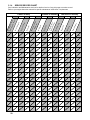

Download SM32S Cart Chipper Operators Manual

Transcript