Download Graco 311876F User's Manual

Transcript

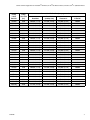

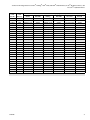

Instructions - Parts List 4-Ball Lower Retrofit Connection Kits 311876F EN Connection kits for 4-Ball Lowers. For professional use only. Important Safety Instructions Read all warnings and instructions in your pump Operation manual. Save these instructions. See the Connection Kit Usage Charts on pages 2-5 to select the correct connection kit for your lower and motor. A Shield Kit may also be required. See manual 406876 to order the correct shield kit for your pump. Contents Connection Kit Usage Chart for President® Air Motors, E-Flo® DC Electric Motors, and Viscount® I+ Hydraulic Motors . . . . . . . . . . . . 2 Connection Kit Usage Chart for Senator®, Bulldog®, NXT® 2200, and NXT® 3400 Air Motors, E-Flo® DC Electric Motors, and Viscount® II Hydraulic Motors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 Connection Kit 288202 . . . . . . . . . . . . . . . . . . . . . . 6 Connection Kit 288209 . . . . . . . . . . . . . . . . . . . . . . 9 Connection Kit 288208 . . . . . . . . . . . . . . . . . . . . . 13 Connection Kit 288504 . . . . . . . . . . . . . . . . . . . . . 17 Connection Kit 24F308 . . . . . . . . . . . . . . . . . . . . . 20 Connection Kits 24J185 (shown) and 24J186 . . . 24 Connection Kit 24F065 . . . . . . . . . . . . . . . . . . . . . 27 Connection Kit 24J390 . . . . . . . . . . . . . . . . . . . . . 30 Graco Information . . . . . . . . . . . . . . . . . . . . . . . . . 32 Connection Kit 24J185 shown mounted on a President air motor TI16810a Connection Kit Usage Chart for President® Air Motors, E-Flo® DC Electric Motors, and Viscount® I+ Hydraulic Motors Connection Kit Usage Chart for President® Air Motors, E-Flo® DC Electric Motors, and Viscount® I+ Hydraulic Motors Refer to the following chart to select the correct Connection Kit for your pump lower and motor. * 2 Connection Kit Part No. (see page numbers) Pump Lower Part No. Pump Lower Size (cc) President President (stubby size) Viscount I+ E-Flo DC 24F413 750 24J185 (24-26) 24J186 (24-26) 24F065 (27-29) 288209 24F414 750 24J185 (24-26) 24J186 (24-26) 24F065 (27-29) 288209 24F415 750 24J185 (24-26) 24J186 (24-26) 24F065 (27-29) 288209 24F416 750 24J185 (24-26) 24J186 (24-26) 24F065 (27-29) 288209 24F420 750 24J185 (24-26) 24J186 (24-26) 24F065 (27-29) 288209 24F421* 750 24J185 (24-26) not recommended not recommended not recommended 24F422* 750 24J185 (24-26) not recommended not recommended not recommended 24F423* 750 24J185 (24-26) not recommended not recommended not recommended 24F424 1000 24J185 (24-26) 24J186 (24-26) 24F065 (27-29) 288209 24F425 1000 24J185 (24-26) 24J186 (24-26) 24F065 (27-29) 288209 24F426 1000 24J185 (24-26) 24J186 (24-26) 24F065 (27-29) 288209 24F427 1000 24J185 (24-26) 24J186 (24-26) 24F065 (27-29) 288209 24F431 1000 24J185 (24-26) 24J186 (24-26) 24F065 (27-29) 288209 24F432 1500 24J185 (24-26) 24J186 (24-26) 24F065 (27-29) 288209 24F433 1500 24J185 (24-26) 24J186 (24-26) 24F065 (27-29) 288209 24F434 1500 24J185 (24-26) 24J186 (24-26) 24F065 (27-29) 288209 24F435 1500 24J185 (24-26) 24J186 (24-26) 24F065 (27-29) 288209 24F439 1500 24J185 (24-26) 24J186 (24-26) 24F065 (27-29) 288209 24F440 2000 not recommended not recommended 24F065 (27-29) 288209 24F441 2000 not recommended not recommended 24F065 (27-29) 288209 24F442 2000 not recommended not recommended 24F065 (27-29) 288209 24F443 2000 not recommended not recommended 24F065 (27-29) 288209 24F447 2000 not recommended not recommended 24F065 (27-29) 288209 Drum mounted pump lower with open wet-cup and spring loaded packings. 311876F Connection Kit Usage Chart for President® Air Motors, E-Flo® DC Electric Motors, and Viscount® I+ Hydraulic Motors Connection Kit Part No. (see page numbers) Pump Lower Part No. Pump Lower Size (cc) President President (stubby size) Viscount I+ E-Flo DC 253033 1000 288504 (17-19) 24J186 (24-26) 24F065 (27-29) 288209 253034 1500 288504 (17-19) 24J186 (24-26) 24F065 (27-29) 288209 253035 2000 288504 (17-19) 24J186 (24-26) 24F065 (27-29) 288209 253061 1000 288504 (17-19) 24J186 (24-26) 24F065 (27-29) 288209 253062 1500 288504 (17-19) 24J186 (24-26) 24F065 (27-29) 288209 253063 2000 288504 (17-19) 24J186 (24-26) 24F065 (27-29) 288209 253085 1500 288504 (17-19) 24J186 (24-26) 24F065 (27-29) 288209 253086 2000 288504 (17-19) 24J186 (24-26) 24F065 (27-29) 288209 253396 2000 288504 (17-19) 24J186 (24-26) 24F065 (27-29) 288209 253397 1500 288504 (17-19) 24J186 (24-26) 24F065 (27-29) 288209 253398 1000 288504 (17-19) 24J186 (24-26) 24F065 (27-29) 288209 253423 1000 288504 (17-19) 24J186 (24-26) 24F065 (27-29) 288209 253520 1000 288504 (17-19) 24J186 (24-26) 24F065 (27-29) 288209 253521 1500 288504 (17-19) 24J186 (24-26) 24F065 (27-29) 288209 253522 2000 288504 (17-19) 24J186 (24-26) 24F065 (27-29) 288209 253523 1000 288504 (17-19) 24J186 (24-26) 24F065 (27-29) 288209 253524 1500 288504 (17-19) 24J186 (24-26) 24F065 (27-29) 288209 253525 2000 288504 (17-19) 24J186 (24-26) 24F065 (27-29) 288209 253568 1000 288504 (17-19) 24J186 (24-26) 24F065 (27-29) 288209 253569 1500 288504 (17-19) 24J186 (24-26) 24F065 (27-29) 288209 253570 2000 288504 (17-19) 24J186 (24-26) 24F065 (27-29) 288209 24E664† 1000 24J185 (24-26) 24J186 (24-26) 24F065 (27-29) 288209 24F062† 1000 24J185 (24-26) 24J186 (24-26) 24F065 (27-29) 288209 24H346† 1500 24J185 (24-26) 24J186 (24-26) 24F065 (27-29) 288209 24H347† 1500 24J185 (24-26) 24J186 (24-26) 24F065 (27-29) 288209 24H348† 2000 24J185 (24-26) 24J186 (24-26) 24F065 (27-29) 288209 24H349† 2000 24J185 (24-26) 24J186 (24-26) 24F065 (27-29) 288209 † Retrofitted lowers. 311876F 3 Connection Kit Usage Chart for Senator®, Bulldog®, NXT® 2200, and NXT® 3400 Air Motors, E-Flo® DC Electric Motors, and Viscount® II Hydraulic Motors Connection Kit Usage Chart for Senator®, Bulldog®, NXT® 2200, and NXT® 3400 Air Motors, E-Flo® DC Electric Motors, and Viscount® II Hydraulic Motors Refer to the following chart to select the correct Connection Kit for your pump lower and motor. 4 Connection Kit Part No. (see page numbers) Pump Lower Part No. Pump Lower Size (cc) Senator NXT 2200 Bulldog NXT 3400 Viscount II E-Flo DC 15D787 1500 not applicable 288202 (6-8) not applicable 288202 (6-8) not recommended 288202 (6-8) 239834 1000 not applicable 288202 (6-8) not applicable not recommended not recommended 288202 (6-8) 239835 1500 not applicable 288202 (6-8) not applicable 288202 (6-8) not recommended 288202 (6-8) 239837 1000 not applicable 288202 (6-8) not applicable not recommended not recommended 288202 (6-8) 239838 1500 not applicable 288202 (6-8) not applicable 288202 (6-8) not recommended 288202 (6-8) 24F424 1000 24F308 (20-23) 288209 not recommended not recommended not recommended 288209 24F425 1000 24F308 (20-23) 288209 not recommended not recommended not recommended 288209 24F426 1000 24F308 (20-23) 288209 not recommended not recommended not recommended 288209 24F427 1000 24F308 (20-23) 288209 not recommended not recommended not recommended 288209 24F431 1000 24F308 (20-23) 288209 not recommended not recommended not recommended 288209 24F432 1500 24F308 (20-23) 288209 24F308 (20-23) not recommended not recommended 288209 24F433 1500 24F308 (20-23) 288209 24F308 (20-23) not recommended not recommended 288209 24F434 1500 24F308 (20-23) 288209 24F308 (20-23) not recommended not recommended 288209 24F435 1500 24F308 (20-23) 288209 24F308 (20-23) not recommended not recommended 288209 24F439 1500 24F308 (20-23) 288209 24F308 (20-23) not recommended not recommended 288209 24F440 2000 24F308 (20-23) 288209 24F308 (20-23) 288209 24J390 (30-31) 288209 24F441 2000 24F308 (20-23) 288209 24F308 (20-23) 288209 24J390 (30-31) 288209 24F442 2000 24F308 (20-23) 288209 24F308 (20-23) 288209 24J390 (30-31) 288209 24F443 2000 24F308 (20-23) 288209 24F308 (20-23) 288209 24J390 (30-31) 288209 24F447 2000 24F308 (20-23) 288209 24F308 (20-23) 288209 24J390 (30-31) 288209 240606 1500 not applicable 288202 (6-8) not applicable 288202 (6-8) not recommended 288202 (6-8) 240607 1500 not applicable 288202 (6-8) not applicable 288202 (6-8) not recommended 288202 (6-8) 240608 1000 not applicable 288202 (6-8) not applicable not recommended not recommended 288202 (6-8) 240609 1000 not applicable 288202 (6-8) not applicable not recommended not recommended 288202 (6-8) 311876F Connection Kit Usage Chart for Senator®, Bulldog®, NXT® 2200, and NXT® 3400 Air Motors, E-Flo® DC Electric Motors, and Viscount® II Hydraulic Motors Connection Kit Part No. (see page numbers) Pump Lower Part No. Pump Lower Size (cc) Senator NXT 2200 253033 1000 288208 (17-19) 288209 Bulldog NXT 3400 not recommended not recommended Viscount II E-Flo DC not recommended 288209 253034 1500 288208 (17-19) 288209 288208 (17-19) 288209 not recommended 288209 253035 2000 288208 (17-19) 288209 288208 (17-19) 288209 not recommended 288209 253061 1000 288208 (17-19) 288209 not recommended not recommended not recommended 288209 253062 1500 288208 (17-19) 288209 288208 (17-19) 288209 not recommended 288209 253063 2000 288208 (17-19) 288209 288208 (17-19) 288209 not recommended 288209 253085 1500 288208 (17-19) 288209 288208 (17-19) 288209 not recommended 288209 253086 2000 288208 (17-19) 288209 288208 (17-19) 288209 not recommended 288209 253396 2000 288208 (17-19) 288209 288208 (17-19) 288209 not recommended 288209 288208 (17-19) 288209 253397 1500 288208 (17-19) 288209 253398 1000 288208 (17-19) 288209 not recommended not recommended not recommended 288209 not recommended 288209 253423 1000 288208 (17-19) 288209 not recommended not recommended not recommended 288209 253520 1000 288208 (17-19) 288209 not recommended not recommended not recommended 288209 253521 1500 288208 (17-19) 288209 288208 (17-19) 288209 not recommended 288209 253522 2000 288208 (17-19) 288209 288208 (17-19) 288209 not recommended 288209 253523 1000 288208 (17-19) 288209 not recommended not recommended not recommended 288209 253524 1500 288208 (17-19) 288209 288208 (17-19) 288209 not recommended 288209 288208 (17-19) 288209 253525 2000 288208 (17-19) 288209 253568 1000 288208 (17-19) 288209 not recommended not recommended 253569 1500 288208 (17-19) 288209 24E664† 1000 24F308 (20-23) 288209 not recommended not recommended 288208 (17-19) 288209 not recommended 288209 not recommended 288209 not recommended 288209 not recommended 288209 24F062† 1000 24F308 (20-23) 288209 not recommended not recommended not recommended 288209 24H346† 1500 24F308 (20-23) 288209 24F308 (20-23) 288209 not recommended 288209 24H347† 1500 24F308 (20-23) 288209 24F308 (20-23) 288209 not recommended 288209 24H348† 2000 24F308 (20-23) 288209 24F308 (20-23) 288209 24J390 (30-31) 288209 24H349† 2000 24F308 (20-23) 288209 24F308 (20-23) 288209 24J390 (30-31) 288209 † Retrofitted lowers. 311876F 5 Connection Kit 288202 Connection Kit 288202 Connects Old Style 4-Ball Lower to NXT 2200 or NXT 3400 Air Motor, or E-Flo DC Electric Motor NOTE: See the Connection Kit Usage Chart on page 4 to find the lowers and motors which use Connection Kit 288202. Parts List and Drawing Ref. Part. 1 2 3 5 7 14 Description 15G924 108683 111368 15H980 100103 108284 Qty 3 3 1 1 1 1 ROD, tie NUT, lock, hex SEALANT; 0.5 cc ADAPTER, lg mr PIN, cotter PACKING, o-ring Using an NXT 2200 motor or an E-Flo DC 2 HP motor with a 750cc lower or using an NXT 3400 motor with a 750cc or 1000cc lower could cause dangerous overpressurization. 1 5 1 7 14 2 TI8984a 1 6 Apply sealant (3) and torque to 145-155 ft-lb (196 -210 N•m) 311876F Connection Kit 288202 Pump Performance Charts NOTE: See pages 10-12 for E-Flo DC Performance Charts. Air Consumption To find air consumption (l/min. or gpm) at a specific fluid flow (l/min. or gpm) and operating pressure (A/B/C): Fluid Outlet Pressure To find fluid outlet pressure (MPa/bar/psi) at a specific flow (lpm/gpm) and operating pressure (A/B/C): 1. Locate desired flow at bottom of chart. 2. Follow vertical line up to intersection with selected operating pressure curve (solid line). Follow left to scale to read fluid outlet pressure. 1. Locate desired flow along bottom of chart. 2. Read vertical line up to intersection with selected air consumption curve (gray line). Follow right to scale to read air consumption. Key A 0.7 MPa, 7 bar (100 psi) air pressure B 0.5 MPa, 4.9 bar (70 psi) air pressure C 0.3 MPa, 2.8 bar (40 psi) air pressure Test Fluid: No. 10 Weight Oil NXT 2200 with 1000cc Lower cycles per minute 7 psi (MPa, bar) 450 (3.1, 31) 400 (2.7, 27) 14 21 28 35 42 49 70 A A 60 B 300 (2.0, 20) B 40 250 (1.7, 17) 200 (1.3, 13) 150 (1.0, 10) 50 C 30 C Air Flow (scfm) Fluid Pressure 350 (2.4, 24) 20 100 (0.68, 6.8) 10 50 (0.34, 3.4) 0 2.0 (7.5) 6.0 8.0 4.0 (15.1) (22.7) (30.2) 12.0 10.0 (37.8) (45.4) 14.0 (53.0) Fluid Flow in gpm (lpm) 311876F 7 Connection Kit 288202 Key A 0.7 MPa, 7 bar (100 psi) air pressure B 0.5 MPa, 4.9 bar (70 psi) air pressure C 0.3 MPa, 2.8 bar (40 psi) air pressure Test Fluid: No. 10 Weight Oil NXT 2200 with 1500cc Lower cycles per minute psi (MPa, bar) 5 10 15 21 26 31 36 300 (2.0, 20) 50 A A 45 40 35 B 200 (1.3, 13) B 30 25 150 (1.0, 10) 20 C 100 (0.68, 6.8) Air Flow (scfm) Fluid Pressure 250 (1.7, 17) 15 C 10 50 (0.34, 3.4) 5 0 2.0 (7.5) 12.0 6.0 8.0 10.0 4.0 (15.1) (22.7) (30.2) (37.8) (45.4) 14.0 (53.0) Fluid Flow in gpm (lpm) NXT 3400 with 1500cc Lower cycles per minute psi (MPa, bar) 5 10 15 21 26 31 36 500 (3.8, 38 450 (3.4, 34) 80 A A 70 400 (3.1, 31) 60 B B 300 (2.4, 24) 250 (2.0, 20) 200 (1.7, 17) 50 40 C 30 C Air Flow (scfm) Fluid Pressure 350 (2.7, 27) 150 (1.3, 13) 20 100 (0.68, 6.8) 10 50 (0.34, 3.4) 0 2.0 (7.5) 12.0 6.0 8.0 10.0 4.0 (15.1) (22.7) (30.2) (37.8) (45.4) 14.0 (53.0) Fluid Flow in gpm (lpm) 8 311876F Connection Kit 288209 Connection Kit 288209 Connects 4-Ball Lower with Torqueable or Spring Loaded Throat Packings to NXT 2200 or NXT 3400 Air Motor, or E-Flo DC Electric Motor NOTE: See the Connection Kit Usage Charts on pages 2-5 to find the lowers and motors which use Connection Kit 288209. Parts List and Drawing Ref. Part. 1 2 3 5 7 8 Description 15G924 108683 111368 15H369 184128 184059 Qty 3 3 1 1 2 1 ROD, tie NUT, lock, hex SEALANT; 0.5 cc ADAPTER COLLAR, coupling NUT, coupling Using an NXT 2200 motor or an E-Flo DC 2 HP motor with a 750cc lower or using an NXT 3400 motor with a 750cc or 1000cc lower could cause dangerous overpressurization. 1 5 1 7 8 2 TI21556a 1 311876F Apply sealant (3) and torque to 145-155 ft-lb (196 -210 N•m) 9 Connection Kit 288209 Pump Performance Charts NOTE: See pages 7-8 for NXT 2200 and NXT 3400 Performance Charts. Fluid Outlet Pressure To find fluid outlet pressure (psi/MPa/bar) at a specific flow (gpm/lpm) and percentage of maximum force (A/B/C): 1. Locate desired flow at bottom of chart. 2. Follow vertical line up to intersection with selected percentage of maximum force (see the Key below). 3. Follow left to vertical scale to read fluid outlet pressure. Key to E-Flo DC Performance Charts NOTE: The charts show the motor operating at 100%, 70%, and 40% of maximum force. These values are approximately equivalent to an air motor operating at 100, 70, and 40 psi.. A 100% of maximum force B 70% of maximum force C 40% of maximum force Test Fluid: No. 10 Weight Oil 1 HP Motor (1400 lb maximum force) with 750cc Lower cycles per minute psi (MPa, bar) Fluid Pressure A B C Fluid Flow in gpm (lpm) 10 311876F Connection Kit 288209 1 HP Motor (1400 lb maximum force) with 1000cc Lower cycles per minute Fluid Pressure psi (MPa, bar) A B C Fluid Flow in gpm (lpm) 2 HP Motor (2800 lb maximum force) with 1000cc Lower cycles per minute psi (MPa, bar) Fluid Pressure A B C Fluid Flow in gpm (lpm) 311876F 11 Connection Kit 288209 2 HP Motor (2800 lb maximum force) with 1500cc Lower cycles per minute psi (MPa, bar) Fluid Pressure A B C Fluid Flow in gpm (lpm) 2 HP Motor (2800 lb maximum force) with 2000cc Lower cycles per minute Fluid Pressure psi (MPa, bar) A B C Fluid Flow in gpm (lpm) 12 311876F Connection Kit 288208 Connection Kit 288208 Connects 4-Ball Lower with Torqueable Throat Packings to Bulldog or Senator Air Motor NOTE: See the Connection Kit Usage Chart on page 5 to find the lowers and motors which use Connection Kit 288208. Parts List and Drawing Ref. 1 2 3 5 8 10 Part. Description 183089 108527 184128 15H981 184059 183079 Qty 3 3 2 1 1 1 ROD, tie NUT, lock, hex COLLAR, coupling ADAPTER, lg mr NUT, coupling NUT, coupling Using a Bulldog air motor with a 1000cc lower could cause dangerous overpressurization. 5 1 2 10 4 3 1 3 8 3 2 2 TI8985a 311876F 1 Torque to 145-150 ft-lb (196-203 N•m). 2 Torque to 50-60 ft-lb (68-91 N•m). 3 Apply lubricant. 4 Torque to 75-80 ft-lb (102-109 N•m). 13 Connection Kit 288208 Pump Performance Charts Fluid Outlet Pressure Air Consumption To find fluid outlet pressure (MPa/bar/psi) at a specific flow (lpm/gpm) and operating pressure (A/B/C): To find air consumption (l/min. or gpm) at a specific fluid flow (l/min. or gpm) and operating pressure (A/B/C): 1. Locate desired flow at bottom of chart. 1. Locate desired flow along bottom of chart. 2. Follow vertical line up to intersection with selected operating pressure curve (solid line). Follow left to scale to read fluid outlet pressure. 2. Read vertical line up to intersection with selected air consumption curve (gray line). Follow right to scale to read air consumption. Key A 0.7 MPa, 7 bar (100 psi) air pressure B 0.5 MPa, 4.9 bar (70 psi) air pressure C 0.3 MPa, 2.8 bar (40 psi) air pressure Test Fluid: No. 10 Weight Oil Senator with 1000cc Lower cycles per minute psi (MPa, bar) 350 (2.4, 24) 7 14 21 28 35 42 49 60 A A 300 (2.0, 20) 50 Fluid Pressure B 200 (1.3, 13) 40 B 30 C 150 (1.0, 10 100 (0.69, 6.9) Air Flow (scfm) 250 (1.7, 17) 20 C 10 50 (0.34, 3.4) 0 2.0 (7.5) 12.0 6.0 8.0 10.0 4.0 (15.1) (22.7) (30.2) (37.8) (45.4) 14.0 (53.0) Fluid Flow in gpm (lpm) 14 311876F Connection Kit 288208 Key A 0.7 MPa, 7 bar (100 psi) air pressure B 0.5 MPa, 4.9 bar (70 psi) air pressure C 0.3 MPa, 2.8 bar (40 psi) air pressure Test Fluid: No. 10 Weight Oil Senator with 1500cc Lower cycles per minute psi (MPa, bar) 300 (2.0, 20) 250 (1.7, 17) 5 10 15 21 26 31 36 45 A A 40 35 Fluid Pressure B B 30 25 150 (1.0, 10 20 C 100 (0.69, 6.9) C Air Flow (scfm) 200 (1.3, 13) 15 10 50 (0.34, 3.4) 5 0 2.0 (7.5) 6.0 8.0 4.0 (15.1) (22.7) (30.2) 12.0 10.0 (37.8) (45.4) 14.0 (53.0) Fluid Flow in gpm (lpm) Senator with 2000cc Lower cycles per minute psi (MPa, bar) 4 7 11 15 19 200 (1.3, 13) 180 (1.2, 12) 23 A A 25 160 (1.1, 11) B B 20 120 (0.82, 8.2) 15 100 (0.69, 6.9) 80 (0.55, 5.5) C C 60 (0.41, 4.1) 40 (0.27, 2.7) Air Flow (scfm) 140 (0.9, 9.6 Fluid Pressure 26 30 10 5 20 (0.13, 1.3 0 2.0 (7.5) 6.0 8.0 4.0 (15.1) (22.7) (30.2) 12.0 10.0 (37.8) (45.4) 14.0 (53.0) Fluid Flow in gpm (lpm) 311876F 15 Connection Kit 288208 Key A 0.7 MPa, 7 bar (100 psi) air pressure B 0.5 MPa, 4.9 bar (70 psi) air pressure C 0.3 MPa, 2.8 bar (40 psi) air pressure Test Fluid: No. 10 Weight Oil Bulldog with 1500cc Lower cycles per minute 5 psi (MPa, bar) 10 15 21 26 31 36 70 450 (3.1, 31) A 400 (2.7, 27) A 60 350 (2.4, 24) Fluid Pressure B B 40 250 (1.7, 17) 200 (1.3, 13) C C 150 (1.0, 10 30 Air Flow (scfm) 50 300 (2.0, 20) 20 100 (0.69, 6.9) 10 50 (0.34, 3.4) 0 2.0 (7.5) 12.0 6.0 8.0 10.0 4.0 (15.1) (22.7) (30.2) (37.8) (45.4) 14.0 (53.0) Fluid Flow in gpm (lpm) Bulldog with 2000cc Lower cycles per minute 4 psi (MPa, bar) 350 (2.4, 24) 300 (2.0, 20) 7 11 15 19 23 26 50 A A 45 40 B 200 (1.3, 13) B 35 30 25 150 (1.0, 10 C C 20 Air Flow (scfm) Fluid Pressure 250 (1.7, 17) 15 100 (0.69, 6.9) 10 50 (0.34, 3.4) 5 0 2.0 (7.5) 6.0 8.0 4.0 (15.1) (22.7) (30.2) 12.0 10.0 (37.8) (45.4) 14.0 (53.0) Fluid Flow in gpm (lpm) 16 311876F Connection Kit 288504 Connection Kit 288504 Connects 4-Ball Lower with Torqueable Throat Packings to President Air Motor NOTE: See the Connection Kit Usage Chart on page 3 to find the lowers and motors which use Connection Kit 288504. Parts List and Drawing Ref. Part. 3 5 7 8 184128 15J948 100579 184059 Description Qty 2 1 1 1 COLLAR, coupling ADAPTER PIN, cotter NUT, coupling 7 5 2 3 8 1 TI8986a 311876F 1 Torque to 145-150 ft-lb (197-203 N•m). 2 Apply lubricant. 17 Connection Kit 288504 Pump Performance Charts Fluid Outlet Pressure To find fluid outlet pressure (MPa/bar/psi) at a specific flow (lpm/gpm) and operating pressure (A/B/C/D): Air Consumption To find air consumption (l/min. or gpm) at a specific fluid flow (l/min. or gpm) and operating pressure (A/B/C/D): 1. Locate desired flow at bottom of chart. 2. Follow vertical line up to intersection with selected operating pressure curve (solid line). Follow left to scale to read fluid outlet pressure. 1. Locate desired flow along bottom of chart. 2. Read vertical line up to intersection with selected air consumption curve (gray line). Follow right to scale to read air consumption. Key A 1.17 MPa, 11.7 bar (170 psi) air pressure B 0.7 MPa, 7 bar (100 psi) air pressure C 0.5 MPa, 4.9 bar (70 psi) air pressure D 0.3 MPa, 2.8 bar (40 psi) air pressure Test Fluid: No. 10 Weight Oil President with 1000cc Lower cycles per minute psi (MPa, bar) 400 (2.7, 27) 350 (2.4, 24) 8 17 25 33 42 51 59 60 A A 50 40 250 (1.7, 17) 200 (1.3, 13) B B 30 C 150 (1.0, 10) C 20 100 (0.69, 6.9) Air Flow (scfm) Fluid Pressure 300 (2.0, 20) D D 10 50 (0.34, 3.4) 0 2.0 (7.5) 6.0 8.0 4.0 (15.1) (22.7) (30.2) 12.0 10.0 (37.8) (45.4) 14.0 (53.0) Fluid Flow in gpm (lpm) 18 311876F Connection Kit 288504 Key A 1.17 MPa, 11.7 bar (170 psi) air pressure B 0.7 MPa, 7 bar (100 psi) air pressure C 0.5 MPa, 4.9 bar (70 psi) air pressure D 0.3 MPa, 2.8 bar (40 psi) air pressure Test Fluid: No. 10 Weight Oil President with 1500cc Lower cycles per minute psi (MPa, bar) 300 (2.0, 20) 6 12 18 25 30 37 43 A A 45 40 250 (1.7, 17) 35 Fluid Pressure 150 (1.0, 10) B 25 B 20 100 (0.69, 6.9) C C Air Flow (scfm) 30 200 (1.3, 13) 15 D 10 D 50 (0.34, 3.4) 5 0 2.0 (7.5) 6.0 8.0 4.0 (15.1) (22.7) (30.2) 12.0 10.0 (37.8) (45.4) 14.0 (53.0) Fluid Flow in gpm (lpm) President with 2000cc Lower cycles per minute psi (MPa, bar) 200 (1.37, 13.7) 4 9 13 18 22 27 A 31 35 A 180 (1.24, 12.4) 30 160 (1.1, 11.0) 25 B 120 (0.82, 8.2) B 20 100 (0.68, 6.8) 80 (0.55, 5.5) 15 C C 60 (0.41, 4.1) 40 (0.27, 2.7) 10 D D 20 (0.13, 1.3) 0 Air Flow (scfm) Fluid Pressure 140 (0.96, 9.6) 2.0 (7.5) 12.0 6.0 8.0 10.0 4.0 (15.1) (22.7) (30.2) (37.8) (45.4) 5 14.0 (53.0) Fluid Flow in gpm (lpm) 311876F 19 Connection Kit 24F308 Connection Kit 24F308 Connects 4-Ball Lower with Spring Loaded Throat Packings to Bulldog or Senator Air Motor NOTE: See the Connection Kit Usage Chart on pages 4-5 to find the lowers and motors which use Connection Kit 24F308. Parts List and Drawing Ref. 1 2 3 4 5 6 Part. Description 183089 108527 16F214 184059 184128 183079 Qty 3 3 1 1 2 1 ROD, tie NUT, lock, hex ADAPTER, lg mr NUT, coupling COLLAR, coupling NUT, coupling Using a Bulldog air motor with a 1000cc lower could cause dangerous overpressurization. 3 4 6 3 5 1 4 1 2 3 5 2 2 20 1 Torque to 145-150 ft-lb (196-203 N•m). 2 Torque to 50-60 ft-lb (68-91 N•m). 3 Apply lubricant. 4 Torque to 75-80 ft-lb (102-109 N•m). 5 Shield Kit is not included. See manual 406876 to order the correct shield kit for your pump. TI8985b 311876F Connection Kit 24F308 Pump Performance Charts Fluid Outlet Pressure Air Consumption To find fluid outlet pressure (MPa/bar/psi) at a specific flow (lpm/gpm) and operating pressure (A/B/C): To find air consumption (l/min. or gpm) at a specific fluid flow (l/min. or gpm) and operating pressure (A/B/C): 1. Locate desired flow at bottom of chart. 1. Locate desired flow along bottom of chart. 2. Follow vertical line up to intersection with selected operating pressure curve (solid line). Follow left to scale to read fluid outlet pressure. 2. Read vertical line up to intersection with selected air consumption curve (gray line). Follow right to scale to read air consumption. Key A 0.7 MPa, 7 bar (100 psi) air pressure B 0.5 MPa, 4.9 bar (70 psi) air pressure C 0.3 MPa, 2.8 bar (40 psi) air pressure Test Fluid: No. 10 Weight Oil Senator with 1000cc Lower cycles per minute psi (MPa, bar) 350 (2.4, 24) 7 14 21 28 35 42 49 60 A A 300 (2.0, 20) 50 Fluid Pressure B 200 (1.3, 13) 40 B 30 C 150 (1.0, 10 100 (0.69, 6.9) Air Flow (scfm) 250 (1.7, 17) 20 C 10 50 (0.34, 3.4) 0 2.0 (7.5) 12.0 6.0 8.0 10.0 4.0 (15.1) (22.7) (30.2) (37.8) (45.4) 14.0 (53.0) Fluid Flow in gpm (lpm) 311876F 21 Connection Kit 24F308 Key A 0.7 MPa, 7 bar (100 psi) air pressure B 0.5 MPa, 4.9 bar (70 psi) air pressure C 0.3 MPa, 2.8 bar (40 psi) air pressure Test Fluid: No. 10 Weight Oil Senator with 1500cc Lower cycles per minute psi (MPa, bar) 300 (2.0, 20) 250 (1.7, 17) 5 10 15 21 26 31 36 45 A A 40 35 Fluid Pressure B B 30 25 150 (1.0, 10 20 C 100 (0.69, 6.9) C Air Flow (scfm) 200 (1.3, 13) 15 10 50 (0.34, 3.4) 5 0 2.0 (7.5) 6.0 8.0 4.0 (15.1) (22.7) (30.2) 12.0 10.0 (37.8) (45.4) 14.0 (53.0) Fluid Flow in gpm (lpm) Senator with 2000cc Lower cycles per minute psi (MPa, bar) 4 7 11 15 19 200 (1.3, 13) 180 (1.2, 12) 23 A A 25 160 (1.1, 11) B B 20 120 (0.82, 8.2) 15 100 (0.69, 6.9) 80 (0.55, 5.5) C C 60 (0.41, 4.1) 40 (0.27, 2.7) Air Flow (scfm) 140 (0.9, 9.6 Fluid Pressure 26 30 10 5 20 (0.13, 1.3 0 2.0 (7.5) 12.0 6.0 8.0 10.0 4.0 (15.1) (22.7) (30.2) (37.8) (45.4) 14.0 (53.0) Fluid Flow in gpm (lpm) 22 311876F Connection Kit 24F308 Key A 0.7 MPa, 7 bar (100 psi) air pressure B 0.5 MPa, 4.9 bar (70 psi) air pressure C 0.3 MPa, 2.8 bar (40 psi) air pressure Test Fluid: No. 10 Weight Oil Bulldog with 1500cc Lower cycles per minute psi (MPa, bar) 5 10 15 21 26 31 36 70 450 (3.1, 31) A 400 (2.7, 27) A 60 350 (2.4, 24) Fluid Pressure B B 40 250 (1.7, 17) 200 (1.3, 13) C C 150 (1.0, 10 30 Air Flow (scfm) 50 300 (2.0, 20) 20 100 (0.69, 6.9) 10 50 (0.34, 3.4) 0 2.0 (7.5) 12.0 6.0 8.0 10.0 4.0 (15.1) (22.7) (30.2) (37.8) (45.4) 14.0 (53.0) Fluid Flow in gpm (lpm) Bulldog with 2000cc Lower cycles per minute psi (MPa, bar) 350 (2.4, 24) 300 (2.0, 20) 4 7 11 15 19 23 26 50 A A 45 40 B 200 (1.3, 13) B 35 30 25 150 (1.0, 10 C C 20 Air Flow (scfm) Fluid Pressure 250 (1.7, 17) 15 100 (0.69, 6.9) 10 50 (0.34, 3.4) 5 0 2.0 (7.5) 6.0 8.0 4.0 (15.1) (22.7) (30.2) 12.0 10.0 (37.8) (45.4) 14.0 (53.0) Fluid Flow in gpm (lpm) 311876F 23 Connection Kits 24J185 (shown) and 24J186 Connection Kits 24J185 (shown) and 24J186 Connects 4-Ball Lower with Spring Loaded Throat Packings to President Air Motor NOTE: See the Connection Kit Usage Chart on pages 2-3 to find the lowers and motors which use Connection Kits 24J185 and 24J186. Parts List and Drawing Ref. Part. 1 Description 16H544 16H375 15G924 16H434 108683 15T311 184128 100103 2 3 4 5 6 ADAPTER; Kit 24J185 only ADAPTER; Kit 24J186 only TIE ROD; Kit 24J185 only TIE ROD; Kit 24J186 only NUT, lock, hex NUT, coupling COLLAR, coupling PIN, cotter Qty 1 1 3 3 3 1 2 1 6 1 5 4 1 2 2 2 5 1 3 TI6809a 24 1 Torque to 145-150 ft-lb (197-203 N•m). 2 Apply lubricant. 5 Shield Kit is not included. See manual 406876 to order the correct shield kit for your pump. 311876F Connection Kits 24J185 (shown) and 24J186 Pump Performance Charts Fluid Outlet Pressure Air Consumption To find fluid outlet pressure (MPa/bar/psi) at a specific flow (lpm/gpm) and operating pressure (A/B/C): To find air consumption (l/min. or gpm) at a specific fluid flow (l/min. or gpm) and operating pressure (A/B/C): 1. Locate desired flow at bottom of chart. 1. Locate desired flow along bottom of chart. 2. Follow vertical line up to intersection with selected operating pressure curve (solid line). Follow left to scale to read fluid outlet pressure. 2. Read vertical line up to intersection with selected air consumption curve (dashed line). Follow left to scale to read air consumption. Key A 0.7 MPa, 7 bar (100 psi) air pressure B 0.5 MPa, 4.9 bar (70 psi) air pressure C 0.3 MPa, 2.8 bar (40 psi) air pressure Test Fluid: No. 10 Weight Oil President with 750cc Lower cycles per minute 500 (3.5, 35) 12 25 37 50 62 A 200 (1.3, 13) B 100 (0.69, 6.9) C 0 2.0 (7.5) 4.0 6.0 (15.1) (22.7) 8.0 10.0 12.0 14.0 (30.2) (37.8) (45.4) (53.0) Fluid Flow in gpm (lpm) 311876F (m3 /min) 50 (1.40) Air Consumption Fluid Pressure 400 (2.7, 27) 300 (2.0, 20) cycles per minute scfm psi (MPa, bar) 12 25 37 40 (1.12) 50 62 A 30 (0.84) B 20 (0.56) C 10 (0.28) 0 2.0 (7.5) 4.0 6.0 (15.1) (22.7) 8.0 10.0 12.0 14.0 (30.2) (37.8) (45.4) (53.0) Fluid Flow in gpm (lpm) 25 Connection Kits 24J185 (shown) and 24J186 Key A 0.7 MPa, 7 bar (100 psi) air pressure B 0.5 MPa, 4.9 bar (70 psi) air pressure C 0.3 MPa, 2.8 bar (40 psi) air pressure Test Fluid: No. 10 Weight Oil President with 1000cc Lower 8 400 (2.7, 27) 17 25 33 42 51 59 68 300 (2.0, 20) 200 (1.3, 13) A B 100 (0.69, 6.9) C 2.0 4.0 6.0 8.0 10.0 12.0 14.0 16.0 (7.5) (15.1) (22.7) (30.2) (37.8) (45.4) (53.0) (60.8) 0 cycles per minute (m3/min) 50 (1.40) Air Consumption Fluid Pressure scfm cycles per minute psi (MPa, bar) 8 17 25 33 42 51 59 68 40 (1.12) A 30 (0.84) B 20 (0.56) C 10 (0.28) 2.0 4.0 6.0 8.0 10.0 12.0 14.0 16.0 (7.5) (15.1) (22.7) (30.2) (37.8) (45.4) (53.0) (60.8) 0 Fluid Flow in gpm (lpm) Fluid Flow in gpm (lpm) President with 1500cc Lower cycles per minute psi (MPa, bar) 9 18 28 37 46 56 scfm (m3/min) 300 (2.0, 20) cycles per minute 9 18 28 37 46 56 40 (1.12) Air Consumption Fluid Pressure 250 (1.7, 17) 200 (1.3, 13) 150 (1.0, 10) A 100 (0.69, 6.9) B 50 (0.34, 3.4) C 0 3.0 (11.4) 6.0 (22.7) 9.0 12.0 (34.2) (45.4) 15.0 18.0 (57.0) (68.4) Fluid Flow in gpm (lpm) 26 30 (0.84) A 20 (0.56) B 10 (0.28) C 0 3.0 (11.4) 6.0 (22.7) 9.0 12.0 (34.2) (45.4) 15.0 18.0 (57.0) (68.4) Fluid Flow in gpm (lpm) 311876F Connection Kit 24F065 Connection Kit 24F065 Connects 4-Ball Lower with Spring Loaded Throat Packings to Viscount I+ Hydraulic Motor NOTE: See the Connection Kit Usage Chart on pages 2-3 to find the lowers and motors which use Connection Kit 24F065. Parts List and Drawing Ref. Part. 1 2 3 4 5 6 Description 16C373 15G924 108683 184059 184128 100579 Qty 1 3 3 1 2 1 ADAPTER TIE ROD NUT, lock, hex NUT, coupling COLLAR, coupling PIN, cotter 6 1 2 2 5 2 1 4 5 3 1 TI8986b 311876F 1 Torque to 145-150 ft-lb (197-203 N•m). 2 Apply lubricant. 5 Shield Kit is not included. See manual 406876 to order the correct shield kit for your pump. 27 Connection Kit 24F065 Pump Performance Charts Fluid Outlet Pressure Hydraulic Oil Consumption To find fluid outlet pressure (psi/MPa/bar) at a specific fluid flow (lpm/gpm) and operating hydraulic pressure (psi/MPa/bar): To find motor hydraulic oil consumption (l/min. or gpm) at a specific fluid flow (l/min. or gpm): 1. Locate desired flow along bottom of chart. 2. Follow vertical line up to intersection with selected fluid outlet pressure curve (black). Follow left to scale to read fluid outlet pressure. 1. Locate desired flow along bottom of chart. 2. Read vertical line up to intersection with hydraulic oil consumption curve (dashes or gray line). Follow right to scale to read hydraulic oil consumption. Key: A 10.3 MPa, 103 bar (1500 psi) hydraulic pressure B 7.2 MPa, 72.4 bar (1050 psi) hydraulic pressure C 4.1 MPa, 41 bar (600 psi) hydraulic pressure Viscount I+ Motor, 750cc Lower CPM psi (MPa, bar) 19 PUMP OUTLET PRESSURE 400 (2.8, 28) 300 2.1, 21) 200 (1.4, 14) 100 (0.7, 7) 37 56 GPM (l/min) 74 5 (19.0) A 4 (15.2) 3 (11.4) B 2 (7.6) C 1 (3.8) HYDRAULIC OIL CONSUMPTION 500 3.4, 34) 0 GPM 0 (l/min) 3 (11) 6 (23) 9 (34) 12 (46) 15 (57) PUMP DELIVERY (Test Fluid: No. 10 Motor Oil) Viscount I+ Motor, 1000cc Lower 28 311876F Connection Kit 24F065 Viscount I+ Motor, 1500cc Lower Viscount I+ Motor, 2000cc Lower CPM psi (MPa, bar) 12 24 GPM 36 48 PUMP OUTLET PRESSURE A 2.5 (9.5) 120 0.84, 8.4) 80 (0.56, 5.6) 40 (0.28, 2.8) 2.0 (7.6) B 1.5 (5.7) 1.0 (3.8) C 0.5 (1.9) HYDRAULIC OIL CONSUMPTION 160 (1.12, 11.2) 60 (l/min) 3.0 (11.4) 0 GPM 0 (l/min) 5 (19) 10 (38) 15 (57) 20 (76) 25 (95) PUMP DELIVERY (Test Fluid: No. 10 Motor Oil) 311876F 29 Connection Kit 24J390 Connection Kit 24J390 Connects 4-Ball Lower with Spring Loaded Throat Packings to Viscount II Hydraulic Motor NOTE: See the Connection Kit Usage Chart on pages 4-5 to find the lowers and motors which use Connection Kit 24J390. Parts List and Drawing Ref. Part. 1 2 3 4 5 8 9 10 15K736 15G924 108683 184059 184128 120558 C19789 183079 Description Qty 1 3 3 1 2 1 3 1 ADAPTER TIE ROD NUT, lock, hex NUT, coupling COLLAR, coupling PLATE, mounting SCREW, cap, socket hd NUT, coupling 8 9 3 1 3 2 10 4 5 2 4 1 5 3 3 TI16940b 30 1 Torque to 90-100 ft-lb (122-135 N•m). 2 Apply lubricant. 3 Torque to 50-55 ft-lb (68-75 N•m). 4 Torque to 75-80 ft-lb (102-109 N•m). 5 Shield Kit is not included. See manual 406876 to order the correct shield kit for your pump. 311876F Connection Kit 24J390 Pump Performance Charts Fluid Outlet Pressure Hydraulic Oil Consumption To find fluid outlet pressure (psi/MPa/bar) at a specific fluid flow (lpm/gpm) and operating hydraulic pressure (psi/MPa/bar): To find motor hydraulic oil consumption (l/min. or gpm) at a specific fluid flow (l/min. or gpm): 1. Locate desired flow along bottom of chart. 2. Follow vertical line up to intersection with selected fluid outlet pressure curve (black). Follow left to scale to read fluid outlet pressure. 1. Locate desired flow along bottom of chart. 2. Read vertical line up to intersection with hydraulic oil consumption curve (dashes or gray line). Follow right to scale to read hydraulic oil consumption. Key: A 10.3 MPa, 103 bar (1500 psi) hydraulic pressure B 7.2 MPa, 72.4 bar (1050 psi) hydraulic pressure C 4.1 MPa, 41 bar (600 psi) hydraulic pressure Viscount II Motor, 2000cc Lower CYCLES PER MIN. 0 4 8 12 16 20 24 28 400 (2.8, 28) A GPM (l/min) 36 8.0 (30.4) 7.0 (26.6) 350 (2.4, 24) 6.0 (22.8) B 300 (2.1, 21) 5.0 (19.0) 250 (1.7, 17) 4.0 (15.2) 200 (1.4, 14) C 3.0 (11.4) 150 (1.0, 10) 2.0 (7.6) 100 (0.7, 7) HYDRAULIC OIL CONSUMPTION FLUID PRESSURE, psi (MPa, bar) 450 (3.1, 31) 32 1.0 (3.8) 50 (0.3, 3) 0 0 (0, 0) 0.0 2.0 4.0 6.0 8.0 10.0 12.0 14.0 16.0 18.0 (0.0) (7.0) (15.0)(22.5) (30.0)(37.9) (45.4) (53.0) (60.6) (68.1) FLUID FLOW, gpm (lpm) 311876F 31 Graco Information For the latest information about Graco products, visit www.graco.com. For patent information, see www.graco.com/patents. TO PLACE AN ORDER, contact your Graco distributor or call to identify the nearest distributor. Phone: 612-623-6921 or Toll Free: 1-800-328-0211 Fax: 612-378-3505 All written and visual data contained in this document reflects the latest product information available at the time of publication. Graco reserves the right to make changes at any time without notice. Original instructions. This manual contains English. MM 311876 Graco Headquarters: Minneapolis International Offices: Belgium, China, Japan, Korea GRACO INC. AND SUBSIDIARIES • P.O. BOX 1441 • MINNEAPOLIS, MN 55440-1441 • USA Copyright 2006, Graco Inc. All Graco manufacturing locations are registered to ISO 9001. www.graco.com Revised May 2013