Download ECO Tronic EBS. Trailer Analyser operating instructions

Transcript

Operating Instructions

Trailer Analyser

Version 1.1

BPW · THE QUALITY FACTOR

ECO Tronic EBS. Trailer Analyser

Operating instructions

Version 1.1

04.001.21.37.5

Trailer Analyser - Operating Instructions

1 Introduction / 2 Minimum requirements

1 Introduction

Contents

Page

With the Trailer Analyser you can read analysis data stored in

the ECO Tronic EBS ECU to a PC and evaluate this data.

1 Introduction

2

2 Minimum requirements

2

3 Abbreviations

3

4 Installation

4

The vehicle data is stored in the ECO Tronic EBS ECU. It remains

stored even when the power to the EBS system is switched off.

5 Start screen - Description

6

6 Main menu - Overview

8

Note:

• The Trailer Analyser diagnostic adapter differs from the

diagnostic adapter used with the Trailer Manager and also

serves as a safety dongle for the programme. It is therefore

not possible to operate the Trailer Analyser with the Trailer

Manager diagnostic adapter or other adapters available in

the market (USB adapters).

7 Main menu - Snapshots

9

8 Main menu - Histogram

12

9 Histogram - Options

14

10 Main menu - Trip Log

17

11 Trip Log - Options

18

12 Main menu - User information

23

4.1

4.2

4.3

Hardware

Software

Installation options

A diagnostic adapter (PC dongle) enables data transfer between

the PC and the ECO Tronic EBS ECU. The connection to the

diagnostic adapter is by means of a USB cable connected to the

USB terminal of the computer and an additional cable connected

to the diagnostic terminal of the EBS ECU.

• The Trailer Analyser can only be opened and used with the

diagnostic adapter connected.

2 Minimum requirements

The minimum requirements for the PC or Laptop for operating

the Trailer Analyser are as follows:

• Processor

- minimum 486

RAM

- 64 MB

Hard disc

- 100 MB

Monitor

- minimum 1024 x 768 VGA

USB connection - for connecting the diagnostic cable

• MS Windows NT

MS Windows 2000

MS Windows XP

MS Windows Vista :

MS Windows 7 :

2

Installation only with administrator

rights

Installation only with administrator

rights

3 Abbreviations

Abbreviations Explanation

Description

2S/2M

2 Sensors / 2 Modulators

ABS system with 2 rotational speed sensors and 2 modulators

ABS

Anti-Lock Braking System

Prevents the locking of braked wheels to maintain lateral grip

ADM

Assembly Data Management

Software function for storing all important vehicle data

ADR

Accord européen relatif au transport European agreement on international transport of dangerous goods by road

international des marchandises

Dangereuses par Route

ASC

Adaptive Surface Control

ABS control that dynamically adapts to road conditions

AUX

AUXiliary

Additional input / output for sensors or actuators / valves

BPM

Brake Performance Monitoring

Software function for monitoring brake performance

Controller Area Network

Data bus system, used for controller communication in vehicles, among others

CAN

®

COLAS +

Lift and lower valve

Valve for lifting and lowering the vehicle body in the case of airsprung vehicles

DCV

Double Check Valve

Anti-compounding valve to prevent simultaneous application of service

brakes and emergency brakes

DTC

Diagnostic Trouble Codes

Brake system error / warning codes for diagnosis and repair

EBS

Electronic Braking System

ECE R13

Economic Comission for

Europe Regulation No. 13

Electro-pneumatic brake system with CAN communication between the truck

and the trailer

European regulation No. 13 - Brake systems

ECU

Electronic Control Unit

EEPROM

ELS

(LSV)

Electrically Erasable Programmable

Read Only Memory

Electronic Load Sensing

Function for automatically adapting the braking force to the load of the vehicle

Load Sensing Valve

EOLT

End Of Line Test

End of line system check to ensure correct system installation

EPRV

Electro Pneumatic Relay Valve

Electro pneumatically piloted relay valve of the EBS

GPI

General Purpose Input

AUX option

General Purpose Output

AUX option

Integrated Lift Axle Steering

EBS controlled lift axle valve

GPO

®

ILAS -E

Electronic controller

ISO 1185

Standardised interface between truck and trailer for lighting control

ISO 11992

CAN bus communication standard between truck and trailer for brake control

ISO 7638

Standardised interface between truck and trailer supplying ABS/EBS systems

with power, transferring a signal for a warning device and, if fitted, enabling

CAN communication as standardised in ISO 11992

LWS

Lining Wear System

Brake pad wear sensing

PPV

Pressure Protection Valve

Pressure protection valve that separates the brake and air suspension circuits

PTC

Push To Connect

Pneumatic connectors to ease installation

QRV

Quick Release Valve

REV

Relay Emergency Valve

Relay valve with emergency brake function

RCM

Road Condition Monitoring

Software function for recording and evaluating road profiles

RtR

Reset to Ride Height

Automatic return to ride height

SAUX

Super AUX

Installation-optimized possibility for three digital inputs

TA

Traction Assist

Starting traction control

TrCM

Trailer Control Module

Parking and manoeuvring valve with emergency brake function (and

integrated pressure protection)

TRS

Trailer Roll Stability

Function that reduces the risk of the trailer rolling over

3

Trailer Analyser - Operating Instructions

4 Installation

The software must be installed before connecting the diagnostic

adapter.

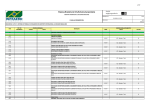

ECO Tronic EBS diagnostic kit

(BPW no. 99.00.000.9.65)

4.1 Hardware

To connect the ECO Tronic EBS to a standard PC the corresponding diagnostic kit (BPW no. 99.00.000.9.65), containing the

diagnostic adapter, the required connecting cables and a USB

stick with the Trailer Analyser software, is required.

If you already have the ECO Tronic EBS diagnostic kit with the

BPW number 99.00.000.9.64 you only need the Trailer Analyser

accessory kit no. 99.00.000.9.66 with the diagnostic adapter

(PC dongle) for use only with the Trailer Analyser. This Trailer

Analyser diagnostic adapter is the prerequisite for using the

software and constitutes the access authorisation. The software

cannot be opened until the diagnostic adapter is connected.

The diagnostic adapter has a multi-functional LED which shows

the proper function of the device as follows:

Yellow: The diagnostic adapter is connected to the PC and

supplied with power from the USB connection (PC

connection only).

Red:

The ECO Tronic EBS ECU is supplied with 24 V

power and connected to the diagnostic adapter.

Green: The data are being transferred.

Note: During connection the red and green LEDs light up

alternately.

4.2 Software

Note: The software will run only with the connected

diagnostic adapter.

Open the „msi file“ (installation file) for the Trailer Analyser and

follow the instructions on the screen to install the programme.

Note: In order to load the data via the Trailer Analyser from

the ECO Tronic EBS, there must be a connection between the

PC and the EBS. Furthermore, the EBS must be supplied with

power via ISO 7638.

The files are installed in the following PC folder:

C:\Program Files\BPW\Trailer Analyser

This concludes the installation.

Keep the installation software in a safe place in case you need

to install the software again.

To obtain the latest version of the Trailer Analyser, download

this in the required language from the BPW homepage under

www.bpw.de

4

Diagnostic adapter

Trailer Analyser

ISO 7638

Interface unit

USB stick

USB cable

Side wall diagnostic cable for adapter

4 Installation

4.3 Installation options

Option 1

Installation option 1

Connect the ECU via the ISO 7638 7-pin interface connection,

in which pins 6 and 7 serve as a CAN data bus. The required

cables are supplied with the ECO Tronic EBS diagnostic kit for

the Trailer Analyser.

Diagnostic

adapter

ISO interface unit

Installation option 2

Connect the ECU via the terminal on the side of the vehicle

(side wall diagnosis). The cable from the side wall diagnosis

interface to the adapter is supplied in the above diagnostic kit.

Option 2

Alternative positions

(side wall diagnosis)

Diagnostic adapter

Installation option 3

Connect the ECU via a cable (not included in the above

diagnostic kit) from the USB adapter directly to the DIAG

interface of the Modulator. You can then directly access the

ECU.

Supply 24 V power to the EBS system from an external source.

Lower voltages can cause connection problems. The LED on

the adapter must light up in red. If this is not the case, check

the connections and try again.

Option 3

Direct connection to

ECU

Diagnostic

adapter

Diagnostic

connection

“DIAG“ o ECU

5

Trailer Analyser - Operating Instructions

5 Start screen - Description

Starting the programme

Start the Trailer Analyser programme with the icon on the

desktop. The start screen is then displayed.

Note: The programme requires a connected diagnostic adapter.

If the adapter is not connected, a diagnostic adapter fault

message is displayed.

Trailer Analyser

Diagnostic adapter fault message

5 tabs

Elements of the Start screen

Five tabs are located at the top of the monitor for the Trailer

Analyser programme:

Overview, Snapshots, Histogram, Trip Log and User Info.

COM:1

Vehicle data window

The vehicle identification information is displayed in the vehicle

data window.

VIN:

Manufacturer:

Brake Calc:

Unit Type:

VIN:

Manufacturer:

Brake Calc:

Unit Type:

Serial:

Version:

Generation:

Dongle version:

6

Vehicle identification number

Name of trailer manufacturer

Brake calculation number

User defined (manufacturer)

The serial number of the ECU

Software version in the ECU

ECU type

Diagnostic adapter version

BPWV00334YHE27006 Serial:

BPW Version:

WS08 3112.00 Generation:

ZTS 34.20 Dongle Version:

M0666_13

C505

GEN 2

G430

5 Start screen - Description

The following soft keys are available with every screen:

Search for ECU:

If an EBS ECU connection exists via the diagnostic adapter,

click on:

Actual ISO km

Trips

DTC Snapshots

Stability Snapshots

Over Speed Snapshots

Over Load Snapshots

Reservoir Snapshots

B+ Snapshots

24N Brake Applications

ISO Brake Applications

ABS Events

Stability Events

AUX1 Drive Activations

AUX2 Drive Activations

AUX3 Drive Activations

AUX4 Analogue GPI Activations

AUX5 Analogue GPI Activations

The Trailer Analyser programme then automatically searches

for an existing ECU connection.

Read from ECU:

To read out data from the ECU connected, click on:

239270.40

5045

32

14

2

1

0

0

160510

3374

10

1780

12173

0

0

0

BPWV00334YHE27006 Serial:

VIN:

Manufacturer:

This button is only active when an ECU has been found.

(“Search For ECU“ successful).

Brake Calc:

BPW Version:

WS08 3112.00 Generation:

ZTS 34.20 Dongle Version:

Unit Type:

M0666_13

C505

GEN 2

G430

0 0 2 3 9 2 7 0 40

COM:1

Note: If the diagnostic adapter is not connected, a fault message

is displayed.

Load from File:

If ECU data are stored in a file, you can display and analyse

these by clicking on

and selecting a stored file.

Save to File:

To store the data from the connected ECU, in a file, click on:

In general, data previously stored from the ECU can be viewed

at any time.

Export to Excel:

The “Export To Excel“ button allows you to save the data shown

in the Trailer Analyser as a .csv file and to process it further in

Excel.

Exit Trailer Analyser:

To exit the Trailer Analyser programme, click on:

Selecting the language

The BPW Trailer Analyser bar is located at the lower edge of the

monitor screen. Clicking with the right mouse button on this bar

or on the BPW logo in the title bar displays a menu in which you

can select the „Language“ option. The following languages are

available: Czech, Dutch, English, French, German, Hungarian,

Italian, Polish, Russian, Spanish, Swedish, Turkish.

Restore

Move

Restore

Size

Move

Minimize

Size

Maximize

Minimize

Language...

Maximize

Close

Language...

Close

A screen with the flags for the languages available with the Trailer

Analyser is displayed. Clicking on the required flag changes the

programme to the selected language. With Windows Vista and

Windows 7, the language setting is stored only if the user has

administrative authorisation rights.

7

Trailer Analyser - Operating Instructions

6 Main menu - Overview

Overview

The first tab displays the following information after loading a

data record:

Actual ISO km:

Shows the travel distance, which the trailer has covered

with a connected ISO 7638 supply. Also the total distance

traveled is calculated during which the trailer was attached

to ISO 7638 and 24N brake lights power supply or only to

24N emergency power supply. This is only an approximate

value, as the distance cannot be continuously recorded

without ISO 7638 power supply.

Trips:

A trip describes the transports in which the vehicle reaches

at least 10 km/h and covers a distance of at least 1 km thus

excluding travel over very short distances.

Number of DTC Snapshots*

Number of Stability Snapshots*

Number of Over Speed Snapshots*

Number of Over Load Snapshots*

Number of Reservoir Snapshots*

Number of B+ Snapshots*

- recorded when the voltage limit set is exceeded (default

setting 32 V)

Total number of 24N Brake Applications counted

Total number of ISO Brake Regulations counted

Total number of ABS Events counted

Total number of Stability Events counted

Total number of AUX1 Drive Activations counted

Total number of AUX2 Drive Activations counted

Total number of AUX3 Drive Activations counted

Total number of AUX4 Analogue GPI Activations counted

Total number of AUX5 Analogue GPI Activations counted

Displays the number of activations of the general purpose

inputs (GPI) when these exceed certain values defined in the

Trailer Manager

* See the following page for the definition of snapshot.

8

Actual ISO km

Trips

DTC Snapshots

Stability Snapshots

Over Speed Snapshots

Over Load Snapshots

Reservoir Snapshots

B+ Snapshots

24N Brake Applications

ISO Brake Applications

ABS Events

Stability Events

AUX1 Drive Activations

AUX2 Drive Activations

AUX3 Drive Activations

AUX4 Analogue GPI Activations

AUX5 Analogue GPI Activations

239270.40

5045

32

14

2

1

0

0

160510

3374

14

1780

12173

0

0

0

7 Main menu - Snapshots

Snapshots menu

{ test.fpf }

With the red „Snapshots“ tab at the top of the monitor screen

you can display the snapshots.

Vehicle Speed (km/h)

ISO Demand Pressure (Bar)

Yellow Line Pressure Demand (Bar)

Battery Voltage (V)

Stop Lamp Power (1/0)

LampOn Fault (1/0)

Lamp On (1/0)

Service Request (1/0)

Brake Apply Active (1/0)

Day

Month

Actual ISO km

Reservoir Pressure (Bar)

Suspension Pressure (Bar)

System On Duration (HH:MM:SS)

Definition: Snapshot is understood to mean the recording of

data at a particular moment in time. The recording is triggered

by threshold values previously set in the Trailer Analyser or the

occurring faults. The default values of these thresholds are

described on the following page.

The snapshots only show the most current events.

Peak

87 km/h

87

0.00

0.00

25.00

0

0

0

0

0

215052.41

7.50

6.80

00:04:28

VIN:

Selecting the snapshot type

Manufacturer:

Brake Calc:

Unit Type:

In the menu in the lower third of the monitor screen you can

select the snapshot type that you want to display. The following

options are available:

DTC:

Diagnostic Trouble Codes

Stability snapshots:

Braking events caused by the

Trailer Roll Stability (TRS)

Speed:

A snapshot is recorded (when the

set speed limit is exceeded)

Suspension:

A snapshot is recorded (when the

set load limit is exceeded)

Excessive pressure events

are displayed

Reservoir pressure:

Battery voltage:

01

02

03

04

05

06

07

08

09

10

11

12

13

14

15

16

17

18

19

20

BPWV00334YHE27006 Serial:

BPW Version:

WS08 3112.00 Generation:

ZTS 34.20 Dongle Version:

M0666_13

C505

GEN 2

G430

COM:1

Here over-voltage events are

displayed

Following selection of the required snapshot type, at the right

side of the monitor screen with a list of the available snapshots

is displayed. Selected snapshots are highlighted by flashing

buttons

as well as a coloured background. The

allow navigation through the individual snapshots. The snapshot

selected from this list is displayed in detail on the screen.

A maximum of 32 DTC snapshots and Stability 32 snapshots

can be stored and a maximum of 20 for the other types.

The most recent snapshot is stored under the number 01.

After exceeding the maximum number of snapshots data is

overwritten, beginning with the oldest snapshot.

9

Trailer Analyser - Operating Instructions

7 Main menu - Snapshots

Main screen

Each snapshot is comprised of the following data elements:

Vehicle Speed (km/h)

ISO Demand Pressure (Bar)

Yellow Line Pressure Demand (Bar)

Battery Voltage (V)

Stop Lamp Power (1/0)

LampOn Fault (1/0)

Lamp On (1/0)

Service Request (1/0)

Brake Apply Active (1/0)

Day

Month

Actual ISO km

Reservoir Pressure (Bar)

Suspension Pressure (Bar)

System On Duration (HH:MM:SS)

Vehicle speed (km/h)

The speed of the vehicle at the time of the recording

is indicated.

ISO Demand Pressure (bar)

The control pressure is transmitted via CAN indicated in

bar.

Yellow Line Pressure Demand (bar)

The control pressure of the yellow line is indicated in bar.

Peak

87 km/h

87

0.00

0.00

25.00

0

0

0

0

0

215052.41

7.50

6.80

00:04:28

01

02

03

04

05

06

07

08

09

10

11

12

13

14

15

16

17

18

19

20

Battery Voltage (V)

The voltage of the battery is indicated.

VIN:

Stop Lamp Power (1/0)

When a 1 is indicated the EBS was not supplied with

power via ISO 7368 but via the emergency power supply

(ISO 1185 / 24N).

Lamp-On Fault (1/0)

The recording shows whether the warning light was

activated at the time of the snapshot. If the warning light

was activated a 1 is displayed. The warning light on fault

is activated as soon as an EBS fault occurs.

Lamp On (1/0)

This recording shows whether the warning light was

activated at the time of the snapshot. The warning

light is activated e.g. in the event of insufficient supply

pressure or insufficient power (see also page 22).

Service Request (1/0)

The recording shows whether the service warning light

was activated at the time of the snapshot. The activation

of the warning lights can be allocated in the Trailer

Manager to certain AUX inputs and outputs. This service

warning light is activated if malfunctions of the AUX inputs

or outputs occur or when the service intervals are

exceeded (can be set in the Trailer Monitor).

Brake Apply Active (1/0)

This recording shows whether a brake actuation solenoid

was active at the time of the snapshot. This indicates

whether the electro-pneumatic relay valves (EPRV) of the

EBS were activated and the braking pressure therefore

applied.

Day

For an exact analysis, the day and month of the

Month event are indicated. These are available only if a Trailer

Monitor (with battery) was connected during the

recording.

Actual ISO km

This indicates the kilometre reading at the time of the

recording.

Reservoir Pressure (bar)

This indicates the air pressure in the reservoir tank.

Suspension Pressure (bar)

This indicates the bellows pressure in the air bags.

System On Duration

This indicates how long the system was supplied with power

(HH:MM:SS).

Remark:

1 = yes (activated)

0 = no (not activated)

10

BPWV00334YHE27006 Serial:

BPW Version:

Manufacturer:

WS08 3112.00 Generation:

Brake Calc:

ZTS 34.20 Dongle Version:

Unit Type:

M0666_13

C505

GEN 2

G430

0 0 2 1 5 0 5 2 41

COM:1

The speed, suspension, reservoir pressure and battery

voltage snapshots are recorded when a certain limit value

is exceeded.

Default values:

Speed:

Suspension:

Reservoir Pressure:

Battery Voltage:

100 km/h

130 %

9.75 bar

32 V

These values can be changed or adapted via the Trailer

Analyser with an ECU connected and supplied with power.

To adapt a value, enter the desired new value in the entry field

and click on the pencil symbol

.

Following successful transmission to the ECU, a green check

mark is displayed

.

Otherwise, a red symbol is displayed

.

7 Main menu - Snapshots

When you have selected a snapshot, clicking the „Hyperlink“

button

occured.

{ test.fpf }

switches to the trip in which the snapshot

DTC

WHEEL SENSOR 1A OUTPUT LEVEL

Vehicle Speed (km/h) 7

ISO Demand Pressure (Bar) 0.00

Yellow Line Pressure Demand (Bar) 0.00

Battery Voltage (V) 27.80

Stop Lamp Power (1/0) 0

LampOn Fault (1/0) 1

Lamp On (1/0) 0

Service Request (1/0) 0

Brake Apply Active (1/0) 0

Day Month Actual ISO km 238585.00

Reservoir Pressure (Bar) 6.65

Suspension Pressure (Bar) 4.95

System On Duration (HH:MM:SS) 00:01:05

This trip is featured in the trip sheet records in color. The mark

. Account must be taken,

may be reversed by the button

however, that only the last 1000 trips are stored (see Trip Log

chapter).

VIN:

01

02

03

04

05

06

07

08

09

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

BPWV00334YHE27006 Serial:

Manufacturer:

M0666_13

BPW Version:

Brake Calc:

C505

WS08 3112.00 Generation:

Unit Type:

GEN 2

ZTS 34.20 Dongle Version:

G430

COM:1

{ test.fpf }

Trips : ( 5045 )

Start Mileage (km)

250000 237851 237852 237924 237996 238175 238231 238351 238464 238585 238642 238709 238828 238946 238947 239064 239183 239251 239254 239259 239261

225000

200000

Start Mileage (km)

175000

150000

125000

100000

75000

50000

25000

0

0

9

8

1

0

9

8

2

0

9

8

3

0

9

8

4

0

9

8

5

0

9

8

6

0

9

8

7

0

9

8

8

0

9

8

9

0

9

9

0

0

9

9

1

0

9

9

2

VIN:

Manufacturer:

Brake Calc:

Unit Type:

0

9

9

3

0

9

9

4

0

9

9

5

0

9

9

6

0

9

9

7

0

9

9

8

BPWV00334YHE27006 Serial:

BPW Version:

WS08 3112.00 Generation:

ZTS 34.20 Dongle Version:

0

9

9

9

1

0

0

0

M0666_13

C505

GEN 2

G430

COM:1

11

Trailer Analyser - Operating Instructions

8 Main menu - Histogram

Histogram menu

{ test.fpf }

With the green „Histogram“ tab at the top of the monitor screen

you can display the histograms.

Brake Applications vs Pressure

test.fpf

80000

76165

72000

The histograms display important data collected over the life of

the EBS. With the exception of „Brake Performance Monitoring,

Resettable“, they cannot be erased.

64000

Brake Applications

56000

In the menu display in the middle of the screen, you can select

which histogram type you want to display. The following options

are available:

48000

40000

36218

32000

24000

22134

16000

13235

8134

8000

2828

61

0

0.5

1.0

1.5

2.0

2.5

3.0

3.5

836

322

111

53

84

140

378

330

13

4.0

4.5

5.0

5.5

6.0

6.5

7.0

7.5

8.0

Pressure (Bar)

Road Condition Monitoring

Brake Performance Monitoring

Brake Performance Monitoring, Resettable

Brake Applications vs Pressure

Brake Applications vs Speed

Brake Applications vs Energy

Braking Time vs Pressure

Braking Time vs Pressure, Hi-Res

Time vs Side Force

Time vs Aux 4

Distance vs Axle Load

Distance vs Reservoir Pressure

Brake Applications vs Pressure

Road Condition Monitoring

Brake Performance Monitoring

Brake Performance Monitoring, Resettable

Brake Applications vs Pressure

Brake Applications vs Speed

Brake Applications vs Energy

Braking Time vs Pressure

Braking Time vs Pressure, Hi-Res

Time vs Side Force

Time vs Aux 4

Distance vs Axle Load

Distance vs Reservoir Pressure

BPWV00334YHE27006 Serial:

M0666_13

BPW Version:

C505

WS08 3112.00 Generation:

GEN 2

ZTS 34.20 Dongle Version:

G430

Main screen

The histograms divide the collected data into classes,

each shown by a bar. The values beneath the bar show the

appropriate top class limit. The last bar shows all the values

greater than the value displayed beneath the bar.

{ test.fpf }

Brake Applications vs Pressure

test.fpf

850

13235

76165

36218

22134

8134

2828

836

765

By using the scrollbar on the left-hand side, you can scale the

histogram down, step by step, to the next lowest bar. In this

way, you can view lower values, which are only visible as a thin

bar in the chart, at a higher resolution.

680

Brake Applications

595

The right-hand chart shows the same values as in the above

chart. However, the chart was scaled up to the seventh-highest

bar by dragging the scroll bar.

510

425

378

340

170

140

111

85

84

61

53

13

0

0.5

1.0

1.5

2.0

2.5

3.0

3.5

4.0

4.5

5.0

5.5

6.0

6.5

7.0

7.5

8.0

Pressure (Bar)

This means that this bar is shown perfectly in the chart. The

bars around the 7.5 bar mark, which can hardly be told apart

in the top chart, are now easily visible and can be compared

graphically.

VIN:

Manufacturer:

Brake Calc:

Unit Type:

COM:1

A red value in the bar means that, due to scaling, the bar can

no longer be shown in full.

Scroll bar

12

330

322

256

BPWV00334YHE27006 Serial:

BPW Version:

WS08 3112.00 Generation:

ZTS 34.20 Dongle Version:

M0666_13

C505

GEN 2

G430

8 Main menu - Histogram

It is also possible to compare the data with another, previously

stored fpf file (e.g. from another vehicle). To load the data from

a second file to the screen, click on:

{ test.fpf }

Brake Applications vs Pressure

Brake Applications

test.fpf

and select the required file in the window which opens.

60000

54000

48000

42000

36000

30000

24000

18000

12000

6000

0

56438

28475

17625

10303

6588

44

0.5

1.0

1.5

2.0

2.5

3.0

2274

3.5

688

249

85

41

68

112

316

282

12

4.0

4.5

5.0

5.5

6.0

6.5

7.0

7.5

8.0

test.fpf

With the soft key

gram from the screen.

Brake Applications

When the file has been opened, two different histograms will

appear on the screen, one above the other.

you can remove the additional histo-

80000

72000

64000

56000

48000

40000

32000

24000

16000

8000

0

76165

36218

22134

13235

8134

61

0.5

1.0

1.5

2.0

2.5

3.0

2828

836

322

111

53

84

140

378

330

13

3.5

4.0

4.5

5.0

5.5

6.0

6.5

7.0

7.5

8.0

Pressure (Bar)

BPWV00334YHE27006 Serial:

VIN:

M0666_13

BPW Version:

Manufacturer:

C505

WS08 3112.00 Generation:

Brake Calc:

GEN 2

ZTS 34.20 Dongle Version:

Unit Type:

G430

COM:1

Clicking the right mouse button once allows you to highlight

the individual bars of the chart. In addition, the corresponding

x and y values (here, for example controlled brake pressure (top

and bottom class limits) and the number of brake applications

at this brake pressure) are shown in an information box.

{ test.fpf }

Brake Applications vs Pressure

test.fpf

80000

76165

72000

64000

Brake Applications

56000

48000

40000

36218

32000

Pressure (Bar) 1.5 2.0

Brake Applications 36218

24000

22134

16000

13235

8134

8000

2828

0

61

0.5

1.0

1.5

2.0

2.5

3.0

3.5

836

322

111

53

84

140

378

330

13

4.0

4.5

5.0

5.5

6.0

6.5

7.0

7.5

8.0

Pressure (Bar)

VIN:

Manufacturer:

Brake Calc:

Unit Type:

BPWV00334YHE27006 Serial:

BPW Version:

WS08 3112.00 Generation:

ZTS 34.20 Dongle Version:

M0666_13

C505

GEN 2

G430

COM:1

13

Trailer Analyser - Operating Instructions

9 Histogram - Options

Histograms

Road Condition Monitoring

test.fpf

90000

70000

This evaluation indicates e.g. that for 92781 kilometres

travelled, 0-5 rough road counts/km were registered. For 20713

kilometres, 5-10 rough road counts/km were registered. A low

number of rough road counts/km indicates that the vehicle was

operating on-road.

50000

40000

30000

20713

10000

6133

0

0

5

10

2252

1155

572

15

20

25

306

170

98

38

17

12

7

6

0

0

30

35

40

45

50

55

60

65

70

75

Rough Road Count / km

Road Condition Monitoring

test.fpf

900

848

810

720

630

Distance (km)

For example, for 160 km of the distance travelled the rough

road count was 30 - 35.

60000

20000

Diagram no. 1-2: Road Condition Monitoring / Off-Road*

This graph is another example of possible data in a Road

Condition Monitoring diagram.

This evaluation shows that rough road counts were repeatedly

registered for a relatively high number of the kilometres travelled.

This indicates increased off-road operation.

92781

80000

Distance (km)

Diagram no. 1-1: Road Condition Monitoring / On-Road*

This diagram shows the number of registered rough road

kilometres. Driving over rough roads is counted in terms of

„rough road counts“. In the diagram, all kilometres driven are

divided into classes according to the number of „rough road

counts“.

100000

540

452

450

373

360

266

270

257

238

193

180

160

131

120

106

98

35

40

45

50

90

* Road Condition Monitoring algorithm is not implemented in some

regional specific versions of BPW ECO Tronic EBS, thus rendering

of RCM data within histograms and trip details is not possible.

0

5

10

15

20

25

30

62

55

59

55

60

65

70

75

Rough Road Count / km

Diagram no. 2-1: Brake Performance Monitoring

The translucent green background represents the range of ECE

brake band. The number of brake actuations and their position

relative to the ECE brake performance are displayed.

Brake Performance Monitoring

test.fpf

7947

8000

7200

7670

6897

6400

Brake Applications

5600

In this case, most of the braking lies within the ECE band. It is

therefore not necessary to make brake adjustments.

77

0

5530

4800

4469

4000

3255

3200

2412

2400

1689

1600

1085

800

0

130

165

1

2

808

414

3

404

4

5

6

7

8

9

10

11

12

13

14

190

265

15

16

Decel Ratio Band

Diagram no. 2-2: Brake Performance Monitoring

In this case most of the braking lies outside the ECE band.

Brake Performance Monitoring

test.fpf

600

574

570

540

The brake settings and setup should be checked.

524

499

491

480

421

Brake Applications

420

382

360

300

240

211

180

113

120

60

47

19

7

3

2

0

2

11

12

13

14

15

16

0

1

2

3

4

5

6

7

8

9

10

Decel Ratio Band

Diagram no. 2-3: Brake Performance Monitoring

In this case part of the braking lies outside the ECE band. The

area with a green background shows the region of the ECE

brake band.

Brake Performance Monitoring

test.fpf

700

630

607

Brake Applications

420

412

395

350

319

280

261

210

131

140

70

0

56

0

0

1

1

12

1

2

3

4

5

12

6

7

8

9

Decel Ration Band

14

506

495

490

The brake settings and setup should be checked.

626

560

10

11

12

13

14

15

16

9 Histogram - Options

Brake Performance Monitoring, Resettable

test.fpf

9000

8017

8100

7200

5572

5400

4503

4500

3600

3276

2700

2425

1702

1800

The soft key for resetting the diagram is displayed

only with the EBS connected and supplied with power.

1100

900

0

130

169

1

2

814

417

3

406

4

5

Note: Diagram no. 2 cannot be erased and displays the data

over the entire life of the EBS.

6

7

8

9

10

11

12

13

14

194

268

15

16

Decel Ratio Band, Resettable

Brake Applications vs Pressure

test.fpf

80000

76165

72000

64000

56000

Brake Applications

Diagram no. 4: Brake Applications vs Pressure

With each application, the brake control pressure provided

via ISO 7368 or the yellow line is recorded. The diagram

displays the number of brake actuations in each of the

0.5 bar pressure intervals from 0 to 8 bar. Brake actuations

with a pressure of more than 8 bar are also stored in the last

class (8 bar).

7727

6949

6300

Brake Applications

Diagram no. 3: Brake Performance Monitoring

This evaluation is similar to diagram no. 2, however with the

possibility to reset and store new data. This tool is used e.g.

when changing tractor units to evaluate new data. Resetting

this function defines a new start point for recording new data.

Already recorded data is lost with this function and available only

via the usual Brake Performance Monitoring function.

48000

40000

36218

32000

24000

22134

16000

13235

8134

8000

0

2828

61

0.5

1.0

1.5

2.0

2.5

3.0

3.5

836

4.0

322

4.5

111

53

84

140

378

330

13

5.0

5.5

6.0

6.5

7.0

7.5

8.0

Pressure (Bar)

Brake Applications vs Speed

test.fpf

40000

36000

32000

30574

28000

Brake Applications

Diagram no. 5: Brake Applications vs Speed

With each application, the speed at the beginning of braking is

recorded. The diagram displays the number of brake actuations

at different start speeds. Recording takes place in 10 km/h steps

from 0 to 160 km/h.

24000

21249

22526

23591

20235

20000

16000

13522

12000

10108

8000

5724

6132

10

20

6980

4000

0

30

40

50

60

70

80

90

100

74

0

0

0

0

0

110

120

130

140

150

160

Speed (km/h)

Diagram no. 6: Brake Actuations vs Energy

The braking energy is estimated on the basis of the chassis load

and the deceleration during braking.

Brake Applications vs Energy

test.fpf

70000

68932

63000

56000

Brake Applications

49000

42000

35000

28000

21000

18750

14000

7000

5546

2903

1677

979

570

433

240

182

113

46

47

12

5

1

2.0

2.5

3.0

3.5

4.0

4.5

5.0

5.5

6.0

6.5

7.0

7.5

8.0

0:06

0:11

0:37

0:42

0:01

6.0

6.5

7.0

7.5

8.0

0

0.5

1.0

1.5

Brake Energy (MJ)

Diagram no. 7: Braking Time vs Braking Pressure

The duration of each application is measured in order to update

the total braking time for each control pressure. The diagram

displays the cumulative braking time in 0.5 bar steps from

0 to 8 bar.

Braking Time vs Pressure

test.fpf

50.0

45.0

47:11

48:37

44:32

40.0

35.0

Time (hours)

30.0

25.0

20.0

21:10

15.0

10.0

7:42

5:09

5.0

2:14

0.0

0:00

0.5

1.0

1.5

2.0

2.5

3.0

3.5

4.0

0:48

0:17

4.5

5.0

0:06

5.5

Pressure (Bar)

15

Trailer Analyser - Operating Instructions

9 Histogram - Options

Diagram no. 8: Braking Time vs Pressure (high resolution)

The diagram displays the total braking time for different

pressures over the range from 0 to 3.4 bar with a higher

resolution over a smaller range than for diagram 7.

Braking Time vs Pressure, Hi-Res

test.fpf

25.0

22.5

21:35

20:39

20.0

20:25

19:42

18:05

17.5

17:24

Time (hours)

15.0

13:57

13:03

12.5

10.0

9:40

7.5

6:21

5.0

4:13

4:04

2.5

1:41

0:49

0.0

0:00

0:05

0.4

0.6

0.8

1.0

1.2

1.4

1.6

1.8

2.0

2.2

2.4

2.6

2.8

3.0

3.2

3.4

Pressure (Bar)

Diagram no. 9: Time vs Side Force

The side force of the wheels is calculated on the basis of the

chassis load and the lateral acceleration (if available). For this

purpose the data taken from the lateral acceleration sensor and

the bellows pressure is evaluated.

Time vs Side Force

test.fpf

600.0

566:27

540.0

480.0

420.0

Time (hours)

360.0

300.0

240.0

180.0

120.0

118:25

60.0

25:52

13:04

7:12

3:17

0:45

0:00

0:00

0:00

0:00

0:00

0:00

0:00

0:00

0:00

30

40

50

60

70

80

90

100

110

120

130

140

150

160

0

10

20

Side Force (KN)

Time vs AUX 4

test.fpf

200

00:03:16

180

160

140

Time (seconds)

Diagram no. 10: Time vs AUX 4

This diagram records the voltage at the input AUX 4 as a

function of time. The possible configurations at AUX 4 are:

- Lining Wear Sensor

- General Purpose Input (GPI)

- Control Line Sensor

- Soft Docking

- Mechanical Height Sensor (leaf spring position sensor)

120

100

00:01:32

80

60

40

In this example, AUX 4 was parameterised as a „General

Purpose Input“ and a simple switch (with states „on“ (5 V) /

„off“ (0 V)) connected.

00:00:00 00:00:00 00:00:00 00:00:00 00:00:00 00:00:00 00:00:00 00:00:00 00:00:00 00:00:00 00:00:00 00:00:00 00:00:00 00:00:00

0

312

625

937

1250

1562

1875

2187

2500

2812

3125

3437

3750

4062

4375

4687

5000

59

32

30

32

ADC Value (mV)

Distance vs Axle Load

test.fpf

65000

63920

58500

52000

46732

45500

Distance (km)

Diagram no. 11: Distance vs Axle Load

This diagram displays the loading in relation to distance. After

each kilometre travelled the bellows pressure is monitored.

The axle load is calculated from the bellows pressure, using

the ELS (Electronic Load Sensing) brake parameters stored in

the ECU by the Trailer Manager. The result is a „load profile“,

as displayed in the diagram.

20

39000

32500

26000

19500

13000

6311

6500

0

0

241

2

4

6

731

552

323

238

297

123

109

300

8

10

12

14

16

18

20

22

24

4583

26

28

Load (1000 kg)

Diagram no. 12: Distance vs Reservoir Pressure

This diagram displays changes in the reservoir pressure over

the course of travel. The reservoir pressure is recorded after

each kilometre travelled in 0.5 bar steps.

Distance vs Reservoir Pressure

test.fpf

70000

68776

63000

55513

56000

Distance (km)

49000

42000

35000

28000

21000

14000

7000

0

0

0

0

0

0

0

3.0

3.5

4.0

4.5

5.0

5.5

5

16

160

6.0

6.5

7.0

Reservoir Pressure (Bar)

16

7.5

8.0

1

0

0

0

0

8.5

9.0

9.5

10.0

10.5

10 Main menu - Trip Logs

Trip Logs

{ test.fpf }

With the blue „Trip Log“ tab at the top of the monitor screen

you can display the transport protocols.

Trips : ( 5045 )

Start Mileage (km)

250000

Trips: The transport runs in which the vehicle reaches at least

10 km/h and covers a distance of at least 1 km, excluding

travel over very short distances.

225000

221925 222022 222098 222127 222189 222200 222216 222222 222256 222270 222321 222359 222454 222466 222476 222578 222593 222652 222654 222723

200000

Start Mileage (km)

175000

A maximum of 1000 trips is stored. After exceeding the maximum

number of trips, the older ones are overwritten. Therefore

numbers greater than 1000 can be displayed at the upper edge

of the screen and in the Trip Info Box.

Irrespective of this, the first 1000 trips are always numbered from

0001 to a maximum of 1000 at the lower edge of the screen.

150000

125000

100000

75000

50000

25000

0

4

6

9

3

4

6

9

4

4

6

9

5

4

6

9

6

4

6

9

7

4

6

9

8

4

6

9

9

4

7

0

0

4

7

0

1

4

7

0

2

4

7

0

3

4

7

0

4

4

7

0

5

4

7

0

7

4

7

0

8

4

7

0

9

4

7

1

0

4

7

1

1

BPWV00334YHE27006 Serial:

VIN:

Main screen

In the menu in the lower section of the monitor screen you can

select the trip variable you want to display.

4

7

0

6

4

7

1

2

M0666_13

BPW Version:

Manufacturer:

C505

WS08 3112.00 Generation:

Brake Calc:

GEN 2

ZTS 34.20 Dongle Version:

Unit Type:

G430

COM:1

The following options are available:

Selection menu

Trips : ( 5045 )

Start Mileage (km)

250000

225000

221925 222022 222098 222127 222189 222200 222216 222222 222256 222270 222321 222359 222454 222466 222476 222578 222593 222652 222654 222723

200000

175000

Start Mileage (km)

Start Mileage (km)

Date

Trip Distance (km)

Trip Distance with Axle Lifted (km)

Brake Demand Average (Bar)

Brake Applications

Brake Applications 24N

Speed Average (km/h)

Speed Max (km/h)

Stability Events

ABS Events

Axle Load Average (kg)

Axle Load Maximum (kg)

Reservoir Pressure Min (Bar)

Reservoir Pressure Max (Bar)

Trip Duration (minutes)

Lift Axle - Number of Operations (from Version C505)

Steer Axle - Number of Operations (from Version C505)

Warning Lamp Ignored (minutes) (from Version C505)

Residual Pressure Time (minutes)

Rough Road Count / km*

Event Codes

150000

125000

100000

75000

50000

25000

0

4

6

9

3

4

6

9

4

4

6

9

5

4

6

9

6

4

6

9

7

4

6

9

9

4

7

0

0

4

7

0

1

4

7

0

2

4

7

0

3

4

7

0

4

4

7

0

5

4

7

0

6

4

7

0

7

4

7

0

8

4

7

0

9

4

7

1

0

4

7

1

1

4

7

1

2

Trips : ( 5045 )

Start Mileage (km)

222200 222216 222222 222256 222270 222321 222359 222454 222466 222476 222578 222593 222652

4700

Clicking and holding down the left mouse button displays the

cursor as a hand. With the hand cursor you can drag the screen

display to the left or right in order to see all the stored data.

Clicking with the right mouse button on a trip bar displays a trip

summary (Trip Info Box). Clicking again removes this display.

The selected bar is given a coloured background.

4

6

9

8

4

6

9

8

4

6

9

9

4

7

0

0

4

7

0

1

Start Mileage (km)

Date

Trip Distance (km)

Trip Distance with Axle Lifted (km)

Brake Demand Average (Bar)

Brake Applications

Brake Applications 24N

Speed Average (km/h)

Speed Max (km/h)

Stability Events

ABS Events

Axle Load Average (kg)

Axle Load Maximum (kg)

Reservoir Pressure Min (Bar)

Reservoir Pressure Max (Bar)

Trip Duration (minutes)

Residual

Pressure

Time

(minutes)

4

4

4

4

Rough

Road

7

7

7 Count7 / km

0

0

0Event Codes

0

2

3

4

5

222222.71

223

107

1.20

230 239

0

73

96

0

0

15100

27000

6.20

8.55

180 189

40

4

72.75

7

00

0

6

7

4

7

0

8

4

7

0

9

4

7

1

0

Note: It is possible that not all variables are available on all

systems, for example the date only with the Trailer Monitor

connected, stability events only with existing stability sensor

and lift axle information only when a lift axle is present.

* Road Condition Monitoring algorithm is not implemented in some

regional specific versions of BPW ECOTronic EBS, thus rendering of

RCM data within histograms and trip details is not possible.

17

Trailer Analyser - Operating Instructions

11 Trip Log - Options

Trip Logs - Diagrams

250000

225000

221925 222022 222098 222127 222189 222200 222216 222222 222256 222270 222321 222359 222454 222466 222476 222578 222593 222652 222654 222723

200000

175000

Start Mileage (km)

Diagram no. 1: Start Mileage (km)

This diagram displays the kilometre reading at the beginning

of a trip. The total number of trips recorded is shown above

the diagram title.

Trips : ( 5045 )

Start Mileage (km)

150000

125000

100000

75000

50000

25000

0

4

6

9

3

4

6

9

4

4

6

9

5

4

6

9

6

4

6

9

7

4

6

9

8

4

6

9

9

4

7

0

0

4

7

0

1

4

7

0

2

Example of kilometre

reading at the beginning

of trip 4703 with the Trip

Info Box (trip summary).

4

7

0

4

4

7

0

5

4

7

0

6

4

7

0

7

4

7

0

8

4

7

0

9

4

7

1

0

4

7

1

1

4

7

1

2

4703

222321.81

Start Mileage (km)

Date

70.00

Trip Distance (km)

69.00

Trip Distance with Axle Lifted (km)

1.20

Brake Demand Average (Bar)

30

Brake Applications

0

Brake Applications 24N

67

Speed Average (km/h)

85

Speed Max (km/h)

0

Stability Events

1

ABS Events

4200

Axle Load Average (kg)

4716

Axle Load Maximum (kg)

7.00

Reservoir Pressure Min (Bar)

8.45

Reservoir Pressure Max (Bar)

61

Trip Duration (minutes)

4

4

4Pressure4 Time (minutes)

4 0

4

Residual

7

7

7

7Rough Road

7

7

2

Count / km

0 Event0 Codes 0 0

0

0

1

4

7

0

4

Diagram no. 2: Date

This diagram displays the date of the trip. The date is recorded

only with the Trailer Monitor (battery) installed. In this example,

no Trailer Monitor was connected for trips 25, 32 and 44.

4

7

0

3

5

7

6

8

9

0

Trips : ( 5045 )

Date

30

30

27

24

24

24

24

25

30

30

30

30

30

30

25

22

21

Date

18

15

12

09

7

7

0

0

4

1

0

0

4

2

06

3

4

4

0

0

3

9

0

0

4

0

03

0

0

0

0

2

5

0

0

2

6

0

0

2

7

0

0

2

8

0

0

2

9

0

0

3

0

Diagram no. 3: Trip Distance (km)

This diagram displays the trip distance in km for each trip.

0

0

3

1

0

0

0

3

2

0

0

3

3

0

0

3

4

0

0

3

5

0

0

3

6

0

0

3

7

0

0

3

8

0

0

4

3

0

0

4

4

Trips : ( 5045 )

Trip Distance (km)

250

225

200

Trip Distance (km)

175

150

133

125

100

88

50

50

0

0

0

4

6

0

0

4

7

15

15

0

0

4

8

0

0

4

9

0

0

5

0

0

0

5

1

3

7

0

0

5

2

0

0

5

3

26

30

0

0

5

4

0

0

5

5

29

0

0

6

0

0

0

6

1

18

17

8

0

0

5

6

0

0

5

7

0

0

5

8

0

0

5

9

0

0

6

2

0

0

6

3

0

0

6

4

0

0

6

5

Trips : ( 5045 )

250

225

200

175

150

125

100

82

69

75

60

48

50

30

28

25

29

17

15

0

0

18

31

Trip Distance with Axle Lifted (km)

Trip Distance with Axle Lifted (km)

Diagram no. 4: Trip Distance with Axle Lifted (km)

This diagram displays the trip distance with lift axle raised in

km for each trip.

10

61

49

28

25

83

70

75

0

0

4

6

0

0

0

4

7

0

0

4

8

0

0

0

4

9

0

0

5

0

0

0

5

1

3

0

0

0

0

5

2

0

0

5

3

0

0

5

4

2

0

0

5

5

0

0

5

6

0

0

0

5

7

0

0

5

8

0

0

0

5

9

0

0

6

0

0

0

0

6

1

0

0

6

2

0

0

0

6

3

0

0

6

4

0

0

6

5

11 Trip Log - Options

Trips : ( 5045 )

Brake Demand Average (Bar)

5,00

4,50

Brake Demand Average (Bar)

Diagram no. 5: Brake Demand Average (bar)

This diagram displays the mean value of the control pressure

transmitted via the ISO 7368 or the yellow line from the tractor

vehicle to the trailer.

4,00

3,50

3,00

2,50

2,00

1,50

1.80

1.40

1.40

1.20

1.50

1.30

1.30

1.40

1.30

1.30

1.00

1.10

1.20

1.20

0

0

5

6

0

0

5

7

0

0

5

8

1.30

1.40

1.20

1.20

1.10

1.10

0

0

6

1

0

0

6

2

0

0

6

3

0

0

6

4

0

0

6

5

159

159

150

150

47

39

45

0

2

8

5

0

2

8

6

0

2

8

7

0

2

8

8

1,00

0,50

0

0

0

4

7

0

0

4

8

0

0

4

9

0

0

5

0

0

0

5

1

0

0

5

2

0

0

5

3

0

0

5

4

0

0

5

5

0

0

6

0

Trips : ( 5045 )

450

405

360

315

229

270

220

225

159

180

189

180

150

135

78

90

45

43

54

55

37

38

28

22

4

0

0

2

6

9

0

2

7

0

0

2

7

1

0

2

7

2

0

2

7

3

0

2

7

4

0

2

7

5

23

24

0

2

8

1

0

2

8

2

0

2

8

3

0

2

8

4

3

0

2

7

6

0

2

7

7

0

2

7

8

0

2

7

9

0

2

8

0

Trips : ( 5045 )

Brake Applications 24N

10

09

Brake Applications 24N

Diagram no. 7: Brake Applications 24N

If the EBS is not supplied with power via ISO 7638, no trips are

recorded. When emergency power is available (via ISO 1185),

the 24N brake applications are displayed in the next recorded

trip when the EBS is again supplied with power via ISO 7638.

0

0

5

9

Brake Applications

Brake Applications

Diagram no. 6: Brake Applications

This diagram displays the number of brake applications per

trip. For higher numbers of brake applications a value range

is specified. E.g. for trip 0277, 220 - 229 brake applications

were recorded.

0

0

4

6

08

07

06

05

4

04

3

03

02

01

0

Diagram no. 8: Speed Average (km/h)

This diagram displays the mean speed for each trip.

0

0

0

0

0

0

0

6

0

0

0

7

0

0

0

8

0

0

0

9

0

0

1

0

0

0

0

0

0

0

0

1

1

0

0

1

2

0

0

1

3

0

0

1

4

0

0

1

5

0

0

1

6

0

0

0

0

0

0

0

0

0

0

0

1

7

0

0

1

8

0

0

1

9

0

0

2

0

0

0

2

1

0

0

2

2

0

0

2

3

0

0

2

4

0

0

2

5

Trips : ( 5045 )

Speed Average (km/h)

80

73

72

64

68

68

67

64

63

65

67

64

60

57

55

56

Speed Average (km/h)

67

53

53

51

4

48

44

41

40

36

32

24

24

16

08

0

0

1

2

2

0

1

2

3

0

1

2

4

0

1

2

5

0

1

2

6

0

1

2

7

Diagram no. 9: Speed Max (km/h)

0

1

2

8

0

1

2

9

0

1

3

0

0

1

3

1

0

1

3

2

0

1

3

3

0

1

3

4

0

1

3

5

0

1

3

6

0

1

3

7

84

86

88

0

1

3

8

0

1

3

9

0

1

4

0

0

1

4

1

Trips : ( 5045 )

Speed Max (km/h)

This diagram displays the maximum speed for each trip.

150

135

120

Speed Max (km/h)

105

90

88

84

88

85

89

88

88

87

86

85

85

89

73

75

89

86

8

70

62

60

45

30

15

0

0

1

2

2

0

1

2

3

0

1

2

4

0

1

2

5

0

1

2

6

0

1

2

7

0

1

2

8

0

1

2

9

0

1

3

0

0

1

3

1

0

1

3

2

0

1

3

3

0

1

3

4

0

1

3

5

0

1

3

6

0

1

3

7

0

1

3

8

0

1

3

9

0

1

4

0

0

1

4

1

19

Trailer Analyser - Operating Instructions

11 Trip Log - Options

Diagram no. 10: Stability Events

This diagram displays the number of brake actuations regulated

by the EBS stability function for each trip.

Trips : ( 5045 )

Stability Events

5

05

4

04

3

Stability Events

03

2

02

01

1

1

1

0

7

2

0

0

7

2

1

0

7

2

2

2

Diagram no. 11: ABS Events

This diagram displays the number of ABS-regulated brake

actuations for each trip.

2

1

0

00

2

0

7

2

3

0

7

2

4

0

7

2

5

0

7

2

6

0

0

7

2

7

0

7

2

8

0

7

2

9

0

7

3

0

0

0

0

0

7

3

1

0

7

3

2

0

7

3

3

0

7

3

4

0

0

0

0

7

3

5

0

7

3

6

0

7

3

7

0

0

7

3

8

0

7

3

9

Trips : ( 5045 )

ABS Events

20

18

16

14

ABS Events

12

10

08

7

06

04

3

3

3

2

02

2

3

2

2

1

0

1

1

2

0

1

1

3

0

1

1

4

2

1

0

0

0

1

1

5

0

1

1

6

Diagram no. 12: Axle Load Average (kg)

This diagram displays the mean axle load for each trip.

0

1

1

7

0

1

1

8

0

1

1

9

0

1

2

0

2

1

0

0

1

2

1

1

0

0

1

2

2

0

1

2

3

0

0

1

2

4

0

1

2

5

0

1

2

6

0

1

2

7

0

0

1

2

8

0

1

2

9

0

1

3

0

0

1

3

1

Trips : ( 5045 )

Axle Load Average (kg)

30000

27000 25700

26100

25700

24900

Axle Load Average (kg)

24300

23800

24000

23400

2

23400

21000

18000

15000

12000

9000

6000

4300

4200

4200

4300

0

1

1

5

0

1

1

6

0

1

1

7

4500

4200

4200

4300

0

1

2

3

0

1

2

4

4700

4200

4200

4300

0

1

3

0

0

1

3

1

3000

0

0

1

1

2

0

1

1

3

0

1

1

4

Diagram no. 13: Axle Load Maximum (kg)

This diagram displays the maximum axle load for each trip.

0

1

1

8

0

1

1

9

0

1

2

0

0

1

2

1

0

1

2

2

0

1

2

5

0

1

2

6

0

1

2

7

0

1

2

8

0

1

2

9

Trips : ( 5045 )

Axle Load Maximum (kg)

36000

32346

Axle Load Maximum (kg)

32400

28800 27972

27243

27243 27243

27486

27243

26271

25542

26514

25200

21600

18000

14400

10800

8

7200

4878

4644

4878

5040

0

0

5

1

0

0

5

2

4716

5130

4716

4554 5130

4716

3600

0

20

0

0

4

6

0

0

4

7

0

0

4

8

0

0

4

9

0

0

5

0

0

0

5

3

0

0

5

4

0

0

5

5

0

0

5

6

0

0

5

7

0

0

5

8

0

0

5

9

0

0

6

0

0

0

6

1

0

0

6

2

0

0

6

3

0

0

6

4

0

0

6

5

11 Trip Log - Options

Diagram no. 14: Reservoir Pressure Min (bar)

Displays the minimum air pressure (bar) in the reservoir.

Trips : ( 5045 )

Reservoir Pressure Min (Bar)

10.00

9.00

8.00

Reservoir Pressure Min (Bar)

7.15

7.35

6.90

7.00

7.15

6.85

6.40

7.10

7.10

7.30

7.40

7.50

7.20

7.30

6.85

7.30

7.05

6.45

6.20

6.20

6.00

4.80

5.00

4.00

3.00

2.00

1.00

0

0

0

7

8

Diagram no. 15: Reservoir Pressure Max (bar)

Displays the maximum air pressure (bar) in the reservoir per trip;

in this example, trip 0046 displays a too high reservoir pressure.

0

0

7

9

0

0

8

0

0

0

8

1

0

0

8

2

0

0

8

3

0

0

8

4

0

0

8

5

0

0

8

6

0

0

8

7

0

0

8

8

0

0

8

9

0

0

9

0

0

0

9

1

0

0

9

2

0

0

9

3

0

0

9

4

0

0

9

5

0

0

9

6

0

0

9

7

8.50

8.50

8.60

0

0

6

3

0

0

6

4

0

0

6

5

Trips : ( 5045 )

Reservoir Pressure Max (Bar)

10.00

9.00

8.80

8.50

8.45

8.55

8.45

8.50

8.40

8.40

8.55

8.50

8.50

8.45

8.65

8.50

8.50

8.50

0

0

4

7

0

0

4

8

0

0

4

9

0

0

5

0

0

0

5

1

0

0

5

2

0

0

5

3

0

0

5

4

0

0

5

5

0

0

5

6

0

0

5

7

0

0

5

8

0

0

5

9

0

0

6

0

0

0

6

1

8.70

Reservoir Pressure Max (Bar)

8.00

7.00

6.00

5.00

4.00

3.00

2.00

1.00

0

0

0

4

6

Trips : ( 5045 )

Trip Duration (minutes)

200

180

Trip Duration (minutes)

Diagram no. 16: Trip Duration (minutes)

The diagram displays the duration of the trips in minutes.

For longer trips a value range is given. E.g. for trip 0062, a trip

duration of 110 - 119 minutes has been recorded.

0

0

6

2

160

119

140

110

120

100

90

80

67

61

60

20

54

47

38

40

28

27

14

31

37

37

20

6

8

0

0

5

2

0

0

5

3

14

16

0

0

5

8

0

0

5

9

32

22

0

0

0

4

6

0

0

4

8

0

0

4

9

0

0

5

1

0

0

5

4

0

0

5

5

0

0

5

6

0

0

5

7

0

0

6

0

0

0

6

1

0

0

6

2

0

0

6

3

0

0

6

4

0

0

6

5

Trips : ( 5045 )

05

04

03

02

1

01

0

00

0

1

2

1

1

0

0

1

2

2

0

1

2

3

1

1

0

1

2

6

0

1

2

7

0

0

1

2

4

Diagram no. 18: Steer Axle - Number of Operations

0

1

2

5

0

0

0

1

2

8

0

1

2

9

1

1

1

0

1

3

0

0

1

3

1

0

1

3

2

1

0

0

1

3

3

1

0

0

1

3

4

0

1

3

5

1

1

0

1

3

8

0

1

3

9

0

1

4

0

1

1

0

1

3

9

0

1

4

0

0

0

1

3

6

0

1

3

7

0

Trips : ( 5045 )

Steer Axle - Number of Operations

05

Steer Axle Number of Operations

Displays the number of operations of the steer axle lock per trip (ECU

Software Version C505 and above). In this example the steer axle lock

was operated once on most trips (e.g. driving in reverse).

0

0

5

0

Lift Axle - Number of Operations

Lift Axle Number of Operations

Diagram no. 17: Lift Axle - Number of Operations

Displays the number of operations of the lift axle per trip (ECU

Software Version C505 and above). In this example, the lift axle

has been lifted once during several trips (e.g. depending on the

load after switching on the ignition) whereas, it was not used

during other trips (e. g. due to high load).

0

0

4

7

04

03

02

01

1

1

1

1

1

0

1

2

1

0

1

2

2

0

1

2

3

0

1

2

4

0

1

2

5

1

0

00

0

1

2

6

1

1

1

1

1

1

1

1

1

0

1

2

9

0

1

3

0

0

1

3

1

0

1

3

2

0

1

3

3

0

1

3

4

0

1

3

5

0

1

3

6

0

1

3

7

0

0

1

2

7

0

1

2

8