, you can read by period value. 200mHz ; 5.000 sec 100 mHz ; 10.000 sec 1-3-2. AMPLITUDE AND ATTENUATION SPECIFICATION Amplitude range ;100mVp-p to 10Vp-p IN TO 50Ω Attenuation ;20 dB ACCURACY Lower than 100mVp-p(IN TO 50Ω) at MIN. Higher than 10Vp-p(IN TO 50Ω) at MAX. 4 EQUIPMENT Oscilloscope AC Millivoltmeter BNC CABLE FEEDTHROUGH TERMINATION 50 Ω PROCEDURE 1. Set this product as follows; - Function ; SINE WAVE ( ) - ATT ; 0 dB(PULL OUT) - AMPLITUDE ; CENTER - COUNT ; INT(PULL OUT) - DC OFFSET ; OFF(PUSH IN) - SYM ; OFF(PUSH IN) - SWEEP ; OFF(PUSH IN) 2. Connect the oscilloscope through FEEDTHROUGH TERMINATION 50 Ω to output terminal. 3. Set Amplitude Control to Min. position and check the output level is lower than 100mVp-p(less 5div in 20mV/div). 4. Set Amplitude Control to Max. position and check the output level is higher than 10Vp-p(higher than 4div in 5V/div). 5. Set Amplitude Control to Min. position and connect AC Millivoltmeter to output terminal. 6. Set the Range of AC millivoltmeter to 3V range and adjust Amplitude control for 0dB reading on AC millivoltmeter. 7. Push in “20dB ATT switch” and check the reading of AC Millivoltmeter is -20 dB. 1-3-3. SINE WAVE CHARACTERISTICS SPECIFICATION Total harmonic Distortion(THD) ; ≤ 1 % (10Hz to 100kHz) EQUIPMENT Distortion analyzer BNC CABLE FEEDTHROUGH TERMINATION 50 Ω (if necessary) PROCEDURE 1. Set this product as follows; - Function ; SINE WAVE ( ) - ATT ; 0 dB(PULL OUT) 5 - AMPLITUDE ; CENTER - COUNT ; INT(PULL OUT) - DC OFFSET ; OFF(PUSH IN) - SYM ; OFF(PUSH IN) - SWEEP ; OFF(PUSH IN) 2. Connect the distortion analyzer to output terminal. 3. Check the distortions of output signal are less than 1% from 10Hz to 100kHz. 1-3-4. TRIANGLE/SQUARE WAVE CHARACTERISTICS SPECIFICATION Linearity of Triangle Wave ; ≥ 99 % (10Hz to 100kHz) Rise and Fall Time of Square Wave ; Less than 120nS at 10MHz Max. output level EQUIPMENT Oscilloscope BNC CABLE FEEDTHROUGH TERMINATION 50 Ω (if necessary) PROCEDURE 1. Set this product as follows; - Function ; TRIANGLE WAVE ( ) - ATT ; 0 dB(PULL OUT) - AMPLITUDE ; CENTER - COUNT ; INT(PULL OUT) - DC OFFSET ; OFF(PUSH IN) - SYM ; OFF(PUSH IN) - SWEEP ; OFF(PUSH IN) 2. Connect the oscilloscope to output terminal. 3. Check the linearity of Triangle wave from 10Hz to 100kHz. 4. Change the function to “SQUARE WAVE( )” and check the rise and fall time at 10MHz Max. output level. 1-3-5. TTL OUTPUT SPECIFICATION TTL OUTPUT - Rise and Fall Time ; Less than 25nS - Output Level ; TTL LEVEL (H ≥ 2.4V , L ≤ 0.4V) EQUIPMENT Oscilloscope BNC CABLE 6 PROCEDURE 1. Set this product as follows; - FREQ. RANGE ; 10k - FREQ. DIAL ; 10kHz - COUNT ; INT(PULL OUT) - DC OFFSET ; OFF(PUSH IN) - SYM ; OFF(PUSH IN) - SWEEP ; OFF(PUSH IN) 3. Set the oscilloscope to 1V/div, 5uS/div and connect to TTL output terminal. 4. Check the rise and fall time of TTL SQUARE WAVE on CRT( 5div ). 1-3-5. DC OFFSET CONTROL SPECIFICATION MIN. ; lower than -10 V DC (Open circuit) MAX. ; higher than +10 V DC (Open circuit) EQUIPMENT Oscilloscope BNC CABLE PROCEDURE 1. Set this product as follows; - Function ; SQUARE ( ) - ATT ; 0 dB(PULL OUT) - FREQ. RANGE ; 10k - FREQ. DIAL ; 10kHz - AMPLITUDE ; CENTER 2. Set Oscilloscope to 5V/DIV, 10uS/DIV, DC Coupling and connect to output terminal. 3. Adjust Amplitude Control for 2DIV on CRT. 4. Pull out “DC OFFSET” Control and set to “MIN.” position and check the DC OFFSET level is lower than -10V(Lower than -2DIV). 5. Set “DC OFFSET” Control to “MAX.” position and check the DC OFFSET level is higher than +10V(Higher than +2DIV). 1-3-6. SYMMETRY CONTROL SPECIFICATION MIN. ; lower than 1:10 MAX. ; higher than 10:1 7 EQUIPMENT Oscilloscope BNC CABLE FEEDTHROUGH TERMINATION 50 Ω (if necessary) PROCEDURE 1. Set this product as follows; - Function ; SQUARE ( ) - ATT ; 0 dB(PULL OUT) - AMPLITUDE ; CENTER - COUNT ; INT(PULL OUT) - DC OFFSET ; OFF(PUSH IN) - SYM ; OFF(PUSH IN) - SWEEP ; OFF(PUSH IN) 2. Connect the oscilloscope to output terminal. 3. Set the output frequency to 10kHz. 4. Pull out SYM Control and adjust to Min. position. And check the symmetry(duty ratio) is “lower than 1:10”. 5. Adjust SYM Control to Max. position and check the symmetry(duty ratio) is”higher than 10:1”. 1-3-7. SWEEP FUNCTION SPECIFICATION Sweep Width ; 1:1 to 100:1 Sweep Rate ; 0.5Hz to 50Hz(20mS to 2 S) EQUIPMENT Oscilloscope Frequency Counter BNC CABLE FEEDTHROUGH TERMINATION 50 Ω (if necessary) PROCEDURE 1. Set this product as follows; - Function ; SINE WAVE ( ) - ATT ; 0 dB(PULL OUT) - AMPLITUDE ; CENTER - COUNT ; INT(PULL OUT) - DC OFFSET ; OFF(PUSH IN) - SYM ; OFF(PUSH IN) 2. Connect the oscilloscope and Frequency Counter to output terminal. 8 3. Set Freq. Range to 10k and adjust Freq. Dial to 1.00 kHz (Start Frequency). 4. Pull out SWIDTH Control and adjust to max. position ( 100kHz, Stop frequency). 5. Adjust Sweep Rate Control for desired rate and check sweep operating. 1-3-8. VCF IN FUNCTION SPECIFICATION Out-put frequency should be changed from minimum frequency to maximum frequency in each frequency range by changing VCF INPUT Voltage from 0 to 10V DC. EQUIPMENT Power supply BNC CABLE PROCEDURE 1. Set this product as follows; - Function ; SINE WAVE ( ) - Frequency Range ; 10K - Frequency Control ; Max. - ATT ; 0 dB(PULL OUT) - AMPLITUDE ; CENTER - COUNT ; INT(PULL OUT) - DC OFFSET ; OFF(PUSH IN) - SYM ; OFF(PUSH IN) 2. Set Power Supply to “0V” and connect to “VCF IN” Terminal. 3. Check the output frequency is “1.00kHz ± 0.2kHz”. 4. Increase the output voltage of Power Supply up to +10V and check the output frequency as following table. VCF Voltage Output Frequency Tolerance 0 1.000 kHz ± 0.2kHz 2.000 V 20.00 kHz ± 4 kHz 4.000 V 40.00 kHz ± 8 kHz 6.000 V 60.00 kHz ± 12 kHz 8.000 V 80.00 kHz ± 16 kHz 10.00 V 100.00 kHz ± 20 kHz 1-3-9. FREQUENCY COUNTER SPECIFICATION Frequency range ; 200mHz to 110MHz Input sensitivity ; 100mVrms EQUIPMENT 9 Signal generator PROCEDURE 1. Set the COUNT to EXT(PUSH IN). 2. Connect the signal generator to EXT COUNT IN terminal. 3. Set the signal generator to 100mVrms, 200mHz and check the reading of 8210. 4. Vary the output frequency from 200mHz to 110MHz and check the 8210 displays correct frequencies. 5. Push in LPF(Low Pass Filter) and check the LPF is working (-3dB +/-0.2dB point at approx. 120kHz). < Check procedure > a. Apply 120KHz signal with minimum input level into EXT COUNT IN. b. Push in LPF switch and check gate time(Frequency display) is stopped. c. Increase input level and check the gate time(Frequency display) is starting to and check the input level is increased about 3dB(+/-0.2dB) from “minimum input level”. 2. ADJUSTMENT PROCEDURE 2-1. Preliminary Set-up Remove top cover. Apply power, and allow at least 30 minutes for warm-up. 2-2. Power supply a. Check the voltage in each position according to table 2-1. Table 2-1 Power supply outputs Check position Supplying Voltage Tolerance Remark Output Pin of U6,15,20 + 5 V ± 0.5V U6,15 : Assembled at Rear panel Output Pin of U5 + 15 V ± 0.5V Output Pin of U7 - 15 V ± 0.5V Anode of ZD1 - 5 V ± 0.5V Upper leg of R68 + 21 V ± 2 V 10 2-4. PRE-ADJUSTMENTS EQUIPMENT Oscilloscope BNC CABLE FEEDTHROUGH TERMINATION 50 Ω (if necessary) PROCEDURE 2-4-1. TRIANGLE WAVE OFFSET 1. Set this product as follows; - Function ; TRIANGLE WAVE ( ) - ATT ; 20 dB(PUSH IN) - AMPLITUDE ; MIN. - FREQUENCY ; 10kHz - COUNT ; INT(PULL OUT) - DC OFFSET ; OFF(PUSH IN) - SYM ; OFF(PUSH IN) 2. Set the oscilloscope to 0.5V/DIV, 20uS/DIV , DC Coupling and set the vertical position to horizontal graticule center. 3. Connect the oscilloscope to output terminal. 4. Set “AMPLITUDE” control for 2DIV on CRT and adjust SFR15(OFFSET ADJUSTER) for “0 OFFSET of waveform”(The waveform should be in center. +/- 0.1DIV from horizontal graticule center). 2-4-2.SQUARE WAVE LEVEL 1. Set this product as follows; - Function ; “SQUARE WAVE ( - )” ATT ; 0 dB(PULL OUT) AMPLITUDE ; MAX. FREQUENCY ; 10kHz COUNT ; INT(PULL OUT) DC OFFSET ; OFF(PUSH IN) SYM ; OFF(PUSH IN) 2. Change the function to “SQUARE WAVE” 3. Set the oscilloscope to 5V/DIV, 20uS/DIV 4. Check the output level of Square Wave is 11 more than 17Vpp. 2-4-3.SINE WAVE LEVEL Adjust. 1. - Set this product as follows; Function ; “SINE WAVE ( ATT ; 0 dB(PULL OUT) AMPLITUDE ; MAX. FREQUENCY ; 10kHz COUNT ; INT(PULL OUT) DC OFFSET ; OFF(PUSH IN) SYM ; OFF(PUSH IN) ) 2. Change the function to “SINE WAVE” 3. Set the oscilloscope to 5V/DIV, 20uS/DIV 4. Adjust SFR10 , SFR13 for displaying “4DIV” on CRT. (SFR10 : + DIV from horizontal graticule center for up-side of waveform , SFR13 : - DIV from horizontal graticule center for down-side of waveform. 2-4-4. SINE WAVE DISTORTION ADJUST EQUIPMENT Distortion Analyzer BNC CABLE FEEDTHROUGH TERMINATION 50 Ω (if necessary) PROCEDURE 1. Set this product as follows; - Function ; SINE WAVE ( ) - ATT ; 0 dB(PULL OUT) - AMPLITUDE ; Max. - FREQUENCY ; 10kHz 2. Connect Distortion analyzer to Output terminal. 3. Adjust SFR8, SFR11, SFR12 for minimum distortion reading on Distortion analyzer. (less than 0.5 %) 12 2-4-5. AMPLITUDE CONTROL AND ATTENUATOR CHECK EQUIPMENT Oscilloscope AC Millivoltmeter BNC CABLE FEEDTHROUGH TERMINATION 50 Ω PROCEDURE 1. Set this product as follows ; - Function ; SINE WAVE ( ) - ATT ; 0 dB(PULL OUT)) - AMPLITUDE ; CENTER - COUNT ; INT(PULL OUT) - DC OFFSET ; OFF(PUSH IN) - SYM ; OFF(PUSH IN) - SWEEP ; OFF(PUSH IN) 2. Connect the oscilloscope through FEEDTHROUGH TERMINATION 50 Ω to output terminal. 3. Set Amplitude Control to Min. position and check the output level is lower than 1Vp-p(less 5div in 200mV/div). 4. Set Amplitude Control to Max. position and check the output level is higher than 10Vp-p(higher than 4div in 5V/div). 5. Set Amplitude Control to Min. position and connect AC Millivoltmeter to output terminal. 6. Set the Range of AC millivoltmeter to 3V range and adjust Amplitude control for 0dB reading on AC millivoltmeter. 7. Push in “20dB ATT switch” and check the reading of AC Millivoltmeter is -20 dB. 8. Check the amplitude of TRIANGLE & SQUARE WAVE same as paragraph 3 to 7. 2-5. FREQUENCY RANGE ADJUSTMENT EQUIPMENT Frequency Counter BNC CABLE FEEDTHROUGH TERMINATION 50 Ω PROCEDURE 1. Set this product as follows; - Function ; TRIANGLE WAVE ( - ATT ; 20 dB(PULL OUT) - AMPLITUDE ; CENTER - COUNT ; INT(PULL OUT) ) 13 2. 2. 3. 4. 5. 6. 7. 8. 9. - DC OFFSET ; OFF(PUSH IN) - SYM ; OFF(PUSH IN) - SWEEP ; OFF(PUSH IN) Connect the Frequency Counter to Output Terminal. Set Frequency Range to “1M” and Frequency Control(Dial) to MAX. Position. Adjust SFR1 for 10.500 MHz frequency reading on counter. Change Frequency Range to “100k” and adjust SFR2 for 1.0500 MHz frequency reading on counter. Change Frequency Range to “10k” and adjust SFR3 for 105.00 kHz frequency reading on counter. Change Frequency Range to “1k” and adjust SFR4 for 10.50 kHz frequency reading on counter. Change Frequency Range to “100” and adjust SFR5 for 1.050 kHz frequency reading on counter. Change the frequency range to 10 and 1, and check the frequency reading in each range. (10 : 105.00 Hz , 1 : 10.500Hz) After adjustment, check the frequency Control(Dial) at MIN. and MAX. as following table. 8210 setting Range Frequency Control 1M MIN. MAX. 100k MIN. MAX. 10k MIN. MAX. 1k MIN. MAX. 100 MIN. MAX. 10 MIN. MAX. 1 MIN. MAX. 2-6. SYMMETRY ADJUST EQUIPMENT Oscilloscope BNC CABLE FEEDTHROUGH TERMINATION 50 Ω (if necessary) PROCEDURE 1. Set this product as follows; 14 Tolerance Less than 100.0 kHz Higher than 10.5 MHz Less than 10.0 kHz Higher than 1.05 MHz Less than 1.0 kHz Higher than 100.5 kHz Less than 100 Hz Higher than 10.5 kHz Less than 10.0 Hz Higher than 1.0 kHz Less than 1 Hz Higher than 100 Hz Less than 100 mHz Higher than 10 Hz - Function ; SQUARE ( ) - ATT ; 0 dB(PULL OUT) - AMPLITUDE ; CENTER - COUNT ; INT(PULL OUT) - DC OFFSET ; OFF(PUSH IN) - SYM ; OFF(PUSH IN) - SWEEP ; OFF(PUSH IN) 2. Connect the oscilloscope to output terminal. 3. Set the output frequency to 100kHz. 4. Pull out SYM Control and adjust to Min. position. And adjust SFR6 the symmetry(duty ratio) is “lower than 1:10”. 5. Adjust SYM Control to Max. position and adjust SFR7 the symmetry(duty ratio) is”higher than 10:1”. 2-7. FREQUENCY COUNTER ADJUST EQUIPMENT 10MHz Standard Signal Source Signal Generator up to 110MHz BNC CABLE FEEDTHROUGH TERMINATION 50 Ω (if necessary) PROCEDURE 1. Set this product as follows; - COUNT ; EXT(PUSH IN) 2. Connect 10MHz Standard Signal to the EXT COUNT IN terminal and adjust TC1 for 10.0000 MHz reading on Counter Display. 3. Set Signal generator to 110MHz, 100mVrms and connect the EXT COUNT IN terminal. 4. Adjust SFR16 (Shield Box IN) for 110.0000 MHz reading on Counter Display. Reduce the output level of Signal Generator Slowly and adjust SFR16 for Minimum input sensitivity(as possible as less than 100mVrms). 5. Change the out frequency of Signal Generator from 110MHz to 200mHz and check the minimum input voltage is less than 100mVrms. 6. Push in LPF(Low Pass Filter) and check the LPF is working (-3dB +/-0.2dB point at approx. 120kHz). < Check procedure > a. Apply 120KHz signal with minimum input level into EXT COUNT IN. b. Push in LPF switch and check gate time(Frequency display) is stopped. c. Increase input level and check the gate time(Frequency display) is starting to and check the input level is increased about 3dB(+/-0.2dB) from “minimum input level”. 15 3. Troubleshooting Procedure 3-1. Troubleshooting techniques 3-1-1. Check the function selector and switch setting. Incorrect switch settings can give a false indication of instrument malfunction. If there is any question about the correct function or operation, refer to OPERATOR'S MANUAL. 3-1-2. Check associated equipments before proceeding, ensure that any equipments used with this product is operating correctly and verify that out and input signals are properly connected and that the interconnecting cables are not defective. 3-1-3. Visual Check Look for broken terminals, damaged components, mounting status of components, damaged circuit boards, or other clues to the cause of a malfunction. 3-2. Troubleshooting procedure 3-2-1. NO Display 1. Check the “FUSE” and if it is broken, change to new one with same rating. 2. Check the output voltage of power transformer. -. 17 to 18 Vac between pin 1 and 2 of CN14, and between pin 2 and 3 of CN14 on main board. -. 8 to 10 Vac between pin 1 and 2 of CN4,CN24, and between pin 2 and 3 of CN4,CN24 on main board. 3. Check the DC Power Voltage. -. +5VDC at U6 and U15 output(U6,15 Assembled at rear panel) 4. Check the frequency at pin 19 of U12. It should be “10MHz”. 5. Check the connector cable from CN12’,CN13’(main board) to display board. 3-2-2. Triangle Wave Out-put 1. Check the Function switch operation and select Triangle Wave. 2. Check the DC Power Voltage for Generator Circuit. -. +15VDC at U5 output -. +5VDC at U6,U15,U20 output ( U6,15 :assembled at rear panel) -. -5VDC at Anode of ZD1. -. -15VDC at U7 output -. +21VDC at upper leg of R68 3. Check the waveform at Q7 Emitter. The Triangle Wave should be appeared. 4. If not, check the operation of Amplifier and Triangle oscillator (U1 A/B/D, U2 A/B, 16 Q1,Q2,Q3,Q4,Q5,Q6,D1,D2,D3,D5,Q7). 5. Check the Range Selector Switch operation and Frequency Control Volume and Cable connection from VR1 to CN2(Main Board). 6. Check the “Amplitude VR4” and Cable connection from VR to CN5 on main board. 7. Check the waveform at R46. The Triangle Wave should be appeared. 8. If not, check the operation of Differential Amplifier(Q12,Q13,Q14,Q15,Q16). 9. Check the Attenuator switch(20 dB) and cable connection from CN7 to Output terminal. 3-2-3. Square Wave Out-put 1. Check the Function switch operation and select Square Wave. 2. Check the waveform at D1(of DD1) Cathode. The Triangle Wave should be appeared. 3. Check the waveform at D2(of DD1) Cathode. The Square Wave should be appeared. 4. If not, check the step 3-2-2. 4 and 5. 5. Check the waveform at 9pin of U3. The Square Wave should be appeared. 6. If not, check the operation of U3. 6. Check the waveform at R45. The Square Wave should be appeared. 7. If not, check the step 3-2-2. 8 and 9. 3-2-4. Sine Wave Out-put 1. Check the Function switch operation and select Sine Wave. 2. Check the waveform at Q7 Emitter. The Triangle Wave should be appeared. 3. If not, check the step 3-2-2. 4 and 5. 4. Check the waveform at Q11 Collector. The Sine Wave should be appeared. 5. If not, check the operation of Sine Shaper(Q8,Q9,Q10,Q11). 6. Check the waveform at R45. The Sine Wave should be appeared. 7. If not, check the step 3-2-2. 8 and 9. 3-2-5. TTL Output 1. Check the connection of cable for TTL Output terminal and Control Volume. 2. Check the waveform at Pin 9 of U3. The Square Wave should be appeared. 3. If not, check the step 3-2-3. 4. Check the waveform at pin 6 of U4. The TTL Level Square Wave should be appeared. 5. If not, check the operation of U4. 3-2-6. Sweep Operation(Width and Rate) 1. Check the cable connection(CN8,CN9) for Width and Rate Control Volume. 2. Vary the Width volumeand check the level of Pulse at pin 7 of U2 is varied. 3. Vary the Rate volume and check the period of Pulse at pin 14 of U2 is varied. 4. If not, check the operation of U2 C/D , D9 and Q17. 17 3-2-7. Frequency Range and Frequency Dial 1. Check the cable connection from CN2(Main Board) to Frequency Control Volume. 2. Check the operation of Range selector switch(Key Switch operation). 3-2-8. Attenuator(20dB) 1. Check the operation of each Attenuator switch. 2. If not working, check the R146,147,148 3-2-9. Frequency Counter(INT/EXT) 1. Check the INT/EXT selector switch operation and set to INT. 2. Check the output frequency at Output terminal by using Frequency counter and check the frequency at R83 is same with output frequency. 3. Check the frequency of reference signal at pin18 and 19 of U12. It should be “10.000MHz”. 4. If not, check Reference Oscillator(X1,T1,C54,). 5. Check the frequency at pin3 of U9 and pin 7of U18. It should be same as output frequency. 6. If not, check the operation of Input Amplifier and Devider(Q18,Q19,U8,Q20,Q21,U18). 7. Check the cable connection between CN12(main board) and CN13(Display Board). 8. Check the operation of Counter Circuit, Micro-processor(U12), Driver(U4,5), Scanner(U10,11) 9. Check the operation of Display Controller(U13,U14,Q22-28) on Display Board. 10. Check LPF function as follows; a. Check the status of LPF S/W(push in) b. Check the voltage at the left leg of R108. It should be around +5V. c. Check the voltage at the anode of D16. It should be around 1.4-1.5V. d. Check the voltage at cathode of D16. It should be around on 0.7-0.8V. 18 4. PARTS LIST 4-1.. Main PCB Parts List Part Name Specification q"ty Referance. CER.CAPACITOR 0.01uF50V(10nF) 2.00 C100,101 CER.CAPACITOR.SMD 3pF 1.00 C72 CER.CAPACITOR.SMD 15pF50V 1.00 C9 CER.CAPACITOR.SMD 22pF50V 1.00 C87 CER.CAPACITOR.SMD 30pF50V 2.00 C54,C84 CER.CAPACITOR.SMD 33pF50V 1.00 C82 CER.CAPACITOR.SMD 50pF50V 2.00 C01,C02 CER.CAPACITOR.SMD 0.01uF50V(10nF) 12.00 C2,8,15,29,31,33,34,39,45,47,90,91 CER.CAPACITOR.SMD 0.1uF50V(100nF) 25.00 C17-19,49-53,56,59,61,67-71,74-76,78,80,81,94,202 CER.CAPACITOR.SMD 130pF50V 3.00 C10,38,41 CER.CAPACITOR.SMD 150pF50V 2.00 C13,66 CER.CAPACITOR.SMD 1.5pF50V 1.00 C73 CER.CAPACITOR.SMD 470pF50V 1.00 C44 CER.CAPACITOR.SMD 4700pF50V(4.7nF) 2.00 C85,86 TRIMMER CAPACITOR CTC05F500,50pF/2READ 1.00 T1 MICA CAPACITOR 33pF/63V 1.00 C3 MICA CAPACITOR 680pF/63V 1.00 C4 M/F.CAPACITOR 0.47uF250V 1.00 C37 M/F CAPACITOR(BOX) 0.0068uF/63V(6.8nF) 1.00 C5 M/F CAPACITOR(BOX) 0.068uF/63V(68nF) 1.00 C6 M/F CAPACITOR(BOX) 0.68uF63V(680nF) 1.00 C7 MYLER CAPACITOR 0.22uF100V(220nF) 1.00 C36 ELEC.CAPACITOR 10uF35V 1.00 C55 ELEC.CAPACITOR 22uF16V ELEC.CAPACITOR 47uF35V 6.00 C27,40,42,43,46,48 ELEC.CAPACITOR 100uF25V 2.00 C77,79 ELEC.CAPACITOR 1000uF35V 2.00 C21,24 ELEC.CAPACITOR 220uF35V 1.00 C20 ELEC.CAPACITOR 2200uF35V 1.00 C58 ELEC.CAPACITOR 470uF25V 3.00 C60,200,201 SWITCHING DIODE.SMD 1N4148 SWITCHING DIODE.SMD HSMS-2825-TR1 10.00 C1,12,14,22,23,25,28,30,32,35 13.00 D3-11,14,15,16,17 1.00 D1-1 19 Part Name Specification q"ty Referance. C/F. RESISTOR.SMD 22J, 1/8W 3.00 28,47,102 C/F. RESISTOR.SMD 220J, 1/8W 3.00 4,29,118 C/F. RESISTOR.SMD 2.2KJ, 1/8W 4.00 9,10,90,91 C/F. RESISTOR.SMD 22KJ, 1/8W 1.00 89 C/F. RESISTOR.SMD 240J, 1/8W 1.00 147 C/F. RESISTOR.SMD 270J, 1/8W 1.00 41 C/F. RESISTOR.SMD 2.7KJ, 1/8W 1.00 11 C/F. RESISTOR.SMD 300J, 1/8W 1.00 39 C/F. RESISTOR.SMD 33J, 1/8W 3.00 27,72,170 C/F. RESISTOR.SMD 330J, 1/8W 4.00 34,95,98,99 C/F. RESISTOR.SMD 33KJ, 1/8W 1.00 40 C/F. RESISTOR.SMD 39KJ, 1/8W 1.00 71 C/F. RESISTOR.SMD 470J, 1/8W 7.00 93,94,96,97,100,101,108 C/F. RESISTOR.SMD 4.7KJ, 1/8W 1.00 30 C/F. RESISTOR.SMD 51J, 1/8W 1.00 114 C/F. RESISTOR.SMD 510J, 1/8W 4.00 86,87,R01,R02 C/F. RESISTOR.SMD 5.1KJ, 1/8W 3.00 74,75,76 C/F. RESISTOR.SMD 62J, 1/8W 2.00 146,148 C/F. RESISTOR.SMD 7.5KJ, 1/8W 2.00 7,73 C/F. RESISTOR.SMD 8.2KJ, 1/8W 1.00 104 SEMI-FIXED RESISTOR VZ067TH1, 100B 1.00 SFR11 SEMI-FIXED RESISTOR VZ067TH1, 1KB 2.00 SFR10,13 SEMI-FIXED RESISTOR VZ067TH1, 10KB 8.00 SFR1,2,3,4,5,6,7,16 SEMI-FIXED RESISTOR VZ067TH1, 100KB 2.00 SFR12,15 SEMI-FIXED RESISTOR VZ067TH1, 2KB 1.00 SFR8 M/F. RESISTOR.SMD 1KF, 1/8W 4.00 21,35,37,38 M/F. RESISTOR.SMD 100KF, 1/8W 1.00 117 M/F. RESISTOR.SMD 11KF, 1/8W 2.00 23,25 M/F. RESISTOR.SMD 120F, 1/8W 1.00 136 M/F. RESISTOR.SMD 1.21KF, 1/8W 2.00 12,16 (1.2K,F) M/F. RESISTOR.SMD 121KF,1/8W 2.00 R13,17 M/F. RESISTOR.SMD 1.5KF, 1/8W 1.00 133 M/F. RESISTOR.SMD 21.5F, 1/8W 2.00 137,139 (22,F) M/F. RESISTOR,SMD 2.2KF, 1/8W 1.00 135 M/F. RESISTOR.SMD 249F, 1/8W 1.00 R115 (243,F) 20 Part Name Specification q"ty Referance. M/F. RESISTOR.SMD 24.9KF, 1/8W 1.00 129 (24.3K,F) M/F. RESISTOR.SMD 3.32KF, 1/8W 1.00 119 (3.4K,F) M/F. RESISTOR.SMD 42.2F, 1/8W 1.00 120 M/F. RESISTOR.SMD 430F, 1/8W 2.00 22,24 M/F. RESISTOR.SMD 4.99KF, 1/8W 1.00 132 M/F. RESISTOR.SMD 56.2F, 1/8W 1.00 138 (56,F) M/F. RESISTOR.SMD 576F, 1/8W 1.00 121 M/F. RESISTOR.SMD 825 2.00 127,130 M/F. RESISTOR 900F, 1/4W 1/8W F 1.00 32 OXIDE FILM RESISTOR 560J, 1W 1.00 66 KEY SWITCH SPUN90X1CO21 1.00 KEY SWITCH SPUN40X1C041 1.00 POWER SWITCH JPP2295MPACS72 1.00 P-S/W1 I.C.(TI) SN75107AN 1.00 U3 I.C.SMD BA10324AF 2.00 U1,2 Rohm I.C.(SAM.MOTO.NS.) MC7805 1.00 U20 I.C.(SAM.MOTO) MC7815 1.00 U5 I.C.(SAM.MOTO) MC7915 1.00 U7 I.C.(MOTO.) MC10116 1.00 U8 I.C.(HAR.RCA) CA3096AE 1.00 U17 I.C.SMD(SIG) SN7400/SN74S00 1.00 U4 I.C(NS) 74F191N 1.00 U18 I.C.SMD(NS.HIT.PHI.) SN74HC393 2.00 U10,11 I.C.SMD(NS.HIT.SGS.) SN74HC138 1.00 U14 I.C.(TOSHIBA) TD62783AP 1.00 U13 I.C.(AMD) GAL16V8 1.00 U9 WIRE ASS'Y(1365#30) IN PUT CABLE,250mm 1.00 CRYSTAL 10.0000MHz(HC-49/U) 1.00 10M 20PPM . MAIN PCB 8210-M12 1.00 SHIELD CASE Zn-pl 0.3t 104x40x18 1.00 NUT M3, NI-PL 1.00 U15 Ass'y SCREW, MACHINE M3x8BH, NI-PL 1.00 U15 Ass'y SCREW, TAPPING T3x6BH,ZN-PL 3.00 U37,15,20 SPRING, COIL 6x2x7(SHIELD 용) 0.00 MAIN PCB GND HEAT SINK TR 용,내경 8.3,외경 16 2.00 Q16,29 Ass'y HEAT SINK 78SERIES 용(ㄷ자모양) 2.00 U7,15 Assy' HEAT SINK 8210 ㄷ자 17x9x19 1.00 U20 Ass'y 21 4-2.. Display PCB Parts List Part Name Specification Q'ty Referance WAFER 8pin,YW02508,연호 2.00 CN12,13 FND(hp) HDSP-H513#001 1.00 FND(SINGLE ) FND(hp) HDSP-K513#001 3.00 FND1,2,3 LED BL-R2130A-T(5x5X10) 5.00 LED 1-5 DISPLAY PCB(80SER.) 8210-DIS-01 1.00 4-3.. VR PCB Parts List Part Name Specification Q'ty Referance WAFER 3pin,YW02503,연호 5.00 CN8(WIDTH),CN9(RATE),CN2(FREQ),CN5(AMP),CN6(OFFSET) WAFER 4pin,YW02504,연호 1.00 CN3(SYM) VARIABLE RESISTOR V16L4(7x5)S15KCB10K 1.00 VR5(WIDTH), VARIABLE RESISTOR V16L4(7x5)S15KCB5K 1.00 VR4(OFFSET) VARIABLE RESISTOR V16L4(7x5)S15KCB50K 1.00 VR2(SYM) VARIABLE RESISTOR V16L4N15KCB10K 2.00 VR6(RATE),VR1(FREQ), VARIABLE RESISTOR V16L4N15KCB500 1.00 VR3(AMP) VR PCB(80SER.) 8210-VR-02 1.00 4-4. Front Panel Assembly Parts. Part Name BNC CONNECTOR Specification Q'ty Referance BNC-RB-4CUTTING 4.00 OUTPUT,TTL SYNC, VCF, EXT COUNTER IN 2pin 150mm 1.00 VCF 2pin 220mm 2.00 TTL.OUTPUT BRACKET, VR PCB BN-LGP,160x25x30 1.00 BRACKET, BNC BN(80SER.)-AG/FG 1.00 FRONT PANEL, ABS BN(80SER-난연)-12965 1.00 KNOB, VR, ABS Pi10x13mm,DARK-GRAY 6.00 PLATE, FRONT, PC 8210DAG 1.00 ACRYLE FILTER 8210-DAG 1.00 WIRE ASS'Y( WIRE ASS'Y( ) ) NUT(VR) 6.00 VR NUT(BNC,F) 4.00 BNC BRACKET NUT M3, NI-PL 2.00 BNC BRACKET SCREW, MACHINE M3x4BH,NI-PL 2.00 BNC BRACKET SCREW, TAPPING T3x8BH, ZN-PL 5.00 VR PCB WASHER, PLAIN 내경:3,외경:12/NI-PL 2.00 EXT COUNT IN BNC WASHER,PLAIN(VR) 7.2x12x0.2t/NI-PL 6.00 VR WASHER,LATCH(BNC) 9.5x13x0.5t/NI-PL 4.00 BNC WASHER,PLAIN(BNC S.) 10x13x0.3t/NI-PL 4.00 BNC DISPLAY PCB ASS'Y FG-8210/DAGA 1.00 VR PCB ASS'Y FG-8210/DAGA 1.00 22 4-5. Rear Panel Assembly Parts. Part Name Specification Q'ty Referance FUSE(UL,VDE) 50F,250V200mA(20mm) 1.00 FUSE HOLDER IN FUSE HOLDER R3-11,BN 1.00 REAR PANEL ASS'Y EMI GASKET 71TS-FK10-R10-170-00 1.00 REAR PANEL ASS'Y MOTOR FAN DC5V,0.5W (40x40) 1.00 REAR PANEL ASS'Y GND CONNECTOR 1.00 REAR PANEL ASS'Y AC INLET(SAM IL) NFU-101,NOISE FILTER 1.00 REAR PANEL ASS'Y POWER TRANS FG-8210,8220 1.00 REAR PANEL ASS'Y I.C.(SAM.MOTO.NS.) MC7805 2.00 REAR PANEL ASS'Y (U5,U15) HEAT TUBE Pi5 x 15 mm 3.00 AC INLET,FUSE HOLDER HEAT TUBE Pi 12 x 60 mm 1.00 FUSE HOLDER WIRE ASS'Y(1015#22) GND WIRE,180mm,LUG 3.00 REAR PANEL ASS'Y WIRE ASS'Y(1015#22) DIW,120mm,BLACK 1.00 AC IN-FUSE WIRE ASS'Y(1015#22) 3pin 2Wire ,220mm 1.00 TRANS BN-DAG, 27x10.5,2T 2.00 TRANS REAR PANEL PRESS BN-DAG,FG-8210 1.00 NUT(GND TERMINAL) INCH 2.00 GND CONNECTOR NUT M3, NI-PL 8.00 TRANS,REGULATOR, FAN SCREW, MACHINE M3x10BH,흑착색 2.00 NOISE FILTER (AC INLET) SCREW,MACHINE M3x16BH 흑착색 2.00 FAN SCREW, MACHINE M3x8BH-W, NI-PL 2.00 TRANS WASHER, PLAIN 내경:3,외경:10/NI-PL 4.00 TRANS,AC INLET WASHER, SPRING 내경:3,외경:5, ZN-PL 2.00 TRANS WASHER, LATCH 4x6.5x0.3t 1.00 GND CONNECTOR BRACKET, POWER 23 4-6. Others. Part Name Specification Q'ty Referance I.C.(ATMEL) AT89C52 CABLE TIE 100mm, WHITE 10.00 WIRE ASS'Y(#24) 3-3pin 150mm 6.00 WIRE ASS'Y(#24) 4-4pin 150mm 1.00 8-8pin 220mm 2.00 3-3pin 150mm 1.00 SHIELD CASE 8210 TOP 0.6t 210x202(156)x35 1.00 MOUNT POLE- TOP SHIELD CASE 8K-BOT Znpl 0.6t 210x202x35 1.00 MONUT POLE-BOTTOM BOTTOM CASE, ABS BN(80SER,난연)-12965 1.00 TOP CASE, ABS BN(80SER.난연)-12965 1.00 HANDLE, ABS BN(80SER.난연)-12965 1.00 RUBBER FOOT BN-DAG,37x8.5,대 2.00 BOTTOM CASE RUBBER FOOT BN-DAG,32x8.5,소 2.00 TOP CASE EMI GASKET 71TS-FK10-R10-170-00 1.00 BOTTOM SHIELD CASE ASS'Y SHIELD PLATE BN-DAG, 248X163 0.00 SHIELD CASE BOTTOM SPONGE PAD 20x40,5T,한쪽 테이프 6.00 MAIN PCB KNOB, POWER, ABS BN-DAG(80SER.) 1.00 POWER STICK KNOB, PUSH S/W, ABS BN(80SER.)-12965 SCREW, MACHINE M3x6BH,H5, NI-PL 0.00 SHIELD TOP + MOUNT POLE SCREW, MACHINE M4x45BH, ZN-PL 4.00 TOP+BOTTOM CASE SCREW, TAPPING T3x8BH, H6, NI-PL 3.00 PCB -BOTTOM CASE MOUNTING POLE Pi3x50,육각 8210MAIN 1.00 MAIN PCB-SHIELD CASE WASHER, SPRING 내경:3,외경:5, ZN-PL 1.00 SHIELD TOP + MOUNT POLE EMI AIR VENT FILTER SUI40-24-125-45-13 2.00 TOP,BOTTOM SHIELD FRONT PANEL ASS'Y FG-8210/DAGA 1.00 REAR PANEL ASS'Y FG-8210/DAGA 1.00 MAIN PCB ASS'Y FG-8210/DAGA 1.00 WIRE ASS'Y( WIRE ASS'Y( ) ) 1.00 U12 AC LINE PART 13.00 KEY S/W 24 4-7. Packing Part Name Specification Q'ty Referance FUSE(UL,VDE) 50F,250V200mA(20mm) 1.00 SPARE FUSE. POWER CORD(230V) KKP-30,SVT3/18A"VDE" 1.00 "VDE" CABLE ASS'Y( BNC TO CLIP( 1.00 ) ) STYROFOAM BOX BENCH, 300x150x65mm 2.00 SILICA GEL 3g 1.00 STICKER, S/N, 230V BN(80SER.),15W200mA 1.00 15w ,230V/200mA F MANUAL(8210) FG8210, DAG 영문 1.00 INNER BOX (8000SER.) DAG-BN,340x310x165 1.00 CARTON BOX(무인쇄) BN,645x355x365 0.25 4CTN.(IN BOX -340x310x165) VINYLE BAG 70x100mm,Zipper Type 1.00 SPARE FUSE. VINYLE BAG 265x400mm 1.00 PRODUCT. 5. CIRCUIT DIAGRAM - Refer to Attached File. 25 5 4 3 2 1 R83 10K D COUNTER +5V(A) D 06-R150#1 + C40 47/16V C39 103 +5VD R87 510 C48 47/16V R85 100K Q18 2N5486 3 1 C9 47/16V 7 R99 330 Q20 2N3906 U8A MC10116 R92 150 U8C MC10116 2 4 15 2 5 9 C38 130P R102 22 13 + 3 12 6 C41 130P Q21 2N3906 14 8 11 2 U8B MC10116 R95 330 10 C37 474/250V SW5 EXT/INT SW R88 150 1 BNC4 EXT COUNT IN 1/16 C44 470P(C/C) C47 103 + D10 1N4148 Q19 2N3906 D11 1N4148 R93 470 3 C R86 510 R97 470 R98 330 R100 470 1 R90 2.2K R91 2.2K C43 47/16V C91 103 + C46 47/16 C45 103 +5VD C90 103 C R103 120 R101 470 2 + D16 1N4148 R96 470 R89 22K SFR16 10K R108 470 R94 470 D17 1N4148 SW6 L.P.F 15 1 10 9 A B C D 3 2 6 7 13 14 4 5 11 QA QB QC QD RCO CLK G D/U LOAD MX/MN 12 C12 103 B U18 74LS191 B 06-U9#3 06-U9#5 06-U9#4 R01 510 Title Model Size A 5 4 3 2 8210 - 05 Drawing Design C01 50P R02 510 Checked C02 50P Approved COUNTER PREAMP CIRCUIT A3 Sheet 5 of 6 Date 2002/04/13 Rev 02 Scale 2:1 DAGATRON 1 A /Se G.T D5 /Sf /Sg /Sa /Sb /F9 D4 1 2 3 4 5 D3 MHZ 10 9 8 7 6 /Se /Sd /Sc /Sh /Se D /F3 /F4 /F5 /F6 /F7 /F8 /F9 18 17 16 15 14 13 12 11 10 /Se /Sd /Sc /Sh /Se /Sd /Sg /Sc /Sh C53 104 18 17 16 15 14 13 12 11 10 C56 104 D2 KHZ /Sf /Sg /Sa /Sb /F7 /F8 /Sf /Sa /Sb FND4 SEGMENT /Se /Sd /Sc /Sh /Se /Sd /Sg /Sc /Sh C52 104 D1 HZ 1 2 3 4 5 6 7 8 9 FND3 SEGMENT 18 17 16 15 14 13 12 11 10 C51 104 FND2 SEGMENT /Se /Sd /Sc /Sh /Se /Sd /Sg /Sc /Sh C50 104 mHZ /Sb /Sd 8.8. 8.8. 8.8. 8. +5V(D) /Sa /Sc FND1 SEGMENT C49 104 1 /Sf /Sg /Sa /Sb /F5 /F6 /Sf /Sa /Sb D 2 1 2 3 4 5 6 7 8 9 3 /Sf /Sg /Sa /Sb /F3 /F4 /Sf /Sa /Sb 4 1 2 3 4 5 6 7 8 9 5 U9 PAL16R4 1 2 3 4 5 6 7 8 05-U18#14 05-U18#7 05-U18#6 13 A 12 CLR QA QB QC QD 11 10 9 8 U11A 74LS393 1 2 A CLR QA QB QC QD 3 4 5 6 U11B 74LS393 13 A 12 CLR QA QB QC QD 11 10 9 8 P2.0 P2.1 P2.2 P2.3 P2.4 P2.5 P2.6 T1 28 14 P2.7 T0 39 38 37 36 35 34 33 32 P0.0 P0.1 P0.2 P0.3 P0.4 P0.5 P0.6 P0.7 1 2 3 4 5 6 7 8 RXD TXD INT0 10 11 12 1 2 3 4 5 6 7 8 Q23 A1015 R105 10 Q24 A1015 R106 10 Q25 A1015 R107 10 1 2 3 + R108 10 C55 10/16V +5V(D) 6 4 5 A B C G1 G2A G2B Y0 Y1 Y2 Y3 Y4 Y5 Y6 Y7 15 14 13 12 11 10 9 7 /CO7 /CO6 /CO5 Q28 A1015 R110 10 Q32 A1015 R111 10 R112 10 B +5V(D) R149 10 Q30 C1815 05-SW5#5 R150 1K 18 R104 8.2K C57 56P T1 20P Title Model A Size 4 Q27 A1015 R109 10 /CM0 /CM1 /CM2 /CM3 /CM4 /CM5 /CM6 /CM7 Y1 10MHZ C64 30P 5 Q26 A1015 U14 74LS138 31 9 19 X2 /CO4 /CO3 /CO0 /CO1 /CO2 /CO3 /CO4 /CO5 /CO6 /CO7 /CO2 /CO1 Q22 A1015 /a /b /c /d /e /f /g /h +5V(D) EA/VP RESET X1 /Sa /Sb /Sc /Sd /Se /Sf /Sg /Sh /CM7 21 22 23 24 25 26 27 15 P1.0 P1.1 P1.2 P1.3 P1.4 P1.5 P1.6 P1.7 1 2 3 4 5 6 7 8 /CM6 WR RD INT1 1 2 3 4 5 6 7 8 /CM5 U10B 74LS393 16 17 13 J3' CN3' /CM4 CLR 3 4 5 6 O1 O2 O3 O4 O5 O6 O7 O8 1 2 3 4 5 6 7 8 /CM3 B QA QB QC QD PSEN ALE/P 2 A I0 I1 I2 I3 I4 I5 I6 I7 J3 CN3 18 17 16 15 14 13 12 11 /CM2 U13 TB62783 1 2 3 4 5 6 7 8 29 30 1 C J13' CN13' U12 89C52 U10A 74LS393 8 7 6 5 4 3 2 1 J13 CN13 1 2 3 4 5 6 7 8 9 11 /CO0 I0 I1 I2 I3 I4 I5 I6 I7 I8 I9 F0 F1 F2 F3 F4 F5 F6 F7 /CM1 12 13 14 15 16 17 18 19 /CM0 C 3 8210 - 06 A3 Sheet 6 of 6 Date 2002/04/13 2 Drawing Design Checked Approved CPU CONTROL CIRCLE Rev 02 Scale 2:1 A DAGATRON 1 5 4 3 2 1 Sweep Width VR5 10KB J8 CN8 SW1 SWEEP WIDTH 3 2 R70 1K 1 2 3 1 8 +15V +15V 1 3 D8 1N4148 D D 2 1 SFR8 2.2KB -15V +15V 8 + 13 U2C GL324 1 R76 5.1K Q17 2N3906 14 12 U2D GL324 + D9 1N4148 R11 2.7K 02-U30A#12 6 - Q2 2N3904 7 U2B GL324 11 R72 33 5 R77 10K + 3 3 R74 5.1K C30 22/16V + 4 9 10 C31 0.01(C/C) + 1 2 3 2 R75 5.1K R71 39K - VR6 10KB J9 CN9 - Sweep Rate C36 0.22uF(MYLER) R73 7.5K C33 0.01(C/C) C C32 22/16V C -15V BNC1 VCF IN 1 J1 CN1 R300 470 R2 1K 3 6 3 1 2 3 2 - R9 2.2K 2 3 2 Q1 2N3906 1 U1B GL324 SFR6 10KB 1 R3 1K 7 + U1A GL324 R8 1K R10 2.2K R114 51 3 1 C29 0.01(C/C) C28 22/25V + -15V J3 CN3 1 3 2 1 R6 1K SFR5 10KB 3 A - 8 U1C GL324 02-U30B#3 VR2 50KB 1 2 2 1 3 1 R7 7.5K 1 C2 0.22uF 22/16 C37 8 Title SW2 Symm Model -5V 5 4 2 2 SFR4 10KB 3 + 9 11 +15V 10 + SFR3 10KB 3 SFR7 10KB 4 3 2 1 4 SFR2 10KB 3 B +21V 1 SFR1 10KB 3 2 B 2 1 VR1 10KB J2 CN2 + R1 10K - 2 C304 104 5 Frequency R4 220 1 2 Size 3 2 8210 - 01 Drawing Design Checked FREQ/VCF IN CIRCUIT A3 Sheet 1 of 6 Date 2002/3/30 Rev 02 Scale 2:1 DAGATRON 1 Approved A 5 4 3 2 1 02-R19#1 02-U4A#1 02-R32#1 +5V R46 2K C19 0.1(MON) 3 R117 100KF R69 10 R118 220 1 C34 0.01 SW1 SINE SW2 TRIANGLE C67 0.1(MON) R140 10(1/2W) SW3 SQUARE R119 3.32KF 1 2 3 Q1B Q1E Q1C 4 5 6 Q2E Q2B Q2C 7 8 Q3E Q3B R120 R121 42.2F 576 SUB 16 Q5C Q5B Q5E 15 14 13 Q4C Q4B Q4E 12 11 10 Q3C 9 R125 1K D D5 1N4148 C78 0.1(MON) R127 825F C75 0.1(MON) + C77 100/25V R139 21.5F R128 150 Q14 2N3563 Q15 2N3906 Q16 2N2219 2 R147 240 1 C17 0.1(MON) SFR10 1KB C C66 150P R37 1KF R33 2K R135 10(1/2W) Q10 C3198 1 3 R122 1.1K 2 3 J5 CN5 2 R43 1K R42 1K 1 1 2 1 C14 22/10V + R44 10 R116 R47 10K 22 VR4 5K C73 1.5pF 1 5 2 4 3 R145 100(1/2W) R142 10(1/2W) OUTPUT 1 SW3 ATT C82 100P RG58 Q29 2N2905 R160 1K Q13 2N3904 B Q12 2N5771 SW4 DC OFFSET 1 2 6 D7 1N4148 R123 1.21K R130 825F J6 CN6 SFR13 1KB R36 1K C69 0.1(MON) C18 0.1(MON) 3 2 C72 1.5pF +15V 3 2 1 VR3 AMP 500B 3 R38 1KF R136 2.2KF D14 1N4148 C80 0.1(MON) C74 0.1(MON) 100/25V C79 + 1 R134 1.5KF Q11 C3198 2 SFR11 100B R144 100(1/2W) R115 249 R42 220 SFR12 100KB R35 1KF C BNC3 R40 33K Q8 Q9 C1815 C3198 B R148 62 R141 10(1/2W) R129 24.9KF R41 270 3 R146 62 C68 0.1(MON) C87 22P R34 330 C71 0.1(MON) R132 4.99KF D6 1N4148 2 3 2 C35 22/16V + R124 1K R138 56.2F U17 CA3096 2 SFR15 100K C76 0.1(MON) R126 100 1 D +15V 3 2 1 R137 21.5F R131 100 R161 1K R136 144F R74 10(1/2W) C70 0.1(MON) C81 0.1(MON) -15V C15 0.01uF(CER) Title A Model -5V Size 5 4 3 2 8210 - 03 Drawing Design Checked AMPLFIER CIRCUIT A3 Sheet 3 of 6 Date 2002/04/13 Rev 02 Scale 2:1 DAGATRON 1 Approved A 5 4 3 2 1 +21V +21V R68 10/0.5W D + D C20 2200/35V +15V U5 7815 2 - + 4 1 VIN 3 VOUT 1 + C22 22/16V C25 22/16V VIN 2 3 + C21 1000/35V U6 7805 +5V VOUT 3 +5V + C23 22/16V 2 1 2 3 GND 1 2 3 DB1 DB06M GND J14 CN14 + J14' CN14' 1 +15V U7 7915 + 3 VOUT -15V C24 1000/35V C -15V 1 C VIN GND 2 R66 560/1W -5V ZD1 5.1V C27 47/35V -5V + +5V(D) T2 TRANSFORMER POWER 1 2 3 J15 CN15 1 2 3 SW8 POWER S/W 1 3 2 4 ST1 SELECT J16' CN16' 1 2 3 J16 CN16 4 5 6 1 2 3 10 C306 104/1KV C307 104/1KV 1 2 3 D12 1N4003 U15 7805 1 1 2 3 C59 104 VIN + C58 2200/16V GND J15' CN15' J4 CN4 VOUT J5' CN5' J5 CN5 D20 1N4003 C60 470/16V B C61 104 U20 7805 1 1 2 3 D22 1N4003 C202 104 VIN + C200 470/16V Model A Size 3 2 FAN DC FAN J17 CN17 VOUT Title 4 +5V(D) + D13 1N4003 7 8 9 1 2 3 5 3 2 F2 FUSE J4' CN4' GND B F1 NOISE FILTER 1 3 2 1 2 3 3 1 2 C201 470/16V 1 2 + 2 11 C203 104 8210 - 04 Drawing Design Checked POWER SUPPLY CIRCUIT A3 Sheet 4 of 6 Date 2002/04/13 Rev 02 Scale 2:1 Approved A DAGATRON 1 5 4 3 2 1 +15V D D R13 120KF +5V L2 INDUCTOR AUDIO C100 10n R26 1K D1-2 HSMS2825 Q5 2N5486 3 C3 33P D3 1N4148 Q7 2N3563 C10 130P C86 472 - Q4 3563 C7 0.68n(BOX) 1 U30A 072 R15 10K R20 1K R21 1KF 2 1 1B 1A 2Y 9 1Y 4 U4 SN75107 R30 4.7K R28 22 J10 CN10 R170 33 OUTPUT C13 150P C 1 1 2 TTL SYNC OUT R29 4.7K 1 Q6 2N5486 3 3 2 L3 INDUCTOR AUDIO 2 2 + 2B 2A 13 3 1 01-CN3#1 C84 30P(C/C) 11 12 U4B 74LS00 1G D4 1N4148 R24 430F C8 0.01(C/C) 5 C6 68n(BOX) R001 ??? R27 33 6 5 14 6 8 D1-1 HSMS2825 BNC2 4 C5 6.8n(BOX) VCC+ S 2G + C85 472 C101 10n(C/C) R23 11KF C4 680P(BOX) 14 U30D 072 C L1 INDUCTOR AUDIO 1 Q3 5771 VCC- - 12 C12 100/10V +5V 14 01-R11#1 + 2 13 R14 10K C305 10n 2 R12 1.2KF U4A 74LS00 R31 240 B R24 430 R18 10 R16 1.2KF R19 1.5K R25 11KF B R32 2.2K -5V C9 15P(C/C) R17 120KF 03-SW3#6 03-SW3#2 03-R46#1 Shield Box Title A Model Size 5 4 3 2 8210 - 02 Drawing Design Checked OSCILLATOR/TTL CIRCUIT A3 Sheet 2 of 6 Date 2002/3/30 Rev 02 Scale 2:1 DAGATRON 1 Approved A